More data for the two situations above (including the exit section of the DF10.171K) -

The peaks and dips in the impedance curves translate somewhat into the frequency responses but only loosely - obviously a lot is missing by omitting the whole internal structure of the driver. But it's (again) clear that the calculated sharp impedance peaks don't cause sharp FR peaks - there must be a lot of real damping somewhere (?).

I'll try to measure the driver in a plane wave tube...

The peaks and dips in the impedance curves translate somewhat into the frequency responses but only loosely - obviously a lot is missing by omitting the whole internal structure of the driver. But it's (again) clear that the calculated sharp impedance peaks don't cause sharp FR peaks - there must be a lot of real damping somewhere (?).

I'll try to measure the driver in a plane wave tube...

Last edited:

Yes, I wish you could sort out this FR / imp enigma... it's so weird that there isn't more correlation... I dont get that.

//

//

I thought people here might be interested in this discussion too. Taken from another thread:

Interestingly, there is a split between those who prefer less HF ringing, and those who prefer more.

As Bennett Prescott of B&C puts it, people like the ringing because it makes it seem like there is more high frequency, "this is the sound that everybody loves".

When they made the DE 880, with HF ringing about half that of the DE900TN, people liked it, but asked for something "more like the DE900TN".

View attachment 1334453

Bennett Prescott of B&C and Matteo Bianchini of 18Sound:

Really good in depth discussion about compression drivers.

Art

My hypothesis is that the listener preference in pro sound for added in HF energy in the time domain might be related to the longer listening distance that mostly effects HF. Whereas in home listening this behavior of TI diaphragms is easily nauseating.

So based on this discussion PET diaphragms (Mylar) or TI diaphragms with PET surround are best choice for home audio. Or polyimide, like the lately discussed LaVoce driver and the B&C DE250. In general not metal for the ringing.

So based on this discussion PET diaphragms (Mylar) or TI diaphragms with PET surround are best choice for home audio. Or polyimide, like the lately discussed LaVoce driver and the B&C DE250. In general not metal for the ringing.

Last edited:

Yeah that was very good video, everyone should watch it to learn about diaphragms and driver tech in general!

I made something up the Peerless DF2535 has a TI surround according to the specs sheet. I remembered that it was some sort of composite but I was wrong.

An extended HF decay time does tend to compensate for the marked drop in high frequency relative to mid or low frequencies, especially in hot, dry listening environments. When I first moved to New Mexico, I thought my HF hearing had dropped, only later did I realize it was the atmospheric absorption, which could be in the .5dB per meter range at 16kHz.My hypothesis is that the listener preference in pro sound for added in HF energy in the time domain might be related to the longer listening distance that mostly effects HF. Whereas in home listening this behavior of TI diaphragms is easily nauseating.

https://sengpielaudio.com/calculator-air.htm

The B&C DE 880TN high frequency ringing was reduced to about half that of other drivers using diaphragms with various plastic surround compounds. The DE 880TN's titanium surround was designed differently to achieve the reduction in decay time.So based on this discussion PET diaphragms (Mylar) or TI diaphragms with PET surround are best choice for home audio. Or polyimide, like the lately discussed LaVoce driver and the B&C DE250. In general not metal for the ringing.

At any rate, the "best choice for home audio" is a personal one which won't be accepted by all.

And as presbycusis (age-related hearing loss) takes it's inevitable toll on HF acuity, preferences may change over time.

Art

It would be interesting to test if the ringing of a metal versus a polymer diaphragm is perceived differently. In the talk they once said polymers are held to sound more natural in general, then, a more specific connection was established that this is due to the suspension ringing with metal diaphragms. This was a bit unclear.

Maybe time domain "enhanced" HF does both help with atmospheric absorption, what I had mentioned as longer listening distance, as well as with age induced hearing loss compensation in home listening. But I am not burdened with such for now and so I was interested to find out more about whether a certain diaphragm material is preferable.

Maybe time domain "enhanced" HF does both help with atmospheric absorption, what I had mentioned as longer listening distance, as well as with age induced hearing loss compensation in home listening. But I am not burdened with such for now and so I was interested to find out more about whether a certain diaphragm material is preferable.

Last edited:

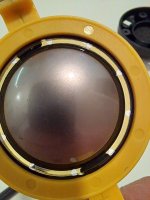

Do you have any guess what it can be? Hardness, thickness, which side, etc. 🙂... coated with some transparent stuff

All i can say about it is that it is transparent, rubbery substance applied to concave side of the dome.

I have no way of precisely determining thickness of the coating without destroying the dome. If i were to really measure it, i should measure dome and coating thickness with micrometer and then remove the coating from the dome and remeasure.

Only violent ways of how to do it come to my mind 🙂

I'll open one of the compression drivers this afternoon, take a bunch of pics and post them here. Maybe someone will know more.

I have no way of precisely determining thickness of the coating without destroying the dome. If i were to really measure it, i should measure dome and coating thickness with micrometer and then remove the coating from the dome and remeasure.

Only violent ways of how to do it come to my mind 🙂

I'll open one of the compression drivers this afternoon, take a bunch of pics and post them here. Maybe someone will know more.

Cool, looking forward for the pics.

Eighteen Sound works with TiN titanium nitride coating that is applied to the convex side:

https://www.eighteensound.it/en/technologies/tmp-true-piston-motion/

Eighteen Sound works with TiN titanium nitride coating that is applied to the convex side:

https://www.eighteensound.it/en/technologies/tmp-true-piston-motion/

That it is rubbery is a basic valuable information, I think.

There are (e.g.) some 2K epoxy resins that are possible to mix to get anything between hard and rubbery.

There are (e.g.) some 2K epoxy resins that are possible to mix to get anything between hard and rubbery.

Me and Zvu bought together DFMs couple of years ago. I remember that I have checked dozens of CDs specs and red at least same amount of reviews and opinions on forums and net. My conclusion was that combination of titanium diaphragm and some kind of polymer surround is best combination regarding diaphragm break up and liveliness of the sound. Complete polymer diaphragm and surround used to be considered on dull side, and full titanium on harsh.

Of course, there are excellent drivers of each kind, and my conclusion is based only on other people experience.

Anyway DFM sound excellent in famous QSC WG clone.

It is my shame to not play in some Ath WG yet.

Of course, there are excellent drivers of each kind, and my conclusion is based only on other people experience.

Anyway DFM sound excellent in famous QSC WG clone.

It is my shame to not play in some Ath WG yet.

Here is some burst decay graphs for CDs with diaphragms/suspensions made from various materials:

https://www.justdiyit.com/grand-comparatif-de-compressions-1-pouce/4/

https://www.justdiyit.com/grand-comparatif-de-compressions-1-pouce/4/

Thanks! So the surround is not flat, interesting.

I don't understand one thing - if it is possible to make a driver this smooth, why they don't make all drivers like this, at least the smaller ones? 🙂

(DFM-2535R00-08 measured with A520G2 waveguide)

I don't understand one thing - if it is possible to make a driver this smooth, why they don't make all drivers like this, at least the smaller ones? 🙂

(DFM-2535R00-08 measured with A520G2 waveguide)

Maybe it is this nice and smooth because it is a labour of love for that particular Tymphany engineer who designed it. Some things you just don't do for money but for personal satisfaction. I know i'd do it: put a hi-end gem hidden in a low cost driver line, just for the heck of it.

Look at how much time you've invested in designing a "perfect" waveguide and you do it for free.

Ps. Thank you one more time 🙂

Look at how much time you've invested in designing a "perfect" waveguide and you do it for free.

Ps. Thank you one more time 🙂

Last edited:

So the "rubbery" coating is the black ring only?

You said before that it was on the concave side. Now I'm a bit confused.

You said before that it was on the concave side. Now I'm a bit confused.

No. The black thing is high temperature glue which is used to attach voice coil former to the dome.

Compare pics of concave and convex side of dome. You'll notice that concave side looks flat while convex looks like it has lacquer on it - that is coating. It is transparent and quite thin. If i try to lightly scratch it with fingernail, it feels like glue that is not completely dry.

Compare pics of concave and convex side of dome. You'll notice that concave side looks flat while convex looks like it has lacquer on it - that is coating. It is transparent and quite thin. If i try to lightly scratch it with fingernail, it feels like glue that is not completely dry.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)