he was grinning away and gong on about the clarity and nuances

Always nice to read. The magic of DML in real!@aagas : Thrill. Awe. Delight. They couldn't stop smiling.

A Study of DMLs as a Full Range Speaker

It is high time!

If anyone here had made a full range DML, how about coming forward and illustrate that?

Some have been in the trade for more than 8 years, some here since the middle of 2019, some from the beginning of 2020, some from 2021...

It is high time!

If anyone here had made a full range DML, how about coming forward and illustrate that?

Some have been in the trade for more than 8 years, some here since the middle of 2019, some from the beginning of 2020, some from 2021...

Last edited:

You can use a 2,000W amp if you like. But as long as you don't drive more than 160W into the load, then it will be fine. A 320W amp will deliver around 160W of music power into a 4-ohm load IF you don't clip it. (However, in reality, a 320W amp will deliver a lot less than 160W of uncompressed music without clipping. It's to do with crest factor. It's complicated. So don't worry about it unless you want to chase rabbit trails)yes ok but according to you for the exciters in general

considering the various aspects and characteristics to avoid breaking or damage but at the same time have the highest possible power do I always stick to taking a 160 rms power amp or do I increase it a bit to avoid clipping? the exciters have to be considered exactly like a traditional loudspeaker or I have to consider the load (the panel) differently.Thanks

On the other hand, if you use a little 50W amp, and drive it into clipping for too long, then it's probably more likely that you will blow your drivers because you're basically feeding square waves into your drivers.

In your setup with 4 x 40W drivers on a decent panel, unless you're doing high crest-factor, live music for an outdoor event, you will probably never clip a 300W amp. But be aware of excursion limitations. I'm not sure which drivers you're using, but most of them will bottom out on the bass end, and you might have to roll off your panel below 150Hz or so and add a sub.

Hi Toddmagic spray foam panels

I've just been playing with what I presume is the same stuff (PU expanding foam?)

Can you pls explain the panel details

Thanks

Eucy

Allllll Right! I've been waiting for someone to try some of this out. I can't say more good things about this material than already stated in prior posts. Please check out some of these images below from said post's and let me know if it is indeed what you have.Can you pls explain the panel details

So this is my original build using the spray foam material if interested. They were made with some DIY exciters. These are the same panels (material) my buddy listened to but refurbished using a pair of DAEX25FHE-4's.

Post #3,207.https://www.diyaudio.com/community/threads/a-study-of-dmls-as-a-full-range-speaker.272576/page-161#post-6685870

I made the panels in this basic ear shape via Bertagni and for asthetics as they are mounted about an inch off the wall at an angle with about 4 1/2" clearance in the rear. I mounted the exciters pretty much center.

They average 1/2" thick as they are not perfect, and are 12" at the lower wide section and 16" tall.

Here are a couple of post's with photos where I explain the material: Post #7,748 https://www.diyaudio.com/community/...ll-range-speaker.272576/page-388#post-7208551

Post # 5,781 https://www.diyaudio.com/community/...ll-range-speaker.272576/page-290#post-7036391

Here is a post explaining my center speakers made from this material for better voice clarity and to conform with the R/L speakers which we are discussing. (I used to listen to my R/L's in conjunction with a nice pair of JBL bookshelfs but just use the panels now.)

Post #6,073 https://www.diyaudio.com/community/...full-range-speaker.272576/page-304#post-70756

Below are some photos from above posts:

Attachments

Hello, the 4 Dayton Audio EX30HESF2-4 High Efficiency speakers are mounted on a 3.8 mm thick 50x40 cm wide carbon-nomex panel, the use is for live applications with cutoff presumably around 100hz, from the first tests, however, I must say that at least closed also the low part is really efficient a little less on the very high frequencies. Therefore it will mainly be supported by subwoofers but probably in light and heavy live applications they could perhaps be autonomous. In the light of this information which power amp would you use to drive them to the maximum but with reasonable safety margin?You can use a 2,000W amp if you like. But as long as you don't drive more than 160W into the load, then it will be fine. A 320W amp will deliver around 160W of music power into a 4-ohm load IF you don't clip it. (However, in reality, a 320W amp will deliver a lot less than 160W of uncompressed music without clipping. It's to do with crest factor. It's complicated. So don't worry about it unless you want to chase rabbit trails)

On the other hand, if you use a little 50W amp, and drive it into clipping for too long, then it's probably more likely that you will blow your drivers because you're basically feeding square waves into your drivers.

In your setup with 4 x 40W drivers on a decent panel, unless you're doing high crest-factor, live music for an outdoor event, you will probably never clip a 300W amp. But be aware of excursion limitations. I'm not sure which drivers you're using, but most of them will bottom out on the bass end, and you might have to roll off your panel below 150Hz or so and add a sub.

Yes, that's exactly the problem I had with those drivers, they are very efficient in the midrange, but lacking on bass and high frequencies. You might have to use a DSP PEQ to get a decent response.Hello, the 4 Dayton Audio EX30HESF2-4 High Efficiency speakers are mounted on a 3.8 mm thick 50x40 cm wide carbon-nomex panel, the use is for live applications with cutoff presumably around 100hz, from the first tests, however, I must say that at least closed also the low part is really efficient a little less on the very high frequencies.

I think sub-woofers in any live application cannot be avoided. Maybe a large enough panel might be ok for home use.Therefore it will mainly be supported by subwoofers but probably in light and heavy live applications they could perhaps be autonomous.

Use anything that will deliver at least 250W into 4-ohms per channel.In the light of this information which power amp would you use to drive them to the maximum but with reasonable safety margin?

on the bass no unlike the previous version of these exciters which had an increase in response to 200 these have a crazy response to 100 with strong attenuation to 200, then obviously the rest is done by the system that holds the panel which therefore allows you to obtain the right response while maintaining a dry sound on the bass.You can use a 2,000W amp if you like. But as long as you don't drive more than 160W into the load, then it will be fine. A 320W amp will deliver around 160W of music power into a 4-ohm load IF you don't clip it. (However, in reality, a 320W amp will deliver a lot less than 160W of uncompressed music without clipping. It's to do with crest factor. It's complicated. So don't worry about it unless you want to chase rabbit trails)

On the other hand, if you use a little 50W amp, and drive it into clipping for too long, then it's probably more likely that you will blow your drivers because you're basically feeding square waves into your drivers.

In your setup with 4 x 40W drivers on a decent panel, unless you're doing high crest-factor, live music for an outdoor event, you will probably never clip a 300W amp. But be aware of excursion limitations. I'm not sure which drivers you're using, but most of them will bottom out on the bass end, and you might have to roll off your panel below 150Hz or so and add a sub.

From my humble experience I have to say that following the tectonic hooking system in principle, therefore 4 fixed points and rubber on the sides, leaving some points free, it seems to work well as a response on low frequencies. What I can do little about are the very highs, in this regard if you have any ideas on a mechanical level that can improve otherwise it will obviously be taken care of by the dsp. As far as the amplifier is concerned, I had thought of taking at least a 320wrms just to avoid clipping of the power amp and then obviously attenuated on the dsp not to risk it, but as you say if it's too low risk the same. for the maqrca I was thinking of Powersoft

Pixel1.

Last night at about 12midnight I went into my room to hook up a eps panel to work on today.

But I changed my mind and put up my aluminium panel instead.

I thought I would do some quick measurements using weights to change frequency response.

I get the impression that no one thinks weights are of much importance ?

If you have a panel that has suck outs in its response in the 100hz to 300hz or any where up to about 1.5k (this is always depending on the particular panel) you can adjust the response (maybe) with weights.

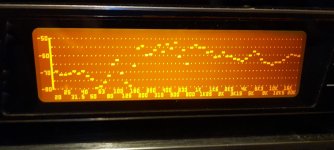

I wanted to get to bed so just quickly attached the magnetic weights into the positions shown in the pictures after moving them around for a few minutes while monitoring the response on my DEQ .

The first picture is the panel with the weights in position.

The second picture is the response without weights.

The third picture is the response with the weights.

The responses with the weights has increased the output in the suck out areas by 10db and by some 5db higher up to about 1.5k.

It took a bit longer than I expected ,as I only have one pair of hands and a rather large dog to contend with,so did not get to bed until 2a.m. 😴

Pictures in next post.

Steve.

Last night at about 12midnight I went into my room to hook up a eps panel to work on today.

But I changed my mind and put up my aluminium panel instead.

I thought I would do some quick measurements using weights to change frequency response.

I get the impression that no one thinks weights are of much importance ?

If you have a panel that has suck outs in its response in the 100hz to 300hz or any where up to about 1.5k (this is always depending on the particular panel) you can adjust the response (maybe) with weights.

I wanted to get to bed so just quickly attached the magnetic weights into the positions shown in the pictures after moving them around for a few minutes while monitoring the response on my DEQ .

The first picture is the panel with the weights in position.

The second picture is the response without weights.

The third picture is the response with the weights.

The responses with the weights has increased the output in the suck out areas by 10db and by some 5db higher up to about 1.5k.

It took a bit longer than I expected ,as I only have one pair of hands and a rather large dog to contend with,so did not get to bed until 2a.m. 😴

Pictures in next post.

Steve.

bye thank you

yes I too used magnets to add weights

I put two small but powerful neodymium magnets on the carbon faces, at the moment I don't use them because I recently managed to find a way to stabilize the exciter magnets which tilted and made everything croak, now even if in a precarious way

it works but I have to find a serious and repeatable way to be able to build a rear frame that includes the support of the exciters

and a way to attach everything to the rectangular frame of the system. At the moment I have no idea how to do it without spending a fortune, to tell the truth I still don't know what material to do it in the powers involved are quite high with 4 exciters and avoid vibrations spurious is not easy

yes I too used magnets to add weights

I put two small but powerful neodymium magnets on the carbon faces, at the moment I don't use them because I recently managed to find a way to stabilize the exciter magnets which tilted and made everything croak, now even if in a precarious way

it works but I have to find a serious and repeatable way to be able to build a rear frame that includes the support of the exciters

and a way to attach everything to the rectangular frame of the system. At the moment I have no idea how to do it without spending a fortune, to tell the truth I still don't know what material to do it in the powers involved are quite high with 4 exciters and avoid vibrations spurious is not easy

hi jaxboy.spedge,

Welcome back!

I presume that greeting isn't another southern way of saying clear off and don't come back, with a smile 😃😁😬

How are things , did you try a whizzer cone to see if it improves clarity for you, or are you happy with the panels as they are?

Steve.

Hi ToddAllllll Right! I've been waiting for someone to try some of this out. I can't say more good things about this material than already stated in prior posts. Please check out some of these images below from said post's and let me know if it is indeed what you have.

So this is my original build using the spray foam material if interested. They were made with some DIY exciters. These are the same panels (material) my buddy listened to but refurbished using a pair of DAEX25FHE-4's.

Post #3,207.https://www.diyaudio.com/community/threads/a-study-of-dmls-as-a-full-range-speaker.272576/page-161#post-6685870

I made the panels in this basic ear shape via Bertagni and for asthetics as they are mounted about an inch off the wall at an angle with about 4 1/2" clearance in the rear. I mounted the exciters pretty much center.

They average 1/2" thick as they are not perfect, and are 12" at the lower wide section and 16" tall.

Here are a couple of post's with photos where I explain the material: Post #7,748 https://www.diyaudio.com/community/...ll-range-speaker.272576/page-388#post-7208551

Post # 5,781 https://www.diyaudio.com/community/...ll-range-speaker.272576/page-290#post-7036391

Here is a post explaining my center speakers made from this material for better voice clarity and to conform with the R/L speakers which we are discussing. (I used to listen to my R/L's in conjunction with a nice pair of JBL bookshelfs but just use the panels now.)

Post #6,073 https://www.diyaudio.com/community/...full-range-speaker.272576/page-304#post-70756

Below are some photos from above posts:

Thanks for the info

The material is of the same family, but specs vary with this stuff. The foam we can buy in a can in Aus has a free expansion of 3x, whereas yours states 25mm filling capacity. The end density is obviously affected by the mould (mold) constraints.

In my previous life as a consulting structural engineer, I was involved in several projects where construction quality Urethane foam was used to lift :

a) a heritage building which had subsided

b) rigid paving areas in building aprons

c) approaches to bridges

The density of the construction material is much higher than the consumer foam.

In the case of a), the foam successfully restored the building, but found and filled breaks in old stormwater pipes, and caused foam geysers to erupt in lawn areas surrounding the building. We were forced to do a dance to avoid the eruptions. 😊

I was experimenting with the foam for a different purpose which I'll spell out in another post, but i would be interested to hear how you made the mould (mold) and what release agent you used.

I believe making a panel from this material is well worth a try

Cheers

Eucy

Hey Steve - forget the aly panel - focus on the domesLast night at about 12midnight I went into my room to hook up a eps panel to work on today.

But I changed my mind and put up my aluminium panel instead.

😉

😉Hello SteveI get the impression that no one thinks weights are of much importance ?

Steve.

You are probably right. I haven't made test with weight. 2 reasons : in my mind (probably wrongly) added weight is synonym of inertia, maybe loss of efficiency (this is only opinion!), I have no clues (and I haven' explored!) or methodology to to it. Would you help on the way to proceed, the range of weight?

Christian

PS : in Tectonic pictures, if I remember, there are some weight added.

Steve,

Oh, no, just as it sounds. Welcome back. I missed your down-to-earth sanity and good advice. I haven't been doing anything to my panels at all. I have been coping with health issues, another neck surgery, a right hand that has little to no grip strength, and ongoing pain. Your posts provide good relief.

Oh, no, just as it sounds. Welcome back. I missed your down-to-earth sanity and good advice. I haven't been doing anything to my panels at all. I have been coping with health issues, another neck surgery, a right hand that has little to no grip strength, and ongoing pain. Your posts provide good relief.

Christian.

every panel is different, so you will have to test your own panels yourself.

The first picture is from the pro dml panel forum on audiocircle.

There are three AA batteries held on with blu-tack, there was originally four but one had fallen off ,I think it was in the top right corner somewhere?

In the second picture I used 6 magnets( 3 pairs) on this smell 1mm veneer panel.

It is easier to just use you fingers to find the correct positions on smaller panels.

some panels ,like the proplex panel ,do not need weights as the frequency response is fine.

The weights I have used here, were only test weights ,and if used permanently I would have tried reducing the size and weight.

or as I have said before, maybe used the positions to mount the panel.

I do not use damping or weights on my EPS panels but maybe very small weights could be used if wanted ?

It all depends if you think the weights improve the sound or are even needed if using a higher XO.

It can be a useful tool of needed.

Steve.

every panel is different, so you will have to test your own panels yourself.

The first picture is from the pro dml panel forum on audiocircle.

There are three AA batteries held on with blu-tack, there was originally four but one had fallen off ,I think it was in the top right corner somewhere?

In the second picture I used 6 magnets( 3 pairs) on this smell 1mm veneer panel.

It is easier to just use you fingers to find the correct positions on smaller panels.

some panels ,like the proplex panel ,do not need weights as the frequency response is fine.

The weights I have used here, were only test weights ,and if used permanently I would have tried reducing the size and weight.

or as I have said before, maybe used the positions to mount the panel.

I do not use damping or weights on my EPS panels but maybe very small weights could be used if wanted ?

It all depends if you think the weights improve the sound or are even needed if using a higher XO.

It can be a useful tool of needed.

Steve.

Attachments

Steve,

I take it that the turntable in the veneer picture is not being used anymore! In one of my many moves in the military, the moving company hastened my transition from vinyl to CDs by reducing my turntable and hand-built amplifier and preamp to boat anchors. Oh, well. I'm in my 46th and hopefully final residence now and have double back-ups to my music on external drives. In response to your question about the whizzer cone, I don't really hear high Hz, so a whizzer would not help me, and I am pleased with my canvas panels as is. It was the amp problems that caused me to put them away. Not being able to use my right hand is why I haven't gotten around to addressing the amplifier problem.

I take it that the turntable in the veneer picture is not being used anymore! In one of my many moves in the military, the moving company hastened my transition from vinyl to CDs by reducing my turntable and hand-built amplifier and preamp to boat anchors. Oh, well. I'm in my 46th and hopefully final residence now and have double back-ups to my music on external drives. In response to your question about the whizzer cone, I don't really hear high Hz, so a whizzer would not help me, and I am pleased with my canvas panels as is. It was the amp problems that caused me to put them away. Not being able to use my right hand is why I haven't gotten around to addressing the amplifier problem.

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker