Just keep posts short!

It is so difficult explaining minor changes to panels and the disastrous effects they can have on a panel sound.

For me a good analogy for people who have been brought up and only know cone type drive units (,which let's face it is practically everybody) let's say we have a very good sounding full range light and delicate sounding cone driver would you even consider attaching a frame of even foam stuck to a frame to the cone itself? How would it effect the overall sound?and to what purpose,to increase the performance in one small area?

Ply and other types of rigid heavy panels is a different matter altogether I have found ,and I treat them differently .

I could go on but This is getting too long.

I can hear that voice again!

Steve

It is so difficult explaining minor changes to panels and the disastrous effects they can have on a panel sound.

For me a good analogy for people who have been brought up and only know cone type drive units (,which let's face it is practically everybody) let's say we have a very good sounding full range light and delicate sounding cone driver would you even consider attaching a frame of even foam stuck to a frame to the cone itself? How would it effect the overall sound?and to what purpose,to increase the performance in one small area?

Ply and other types of rigid heavy panels is a different matter altogether I have found ,and I treat them differently .

I could go on but This is getting too long.

I can hear that voice again!

Steve

Totally agree with your philosophy. Find a good panel. Let it do it’s thing. Minor modifications

Last edited:

Corrections

Just tried to make corrections to a statement in my last post only to find I was out side a 30 minute window!!! What a waste of time!!

Anyway,what I should have said was that if you wanted to,you could clamp or whatever a ply panel ,they are much more forgiving hence me rigidly mounting my pro type panel to enhance it's performance.

I said a lot more but lost my thread!!

Steve

Just tried to make corrections to a statement in my last post only to find I was out side a 30 minute window!!! What a waste of time!!

Anyway,what I should have said was that if you wanted to,you could clamp or whatever a ply panel ,they are much more forgiving hence me rigidly mounting my pro type panel to enhance it's performance.

I said a lot more but lost my thread!!

Steve

Geosand

Cripes ,that sounds like a lot of hard work and not very frugal to me ,let alone WAF factor,🙄.

One exciter and a low end driver per channel is all I use ,my neighbours can vouch for that,the panel size is up to you,even my rigid p!y panels can rock the neighbours ,but playing rock will get my poor 10watt exciters hot!

Steve

Cripes ,that sounds like a lot of hard work and not very frugal to me ,let alone WAF factor,🙄.

One exciter and a low end driver per channel is all I use ,my neighbours can vouch for that,the panel size is up to you,even my rigid p!y panels can rock the neighbours ,but playing rock will get my poor 10watt exciters hot!

Steve

I tried the tall panel idea with my favorite 4.6 mm plywood but did not find them to provide more bass than my regular 16" x 23" panel.

Here's what I measured for the 12" x 48" panel. I supported it with soft foam along the full length of the long edges and left the short edges free:

In comparison, my "usual" size of 16" x 23" did better below about 150 Hz, without compromise anywhere else:

On the other hand, I kinda like this result for a 24" x 24" panel:

It's a little weak at low frequency, but not as bumpy at my 16x23, so can be pretty easily eq'ed with boost to the bass knob:

Pretty good output down to 60 Hz with a gentle roll off below that.

Here's what I measured for the 12" x 48" panel. I supported it with soft foam along the full length of the long edges and left the short edges free:

In comparison, my "usual" size of 16" x 23" did better below about 150 Hz, without compromise anywhere else:

On the other hand, I kinda like this result for a 24" x 24" panel:

It's a little weak at low frequency, but not as bumpy at my 16x23, so can be pretty easily eq'ed with boost to the bass knob:

Pretty good output down to 60 Hz with a gentle roll off below that.

Useful. Thank you Veleric.

My pleasure. But I do wish the tall panel worked for me too!

Eric

I tried the tall panel idea with my favorite 4.6 mm plywood but did not find them to provide more bass than my regular 16" x 23" panel.

Here's what I measured for the 12" x 48" panel. I supported it with soft foam along the full length of the long edges and left the short edges free:

In comparison, my "usual" size of 16" x 23" did better below about 150 Hz, without compromise anywhere else:

On the other hand, I kinda like this result for a 24" x 24" panel:

It's a little weak at low frequency, but not as bumpy at my 16x23, so can be pretty easily eq'ed with boost to the bass knob:

Pretty good output down to 60 Hz with a gentle roll off below that.

Thanks Valeric! The graphs are interesting, but I see 2 possible effects happening on the low-end.

1. The long panel starts to drop off quickly at 190 Hz. The 24 x 24 starts to drop off just above 300 Hz. So the long panel is giving you more SPL's at the low end. But also it looks like the long panel has an overall smoother response above useable bass cut-off than the square panel has. So it appears that the longer panel may be a better overall solution than a square shaped panel of the same total area (at least in FR, only you know which actually sounds better 🙂)

2. On the rectangle panel the low-end drops off at around 250Hz. But its a more gentle drop-off. My only thought is that the more rectangular shape still provides a relatively smooth response through out the FR and not all that different than the long panel...however the better output lower end on the rectangle may just be because its total area is smaller and thus the exciter's power may come into play and drive the smaller panel better (its only 368 sq in vs 576 sq in).

So I see 2 different effects here:

The square panel is not as smooth a response overall compared to either a rectangle or a long panel (and I might also believe the long panel is slightly smoother than the rectangle over its usable range). So a longer shape panel may be an advantage and seems better than a square (which theory seems to say is not a good shape for dml).

Secondly, the larger panel area being "better" may also be dependent on the exciters ability to drive it power wise. Of course larger panel area also means more weight, etc... and it also will have a larger modal density to better smooth out the peaks/valleys (of course within its usable range)

So I'm thinking that going to a longer panel with greater total area and more powerful exciters is a good thing to try. If not for the bass then at least for overall smoother FR down to its usable cut-off.

What exciter are you using?I tried the tall panel idea with my favorite 4.6 mm plywood but did not find them to provide more bass than my regular 16" x 23" panel.

Here's what I measured for the 12" x 48" panel. I supported it with soft foam along the full length of the long edges and left the short edges free:

In comparison, my "usual" size of 16" x 23" did better below about 150 Hz, without compromise anywhere else:

On the other hand, I kinda like this result for a 24" x 24" panel:

It's a little weak at low frequency, but not as bumpy at my 16x23, so can be pretty easily eq'ed with boost to the bass knob:

Pretty good output down to 60 Hz with a gentle roll off below that.

Strange

This measurement looks a little odd to me,a sharp roll off at 200hz ,down 15db at 150hz ?,no exciter or panel resonance?,to be honest if you wanted to xo at 200hz this would be perfect,can you give the mic position please.

You say you supported the panel along the long edges with foam ? Against what?and why?

Did you find the spot where the exciter makes the panel rumble before applying the foam strip?

If I placed 8ft of foam along the long edges of any panel let alone A very narrow panel I would expect damping of panel movement to happen,but I must say I'll be surprised ,a little anyway,if it caused that heavy a drop .

Sorry for rambling on I'm just thinking out aloud .

Steve

This measurement looks a little odd to me,a sharp roll off at 200hz ,down 15db at 150hz ?,no exciter or panel resonance?,to be honest if you wanted to xo at 200hz this would be perfect,can you give the mic position please.

You say you supported the panel along the long edges with foam ? Against what?and why?

Did you find the spot where the exciter makes the panel rumble before applying the foam strip?

If I placed 8ft of foam along the long edges of any panel let alone A very narrow panel I would expect damping of panel movement to happen,but I must say I'll be surprised ,a little anyway,if it caused that heavy a drop .

Sorry for rambling on I'm just thinking out aloud .

Steve

XPS with PVA

I really want PS foam to work well for me in a DML. In my former job, I made PS foam! The output of PS foam (XPS or EPS) is impressive, and far higher than any other panel material I have tried so far. But, so far, I have not been able to make it sound good. It's LOUD, for sure, but not good.

Like many of us, inspired by the Parts Express post, I tried PS foam in my first DML attempt. I was impressed by how loud it was. But I thought it sounded "muddy". When I played it for my wife, she called it "muffled." We agreed, it sounded "unfocused". Soon thereafter, I tried plywood. I was disappointed by how much less sound volume plywood produced, but loved how much crisper and clearer the music, and especially vocals, sounded.

I've spent a good part of the last six months trying to find something as loud as PS and as clear as plywood. Sorry to say, I haven't found it yet.

I have to admit, it took me a while before I tried the PVA coating technique for PS foam. I was skeptical. But I finally did. Spoiler alert: for me it doesn't hurt, but doesn't help much either, as far as I can tell.

The results below are for 1/2 inch thick pink XPS foam. The foam I bought came with thin plastic films applied to both front and back. I tried that in my usual 16"x23" size, attached to a frame by a soft, thick PVC insulation foam around the full perimeter.

As I had observed previously for PS foams, it was loud, but it faded badly above 2 khz. It also sound muddy. Sadly, I can't measure muddy, but I can hear it.

I peeled of the film and sanded it, then remeasured:

Removing the plastic skin and sanding resulted in a dip output between 100 and 200 Hz. Still faded above 2 kHz. Still sounded muddy.

I applied 2 coats of PVA and measured this:

The dip between 100 and 200 Hz improved. Still faded above 2 kHz. Still sounded muddy.

I applied 2 more coats of PVA and measured this:

Output now peaked at 200 Hz. Still faded above 2 kHz. Still sounded muddy.

My conclusion is that applying the PVA coating made a slight improvement, basically restoring the performance provided by the pre applied film. But it did nothing to improve the major deficiencies of PS foam, that is, the muddy sound and the fade above 2 kHz. YMMV.

Eric

I really want PS foam to work well for me in a DML. In my former job, I made PS foam! The output of PS foam (XPS or EPS) is impressive, and far higher than any other panel material I have tried so far. But, so far, I have not been able to make it sound good. It's LOUD, for sure, but not good.

Like many of us, inspired by the Parts Express post, I tried PS foam in my first DML attempt. I was impressed by how loud it was. But I thought it sounded "muddy". When I played it for my wife, she called it "muffled." We agreed, it sounded "unfocused". Soon thereafter, I tried plywood. I was disappointed by how much less sound volume plywood produced, but loved how much crisper and clearer the music, and especially vocals, sounded.

I've spent a good part of the last six months trying to find something as loud as PS and as clear as plywood. Sorry to say, I haven't found it yet.

I have to admit, it took me a while before I tried the PVA coating technique for PS foam. I was skeptical. But I finally did. Spoiler alert: for me it doesn't hurt, but doesn't help much either, as far as I can tell.

The results below are for 1/2 inch thick pink XPS foam. The foam I bought came with thin plastic films applied to both front and back. I tried that in my usual 16"x23" size, attached to a frame by a soft, thick PVC insulation foam around the full perimeter.

As I had observed previously for PS foams, it was loud, but it faded badly above 2 khz. It also sound muddy. Sadly, I can't measure muddy, but I can hear it.

I peeled of the film and sanded it, then remeasured:

Removing the plastic skin and sanding resulted in a dip output between 100 and 200 Hz. Still faded above 2 kHz. Still sounded muddy.

I applied 2 coats of PVA and measured this:

The dip between 100 and 200 Hz improved. Still faded above 2 kHz. Still sounded muddy.

I applied 2 more coats of PVA and measured this:

Output now peaked at 200 Hz. Still faded above 2 kHz. Still sounded muddy.

My conclusion is that applying the PVA coating made a slight improvement, basically restoring the performance provided by the pre applied film. But it did nothing to improve the major deficiencies of PS foam, that is, the muddy sound and the fade above 2 kHz. YMMV.

Eric

What exciter are you using?

Two exciters actually. My favorite combination so far. One Dayton Ultra (better LF), one TEAX32C30-4/B (better HF).

So I'm thinking that going to a longer panel with greater total area and more powerful exciters is a good thing to try. If not for the bass then at least for overall smoother FR down to its usable cut-off.

My interpretation is slightly different. To me, without EQ, the smallest panel (16x23) seems best. If you want to apply EQ, but only have bass and treble knobs, then the 24 x 24 looks best. And if you have more refined EQ capability, maybe the long panels are better, since they need boost only below 200 Hz, but still need more boost below 100 Hz than either of the other sizes. Regardless, the differences are subtle. IMO, they all need help from a subwoofer.

Eric

I really want PS foam to work well for me in a DML. In my former job, I made PS foam! The output of PS foam (XPS or EPS) is impressive, and far higher than any other panel material I have tried so far. But, so far, I have not been able to make it sound good. It's LOUD, for sure, but not good.

Like many of us, inspired by the Parts Express post, I tried PS foam in my first DML attempt. I was impressed by how loud it was. But I thought it sounded "muddy". When I played it for my wife, she called it "muffled." We agreed, it sounded "unfocused". Soon thereafter, I tried plywood. I was disappointed by how much less sound volume plywood produced, but loved how much crisper and clearer the music, and especially vocals, sounded.

I've spent a good part of the last six months trying to find something as loud as PS and as clear as plywood. Sorry to say, I haven't found it yet.

I have to admit, it took me a while before I tried the PVA coating technique for PS foam. I was skeptical. But I finally did. Spoiler alert: for me it doesn't hurt, but doesn't help much either, as far as I can tell.

The results below are for 1/2 inch thick pink XPS foam. The foam I bought came with thin plastic films applied to both front and back. I tried that in my usual 16"x23" size, attached to a frame by a soft, thick PVC insulation foam around the full perimeter.

As I had observed previously for PS foams, it was loud, but it faded badly above 2 khz. It also sound muddy. Sadly, I can't measure muddy, but I can hear it.

I peeled of the film and sanded it, then remeasured:

Removing the plastic skin and sanding resulted in a dip output between 100 and 200 Hz. Still faded above 2 kHz. Still sounded muddy.

I applied 2 coats of PVA and measured this:

The dip between 100 and 200 Hz improved. Still faded above 2 kHz. Still sounded muddy.

I applied 2 more coats of PVA and measured this:

Output now peaked at 200 Hz. Still faded above 2 kHz. Still sounded muddy.

My conclusion is that applying the PVA coating made a slight improvement, basically restoring the performance provided by the pre applied film. But it did nothing to improve the major deficiencies of PS foam, that is, the muddy sound and the fade above 2 kHz. YMMV.

Eric

Hi Eric,

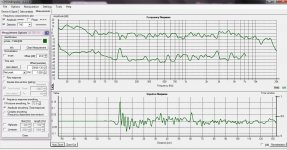

Sorry you haven't had good results with XPS. I have gotten pleasing mids and highs with Foamular 250 in 1", coated front and back, 19x32, with 1 Thruster, no frame or spine. The attached response is with a sub to 70 Hz, 70-300 cones and DML for everything else.

Tri-amped. EQ is 6 db hi pass at 7K. No muddiness quality at all. My main complaint with DML bass is that the distortion goes up (with my panels anyway) starting around 300 and down so I'm using cones for now. My goal is to have low distortion, high output DML down to 100 and then use the cone sub from there. Does anyone think that is really possible?

Bruce

Attachments

Last edited:

Hi Eric,

Sorry you haven't had good results with XPS. I have gotten pleasing mids and highs with Foamular 250 in 1", coated front and back, 19x32, with 1 Thruster, no frame or spine. The attached response is with a sub to 70 Hz, 70-300 cones and DML for everything else.

Tri-amped. EQ is 6 db hi pass at 7K. No muddiness quality at all. My main complaint with DML bass is that the distortion goes up (with my panels anyway) starting around 300 and down so I'm using cones for now. My goal is to have low distortion, high output DML down to 100 and then use the cone sub from there. Does anyone think that is really possible?

Bruce

Bruce,

I have tried 1" Foamular 250 also, but without PVA coating. Since it didn't eliminate the muddy with 1/2 inch, I didn't bother trying with the 1".

I see the same with distortion, but I would say mainly below 200 Hz.

I haven't used HOLM, is the lower line in your plot THD?

Thrusters arrived just today. I'll see what they do, but I'll be surprised if they make the difference, WRT muddiness.

I must admit I hate that I don't know how to measure muddiness. I hear it but don't see anything I can point to in REW measurements. I do see the HF fade with PS in REW but I don't believe that's what causes the muddiness I hear.

Eric

Eric

Pic foam strips

Veleric.

Your frequency response is down 10db at 4k and 20db at 8k something is very wrong,I have only seen foamcore measure this badly.

Pva glue takes a long time to harden 4days maybe ,used lightly it can help The sound propagate across the panel,over used and it will dampen The panel making it sound dull,but not as bad as foam strips mounting to a frame.

The guy from parts express used idea's learnt very quickly from audiocircle forum and the sanded panel with the 50x50 mix of water and pva was my idea and he did acknowledge this but I can't say that I was impressed with his square panels and how he mounted them , such a shame.

Steve

Veleric.

Your frequency response is down 10db at 4k and 20db at 8k something is very wrong,I have only seen foamcore measure this badly.

Pva glue takes a long time to harden 4days maybe ,used lightly it can help The sound propagate across the panel,over used and it will dampen The panel making it sound dull,but not as bad as foam strips mounting to a frame.

The guy from parts express used idea's learnt very quickly from audiocircle forum and the sanded panel with the 50x50 mix of water and pva was my idea and he did acknowledge this but I can't say that I was impressed with his square panels and how he mounted them , such a shame.

Steve

This measurement looks a little odd to me,a sharp roll off at 200hz ,down 15db at 150hz ?,no exciter or panel resonance?,to be honest if you wanted to xo at 200hz this would be perfect,can you give the mic position please.

You say you supported the panel along the long edges with foam ? Against what?and why?

Did you find the spot where the exciter makes the panel rumble before applying the foam strip?

If I placed 8ft of foam along the long edges of any panel let alone A very narrow panel I would expect damping of panel movement to happen,but I must say I'll be surprised ,a little anyway,if it caused that heavy a drop .

Sorry for rambling on I'm just thinking out aloud .

Steve

Steve,

Generally I've found the response for my plywood panels above 200 Hz to be pretty flat, almost regardless of how I mount them and I agree if you use a sub below that it works pretty well.

Now, with respect to the foam mounting: My intention was to support the tall panels similarly to BurntCoil. Admittedly, he used foam in shorter intermittent strips along the long sides, rather than continuous strips, but in my judgement, that difference is trivial.

To further clarify, in my view, the "default" support for a DML panel is to mount the panel to a frame of the same outside dimensions with a soft foam around most of its perimeter. I can't say for sure if the primary function of the frame and foam is damping, or if it is modification of the boundary conditions of the panel, or a combination of the two. But I can say that I have found that when less than roughly half of the panel perimeter is attached to a a frame via foam, the likelihood and extent of lumpiness in the LF response increases significantly.

So for me, the use of foam support on JUST the long edges is actually less support than "normal".

Eric

Thanks!Two exciters actually. My favorite combination so far. One Dayton Ultra (better LF), one TEAX32C30-4/B (better HF).

Hf roll off

I get the impression that whatever I say regarding your xps panels, isn't going to go down well.

So let's look at your measurements and your own words.

Your measured response fall off after 2k !

You say your panels sound muddy,muffled and unfocused.

And you also say applying the default ? foam around most of the outside of the panel basically reduces lumpiness in the LF(without affecting the sound of the panel above100z?)

For me the measurements say it all,and you are actually confirming what they show.

Steve

I get the impression that whatever I say regarding your xps panels, isn't going to go down well.

So let's look at your measurements and your own words.

Your measured response fall off after 2k !

You say your panels sound muddy,muffled and unfocused.

And you also say applying the default ? foam around most of the outside of the panel basically reduces lumpiness in the LF(without affecting the sound of the panel above100z?)

For me the measurements say it all,and you are actually confirming what they show.

Steve

I must admit I hate that I don't know how to measure muddiness. I hear it but don't see anything I can point to in REW measurements. I do see the HF fade with PS in REW but I don't believe that's what causes the muddiness I hear.

Eric

Eric

muddiness is between 200-500Hz. Basically, that's all that your panels are giving you.

Generally I've found the response for my plywood panels above 200 Hz to be pretty flat

Well, if you were looking at that 20dB scale you've shown, anything can be made to look flat!

How about changing the scale to 5dBs... you'll see a lot better.

Personally, I would've thrown the panels away after seeing that FR curve and started experimenting with another material.

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker