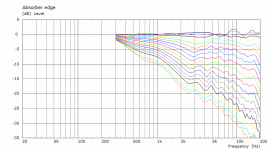

Surprising since we thought a perfect absorber would be a bad reflector.

I suppose that it would depend on how this is handled in the software.

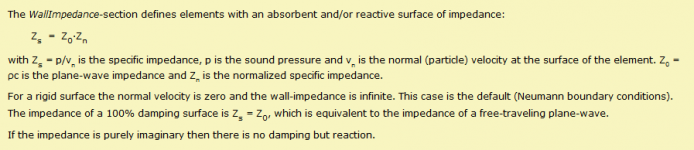

From the documentation:

It may seem unintuitive. But I think it's the same reason why a PWT must be dampened very gradually even with a good absorber for a reflection not to happen, right?

-Oh, wait a minute. I think I could simulate an infinite tube by placing a perfect absorber at the end of it?! 😕

It may seem unintuitive. But I think it's the same reason why a PWT must be dampened very gradually even with a good absorber for a reflection not to happen, right?

-Oh, wait a minute. I think I could simulate an infinite tube by placing a perfect absorber at the end of it?! 😕

Attachments

Last edited:

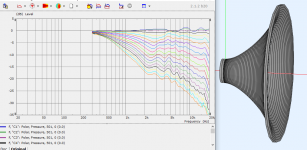

This is a free standing waveguide? Why not roll the edge round to the back side so there's no discontinuity rather than use absorption?

It is and there's really no such reason. This was purely a "what if" scenario, from which one can still learn a lot.

I want to acquire my own tooling, just because I like the idea, but what will I be able to make and offer, that's still to be seen. I can offer any design right away.Promotion. Should I understand it that you plan to sell your designs, make custom ones or even sell ready made horns? That would be really cool! I'd definitely buy some🙂

- I'm already rebuilding a pottery wheel for mold making 🙂

Frankly, with the latest advancements in the free standing axisymmetric designs, I really feel I have something special now. It would be a pity not to be able to make some money on that. Maybe making whole finished speakers would make the most sense but I'm not sure I want to go that route.

Last edited:

It may seem unintuitive. But I think it's the same reason why a PWT must be dampened very gradually even with a good absorber for a reflection not to happen, right?

-Oh, wait a minute. I think I could simulate an infinite tube by placing a perfect absorber at the end of it?! 😕

The problem is the difference between "real" absorbers and software "infinite absorption". In software it's just a condition placed on a set of nodes, but in reality that can never be accomplished. Hence, you might get results that are completely "unintuitive" because they are completely impossible in reality.

I want to acquire my own tooling, just because I like the idea, but what will I be able to make and offer, that's still to be seen. I can offer any design right away.

- I'm already rebuilding a pottery wheel for mold making 🙂

Honestly, having a mold cut in a dense polyurethane stacked boards at a CNC shop is the way to go. Being soft"ish" poly is not so rough on the cutters as steel or aluminum so it should not cost too much - it goes fast. But I did cut my first molds on a lathe, that worked well for awhile, but got untenable with larger devices.

By unintuitive I meant what you said, that "a perfect absorber would also be a near perfect reflector". I still don't quite understand what's happening in the simulations above. I used perfectly absorbing BEM elements before and there really wasn't any reflection I think, for example when it was used as a "cover" of a waveguide. Now it seems to behave differently but it's still not clear to me why. All I can see is that the contour is not well terminated, somehow.

Thanks, it's quite possible I will end up with that. My current (still a lot cheaper) plan is to use an epoxy coated XPS ("Styrofoam"). It should stay fairly flexible. I want to try a slow epoxy for casting, it cures at the normal (room) temperature. It may take days to set but I don't mind (yet).Honestly, having a mold cut in a dense polyurethane stacked boards at a CNC shop is the way to go. Being soft"ish" poly is not so rough on the cutters as steel or aluminum so it should not cost too much - it goes fast. But I did cut my first molds on a lathe, that worked well for awhile, but got untenable with larger devices.

Is it simply because there is a sudden impedance change at the edge, almost like if the absorbing elements were not there at all?... All I can see is that the contour is not well terminated, somehow.

Last edited:

Honestly, having a mold cut in a dense polyurethane stacked boards at a CNC shop is the way to go. Being soft"ish" poly is not so rough on the cutters as steel or aluminum so it should not cost too much - it goes fast. But I did cut my first molds on a lathe, that worked well for awhile, but got untenable with larger devices.

What shore hardness is dense and softish?

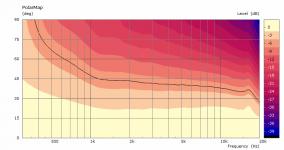

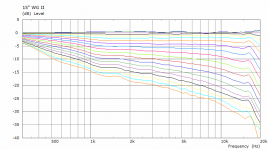

However good that may look, I think there would be even a better option. Personally, I would make it smaller, a little bit less CD with a smoother overall DI curve, use a good 1.4" driver and cross it lower than what would be possible with a 1" driver. Together with a smaller woofer, like 12" (could be 15" if needed), I think the performace would be absolutely stellar.

BTW, the waveguide above is only 127 mm (5") deep.

BTW, the waveguide above is only 127 mm (5") deep.

Last edited:

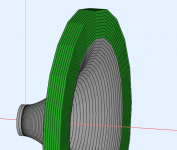

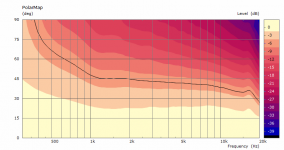

Indeed, this is the same waveguide left "underterminated" -

What do you mean with underterminated? That the roll-back is missing or something else?

By that I mean that it is not fully terminated, i.e. there's still a noticeable impedance mismatch. I would call it fully terminated once all the ripples are gone (as they can).

However good that may look, I think there would be even a better option. Personally, I would make it smaller, a little bit less CD with a smoother overall DI curve, use a good 1.4" driver and cross it lower than what would be possible with a 1" driver. Together with a smaller woofer, like 12" (could be 15" if needed), I think the performace would be absolutely stellar.

BTW, the waveguide above is only 127 mm (5") deep.

Ok, perhaps you did already show such a creation? If not, please do.

//

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)