Christian.

I just went into my room and had a quick look at the frequencies changed by holding the 5mm panel at the edges with my hands.

I zoomed in to a 15db window in 5db steps which only went up to 8k, but the frequencies were being moved about up to the 6k point.

It was too difficult to judge any higher than that. ?

While I was on the floor I made some measurements of all around the edge of the panel response , then 3inches from the exciter area, and last in front of the exciter, this was all at 1inch from the panel.

This is why microphone positioning is very important.

Steve.

I just went into my room and had a quick look at the frequencies changed by holding the 5mm panel at the edges with my hands.

I zoomed in to a 15db window in 5db steps which only went up to 8k, but the frequencies were being moved about up to the 6k point.

It was too difficult to judge any higher than that. ?

While I was on the floor I made some measurements of all around the edge of the panel response , then 3inches from the exciter area, and last in front of the exciter, this was all at 1inch from the panel.

This is why microphone positioning is very important.

Steve.

Attachments

Leob.

I'd keep an eye on the exciter temperature if you are driving them that hard.

it is never a good idea to turn an amp up to full power ,clipping can be fatal to any speaker, I know this from experience😩

The distortion or noise could be a noise the exciter is making ,because it is on a hard panel.

If you turn the volume up too high, it's like it is banging its head on a brick wall and the exciter can start to make cracking noises ?

Steve.

I'd keep an eye on the exciter temperature if you are driving them that hard.

it is never a good idea to turn an amp up to full power ,clipping can be fatal to any speaker, I know this from experience😩

The distortion or noise could be a noise the exciter is making ,because it is on a hard panel.

If you turn the volume up too high, it's like it is banging its head on a brick wall and the exciter can start to make cracking noises ?

Steve.

If I don't filter the very bottom end it can make weird noises just turning up to half volume, but with 150hz HPF it is at around 70% volume that regular distortion is being introduced, nothing nasty. With the HPF I can also drive them at just before distorting for long time without them becoming burning hot.Leob.

I'd keep an eye on the exciter temperature if you are driving them that hard.

it is never a good idea to turn an amp up to full power ,clipping can be fatal to any speaker, I know this from experience😩

The distortion or noise could be a noise the exciter is making ,because it is on a hard panel.

If you turn the volume up too high, it's like it is banging its head on a brick wall and the exciter can start to make cracking noises ?

Steve.

I got them partly to experiment with how hard they can be pushed and how much amp power they actually need, but I am a bit surprised that I could turn the A08 up full without feeling like they where nearly blowing up.

I wonder what exciters Tectonic use for the DLM500? According to the spec sheet they have 4x 32mm exciters and can handle 300w. The most powerful exciter they sell is 30w and 32 mm (TEAX32C30-4/B). Do they have a secret 32mm 75w exciter?

Loeb,Sorry , I just saw the 6mm and just presumed it was fluted, that is a very thick heavy panel and will take a lot to drive.

I really wished I could have found a clear panel that worked for me , they look so cool.

As much as it pains me, I have to agree with Spedge! Polycarbonate (or PMMA) might have some good attributes, but efficiency is not one of them. It's too heavy, and not stiff enough. If you want loud panels you have to use PS foam panels, or some sort of composite panels with a light core and stiff skins. But there are no such composite panels (as far as I know) that are commercially available for a reasonable price that would come close to the efficiency of PS foam. To be clear, I'm not a fan of the sound of PS foam, but for efficiency it's really hard to beat. If you are skilled in composite construction, you may be able to make your own panels, but otherwise, you may want to stick with PS foam.

Eric

Yes, I know the polycarbonate plates would not be efficient enough when I ordered them, but for home use I'm very happy with them.

Only just now been reading up a bit about composite construction, and it definitely seems like a skill. Nomex/carbon sandwich is available, but costly. If it is really needed to get enough loudness for a sensible surface area I wouldn't say the cost seems totally unreasonable. For example here is one supplier: https://shop1.r-g.de/en/art/6195K

Even if I would only need around 8 panels it is a bit of cash, but compared to the cost of regular line array speakers or actual Tectonic panels it still seems cheap.

Will definitely get some foam to try. Seems fragile to transport, and could break in the wind as Steve suggested, but with a proper frame it might work.

I saw someone had good result with thick carbon fibre sheets. They are not cheap either (€90 for 400x500x3mm), but cheaper than composite and very sturdy and easy to handle.

Only just now been reading up a bit about composite construction, and it definitely seems like a skill. Nomex/carbon sandwich is available, but costly. If it is really needed to get enough loudness for a sensible surface area I wouldn't say the cost seems totally unreasonable. For example here is one supplier: https://shop1.r-g.de/en/art/6195K

Even if I would only need around 8 panels it is a bit of cash, but compared to the cost of regular line array speakers or actual Tectonic panels it still seems cheap.

Will definitely get some foam to try. Seems fragile to transport, and could break in the wind as Steve suggested, but with a proper frame it might work.

I saw someone had good result with thick carbon fibre sheets. They are not cheap either (€90 for 400x500x3mm), but cheaper than composite and very sturdy and easy to handle.

Hello Steve,Christian.

...

I usually concentrate on one panel only(that's the idea anyway) and if I like the sound I see how I can improve it, swapping between many panels and not understanding what is happening in and outside would give me a headache.

You need some consistency, measuring in the best sounding position in the room .

...

Steve.

I see we have the same floor lamp! 🙂

More seriously : sorry for the confusion. Far from me to be the cause of headache.

Let me a moment to be more consistent and clear... Dealing with standard loudspeaker is already not simple (ie how to make relevant measurement), with in addition the questions related to the DML, it becomes... difficult.

Christian

Yes!!!! Upper traces more than 0.5m, lower traces : 0.3, 0.2m from the back wallChristian.

ok so the lower traces are very close to the back wall which is causing a large hump In the response at 300hz to 400hz .

And a rolling off of the frequencies below this hump, which makes sense.

When you are playing the pink noise ,do you listen to the harsh tinny sound that is produced , the closer to the wall the panel gets ?

I described this hollow tinny noise, as I would call it ,in the recording I made ,when I moved the art panel closer to the wall.

Steve

Yes the indoor conditions mainly while approaching the back wall reduce the low frequency (I see taht on the canvas and the plywood model) and it amplifies the hump already in the canvas FR.

I don't use a lot pink noise but I can prepare something like a recording to share. Let see for the coming days...

Christian

Thank you SteveChristian.

I just went into my room and had a quick look at the frequencies changed by holding the 5mm panel at the edges with my hands.

I zoomed in to a 15db window in 5db steps which only went up to 8k, but the frequencies were being moved about up to the 6k point.

It was too difficult to judge any higher than that. ?

While I was on the floor I made some measurements of all around the edge of the panel response , then 3inches from the exciter area, and last in front of the exciter, this was all at 1inch from the panel.

This is why microphone positioning is very important.

Steve.

I have clearly in mind that the position of the mic at short distance changes completely the FR.

I am not sure to understand your conclusion of the first picture : you were holding the panel at edge by hand, the mic was... away? 1m or more perhaps? and you see that level above 6k/8k is lost ? Correct?

Christian

Christian.

Sorry, that was my fault, not being clear enough.

The first picture has nothing to do with holding the edges.

I could not see a way to show The difference using my setup, and my old knees were hurting 😬

The large 5mm epoxy coated xps panel is a little too large .

The hf does not reach the edges of the panel, I have in the past described this type of panel as being lossy !

But I was mainly referring to the hf, which travels only a few inches from the exciter area.

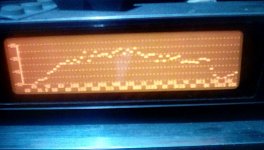

The first picture is the frequency response at the edge of the panel, I moved the microphone all around the outside edge of the panel on peak hold, to show what frequencies were reaching the edge.

On a smaller panel using this same material the hf would reach closer to the edges ?

Steve.

Sorry, that was my fault, not being clear enough.

The first picture has nothing to do with holding the edges.

I could not see a way to show The difference using my setup, and my old knees were hurting 😬

The large 5mm epoxy coated xps panel is a little too large .

The hf does not reach the edges of the panel, I have in the past described this type of panel as being lossy !

But I was mainly referring to the hf, which travels only a few inches from the exciter area.

The first picture is the frequency response at the edge of the panel, I moved the microphone all around the outside edge of the panel on peak hold, to show what frequencies were reaching the edge.

On a smaller panel using this same material the hf would reach closer to the edges ?

Steve.

Christian.

Holding the panel edges.

Basically I just propped the microphone up about a couple of feet, 60cm, away (not very scientific) and watched how or if the frequencies moved using pink noise.

I did not really need to see the measurements as I could hear the sound changing well up into the upper midrange.

This is the problem when using this method and also weights to fill in the response below the 400hz point.

it affects all the other frequencies.

This should be easy for you to test yourself.

Steve.

Holding the panel edges.

Basically I just propped the microphone up about a couple of feet, 60cm, away (not very scientific) and watched how or if the frequencies moved using pink noise.

I did not really need to see the measurements as I could hear the sound changing well up into the upper midrange.

This is the problem when using this method and also weights to fill in the response below the 400hz point.

it affects all the other frequencies.

This should be easy for you to test yourself.

Steve.

Eric.

I'm sorry it pains you so much ,having to agree with me, but I can't help always being right 😁

Steve.

I'm sorry it pains you so much ,having to agree with me, but I can't help always being right 😁

Steve.

Those carbon/nomex panels look like a possibility, if you can tolerate the cost. They just might rival the PS foam in terms of efficiency. Although they seem a bit heavier than I would have expected. Based on the weight of the CF/epoxy skins and the nomex only, the 5.5 mm panel could weigh as little as about 0.85 kg/m2. But when I look at their estimated panel weights for each of the sizes, the panel weight seems to be at least 1.16kg/m2. Hopefully, those panel weights are purposely overestimated for some reason, as that much extra weight will cut into the efficiency.Only just now been reading up a bit about composite construction, and it definitely seems like a skill. Nomex/carbon sandwich is available, but costly. If it is really needed to get enough loudness for a sensible surface area I wouldn't say the cost seems totally unreasonable. For example here is one supplier: https://shop1.r-g.de/en/art/6195K

Even if I would only need around 8 panels it is a bit of cash, but compared to the cost of regular line array speakers or actual Tectonic panels it still seems cheap.

Will definitely get some foam to try. Seems fragile to transport, and could break in the wind as Steve suggested, but with a proper frame it might work.

I saw someone had good result with thick carbon fibre sheets. They are not cheap either (€90 for 400x500x3mm), but cheaper than composite and very sturdy and easy to handle.

They have it available in 5.5 and 3.5 mm versions. I'd be inclined to choose the 3.5 mm version instead of the 5.5 mm version. The thicker one will probably play a bit louder, but with two downsides. One is that it will require a larger panel area to get down to a reasonable low frequency. The 5.5 mm one will require more than 50% more area than the thinner one to reach the same low end frequency limit. Bottom line is you would probably need the biggest size (1100x700 mm) for the 5.5 mm panel, but might be able to get away with the 700x550 mm for the 3.5 mm panel.

The second issue is that the coincidence frequency (Fc) for the 5.5 mm panel will be very low, in the neighborhood of 1500Hz, I think. This is the frequency above which the panels theoretically start beaming (off axis). For the thinner panels, the Fc is probably closer to 2500Hz, which still may lower than ideal, but not as bad as the thicker ones. For reference, Fc of the Tectonic panels appears to be around 5000-6000 Hz.

Note, this is based almost entirely on calculations, rather than actual experience with this type of panel, so take it all with a grain of salt!

Eric

I know, I have the same problem!Eric.

I'm sorry it pains you so much ,having to agree with me, but I can't help always being right 😁

Steve.

Eric

Very interesting. I was thinking I might need the 5.5mm if I would like it to handle a lot of exciter power, but I also would like to have them smaller than 700x550mm. I realize this is the full range thread, but I'm gonna use subs up to 150hz or so. Tectonic uses 400 x 575mm in DLM500 and claim 75hz at -6dB, so should be doable with optimal material it seems.Those carbon/nomex panels look like a possibility, if you can tolerate the cost. They just might rival the PS foam in terms of efficiency. Although they seem a bit heavier than I would have expected. Based on the weight of the CF/epoxy skins and the nomex only, the 5.5 mm panel could weigh as little as about 0.85 kg/m2. But when I look at their estimated panel weights for each of the sizes, the panel weight seems to be at least 1.16kg/m2. Hopefully, those panel weights are purposely overestimated for some reason, as that much extra weight will cut into the efficiency.

They have it available in 5.5 and 3.5 mm versions. I'd be inclined to choose the 3.5 mm version instead of the 5.5 mm version. The thicker one will probably play a bit louder, but with two downsides. One is that it will require a larger panel area to get down to a reasonable low frequency. The 5.5 mm one will require more than 50% more area than the thinner one to reach the same low end frequency limit. Bottom line is you would probably need the biggest size (1100x700 mm) for the 5.5 mm panel, but might be able to get away with the 700x550 mm for the 3.5 mm panel.

The second issue is that the coincidence frequency (Fc) for the 5.5 mm panel will be very low, in the neighborhood of 1500Hz, I think. This is the frequency above which the panels theoretically start beaming (off axis). For the thinner panels, the Fc is probably closer to 2500Hz, which still may lower than ideal, but not as bad as the thicker ones. For reference, Fc of the Tectonic panels appears to be around 5000-6000 Hz.

Note, this is based almost entirely on calculations, rather than actual experience with this type of panel, so take it all with a grain of salt!

Eric

Still wonder how they get 300w from 4x 32mm exciters though...

Loeb,Very interesting. I was thinking I might need the 5.5mm if I would like it to handle a lot of exciter power, but I also would like to have them smaller than 700x550mm. I realize this is the full range thread, but I'm gonna use subs up to 150hz or so. Tectonic uses 400 x 575mm in DLM500 and claim 75hz at -6dB, so should be doable with optimal material it seems.

Still wonder how they get 300w from 4x 32mm exciters though...

Yes, Christian and I were trying to reverse engineer the Tectonic panels based on the information in their website and videos. I must confess we did not quite sort it out. But one thing is clear, the Fc of their panel is over 5000 Hz, which clearly indicates a less stiff panel than either the 3.5 or 5.5 mm panels from your link.

I kind of suspect they use a thinner panel, with both a thinner core and thinner skins. Such a construction should maintain high efficiency, but allow a smaller panel (for a given low end frequency) and provide a higher Fc. Unfortunately, I don't think such panels are commonly available. Probably they are too flexible for other applications that people typically use CF composites for.

I forgot to mention it earlier, but I don't think you should bother considering solid CF panels, that is, CF panels without a lightweight core. Such panels may provide good overall sound quality, but will not provide impressive efficiency. I would expect the efficiency of solid CF to be similar to that of plywood, not horrible, but very mediocre in that respect.

Eric

Eric.

For use in a domestic environment , even my very small 1mm panels can be used down to about 160hz, they can go loud without strain of compression.

The materials are easy to obtain and sometimes free.

Last night I coated one side of the small 1mm corrugated cardboard (I might have made a mess of it though,we shall see) and hopefully when dry I will coat the other side.

it will be interesting to see how it sounds and measures compared to the pva ?

as for the tectonic clone, tectonic are very clever at covering up what they are doing to their panels.

I could be wrong 😁 but last night while looking at the dml 500 down load ,I had a bit of a lightbulb moment(no it hasn't blown) which started me thinking(oh no , not again).

I mentioned a page of two back ,that I used weights to force a small panel to go lower in frequency, but I thought it made the panel sound too much like an ordinary cone driver, so dismissed it.

I think they might be using the same method I used ?

I also mentioned in post 4501 the 5 weights I saw on the back of the panel drawing(which I can't find any more ? It seems to have vanished ? ) if anyone knows where I can find this again it would be very helpful,

But there was also something else I noticed, in the photo of the back of the dml 500 there is a green plate going between the 4 exciters and the panel ?

in the drawing it shows what looks like 2 electrical contact points, which are blocked out in the photo ?

