@spedge

Steve,

I had the possibility of some tests this afternoon.

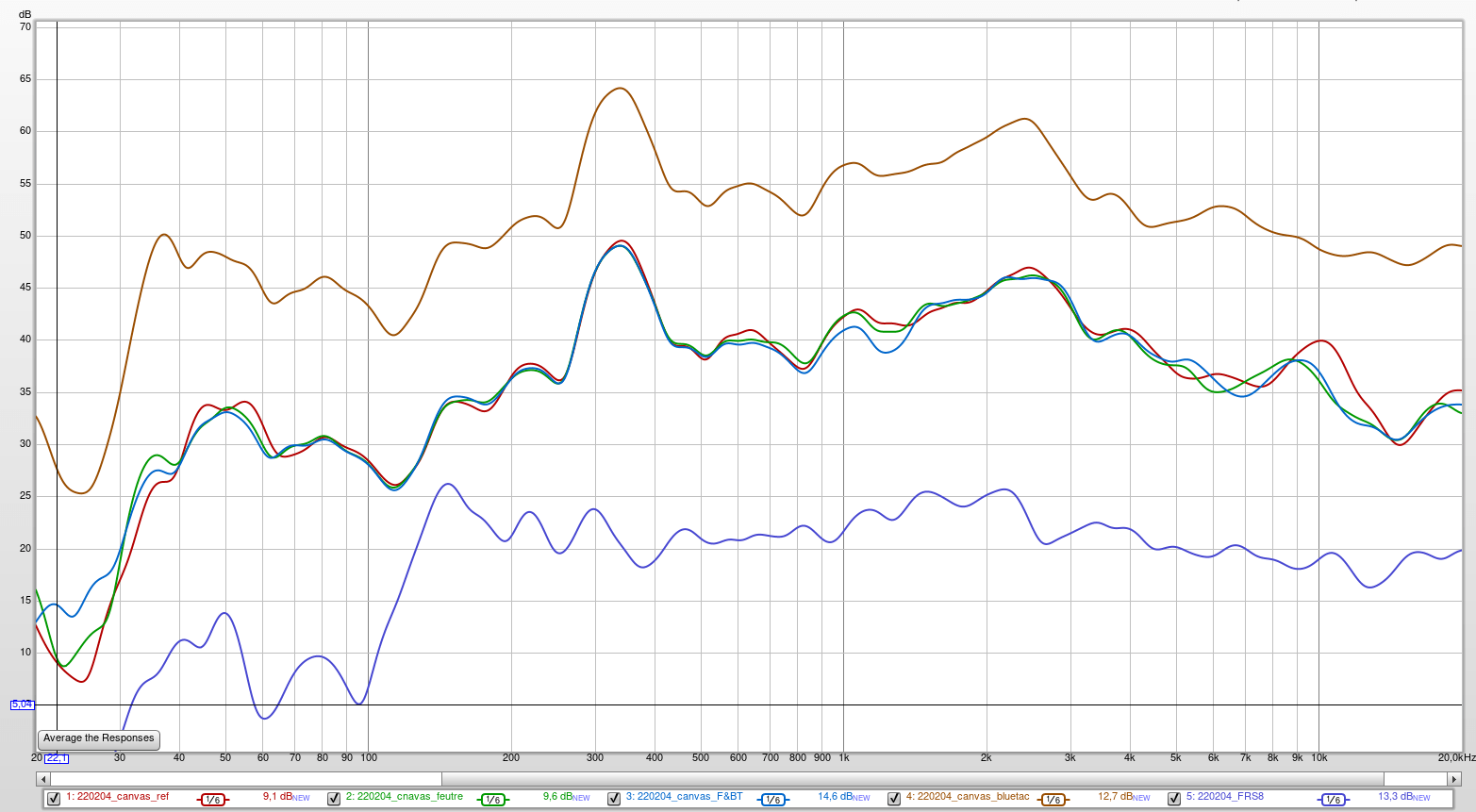

First part of the tests : adding some damping or mass at the center of my canvas panel.

See below

1- red : the original canvas (with the peak 40dB@10kHz)

2 - green : with a self adhesive disk of felt (20mm diameter to put under legs of chairs)

3 - light blue : the felt plus a small ball of blue tack (or similar)

4 - brown (+15dB offset) : only the small ball

5 - dark blue (-15dB) : a small 1.2l closed box with a Visaton FRS8 at the same position in the room than the canvas (as a sort of reference)

My conclusion at this time :

So next step will be to have this while the canvas are playing. I am afraid the peaks before mask the effect.

Additional information (it is part of the goal of those tests) : there is a gain of +4 or +5dB in SPL in favor of the canvas compare to the FRS8 (which is said for 82dB@1m). No change of volume setting during the test. The mic here was at about 2.2m from the speaker so a little bit in front of the listening position.

Christian

Steve,

I had the possibility of some tests this afternoon.

First part of the tests : adding some damping or mass at the center of my canvas panel.

See below

1- red : the original canvas (with the peak 40dB@10kHz)

2 - green : with a self adhesive disk of felt (20mm diameter to put under legs of chairs)

3 - light blue : the felt plus a small ball of blue tack (or similar)

4 - brown (+15dB offset) : only the small ball

5 - dark blue (-15dB) : a small 1.2l closed box with a Visaton FRS8 at the same position in the room than the canvas (as a sort of reference)

My conclusion at this time :

- little effect of the disk of felt

- the effect of the blue tack ball seems similar to what you have.

So next step will be to have this while the canvas are playing. I am afraid the peaks before mask the effect.

Additional information (it is part of the goal of those tests) : there is a gain of +4 or +5dB in SPL in favor of the canvas compare to the FRS8 (which is said for 82dB@1m). No change of volume setting during the test. The mic here was at about 2.2m from the speaker so a little bit in front of the listening position.

Christian

Last edited:

Second part of the today measurements... for those one help and advice welcome!

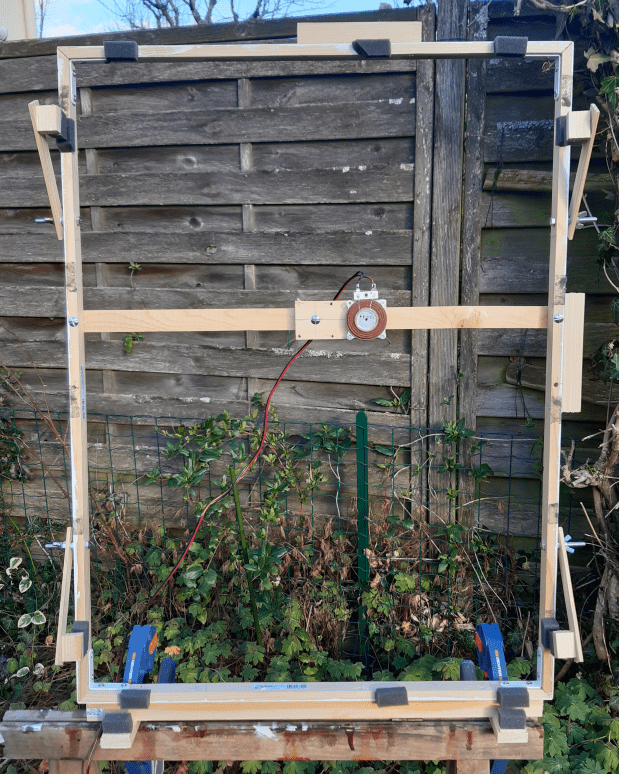

For that I have adapted a 60x80cm frame built some month ago and not used in order to have the possibility to easily change the panel to test different materials and different exciter positions and other things...

As starting point, I choose the 9mm XPS which made my second pair of panels and was a failure. So first goal is to try to understand why it is a failure (if possible).

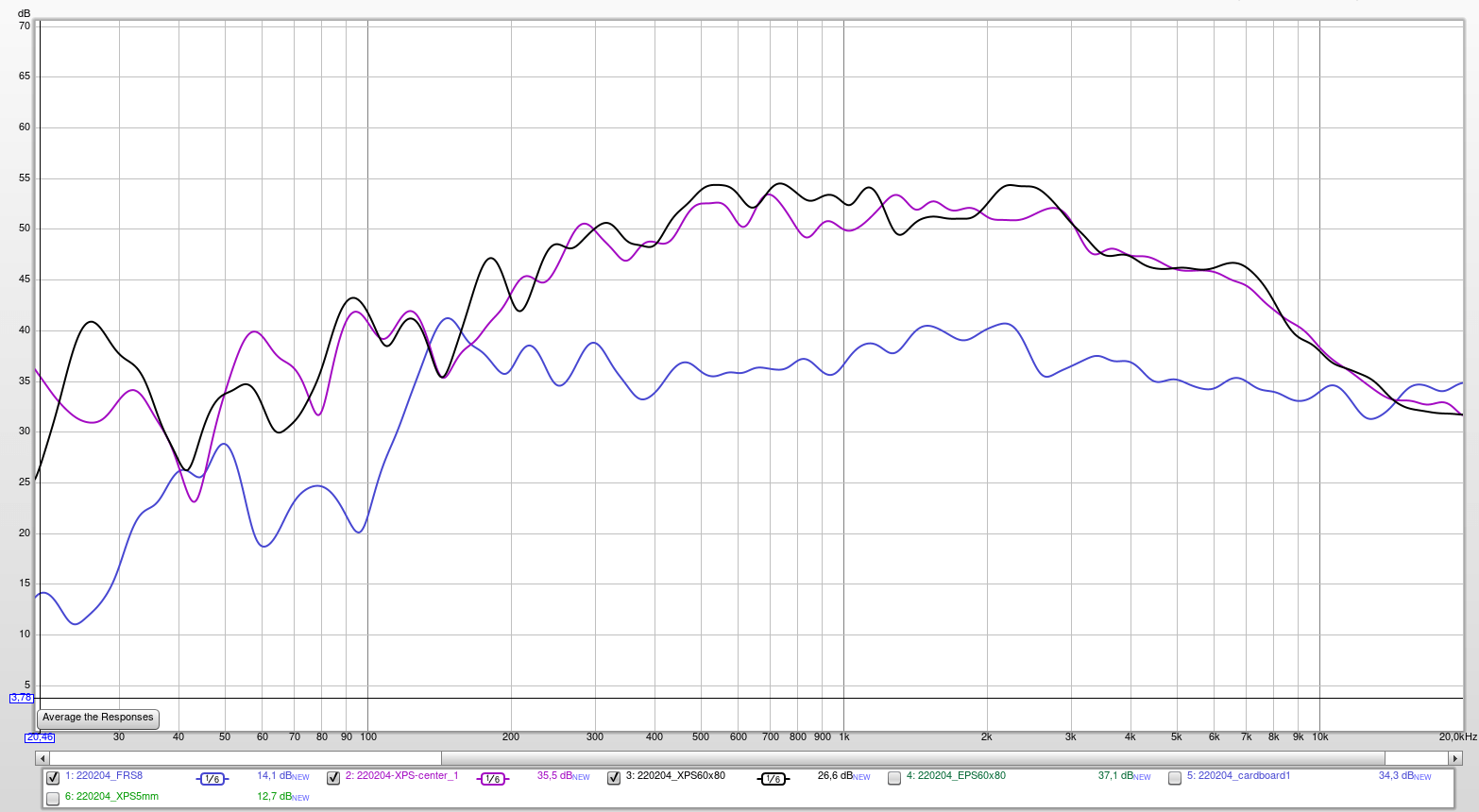

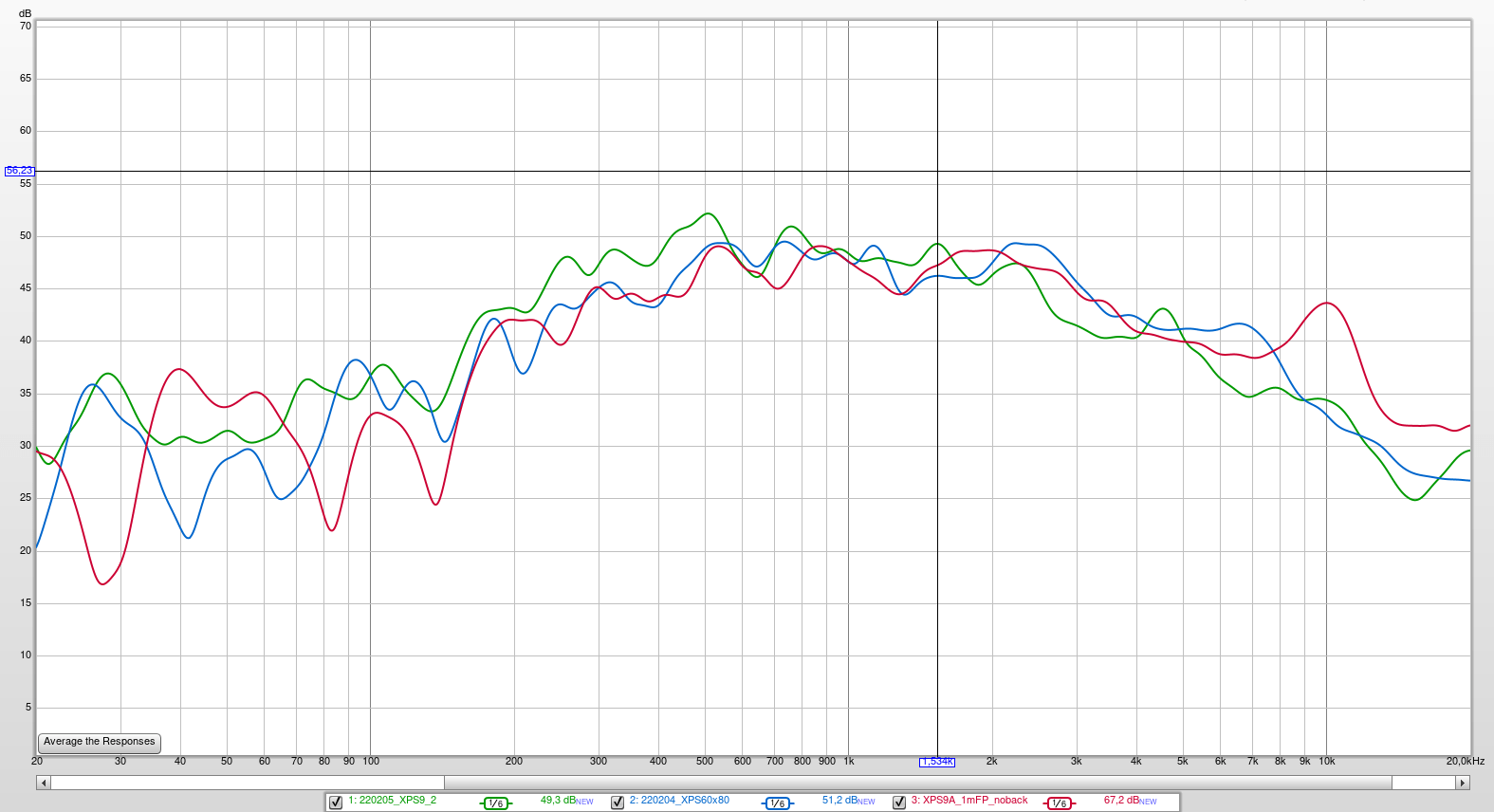

One characteristic of this panel was to have the exciter right on the center. So today, I tested :

1 - pink : exciter at the center. The behavior seen and heard with the prototype is confirmed. no low freq, no high freq.

2 - black : exciter at 2/5. The exciter position is not the reason. Hmm... For the high freq ok but for the low freq it would have been a nice explanation. It isn't!

3 - blue : the FRS8 has level reference. The XPS is 12 to 13 db better in efficiency.. ok on a small band.

Somebody has an idea?

I am not sure it is the same XPS than the one coming in 20mm thick and larger panel. It seems more airy, like a foam. It is also shiny.

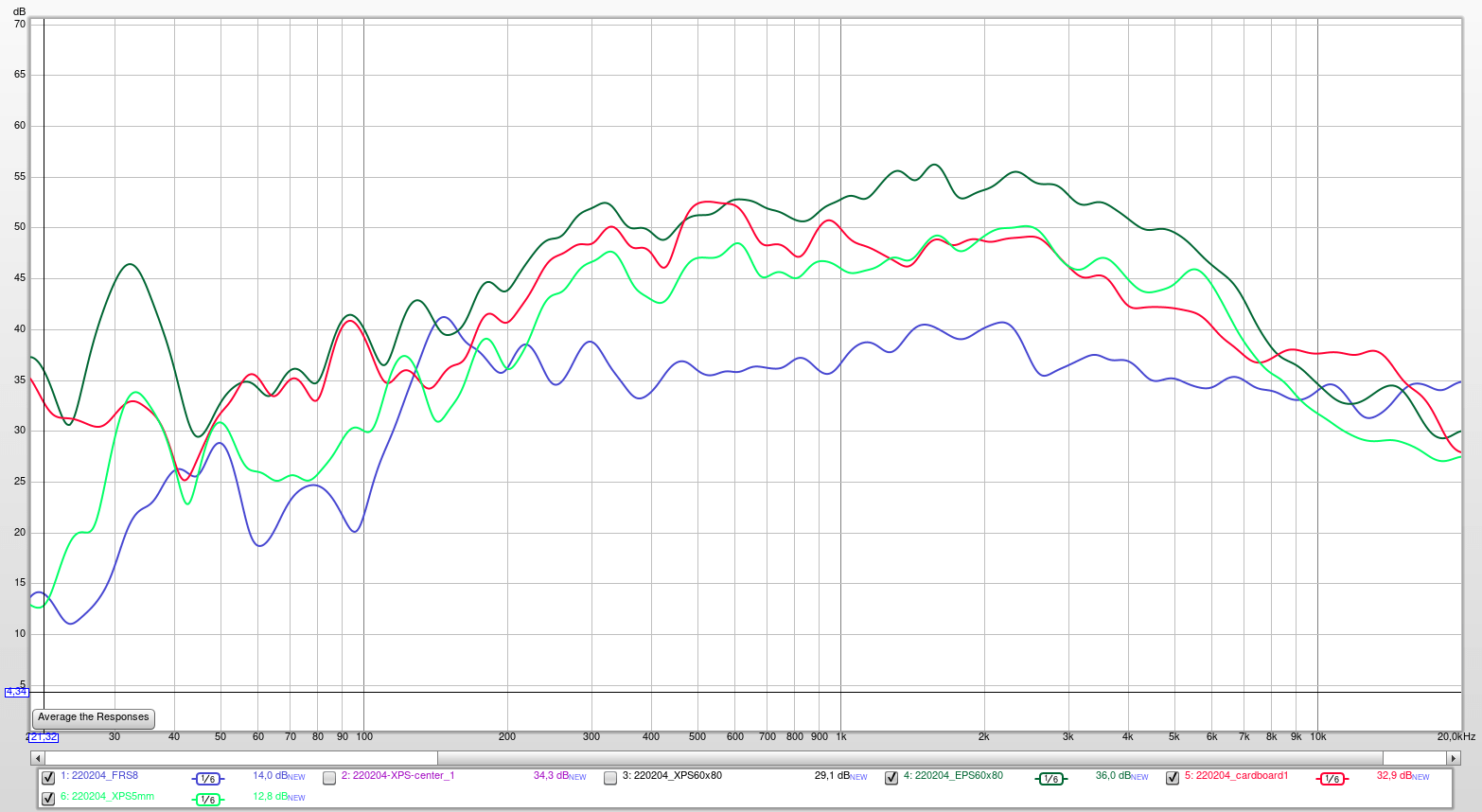

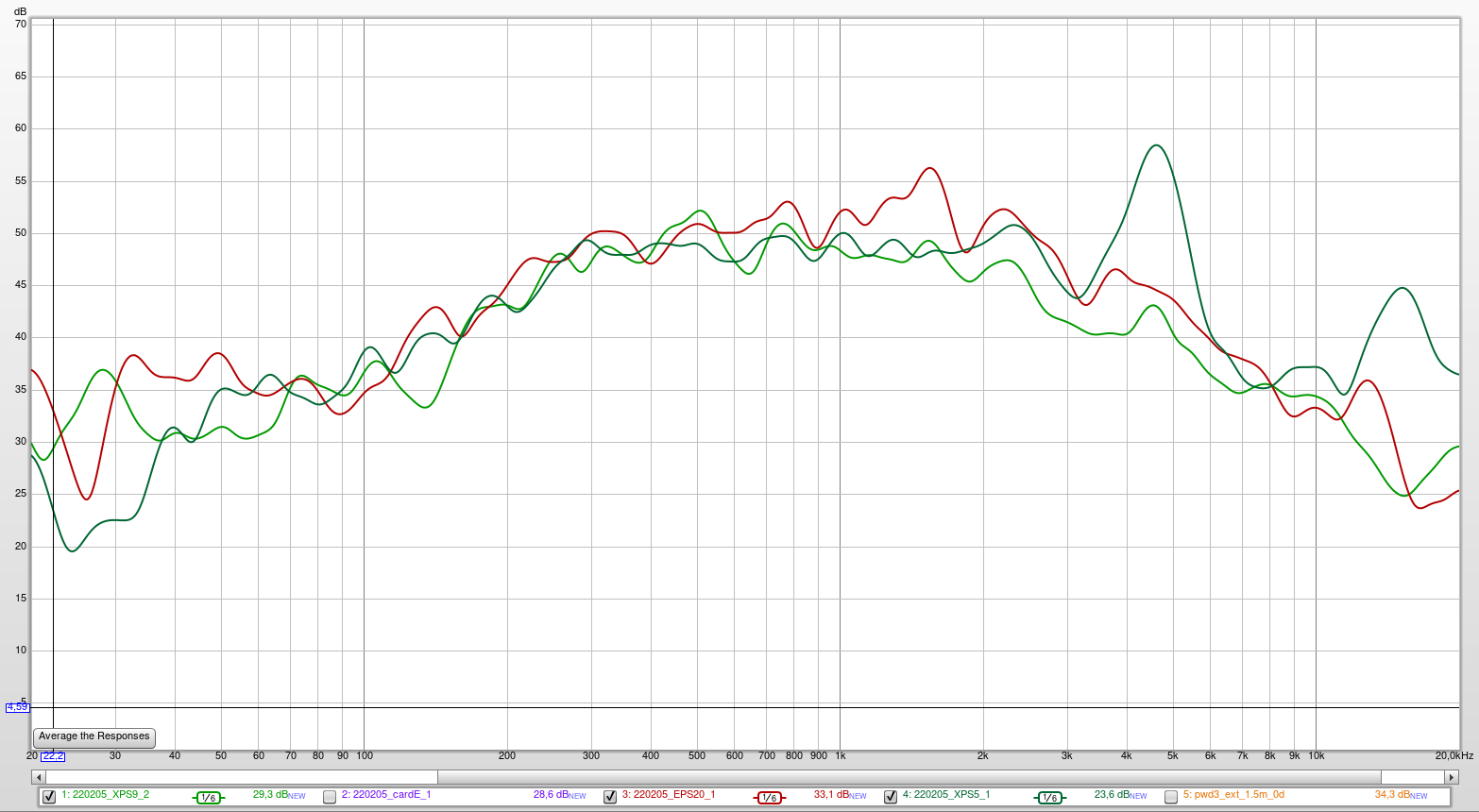

Next, I have changed the material

4 - dark green is a 20mm thick EPS (15kg/m³). No low freq, no high freq. What's happen? not expected from EPS

5 - red is a cardboard E flute (2mm thick). Well there is a small portion flat at 10k but 10dB lower than the mids; I am not used to see so important difference.

6 - light green is a 5mm XPS like the one to put under a floor. Its aerial mass is very low

3 - blue : the FRS8 has level reference. The unexpected thing is the level of the 5mm XPS. It is the lightest one and not the highest SPL. Again what's wrong?

Somebody has an idea of what happens?

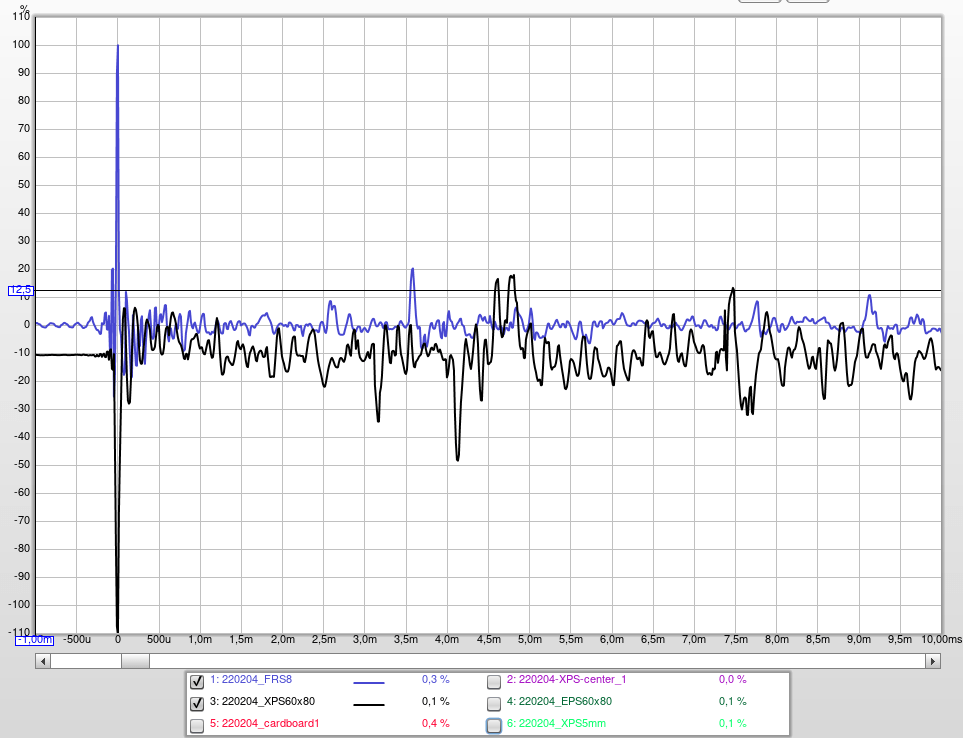

Just as a curiosity here are 2 impulses responses :

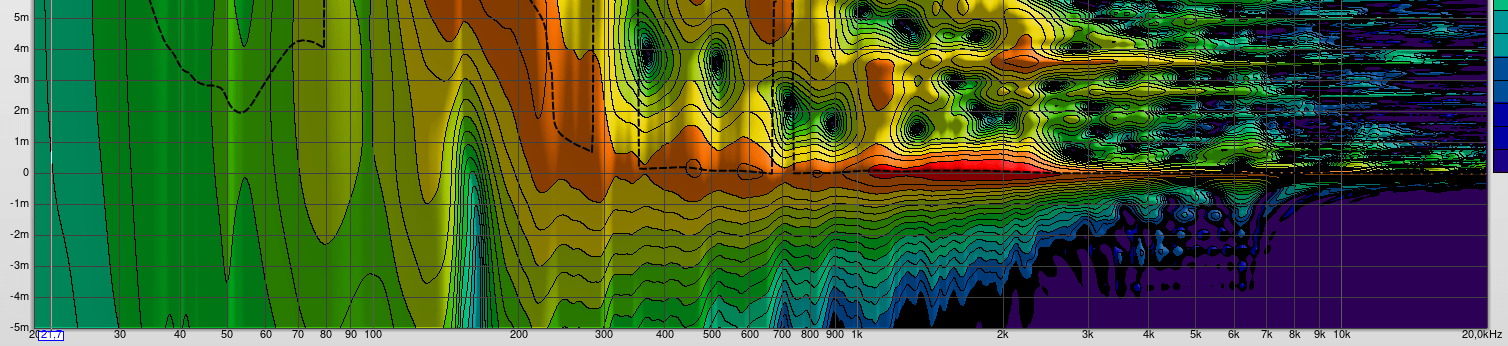

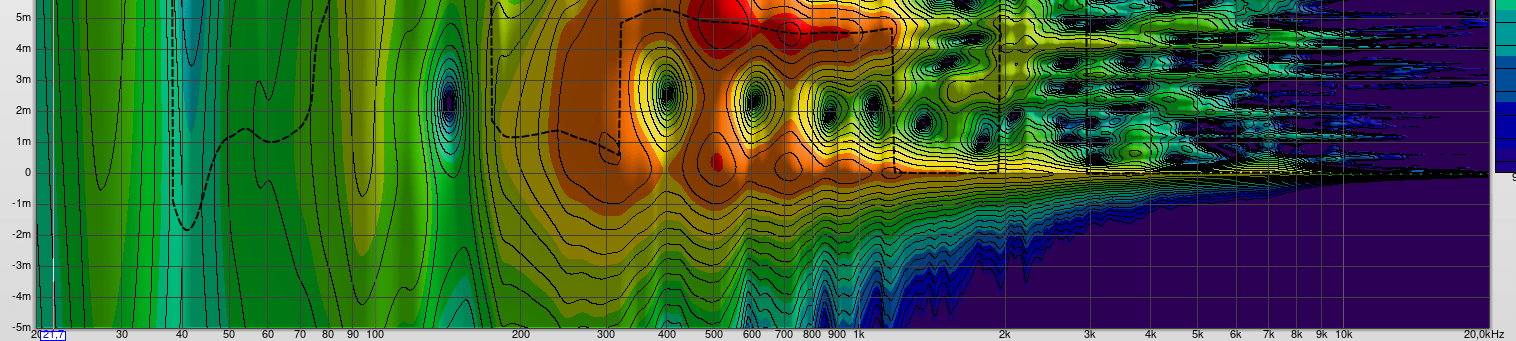

Also because it is not often share, here are 2 spectrograms ( wavelet time). I like wavelets.

The FRS8

The 9mm XPS

The level in the area 4...5ms is really high. Would it be the internal damping of the panel not high enough?

I thought to make some outdoor measurements to "eliminate" the hypothesis of room reflections but the weather was not good enough and not really the time for..; so let see next time.

Additional information : all the panels except the EPS are raw. No PVA coating. Is the coating that could make the difference? This said, the EPS FR is not really nice. When I built the prototype with the 9mm XPS, it was PVA coated... no good results.

Christian

For that I have adapted a 60x80cm frame built some month ago and not used in order to have the possibility to easily change the panel to test different materials and different exciter positions and other things...

As starting point, I choose the 9mm XPS which made my second pair of panels and was a failure. So first goal is to try to understand why it is a failure (if possible).

One characteristic of this panel was to have the exciter right on the center. So today, I tested :

1 - pink : exciter at the center. The behavior seen and heard with the prototype is confirmed. no low freq, no high freq.

2 - black : exciter at 2/5. The exciter position is not the reason. Hmm... For the high freq ok but for the low freq it would have been a nice explanation. It isn't!

3 - blue : the FRS8 has level reference. The XPS is 12 to 13 db better in efficiency.. ok on a small band.

Somebody has an idea?

I am not sure it is the same XPS than the one coming in 20mm thick and larger panel. It seems more airy, like a foam. It is also shiny.

Next, I have changed the material

4 - dark green is a 20mm thick EPS (15kg/m³). No low freq, no high freq. What's happen? not expected from EPS

5 - red is a cardboard E flute (2mm thick). Well there is a small portion flat at 10k but 10dB lower than the mids; I am not used to see so important difference.

6 - light green is a 5mm XPS like the one to put under a floor. Its aerial mass is very low

3 - blue : the FRS8 has level reference. The unexpected thing is the level of the 5mm XPS. It is the lightest one and not the highest SPL. Again what's wrong?

Somebody has an idea of what happens?

Just as a curiosity here are 2 impulses responses :

- blue : the FRS8 (Visaton cone full range); some peaks after the 2 first ms; Most probably reflections.

- black : the 9mm XPS. Typical of a DML. Many peaks for a long time. An it gives a pretty good sound; sure not this one but even the best one I know have this signature. It is reported in paper like the one from M Azima.

Also because it is not often share, here are 2 spectrograms ( wavelet time). I like wavelets.

The FRS8

The 9mm XPS

The level in the area 4...5ms is really high. Would it be the internal damping of the panel not high enough?

I thought to make some outdoor measurements to "eliminate" the hypothesis of room reflections but the weather was not good enough and not really the time for..; so let see next time.

Additional information : all the panels except the EPS are raw. No PVA coating. Is the coating that could make the difference? This said, the EPS FR is not really nice. When I built the prototype with the 9mm XPS, it was PVA coated... no good results.

Christian

Last edited:

Christian.

In answer to your post 4542 first.

You must show detailed photos of your test set up and how the panels and exciters are mounted .

If you know that the exciter you are using can output up to 20k , then by looking at the similar hf response of all the panels, I would guess that there was a problem with the way you are sticking the exciter onto the panels?

If I saw this response on one of my panels, I would think the exciter was about to fall off.

Steve.

In answer to your post 4542 first.

You must show detailed photos of your test set up and how the panels and exciters are mounted .

If you know that the exciter you are using can output up to 20k , then by looking at the similar hf response of all the panels, I would guess that there was a problem with the way you are sticking the exciter onto the panels?

If I saw this response on one of my panels, I would think the exciter was about to fall off.

Steve.

If you're using the ones that come with adhesive, I would replace it. It's a 3m product that I work with often, and it's an excellent adhesive but never cures and remains gummy and very elastic. I really don't think that would be very good for high frequencies... or at all for good conduction. Try a proper epoxy and see if that helps.I would guess that there was a problem with the way you are sticking the exciter onto the panels?

If I saw this response on one of my panels, I would think the exciter was about to fall off.

Oh yeah, and it's also a pressure sensitive adhesive that needs pressure you cannot put on a voice coil.

Christian.

in response to your post 4542 .

As I would have expected the felt is trying to damp everthing.

yes it looks like there is a little too much blu-tack ,the spike has come down at about 10k and the dip at 15k is coming back up.

If you are listening with music I would recommend using female close mic recordings that have a lot of sibilance.

If you have you RTA set up at the same time ,and set for peak hold ,you can see the difference to the 10k peak has on the sibilance, which always happens at this same frequency.

The huge peak between 300hz and 400hz looks a little odd as does the roll off there after ?

And the hump in response at about 2.5k is still there.

When I first looked at the responses I hadn't read you post so i thought the lower blue line was a panel.

Which I thought was very good , but I could still see the hump in the 2.5k area, in fact very similar ?

Is this the spider noise or the cavity noise or both ? From a cone driver ?

I suddenly, remembered I have a very old 5inch driver under my stairs ,I've taken some pictures.

Sorry about the quality(still have not got around to buying a new phone) but in the first picture you might be able to see the different type of spider used in this unit.

It looks like it is made from card and is about 2mm wide ,it is made into a ring on each side.

I would expect this spider to make far less noise ?

The spiders we use now days are great for long throw use, but I wonder if for midrange use they should be using something like the old drive unit ?

I don't know if the old unit lost its dust cap or if it never had one, but would expect without these two problems ,that this unit would not suffer from the same problems as my exciters and modern drive units ?

Steve.

in response to your post 4542 .

As I would have expected the felt is trying to damp everthing.

yes it looks like there is a little too much blu-tack ,the spike has come down at about 10k and the dip at 15k is coming back up.

If you are listening with music I would recommend using female close mic recordings that have a lot of sibilance.

If you have you RTA set up at the same time ,and set for peak hold ,you can see the difference to the 10k peak has on the sibilance, which always happens at this same frequency.

The huge peak between 300hz and 400hz looks a little odd as does the roll off there after ?

And the hump in response at about 2.5k is still there.

When I first looked at the responses I hadn't read you post so i thought the lower blue line was a panel.

Which I thought was very good , but I could still see the hump in the 2.5k area, in fact very similar ?

Is this the spider noise or the cavity noise or both ? From a cone driver ?

I suddenly, remembered I have a very old 5inch driver under my stairs ,I've taken some pictures.

Sorry about the quality(still have not got around to buying a new phone) but in the first picture you might be able to see the different type of spider used in this unit.

It looks like it is made from card and is about 2mm wide ,it is made into a ring on each side.

I would expect this spider to make far less noise ?

The spiders we use now days are great for long throw use, but I wonder if for midrange use they should be using something like the old drive unit ?

I don't know if the old unit lost its dust cap or if it never had one, but would expect without these two problems ,that this unit would not suffer from the same problems as my exciters and modern drive units ?

Steve.

Attachments

Pontos.

Thanks, I have been saying this for years.

I am beginning to think that because the manufacturers know there is an HF problem with this type of exciter ,and that the soft tacky rings are used as damping to cover the problem?

But most people who buy these will probably just peel off the sticky cover and stick the toy exciter onto a door, wow doesn't that sound great 😁 😢

Steve.

Thanks, I have been saying this for years.

I am beginning to think that because the manufacturers know there is an HF problem with this type of exciter ,and that the soft tacky rings are used as damping to cover the problem?

But most people who buy these will probably just peel off the sticky cover and stick the toy exciter onto a door, wow doesn't that sound great 😁 😢

Steve.

I organize small non-commercial dance parties sometimes, and since I really like the sound of DML I have been getting obsessed with the crazy idea of using DML panels for a PA system.

Typically the dancefloor is outdoors and around 20x20m with around 200 people, and we use a JBL system totaling around 25000w, so we are still talking a decent size system that it would have to replace. I would of course still have traditional subs taking care of the bottom end.

As I understand with the right material it is possible to get decent sensitivity, but still unsure if it is feasible to get SPL similar to these:

https://jblpro.com/en-US/products/vrx932la-1Obviously one would need many exciters and plates, but of course there is a limit to how much a single plate can handle, and it not practical to have 100s of plates. So I will have to experiment with how much effect different materials can handle and in what sizes, trying to get as much effect I can into a small area as possible.

Will be a lot of material and exciters to try out, and I'm counting on it taking a couple of years, so some pointers in the right direction to start would be fantastic. Anyone have experiences regarding materials and power handling they can share?

Been reading the thread, but still have a lot of questions.

What is the max sensitivity measured with DML speakers?

How much does size affect the amount of power they can handle, and are more sensitive materials usually capable of higher SPL, or do they perhaps also saturate at lower levels?

Better to use larger exciters or several smaller?

What is the minimum size needed to get good response down to 150-200hz for common materials?

Going on the most powerful exciters I can find (50w into 8ohm), I would need 32 exciters to replace one 1600w JBL VFX speaker it terms of wattage, and they are 95dB efficient. I could maybe do with a bit less, and could connect them to run at 100w each at 4ohm, but we are still talking a lot of surface if it should be comparable on paper.

I'm guessing I will need to construct a composite to get good sound and high efficiency. Since I need quite many plates I would like to keep the cost down, so carbon fibre with nomex for example would be probably be out.

One idea is 3d printing honeycomb fill with for example Carbon added PETG, and covering with mylar or aluminium. However my printbed is 310x310, so probably to small to make anything useable.

Typically the dancefloor is outdoors and around 20x20m with around 200 people, and we use a JBL system totaling around 25000w, so we are still talking a decent size system that it would have to replace. I would of course still have traditional subs taking care of the bottom end.

As I understand with the right material it is possible to get decent sensitivity, but still unsure if it is feasible to get SPL similar to these:

https://jblpro.com/en-US/products/vrx932la-1Obviously one would need many exciters and plates, but of course there is a limit to how much a single plate can handle, and it not practical to have 100s of plates. So I will have to experiment with how much effect different materials can handle and in what sizes, trying to get as much effect I can into a small area as possible.

Will be a lot of material and exciters to try out, and I'm counting on it taking a couple of years, so some pointers in the right direction to start would be fantastic. Anyone have experiences regarding materials and power handling they can share?

Been reading the thread, but still have a lot of questions.

What is the max sensitivity measured with DML speakers?

How much does size affect the amount of power they can handle, and are more sensitive materials usually capable of higher SPL, or do they perhaps also saturate at lower levels?

Better to use larger exciters or several smaller?

What is the minimum size needed to get good response down to 150-200hz for common materials?

Going on the most powerful exciters I can find (50w into 8ohm), I would need 32 exciters to replace one 1600w JBL VFX speaker it terms of wattage, and they are 95dB efficient. I could maybe do with a bit less, and could connect them to run at 100w each at 4ohm, but we are still talking a lot of surface if it should be comparable on paper.

I'm guessing I will need to construct a composite to get good sound and high efficiency. Since I need quite many plates I would like to keep the cost down, so carbon fibre with nomex for example would be probably be out.

One idea is 3d printing honeycomb fill with for example Carbon added PETG, and covering with mylar or aluminium. However my printbed is 310x310, so probably to small to make anything useable.

Christian.

In the same tectonics video with the oil can quote, he also mentioned impulse responses.

Which makes them not very informative for dml panels ? As the tail will always be longer.

Although I do wonder if my very small dml panels would show a shorter tail ?

Large cone drivers will always have longer tails than small cone drivers, if done well that is ?

Steve.

In the same tectonics video with the oil can quote, he also mentioned impulse responses.

Which makes them not very informative for dml panels ? As the tail will always be longer.

Although I do wonder if my very small dml panels would show a shorter tail ?

Large cone drivers will always have longer tails than small cone drivers, if done well that is ?

Steve.

Leob.

In post 4524 it shows 2 small tectonic + subs dml in a large hall.

Hopefully this will give you an idea of what a smallish dml can do ?

This link is to my ply panels for pro use, but I only had one 10watt exciter with good volume.

But I do recommend a more powerful exciter for pro use.

https://www.audiocircle.com/index.php?topic=138277.40

I did listen to them outdoors and walked down the garden which gave a good performance.

I had to stop as the wind started picking up.

This is something to think of when building your panels , very light panels will blow away or even break with a strong breeze.

Even my rigid ply panels were acting like sails in the wind, so solid mounting is essential.

Eps gives the highest db per watt but I think it is too delicate for outside use ,unless we are talking 2inches thick.

https://dmlspeakers.com/articles/101 - Introduction to Distributed Mode Loudspeakers

Or this.

http://www.soundright.org.uk/flatpanels.htmlHopefully you won't need 2 years ,but it is good to set a goal.

I'm not too sure of the efficiency of ply or similar hard panels ,maybe veleric might have an idea of that ?

But rigidly mounting usually increases db output , or it did for my panels ,which was useful as I only had 10watt exciters.

Steve

In post 4524 it shows 2 small tectonic + subs dml in a large hall.

Hopefully this will give you an idea of what a smallish dml can do ?

This link is to my ply panels for pro use, but I only had one 10watt exciter with good volume.

But I do recommend a more powerful exciter for pro use.

https://www.audiocircle.com/index.php?topic=138277.40

I did listen to them outdoors and walked down the garden which gave a good performance.

I had to stop as the wind started picking up.

This is something to think of when building your panels , very light panels will blow away or even break with a strong breeze.

Even my rigid ply panels were acting like sails in the wind, so solid mounting is essential.

Eps gives the highest db per watt but I think it is too delicate for outside use ,unless we are talking 2inches thick.

https://dmlspeakers.com/articles/101 - Introduction to Distributed Mode Loudspeakers

Or this.

http://www.soundright.org.uk/flatpanels.htmlHopefully you won't need 2 years ,but it is good to set a goal.

I'm not too sure of the efficiency of ply or similar hard panels ,maybe veleric might have an idea of that ?

But rigidly mounting usually increases db output , or it did for my panels ,which was useful as I only had 10watt exciters.

Steve

Thanks Steve, very interesting thread!

I figure I need some proper mounting. So far I only really tried 500x400x6mm polycarbonate, and it can handle a 50w exciter, but if it is free hanging it has some bad resonance, but sounds great as soon as I hold one edge lightly. I would think other materials act the same, though it would be less pronounced with something like XPS.

While PC panel is loud and sounds great as long as I have decent amp to drive it and some damping, I'm guessing it is not much louder than XPS with a 10w exciter 🙁

Reading your comment about wattage and saturation in the audiocircle thread, I guess it confirms my suspicion that the most sensitive materials doesn't necessarily mean the highest SPL though if you think XPS cannot handle much more than 10w.

Possibly acrylic or PC can reach higher SPL before saturating, but then will need perhaps 10x the power to do so 🙁

I saw the Techtonic video earlier, and it is hard to say. To be anything close to the system we usually use in SPL, we surely would need lots of those panels. They claim 300w per panel, which is very impressive with a 400 x 575mm plate...I guess one needs expensive composite to achieve that. And they claim 91dB sensitivity. So to get same SPL as a JBL VFX you need more than double the wattage, since they are 4dB less sensitive.

So that means 8 panels to replace one VFX with them being rated at 1600w, and then it is using over double the power.

I figure I need some proper mounting. So far I only really tried 500x400x6mm polycarbonate, and it can handle a 50w exciter, but if it is free hanging it has some bad resonance, but sounds great as soon as I hold one edge lightly. I would think other materials act the same, though it would be less pronounced with something like XPS.

While PC panel is loud and sounds great as long as I have decent amp to drive it and some damping, I'm guessing it is not much louder than XPS with a 10w exciter 🙁

Reading your comment about wattage and saturation in the audiocircle thread, I guess it confirms my suspicion that the most sensitive materials doesn't necessarily mean the highest SPL though if you think XPS cannot handle much more than 10w.

Possibly acrylic or PC can reach higher SPL before saturating, but then will need perhaps 10x the power to do so 🙁

I saw the Techtonic video earlier, and it is hard to say. To be anything close to the system we usually use in SPL, we surely would need lots of those panels. They claim 300w per panel, which is very impressive with a 400 x 575mm plate...I guess one needs expensive composite to achieve that. And they claim 91dB sensitivity. So to get same SPL as a JBL VFX you need more than double the wattage, since they are 4dB less sensitive.

So that means 8 panels to replace one VFX with them being rated at 1600w, and then it is using over double the power.

I think I should clarify my findings of the art panel up close to a wall.

If you are using the panel closer than say 12inches to the wall ,which is where the panel will start to suffer from bad parallel reflections, bouncing back and forth.

The bigger the panel properly the bigger the problem ?

smaller panels the less so.

but these bad reflections can be minimised if the panel is at an angle from the wall.

The natural toe in that is normally used for normal cone speakers would probably be enough to offset this problem ,without rear damping.

If mounting the art panel on a side wall ,or ceiling, I personally would probably have one of the edges (the choice would be yours) hinged to the wall ,so that it looked like a picture when not in use, but could be swung out to whatever angle was wished, but the further out the less affect the wall has on the sound.

I was quite surprised by how natural the art panel sounded on the side walls and ceiling .

So if going very close to a wall always angle them out ,this will mostly keep the full frequency response even if you have one side attached to the wall .

If you hold the panel up close to the wall the sound becomes compressed and tinny with the loss of frequencies below 500hz.

wall damping will help this a little bit , but will not sort out these problems totally and will restrict the natural rear wave that is part of dml.

so what I am saying is that you can go closer to the wall without suffering the frequency loss in the low end ,and without the heavy loss in quality.

So with a little experimentation , good results should be possible, hopefully without added damping ?

I have tried this with smaller panels and they seem less troubled by wall closeness .

but I would think larger panels might not do so well ,but I have not tested this.I

I hope this clarifies my tests with wall placements?

questions welcomed.

steve

If you are using the panel closer than say 12inches to the wall ,which is where the panel will start to suffer from bad parallel reflections, bouncing back and forth.

The bigger the panel properly the bigger the problem ?

smaller panels the less so.

but these bad reflections can be minimised if the panel is at an angle from the wall.

The natural toe in that is normally used for normal cone speakers would probably be enough to offset this problem ,without rear damping.

If mounting the art panel on a side wall ,or ceiling, I personally would probably have one of the edges (the choice would be yours) hinged to the wall ,so that it looked like a picture when not in use, but could be swung out to whatever angle was wished, but the further out the less affect the wall has on the sound.

I was quite surprised by how natural the art panel sounded on the side walls and ceiling .

So if going very close to a wall always angle them out ,this will mostly keep the full frequency response even if you have one side attached to the wall .

If you hold the panel up close to the wall the sound becomes compressed and tinny with the loss of frequencies below 500hz.

wall damping will help this a little bit , but will not sort out these problems totally and will restrict the natural rear wave that is part of dml.

so what I am saying is that you can go closer to the wall without suffering the frequency loss in the low end ,and without the heavy loss in quality.

So with a little experimentation , good results should be possible, hopefully without added damping ?

I have tried this with smaller panels and they seem less troubled by wall closeness .

but I would think larger panels might not do so well ,but I have not tested this.I

I hope this clarifies my tests with wall placements?

questions welcomed.

steve

Hello Christian,

In response to #4532. The way I have been getting my head around the "DML" phenomena is to think that it is a heat engine or thermoacoustic engine rather than a electromechanical engine. Taking the thermo route I can see why a plasma tweeter is far superior to any mechanical tweeter since the plasma is basically massless and heats the air so efficiently. It is not constrained by Newton's laws of motion like a mechanical engine such as a panel.

If one goes with multiple exciter then I see one running into a cost to performance issues. Look at it this way one has to spend at least $25 an exciter so for a pair of speakers with four to five drivers one is already up to a couple of hundred dollars for a very limited frequency operating range.

I say a limited frequency range because no one every post a waveform of a panel generating a 10KHz sine wave of square wave. Everyone shows the frequency response and at the high frequency range their are a lot of harmonics that contributing to the frequency response. I would like some to show me a panel that can accurately reproduce a 10KHz square wave. Its no going to happen ones sees ring accruing that is from what the panel is fabricated from and can explain the "sound quality of the panel".

For the conical force multiplier the exciter usually has a 32 mm diameter contact ring that is coupled to the panel therefore the force of the exciter is divided by the area of the 32 mm contact ring. Now but a conical force multiplier in where the contact area is say 2mm you have increase the force by 16 times.

This is why I have been focusing my attention on thermoacoustic transducers they really do reproduce a superior replication of music. (this will generate a lot of contra-verse in such statement as it did in going from earth centric and atom with as circling particles).

Cheers

Steve

In response to #4532. The way I have been getting my head around the "DML" phenomena is to think that it is a heat engine or thermoacoustic engine rather than a electromechanical engine. Taking the thermo route I can see why a plasma tweeter is far superior to any mechanical tweeter since the plasma is basically massless and heats the air so efficiently. It is not constrained by Newton's laws of motion like a mechanical engine such as a panel.

If one goes with multiple exciter then I see one running into a cost to performance issues. Look at it this way one has to spend at least $25 an exciter so for a pair of speakers with four to five drivers one is already up to a couple of hundred dollars for a very limited frequency operating range.

I say a limited frequency range because no one every post a waveform of a panel generating a 10KHz sine wave of square wave. Everyone shows the frequency response and at the high frequency range their are a lot of harmonics that contributing to the frequency response. I would like some to show me a panel that can accurately reproduce a 10KHz square wave. Its no going to happen ones sees ring accruing that is from what the panel is fabricated from and can explain the "sound quality of the panel".

For the conical force multiplier the exciter usually has a 32 mm diameter contact ring that is coupled to the panel therefore the force of the exciter is divided by the area of the 32 mm contact ring. Now but a conical force multiplier in where the contact area is say 2mm you have increase the force by 16 times.

This is why I have been focusing my attention on thermoacoustic transducers they really do reproduce a superior replication of music. (this will generate a lot of contra-verse in such statement as it did in going from earth centric and atom with as circling particles).

Cheers

Steve

Hello Steve,Hello Christian,

In response to #4532. The way I have been getting my head around the "DML" phenomena is to think that it is a heat engine or thermoacoustic engine rather than a electromechanical engine. Taking the thermo route I can see why a plasma tweeter is far superior to any mechanical tweeter since the plasma is basically massless and heats the air so efficiently. It is not constrained by Newton's laws of motion like a mechanical engine such as a panel.

If one goes with multiple exciter then I see one running into a cost to performance issues. Look at it this way one has to spend at least $25 an exciter so for a pair of speakers with four to five drivers one is already up to a couple of hundred dollars for a very limited frequency operating range.

I say a limited frequency range because no one every post a waveform of a panel generating a 10KHz sine wave of square wave. Everyone shows the frequency response and at the high frequency range their are a lot of harmonics that contributing to the frequency response. I would like some to show me a panel that can accurately reproduce a 10KHz square wave. Its no going to happen ones sees ring accruing that is from what the panel is fabricated from and can explain the "sound quality of the panel".

For the conical force multiplier the exciter usually has a 32 mm diameter contact ring that is coupled to the panel therefore the force of the exciter is divided by the area of the 32 mm contact ring. Now but a conical force multiplier in where the contact area is say 2mm you have increase the force by 16 times.

This is why I have been focusing my attention on thermoacoustic transducers they really do reproduce a superior replication of music. (this will generate a lot of contra-verse in such statement as it did in going from earth centric and atom with as circling particles).

Cheers

Steve

I did a quick search on thermoacoustic transducers, it's very interesting. I did find information about graphene-based transducers from GraphAudio. However there doesn't appear to be any real products available yet based on this technology. Can you point me to any references? Of course I'm not really sure it relates to DML so I don't want to side track this thread.

Thanks,

Dave

@spedge , @Pontos

Thank you for your feedback

The exciters I use are Dayton Audio DAEX25FHE-4 which come with the 3M VHB. So when I use new one, it is with the 3M tape.

For my last tests, the exciter was already used, the 3M original tape was removed. Unfortunately I haven't found 3M VHB in the DIY store close to me. Sad... it introduces a new variable in the game. In addition, my goal is to make comparisons between different materials in a "short time" (say 1 hour or 2). The reason of that is not changing something else than what I want. In the family environment even if there is a nice tolerance to my game, it is better to have not too long test cession, with everything put away at the end.

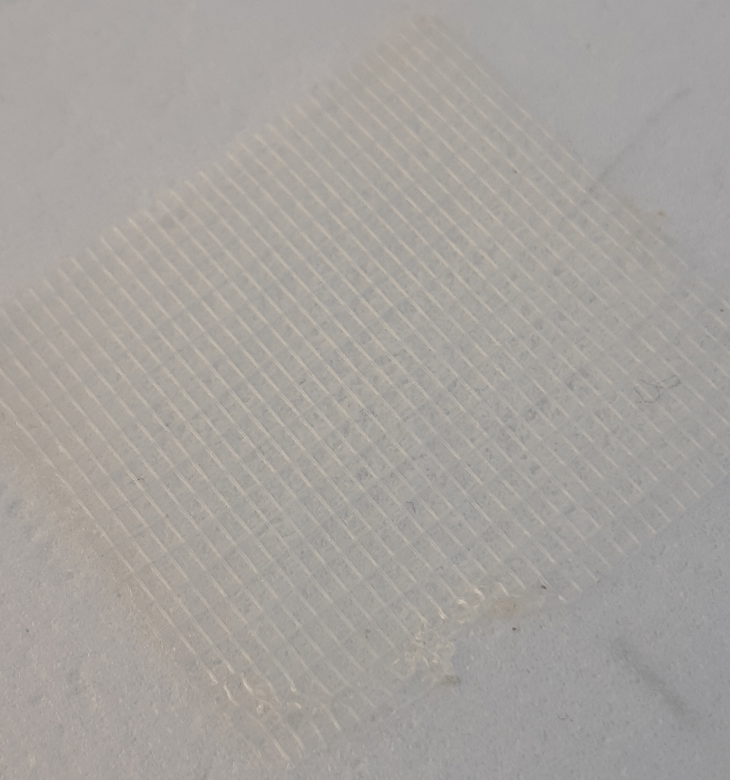

So I looked at the gluing more carefully. Yesterday the adherence to the panel was poor, much better at the voice coil, so I prepared a 10x10cm PVA coated area for new test. I also bought another double side tape which is said "extra strong" but in fact with a lower adherence than the previous one. So in fact, the tape of the post 4542 is quite strong but its main characteristic is to have a wire mesh so I think it has its own behavior changing what happens above 6or 7kHz.

Below the picture of the test frame, the tape with its mesh.

After 3 measurements of the 9mm XPS

My canvas panel are glued with epoxy and show similar HF behavior has with the original 3M VHB, so I don't think for now the 3M tape acts as a filter. do you have some "evidence" of that?

In addition, I made outdoor measurements of the other materials... need more time to have a look at them.

Christian

Thank you for your feedback

The exciters I use are Dayton Audio DAEX25FHE-4 which come with the 3M VHB. So when I use new one, it is with the 3M tape.

For my last tests, the exciter was already used, the 3M original tape was removed. Unfortunately I haven't found 3M VHB in the DIY store close to me. Sad... it introduces a new variable in the game. In addition, my goal is to make comparisons between different materials in a "short time" (say 1 hour or 2). The reason of that is not changing something else than what I want. In the family environment even if there is a nice tolerance to my game, it is better to have not too long test cession, with everything put away at the end.

So I looked at the gluing more carefully. Yesterday the adherence to the panel was poor, much better at the voice coil, so I prepared a 10x10cm PVA coated area for new test. I also bought another double side tape which is said "extra strong" but in fact with a lower adherence than the previous one. So in fact, the tape of the post 4542 is quite strong but its main characteristic is to have a wire mesh so I think it has its own behavior changing what happens above 6or 7kHz.

Below the picture of the test frame, the tape with its mesh.

After 3 measurements of the 9mm XPS

- 1, green : outdoor measurement @1.5m

- 2, blue : indoor post 4542

- 3, red : indoor (in june, other room) @1m

My canvas panel are glued with epoxy and show similar HF behavior has with the original 3M VHB, so I don't think for now the 3M tape acts as a filter. do you have some "evidence" of that?

In addition, I made outdoor measurements of the other materials... need more time to have a look at them.

Christian

Hello SteveChristian.

In the same tectonics video with the oil can quote, he also mentioned impulse responses.

Which makes them not very informative for dml panels ? As the tail will always be longer.

Although I do wonder if my very small dml panels would show a shorter tail ?

Large cone drivers will always have longer tails than small cone drivers, if done well that is ?

Steve.

IR and FR are 2 representations of the same reality. REW is based on the IR. The "trick" is the use of a logsweep to get the IR with an excellent signal to noise ratio (from M Farina's works if I remember). The FR is the result of mathematical operation (FFT) and then filtered. This is my understanding. It is a bit different of an RTA that shows directly the output of filters. The spectrogram in REW works also with filters or equivalent (wavelets).

The point is we can read FR or spectrogram but in a much lower level IR.

In my opinion, the long tail IR shows that the energy is circulating in the panel for a long time which should lead to peaks in the FR or spectrogram with high Q (slow decay time).

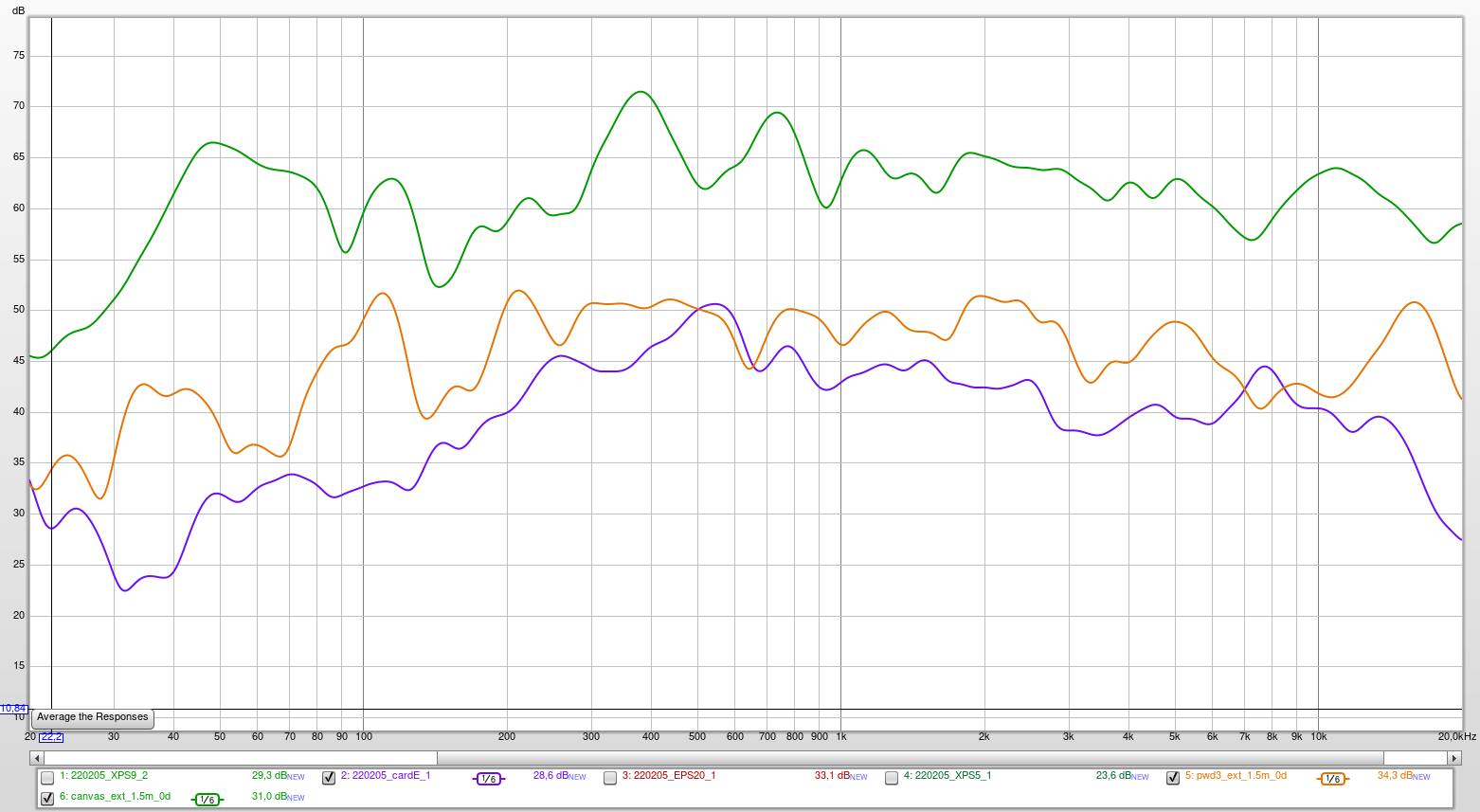

To continue in the curiosity, below the IR of my outdoor tests.

1 - light green : XPS 9mm

3 - dark red : ESP 20mm (medium density)

4 - dark green : XPS 5mm

2 - purple : cardboard E flute

3 - orange : plywwod 3mm

It is like the "long tail" effect is linked to the thickness.

Already reported?

Christian

Hello SteveHello Christian,

In response to #4532. The way I have been getting my head around the "DML" phenomena is to think that it is a heat engine or thermoacoustic engine rather than a electromechanical engine. Taking the thermo route I can see why a plasma tweeter is far superior to any mechanical tweeter since the plasma is basically massless and heats the air so efficiently. It is not constrained by Newton's laws of motion like a mechanical engine such as a panel.

If one goes with multiple exciter then I see one running into a cost to performance issues. Look at it this way one has to spend at least $25 an exciter so for a pair of speakers with four to five drivers one is already up to a couple of hundred dollars for a very limited frequency operating range.

I say a limited frequency range because no one every post a waveform of a panel generating a 10KHz sine wave of square wave. Everyone shows the frequency response and at the high frequency range their are a lot of harmonics that contributing to the frequency response. I would like some to show me a panel that can accurately reproduce a 10KHz square wave. Its no going to happen ones sees ring accruing that is from what the panel is fabricated from and can explain the "sound quality of the panel".

For the conical force multiplier the exciter usually has a 32 mm diameter contact ring that is coupled to the panel therefore the force of the exciter is divided by the area of the 32 mm contact ring. Now but a conical force multiplier in where the contact area is say 2mm you have increase the force by 16 times.

This is why I have been focusing my attention on thermoacoustic transducers they really do reproduce a superior replication of music. (this will generate a lot of contra-verse in such statement as it did in going from earth centric and atom with as circling particles).

Cheers

Steve

I came to the DML because they are flat panel with the hope to hang them to the front wall... this doesn't work (see Spedge's post just above) but testing them I get a quite sound with a good image. Probably not the top of what HiFi can produce but really a living sound, with very good transient. They completely disappear in the room even being far to be perfect. In that, the 10khz square signal is not in my requirements...

Long time ago, I had interest to thermo-acoustic speaker but I stopped looking at that by their limit to go low.

To me, a DML remains a electromechanical device. For my use, one exciter per channel seems enough; perhaps 2 if we understand there is a possibility of more flat response thanks to the second exciter... and a sub in addition

About the cone, I see. It is more a pressure amplifier. I plan for my next tests something close to that.

Christian

Here are some outdoor measurements. The idea I have with outdoor measurements is to reduce enough 1st reflections in order to see what is a characteristic of the material, not its interaction with the room. The materials used here are probably not completely relevant for a direct use or at least like that (ie the 5mm XPS with no coating).

I have split the measurements in 2 set : polystyrene, others.

Each has a 10x10cm PVA coated area centered on the exciter. The exciter is @2/5

1 - light green : XPS 9mm 60x80cm not coated

3 - red : EPS 20mm 60x80cm PVA coated

4 - green : XPS 5mm 60x80cm not coated

2 - purple : cardboard E flute 48x77cm

5 - orange : poplar plywood 3mm 45x120cm. currently my reference

6 - green : canvas panel 33x41cm (my version!), also good.

Plywood and canvas were measured an other day so no link in the levels. The canvas has +15dB offset.

Seems like the low frequency downfall from 200/300Hz is directly linked to the panel dimension.

Exception is the canvas which is the smaller one but have the property of having bass.

Up to now, I see the geometry driven the modal properties of the panel but nothing explaining the high pass effect. I miss something?

The group of polystyrene shows a low pass effect from 3kHz.

Hopefully, I will put again an exciter on my XPS 20mm panel (coated and acrylic painted) to get the same kind of outdoor measurement.

Seen like that, the cardboard is good candidate as standalone material. The HF extension seems good. It as the reputation of a"cardboard sound"..?

Does that mean the polystyrene needs a skin, by any mean like added layer or coating?

An other observation is that the IRs of second group don't show a long tail characteristic. This is probably linked to there quite extended FR that is mirrored in the time view by a concentrated pulse.

I have several ideas of "simple" steps; The question is to decide among them what is the next one...

@spedge : for the canvas, you are right, the peaks are far to be cured or even explained like the in the 300/400Hz area.

Christian

I have split the measurements in 2 set : polystyrene, others.

Each has a 10x10cm PVA coated area centered on the exciter. The exciter is @2/5

1 - light green : XPS 9mm 60x80cm not coated

3 - red : EPS 20mm 60x80cm PVA coated

4 - green : XPS 5mm 60x80cm not coated

2 - purple : cardboard E flute 48x77cm

5 - orange : poplar plywood 3mm 45x120cm. currently my reference

6 - green : canvas panel 33x41cm (my version!), also good.

Plywood and canvas were measured an other day so no link in the levels. The canvas has +15dB offset.

Seems like the low frequency downfall from 200/300Hz is directly linked to the panel dimension.

Exception is the canvas which is the smaller one but have the property of having bass.

Up to now, I see the geometry driven the modal properties of the panel but nothing explaining the high pass effect. I miss something?

The group of polystyrene shows a low pass effect from 3kHz.

Hopefully, I will put again an exciter on my XPS 20mm panel (coated and acrylic painted) to get the same kind of outdoor measurement.

Seen like that, the cardboard is good candidate as standalone material. The HF extension seems good. It as the reputation of a"cardboard sound"..?

Does that mean the polystyrene needs a skin, by any mean like added layer or coating?

An other observation is that the IRs of second group don't show a long tail characteristic. This is probably linked to there quite extended FR that is mirrored in the time view by a concentrated pulse.

I have several ideas of "simple" steps; The question is to decide among them what is the next one...

@spedge : for the canvas, you are right, the peaks are far to be cured or even explained like the in the 300/400Hz area.

Christian

I have recently found a tape that works especially well for temporary mounting of exciters. It's 3M 9589.Unfortunately I haven't found 3M VHB in the DIY store close to me. Sad... it introduces a new variable in the game. In addition, my goal is to make comparisons between different materials in a "short time" (say 1 hour or 2).

https://www.3m.com/3M/en_US/p/d/b40070392/

It is a bit expensive (about $70 for a roll 2 inch wide x36 yard long), but I expect a roll will last a long time.

You can cut out out a 2" square, apply it to the panel, remove the release paper, and then press the exciter onto the tape.

After you are done testing, you can easily slide a thin putty knife or similar between the tape and the foot of the exciter and pry the exciter off the tape. Usually, neither the exciter nor the tape is damaged. You can leave the tape there on the panel for later re-use, or peel it off the panel and place it on the panel in a different location, and remount the exciter in the new position. Dismounting an exciter and remounting in a new position probably takes about a minute, I would guess.

Sometimes I cut and apply a longer strip, and then move the exciter along the strip in increments of 1/4" to 2 inches. That way I don't have to reapply a new piece of tape for every position I want to try.

And just for you Christian, I tried the tape on a piece of scrap PS foam I had. It stuck well, but I was also able to pry the exciter off the tape and then peel the tape of the PS foam panel without any damage to the panel, just like for plywood.

I have bought some VHB tape in the past, but it was even more expensive (per use), and it always gets destroyed when you remove the exciter.

I have not made direct comparisons of the 9859 tape to the VHB, but my impression is that it's no worse in any way. With the 3M 9589 there's no obvious roll off at either end of the frequency range. It may even be better, in fact. It's a 9 mil (0.2 mm) thick HDPE carrier, so it's actually much more firm than the soft, rubbery VHB.

It may even be perfectly good for permanent mounting too. I have not tried it that way, so I don't know for sure how long it will hold old on. The VHB doesn't hold exciters forever either, anyway, at least not on plywood, without a spine. You can probably guess how I know that!

I suspect that if used with a spine, this tape would work perfectly well for permanent mounting.

Eric

Christian.

I was looking at your plots of the canvas panels on post 4541 and 4558 and apart from the large hump at 400hz there seems very little similarity ?

Below 1k you now have two large humps, and a far higher output in the low end ?

They look like two different panels ?

On the other panels , the polystyrene plots all seem to mirror each other ?

also the frame foam mountings you have will have a profound affect on the sound of the polystyrene panels.

I have mentioned that just touching a polystyrene panel with your fingers will alter the sound greatly.

The roll off after 3k reminds me more of foamcore from years back.

The roll off at 3k just sets off bells in my head ,that something is wrong ?

I would always measure a panel free floating ,without any obstructions to the response, how do you measure the pressure of each of those foam pads are applying to the poly panels ?

It's all a bit confusing ?

Steve.

I was looking at your plots of the canvas panels on post 4541 and 4558 and apart from the large hump at 400hz there seems very little similarity ?

Below 1k you now have two large humps, and a far higher output in the low end ?

They look like two different panels ?

On the other panels , the polystyrene plots all seem to mirror each other ?

also the frame foam mountings you have will have a profound affect on the sound of the polystyrene panels.

I have mentioned that just touching a polystyrene panel with your fingers will alter the sound greatly.

The roll off after 3k reminds me more of foamcore from years back.

The roll off at 3k just sets off bells in my head ,that something is wrong ?

I would always measure a panel free floating ,without any obstructions to the response, how do you measure the pressure of each of those foam pads are applying to the poly panels ?

It's all a bit confusing ?

Steve.

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker