If you want a printer that works out of the box, go for a Bambulab, especially if you have no prior 3dprinting experience. I was in your shoes last summer and am very happy with my choice (P1S).

it is double priced. For couple horns printed it is not worth IMO, but as I said has no experience and any advice id good./

The latest STL kits are certainly not difficult prints and I'm pretty sure you should have no problems printing them e.g. with the Ender-5 S1. But as mentioned above, the cheaper the printer, the higher the chance that you will need to spend some more time with the process. It really depends on your motivations, expectations and further plans.

Finally did some test with DCX464. Hoped for a bit more low end extension but not bad overall. Almost spent 3kg PetG for the print.

Attachments

Last edited:

Certainly not bad. It's not reflection-free, but gives you an idea.

You could try to insert a longer extension piece but I doubt it would change much.

You could try to insert a longer extension piece but I doubt it would change much.

Where do you see reflections? That 4kHz of the midrange? This is driver....all measurements show this one. Must be crossed with caution and high order filters but no problem in my opinion.

The measurement doesn't seem gated, it looks like that it includes reflections from the room.

It's not easy do to this properly indoors - I would have trouble as well.

It's not easy do to this properly indoors - I would have trouble as well.

It isnt. Correct. If you want I can send you the .mdat file.

Compared with other horns the low end loading seems good. I think this is as good as it can get for that setup.

Compared with other horns the low end loading seems good. I think this is as good as it can get for that setup.

Well it would be nice to see the horn itself more clearly, but it seems that only a very short time window is available. That can also be a problem.

Is this a exar 550, did you get the files via cults 3d?Finally did some test with DCX464. Hoped for a bit more low end extension but not bad overall. Almost spent 3kg PetG for the print.

Ok, I will wait for the gen2. I am also considering getting a 3d printer. I have always worked with wood and cnc and never with 3d printers. Your projects want me to get into it. Maybe I should get a bambulab x1 carbon, I hear they are easy to use and can still deliver professional results.

CNC is great but wood is costly. I love building out of solid walnut. It means getting all that walnut (expensive), laminating it (time consuming) and then spending a lot of time on cnc. You have to sand before and after. Then apply finish too. Great for final products but too costly for prototyping. You do not have to use solid wood or even plywood with prototypes but it still is costly.

Here are some of the last months builds from cnc. When I have the time, I will try and build one of your designs on the cnc as well. Right now I am divided (more like torn) between work and my 9 month kid who doesn't care too much for sleeping at night 🙂

Here are some of the last months builds from cnc. When I have the time, I will try and build one of your designs on the cnc as well. Right now I am divided (more like torn) between work and my 9 month kid who doesn't care too much for sleeping at night 🙂

Attachments

My first try, I bought EXAR 400 files and scaled them to 1.4

All the pieces were able to fit on the table of Ender 3s1. Two weeks of printing, some difficulty aligning the halves of one of the horns, I still needed to finish painting and adjust the crossovers, but it all worked out!

@mabat thank you, appreciate your work!

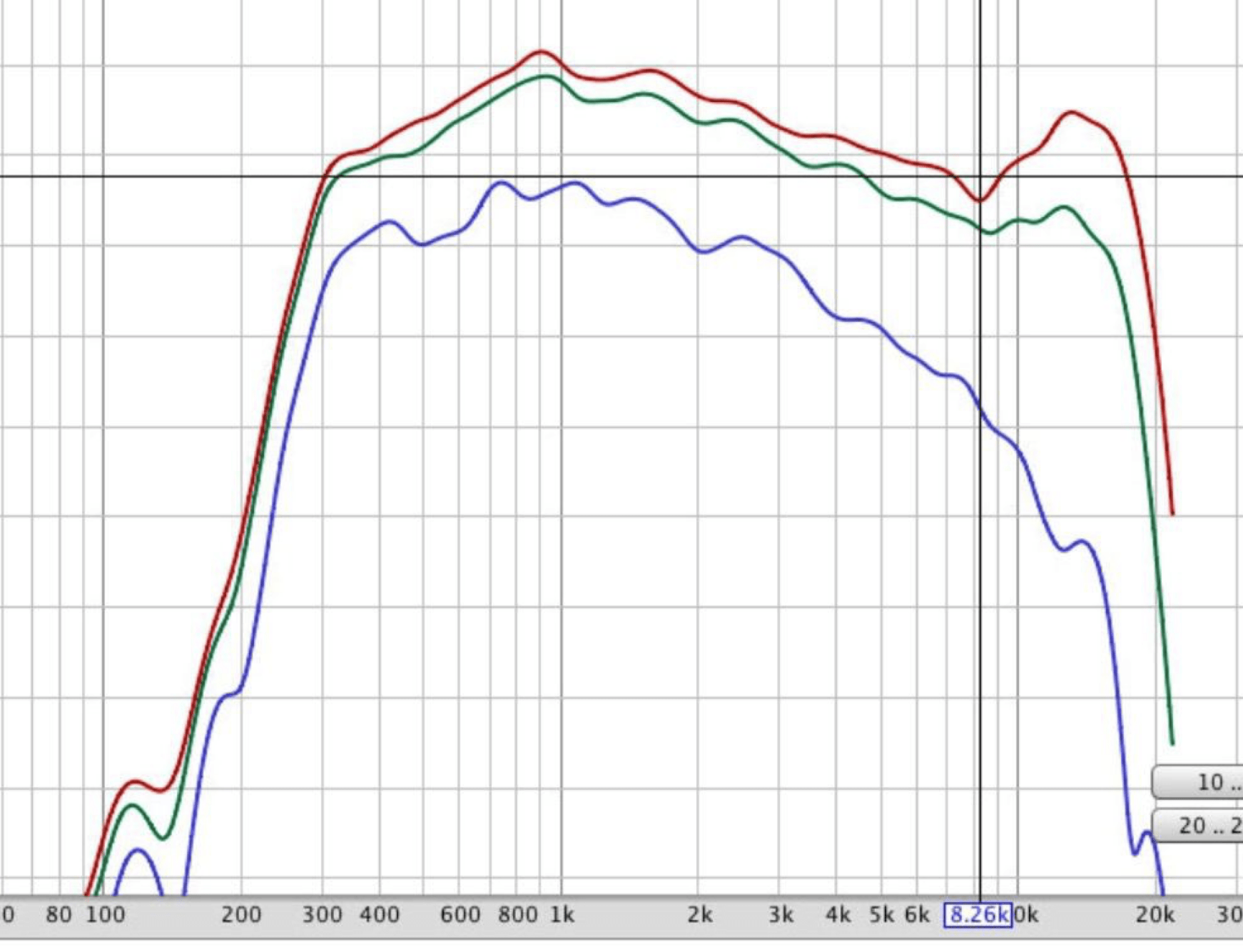

With RCF HF940 ~80cm ~0-30-50° (has yet to take normal measurements, this was the first quick attempt):

And a little demo just for fun:

All the pieces were able to fit on the table of Ender 3s1. Two weeks of printing, some difficulty aligning the halves of one of the horns, I still needed to finish painting and adjust the crossovers, but it all worked out!

@mabat thank you, appreciate your work!

With RCF HF940 ~80cm ~0-30-50° (has yet to take normal measurements, this was the first quick attempt):

And a little demo just for fun:

I don't get what you've done 🙂 Isn't HF940 a horn? So what do we see in the measurement?With RCF HF940 ~80cm ~0-30-50° ...

I do understand that you scaled the whole device to be used with a 1.4" throat driver.

Any such data are of course always highly appreciated.

I don't get what you've done 🙂 Isn't HF940 a horn? So what do we see in the measurement?

I do understand that you scaled the whole device for a 1.4" throat.

Any such data are of course always highly appreciated.

Pardon me, made a mistake — RCF ND940 driver.

And yes, I scaled the EXAR 400 for a 1.4" throat, the horn is about 55 cm in diameter. I first bought the file to see how the slicing into segments was done and just to support your work. And since it was already there, I decided to enlarge it and print it to evaluate the result. The result is more than satisfactory 🙂

The measurements were done with this driver without crossover. I'll try to take better measurements soon and post them if that makes sense.

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)