I think these are the special drivers as leob mentions ?

does this plate join all the exciter together in some way ?

Is it used as a spider with the coil wires integral ?

Does it bridge the coil and panel ?

I shall wait and see if the picture turns up of the 5 weights , in case it was my imagination ?

I also see there is a 6th weight ,it looks like a metal disc ?

Steve.

For use in a domestic environment , even my very small 1mm panels can be used down to about 160hz, they can go loud without strain of compression.

The materials are easy to obtain and sometimes free.

Last night I coated one side of the small 1mm corrugated cardboard (I might have made a mess of it though,we shall see) and hopefully when dry I will coat the other side.

it will be interesting to see how it sounds and measures compared to the pva ?

as for the tectonic clone, tectonic are very clever at covering up what they are doing to their panels.

I could be wrong 😁 but last night while looking at the dml 500 down load ,I had a bit of a lightbulb moment(no it hasn't blown) which started me thinking(oh no , not again).

I mentioned a page of two back ,that I used weights to force a small panel to go lower in frequency, but I thought it made the panel sound too much like an ordinary cone driver, so dismissed it.

I think they might be using the same method I used ?

I also mentioned in post 4501 the 5 weights I saw on the back of the panel drawing(which I can't find any more ? It seems to have vanished ? ) if anyone knows where I can find this again it would be very helpful,

But there was also something else I noticed, in the photo of the back of the dml 500 there is a green plate going between the 4 exciters and the panel ?

in the drawing it shows what looks like 2 electrical contact points, which are blocked out in the photo ?

I think these are the special drivers as leob mentions ?

does this plate join all the exciter together in some way ?

Is it used as a spider with the coil wires integral ?

Does it bridge the coil and panel ?

I shall wait and see if the picture turns up of the 5 weights , in case it was my imagination ?

I also see there is a 6th weight ,it looks like a metal disc ?

Steve.

Eric.

Also ,I was thinking about the 5mm xps.

As you know at the moment I am using the epoxy as the skin for this panel,with good sounding results.

but I was wondering how much stiffer the panels would be if I included the fibre glass netting ?

would it make it too heavy, what would it sound like ?

in the tech ingredients video, they used 1inch xps, which was incredibly strong and rigid.

which would be ok for large panels , but I was wondering how well it would scale down to a thinner smaller panel like my 5mm xps or even eps ?

I don't like my panels to be too figid, I can imagine what that small 1inch panel in the tech ingredients video would sound like.

But on a very large panel I can imagine it doing quite well ?

I think the 5mm xps with epoxy (plus fibre glass matting ?)could be a good cheap candidate for the tectonic clone.

Also ,wouldn't the beaming off axis be a bonus for pro use ,covering a wider area ?

Also if I remember correctly, the only panel I seemed to have a problem with side beaming was the 1inch eps panel also in my last photo.

The sound was excellent once I placed damping cushions on the walls to prevent the reflections.

does not the beaming come from the central area ? I can't remember my conclusion on that ?

If I get time I might have a listen and see what frequency this (I think it was more of a spike) off axis response was ?

Steve.

Also ,I was thinking about the 5mm xps.

As you know at the moment I am using the epoxy as the skin for this panel,with good sounding results.

but I was wondering how much stiffer the panels would be if I included the fibre glass netting ?

would it make it too heavy, what would it sound like ?

in the tech ingredients video, they used 1inch xps, which was incredibly strong and rigid.

which would be ok for large panels , but I was wondering how well it would scale down to a thinner smaller panel like my 5mm xps or even eps ?

I don't like my panels to be too figid, I can imagine what that small 1inch panel in the tech ingredients video would sound like.

But on a very large panel I can imagine it doing quite well ?

I think the 5mm xps with epoxy (plus fibre glass matting ?)could be a good cheap candidate for the tectonic clone.

Also ,wouldn't the beaming off axis be a bonus for pro use ,covering a wider area ?

Also if I remember correctly, the only panel I seemed to have a problem with side beaming was the 1inch eps panel also in my last photo.

The sound was excellent once I placed damping cushions on the walls to prevent the reflections.

does not the beaming come from the central area ? I can't remember my conclusion on that ?

If I get time I might have a listen and see what frequency this (I think it was more of a spike) off axis response was ?

Steve.

@Leob , @cheapvega, @VelericLoeb,

Yes, Christian and I were trying to reverse engineer the Tectonic panels based on the information in their website and videos. I must confess we did not quite sort it out. But one thing is clear, the Fc of their panel is over 5000 Hz, which clearly indicates a less stiff panel than either the 3.5 or 5.5 mm panels from your link.

I kind of suspect they use a thinner panel, with both a thinner core and thinner skins. Such a construction should maintain high efficiency, but allow a smaller panel (for a given low end frequency) and provide a higher Fc. Unfortunately, I don't think such panels are commonly available. Probably they are too flexible for other applications that people typically use CF composites for.

I forgot to mention it earlier, but I don't think you should bother considering solid CF panels, that is, CF panels without a lightweight core. Such panels may provide good overall sound quality, but will not provide impressive efficiency. I would expect the efficiency of solid CF to be similar to that of plywood, not horrible, but very mediocre in that respect.

Eric

I agree on the fact we are probably looking for panel that are in a certain way "flexible" where other applications search for the higher stiffness to mass efficiency... so our application is probably not in the main steam application

About solid CF, are you talking about what was test by Cheepvega : see post around #4334

Thank you for the link to composite panel supplier.

Eric,

When you evaluate the possible Fc, how do you get or infer the bending stiffness? Your experience of composite? In a quick look to the web site, I haven't seen information except thickness and mass.

... composites are strange things to me currently!

Christian

Been looking for thin XPS to try out, but minimum thickness I can find is 20mm and that seems only to be available in bulk, but will keep digging around.

Regarding the exciters in the DLM500, it just seems unlikely looking at what is available on the market that they indeed have a secret 32mm 75w 8ohm driver. 30w from a 32mm exciter is already decent output for its size, but 75w just seems unbelievable.

Regarding the exciters in the DLM500, it just seems unlikely looking at what is available on the market that they indeed have a secret 32mm 75w 8ohm driver. 30w from a 32mm exciter is already decent output for its size, but 75w just seems unbelievable.

My first panel was a 60x125cm 20mm XPS panel. It worked not to badly but not excellent; far from plywood or canvas. Not possible to use it without EQ. Not enough low medium if I remember but mainly as if some energy was store and later relax... I am not sure it is a good way to increase the thickness to get stiffness. Then other behavior should appear in high frequency in the thickness of the panel... being no more a thin but a thick plate... I will try to find where I read things about the thickness limit.Eric.

Also ,I was thinking about the 5mm xps.

As you know at the moment I am using the epoxy as the skin for this panel,with good sounding results.

but I was wondering how much stiffer the panels would be if I included the fibre glass netting ?

would it make it too heavy, what would it sound like ?

in the tech ingredients video, they used 1inch xps, which was incredibly strong and rigid.

which would be ok for large panels , but I was wondering how well it would scale down to a thinner smaller panel like my 5mm xps or even eps ?

I don't like my panels to be too figid, I can imagine what that small 1inch panel in the tech ingredients video would sound like.

But on a very large panel I can imagine it doing quite well ?

I think the 5mm xps with epoxy (plus fibre glass matting ?)could be a good cheap candidate for the tectonic clone.

Also ,wouldn't the beaming off axis be a bonus for pro use ,covering a wider area ?

Also if I remember correctly, the only panel I seemed to have a problem with side beaming was the 1inch eps panel also in my last photo.

The sound was excellent once I placed damping cushions on the walls to prevent the reflections.

does not the beaming come from the central area ? I can't remember my conclusion on that ?

If I get time I might have a listen and see what frequency this (I think it was more of a spike) off axis response was ?

Steve.

One difficulty with XPS is to control what we can add on it to give it a good looking. The variability of the result might be high considering all the possible material, sourcing according our respective countries, process or condition to apply coating or painting.

Christian

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker