Eventually I will get around to fabricating my own version of something like that. But truth be told I'm not sure CF is the optimum skin layer. It may sound wrong but CF is actually, um, heavy, at least compared to wood. My belief is that a wood veneer skin on both sides of a very light (but hard) core could be even better than CF/foam/CF. I have come to believe that B/m^3 is critical, and on that basis, my estimates suggest wood veneer is better than CF.

Eric

Actually I agree with you but I want to hear your theory on why you think wood veneer is better?

Eventually I will get around to fabricating my own version of something like that. But truth be told I'm not sure CF is the optimum skin layer. It may sound wrong but CF is actually, um, heavy, at least compared to wood. My belief is that a wood veneer skin on both sides of a very light (but hard) core could be even better than CF/foam/CF. I have come to believe that B/m^3 is critical, and on that basis, my estimates suggest wood veneer is better than CF.

Eric

But isn't wood veneer/foam/wood veneer in the form of GatorBoard what got all this DML fascination started back in 2009 with Ziggy's original threads? We know that gatorbaord sounds good, but completely lacks HE, which is why most have abandoned it...now I've never seen Gatorboard so not sure what kind of veneer or foam they use in it, but making your own might be a worthwhile attempt especially with all the newer excitors we have today...YMMV

geosand

But isn't wood veneer/foam/wood veneer in the form of GatorBoard what got all this DML fascination started back in 2009 with Ziggy's original threads? We know that gatorbaord sounds good, but completely lacks HE, which is why most have abandoned it...now I've never seen Gatorboard so not sure what kind of veneer or foam they use in it, but making your own might be a worthwhile attempt especially with all the newer excitors we have today...YMMV

geosand

Ziggy loved High density Expanded Polystyrene as his main panel material.

Yesterday I finally started working on my larger panels. Panel size is 47inches height X 13inches width. Painted one side of the panels and letting them dry and tomorrow I will paint the other side. One thing I noticed as soon as I cut the panels from 20inches down to 13inches is that the panels do bend/flex more easily. While I was sanding the corner of the panel a gust of wind blew and the panels easily bend so much that it hit the corner of the table leaving a slight impression on the panel.

Hopefully these thinner panels will produce more bass. If not I am going back to 20inches.

In the meantime listening to some Hansthreesink on my DML sat/ DML sub combo while riding on the slow train. lol

Hopefully these thinner panels will produce more bass. If not I am going back to 20inches.

In the meantime listening to some Hansthreesink on my DML sat/ DML sub combo while riding on the slow train. lol

Tall Blondes

I tried another experiment today which some of you might be interested in.

A couple of comments first on my design objectives because I have not always made this clear.

Firstly, this started off and remans an experiment to see if you could get good quality sound from a format that would fit into the average home, which forces you away from the accepted best ratio of 1:1.618.

Secondly, along the way I stumbled over a ratio that had a better bass performance than my large 1200 by 600 panels, which came as a surprise to me and was not a design goal but an interesting discovery.

But having discovered a new ratio with potential I want to push this ratio as far as it will go, not to be controversial, but simply to explore the boundaries of what will and will not work with DML’s. Thats because I have a hunch that this technology is remarkably tolerant, and offers us a huge design space to explore.

That includes discovering how minimal you can make a floor stander before it stops performing.

In a previous life I developed design methods that strove for the utmost simplicity, which is why I like the suspended approach for all its problems.

So this is as far as I have got to date. A tall panel on a simple stand. No frame. No Spine. No damping. Just tall Scandinavian Birch ply and an exciter.

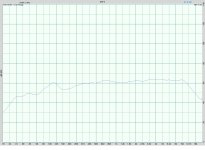

I have included an averaged FFT scan of the raw panels response. I have also included a couple of very rough recordings so you can hear for yourself. They are not great recordings as there are noises off ( including a Spaniel snoring) and the room is inevitably having effecting the sound. Listening live the panels sound cleaner and more spacious, but it will give you some idea.

The recordings includes a small amount of eq at 60 Hz and 30 hz to level up the frequency response in those regions to mimic the response of my Bowers & Wilkins CM1’s

I like tall blondes.

Burnt

P.S As before you may need this free App to listen to the recordings. Its something to do with the format Download VLC Media Player – VLC

I tried another experiment today which some of you might be interested in.

A couple of comments first on my design objectives because I have not always made this clear.

Firstly, this started off and remans an experiment to see if you could get good quality sound from a format that would fit into the average home, which forces you away from the accepted best ratio of 1:1.618.

Secondly, along the way I stumbled over a ratio that had a better bass performance than my large 1200 by 600 panels, which came as a surprise to me and was not a design goal but an interesting discovery.

But having discovered a new ratio with potential I want to push this ratio as far as it will go, not to be controversial, but simply to explore the boundaries of what will and will not work with DML’s. Thats because I have a hunch that this technology is remarkably tolerant, and offers us a huge design space to explore.

That includes discovering how minimal you can make a floor stander before it stops performing.

In a previous life I developed design methods that strove for the utmost simplicity, which is why I like the suspended approach for all its problems.

So this is as far as I have got to date. A tall panel on a simple stand. No frame. No Spine. No damping. Just tall Scandinavian Birch ply and an exciter.

I have included an averaged FFT scan of the raw panels response. I have also included a couple of very rough recordings so you can hear for yourself. They are not great recordings as there are noises off ( including a Spaniel snoring) and the room is inevitably having effecting the sound. Listening live the panels sound cleaner and more spacious, but it will give you some idea.

The recordings includes a small amount of eq at 60 Hz and 30 hz to level up the frequency response in those regions to mimic the response of my Bowers & Wilkins CM1’s

I like tall blondes.

Burnt

P.S As before you may need this free App to listen to the recordings. Its something to do with the format Download VLC Media Player – VLC

Attachments

-

C7D81027-B53F-4C9D-A2BB-63A6659BFD2A_1_105_c.jpg526.7 KB · Views: 612

C7D81027-B53F-4C9D-A2BB-63A6659BFD2A_1_105_c.jpg526.7 KB · Views: 612 -

AD47075E-D624-421B-9789-91ED3A526143_1_105_c.jpg353.4 KB · Views: 594

AD47075E-D624-421B-9789-91ED3A526143_1_105_c.jpg353.4 KB · Views: 594 -

86990BD3-8E7F-4105-AB9A-8168861ED85B_1_105_c.jpg327.7 KB · Views: 603

86990BD3-8E7F-4105-AB9A-8168861ED85B_1_105_c.jpg327.7 KB · Views: 603 -

Raw Tall Skandi Blonde.jpeg461.9 KB · Views: 606

Raw Tall Skandi Blonde.jpeg461.9 KB · Views: 606 -

Lou Reed - Walk on the Wild Side.mp43.8 MB

-

Sade - Cherish the Day.mp45 MB

Last edited:

Eventually I will get around to fabricating my own version of something like that. But truth be told I'm not sure CF is the optimum skin layer. It may sound wrong but CF is actually, um, heavy, at least compared to wood. My belief is that a wood veneer skin on both sides of a very light (but hard) core could be even better than CF/foam/CF. I have come to believe that B/m^3 is critical, and on that basis, my estimates suggest wood veneer is better than CF.

Eric

I agree wood is an excellent material and some form of wood foam composite is heading in the right direction. I just thought the CF/foam?CF board was interesting but as DMLBES points out it is rock-off expensive.

Anistropic foams have peaked my interest as they could give interesting options with tall profiles. I have a hunch a higher degree of stiffness on the shorter axis and relatively lower stiffness on the long axis might enhance the effect I have stumbled onto with the taller profiles.

Anisotropy of the stiffness and strength of rigid low-density closed-cell polyisocyanurate foams - ScienceDirect

Hi BC,

Thanks for uploading the sound files. I love the look of your "Tall Blonde" speakers - perfect name for them. You need to play some Diana Krall to go with that. I got a sense of real bass from that. The vocals however, seemed to lack a bit of midbass - it might just be the effect of the room though. Your FFT shows a very uniform response so I am surprised it sounded off on the vocals. What amp are you driving this with? If you can try and connect a decent Class AB rather than a cheap Class D that would be interesting to see if there was a difference.

Regarding constructon - we are now looking at a simple cantilever support from the entire bottom edge. Is it glued along the whole edge? I wonder if for instance, a sheet of wool felt along the bottom edgee and clamped with spring loaded bolts at say 3 places might make a difference to allow it to resonate a little more freely? But this has now a classic 1/4 wave cantilever and the bass might actually go deeper relative to the length because of it. This may have double the bass extension of a floating board which is at best, a 1/2 wave resonator due to the freely supported end boundary conditions.

Is the recording made with something like a deidcated XY mic digital sound recorder? If you ever get a chance to do that - it makes a huge difference in the stereo presentation. They are getting a lot cheaper now (like a Zoom H1n). Years ago, I uploaded lots of sample sound clips on my Virtual Blind Audition speaker threads and ran into a DIYA max file size limit of 1.8MB. It seems to not be such a low limit and they now allow .mp4 file extensions. Back then I had to rename mp3 files to .asc files and people had to rename them to listen.

Thanks!

X

Thanks for uploading the sound files. I love the look of your "Tall Blonde" speakers - perfect name for them. You need to play some Diana Krall to go with that. I got a sense of real bass from that. The vocals however, seemed to lack a bit of midbass - it might just be the effect of the room though. Your FFT shows a very uniform response so I am surprised it sounded off on the vocals. What amp are you driving this with? If you can try and connect a decent Class AB rather than a cheap Class D that would be interesting to see if there was a difference.

Regarding constructon - we are now looking at a simple cantilever support from the entire bottom edge. Is it glued along the whole edge? I wonder if for instance, a sheet of wool felt along the bottom edgee and clamped with spring loaded bolts at say 3 places might make a difference to allow it to resonate a little more freely? But this has now a classic 1/4 wave cantilever and the bass might actually go deeper relative to the length because of it. This may have double the bass extension of a floating board which is at best, a 1/2 wave resonator due to the freely supported end boundary conditions.

Is the recording made with something like a deidcated XY mic digital sound recorder? If you ever get a chance to do that - it makes a huge difference in the stereo presentation. They are getting a lot cheaper now (like a Zoom H1n). Years ago, I uploaded lots of sample sound clips on my Virtual Blind Audition speaker threads and ran into a DIYA max file size limit of 1.8MB. It seems to not be such a low limit and they now allow .mp4 file extensions. Back then I had to rename mp3 files to .asc files and people had to rename them to listen.

Thanks!

X

Last edited:

Hi BC,

Thanks for uploading the sound files. I love the look of your "Tall Blonde" speakers - perfect name for them. You need to play some Diana Krall to go with that. I got a sense of real bass from that. The vocals however, seemed to lack a bit of midbass - it might just be the effect of the room though. Your FFT shows a very uniform response so I am surprised it sounded off on the vocals. What amp are you driving this with? If you can try and connect a decent Class AB rather than a cheap Class D that would be interesting to see if there was a difference.

Regarding constructon - we are now looking at a simple cantilever support from the entire bottom edge. Is it glued along the whole edge? I wonder if for instance, a sheet of wool felt along the bottom edgee and clamped with spring loaded bolts at say 3 places might make a difference to allow it to resonate a little more freely? But this has now a classic 1/4 wave cantilever and the bass might actually go deeper relative to the length because of it. This may have double the bass extension of a floating board which is at best, a 1/2 wave resonator due to the freely supported end boundary conditions.

Is the recording made with something like a deidcated XY mic digital sound recorder? If you ever get a chance to do that - it makes a huge difference in the stereo presentation. They are getting a lot cheaper now (like a Zoom H1n). Years ago, I uploaded lots of sample sound clips on my Virtual Blind Audition speaker threads and ran into a DIYA max file size limit of 1.8MB. It seems to not be such a low limit and they now allow .mp4 file extensions. Back then I had to rename mp3 files to .asc files and people had to rename them to listen.

Thanks!

X

Thanks X!

The recording is done on an iPhone and I agree the vocals sound a bit off to me as well. I get much more air and tonal richness listening live. I have just received a UMIK-1 mike today so I can get serious about measurement and recording. Better next time I promise.

The panels are just taped to the base upright using foamed tape-1mm thick max. I agree a damping layer between panel and base would be better. I am going to explore this format more as I think it has potential. More news latter on that.

Currently I am driving them with a tiny Class D. I have a Copland Valve amp for serious listening but the baby D does a good enough job I feel. It’s also much easier to lug around when I move the panels into different rooms. I also have a Hypex amp, a Crown which is surprisingly good for the price and some of the original Tripath modules that took the high-end by suprise when they were launched.

Thanks for the feedback. It’s always helpful and together we make progress.

Burnt

Actually I agree with you but I want to hear your theory on why you think wood veneer is better?

Sorry, upon review of my calculations I have to correct myself.

First let me distinguish between two classes of panels:

1) solid panels where the same material is used throughout the full thickness and

2) skinned panels where a stiff skin layer is applied on both sides of a lightweight core.

In the first case (solid panels), and speaking in terms of B/m^3 (where B is panel stiffness and m is panel surface density), my estimate suggest plywood is better (higher B/m^3) than "solid" carbon fiber.

But for the second case (skinned panels), depending on the construction (i.e. core density and thickness, skin thickness), it may be the opposite. That is, B/m^3 may be higher for the carbon fiber skinned panel than for a wood veneer skinned panel of the same core and dimensions.

So, depending on the exact configuration, either wood or carbon fiber can be "better". All that said, I think it's interesting that wood competes pretty well with carbon in many cases.

Eric

But isn't wood veneer/foam/wood veneer in the form of GatorBoard what got all this DML fascination started back in 2009 with Ziggy's original threads? We know that gatorbaord sounds good, but completely lacks HE, which is why most have abandoned it...now I've never seen Gatorboard so not sure what kind of veneer or foam they use in it, but making your own might be a worthwhile attempt especially with all the newer excitors we have today...YMMV

geosand

geosand,

Yeah, great question. When I first heard about the DML concept myself I too immediately thought "Gatorboard!" and then was disappointed when I tried it.

I think part of the reason gatorboard isn't as good as we might expect is that the skins are not actually wood, but rather a wood composite, kind of like hardboard. So, compared to actual wood the skins are not as stiff as wood and heavier than wood. But the big reason (IMHO) that gatorboard isn't great is because the foam core is just too soft.

My thinking is that a wood veneer with a light but very hard core, should give us the high efficiency of gatorboard, combined with the great frequency range of plywood.

I plan to spend more effort trying different panel constructions of wood veneer skins combined with light cores, including possibly: drilled plywood, balsa, end grain balsa, nomex, etc.

Eric

£181.00+VAT / m2 (=2 panels) is not to bad if we would know it to be the best panel.That could work but did you see the PRICE!!!!!

CELPANEL - Tom SoldEventually I will get around to fabricating my own version of something like that. But truth be told I'm not sure CF is the optimum skin layer. It may sound wrong but CF is actually, um, heavy, at least compared to wood. My belief is that a wood veneer skin on both sides of a very light (but hard) core could be even better than CF/foam/CF. I have come to believe that B/m^3 is critical, and on that basis, my estimates suggest wood veneer is better than CF.

Eric

The PP honeycomb panels (with polyesther top) are even lighter and stiffer then foam panels, but would they be better then foam?

0,65kg/M² - 10mm thickness - €36 + vat. (2500 x 1220 x 10 mm)

Gluing wood veneer on it instead of glass or carbon fibres, sounds like a good idea to me.

I tried another experiment today which some of you might be interested in.

Burnt,

Way cool. That's too simple NOT to try myself. I assume the panels are the same dimensions as your original framed "tall story" panels, correct?

Birch Ply DML Panels - 300mm by 1160mm by 4mm B/BB Grade

Maybe even the exact same panels?

How did you attach the panels to the base?

Thanks,

Eric

Yes Eric the dimensions are the same. The panels are stuck to the upright face of the ply base using three strips of 50mm foamed double sided tape. I am experimenting with elastomeric damping on the edges immediately adjacent the exciter as with heavy bass the edges flutter visibly

Just to add that I am seeing a displacement of up to 3mm on the exciter without a spine. Doubling up the panel and exciter brings that back to manageable levels and four panels, which I admit sounds nuts, and we are back to circa .75 mm maximum displacement which is trivial. This allows for very high volume with bass without stressing the exciters.

Although that sounds like a lot of panels if you are wall hanging them it’s feasible. I tell the wife I am planning an art installation.

Burnt.

Although that sounds like a lot of panels if you are wall hanging them it’s feasible. I tell the wife I am planning an art installation.

Burnt.

The PP honeycomb panels (with polyesther top) are even lighter and stiffer then foam panels, but would they be better then foam?

0,65kg/M² - 10mm thickness - €36 + vat. (2500 x 1220 x 10 mm)

Gluing wood veneer on it instead of glass or carbon fibres, sounds like a good idea to me.

I built with plastic honeycomb because I wanted the internal dampening. It works. But I built a DML array so I don't know if it would work well for a single actuator panel. My intuition is that a single actuator would work better with a structural foam (twice as expensive) core. But at the same time, if you can spend that kind of money on materials why not just build an array?

Even if you could build a sublimely tuned Stradivarius DML panel in a Northern Italian hamlet while abstaining from carnal pleasures it still wouldn't sound as good as an orgy of Chinese electronics and brutish algorithmic signal violation.

I tried another experiment today which some of you might be interested in.

A couple of comments first on my design objectives because I have not always made this clear.

Firstly, this started off and remans an experiment to see if you could get good quality sound from a format that would fit into the average home, which forces you away from the accepted best ratio of 1:1.618.

Secondly, along the way I stumbled over a ratio that had a better bass performance than my large 1200 by 600 panels, which came as a surprise to me and was not a design goal but an interesting discovery.

But having discovered a new ratio with potential I want to push this ratio as far as it will go, not to be controversial, but simply to explore the boundaries of what will and will not work with DML’s. Thats because I have a hunch that this technology is remarkably tolerant, and offers us a huge design space to explore.

That includes discovering how minimal you can make a floor stander before it stops performing.

In a previous life I developed design methods that strove for the utmost simplicity, which is why I like the suspended approach for all its problems.

So this is as far as I have got to date. A tall panel on a simple stand. No frame. No Spine. No damping. Just tall Scandinavian Birch ply and an exciter.

I have included an averaged FFT scan of the raw panels response. I have also included a couple of very rough recordings so you can hear for yourself. They are not great recordings as there are noises off ( including a Spaniel snoring) and the room is inevitably having effecting the sound. Listening live the panels sound cleaner and more spacious, but it will give you some idea.

The recordings includes a small amount of eq at 60 Hz and 30 hz to level up the frequency response in those regions to mimic the response of my Bowers & Wilkins CM1’s

I like tall blondes.

Burnt

P.S As before you may need this free App to listen to the recordings. Its something to do with the format Download VLC Media Player – VLC

You should have recorded the same songs from before so we can compare them better.

Do you want my honest opinion or do you want me to hype it? LOL ...they sound exactly like panels without any dampening.

Last edited:

Good thought. I will do it on the morning DMLBES. I am looking forward to seeing and hearing yours!

Even if you could build a sublimely tuned Stradivarius DML panel in a Northern Italian hamlet while abstaining from carnal pleasures it still wouldn't sound as good as an orgy of Chinese electronics and brutish algorithmic signal violation.

I am left speechless. The depth and subtlety of this nuanced expression brings tears of joy to my brain. Thank you!

I tried another experiment today which some of you might be interested in.

A couple of comments first on my design objectives because I have not always made this clear.

Firstly, this started off and remans an experiment to see if you could get good quality sound from a format that would fit into the average home, which forces you away from the accepted best ratio of 1:1.618.

Secondly, along the way I stumbled over a ratio that had a better bass performance than my large 1200 by 600 panels, which came as a surprise to me and was not a design goal but an interesting discovery.

But having discovered a new ratio with potential I want to push this ratio as far as it will go, not to be controversial, but simply to explore the boundaries of what will and will not work with DML’s. Thats because I have a hunch that this technology is remarkably tolerant, and offers us a huge design space to explore.

That includes discovering how minimal you can make a floor stander before it stops performing.

In a previous life I developed design methods that strove for the utmost simplicity, which is why I like the suspended approach for all its problems.

So this is as far as I have got to date. A tall panel on a simple stand. No frame. No Spine. No damping. Just tall Scandinavian Birch ply and an exciter.

I have included an averaged FFT scan of the raw panels response. I have also included a couple of very rough recordings so you can hear for yourself. They are not great recordings as there are noises off ( including a Spaniel snoring) and the room is inevitably having effecting the sound. Listening live the panels sound cleaner and more spacious, but it will give you some idea.

The recordings includes a small amount of eq at 60 Hz and 30 hz to level up the frequency response in those regions to mimic the response of my Bowers & Wilkins CM1’s

I like tall blondes.

Burnt

P.S As before you may need this free App to listen to the recordings. Its something to do with the format Download VLC Media Player – VLC

Simplicity is beautiful. You are now going down the road of ideas I've had for awhile, but lack the $$$ to make happen. So if I may be so bold as to offer some ideas for further investigation.

1. Instead of the wood pedestal stand, lets make it even simpler. Just use a steel L-bracket on the bottom-middle of the panel backside. Let the panel itself rst on the floor/carpet (to provide bottom edge damping) and then the L-bracket provides the "tripod" effect to keep the panel standing upright. Of course you would again want to use some damping/adsorption material between the panel back and the L-bracket.

2. Another variation of this is instead of having the panel bottom resting directly on the floor, place some foam weather stripping along the bottom edge to provide even more damping.

3. Another idea is instead of using just one L-Bracket, try 2. One each on the back at the sides/corners instead of the middle. This will provide more stability and a bit more clamping effect. The you could also try, the same but this time raise the panel an inch or two off the floor so just the 2 L-brackets hold it up. Then the bottom edge won't be damped on the floor, but also you will tend to have some floor decoupling on the bass end as well.

4. Another variation maybe more for looks: Use variation #3, but instead of putting the exciter towards the middle of the panel, put it at the middle-bottom of the panel. The make a small box enclosure to "hide" the exciter that can also support the exciter and hide its cabling within the box and use some banana plugs on the box to connect the exciter wires and have a nice clean speaker connection. This would make the speaker look like just a single thin sheet of wood from front and back and people will be amazed at how it could possibly work 🙂

5. Yet another variation is instead of wood, try a sheet of acrylic or poly-carbonate or even glass so the panel is completely see-thru, with the exciter hidden at the bottom not to be seen. Of course then you could go overbaord and place some colored leds at the bottom of the panel that would make the speaker seemly glow, lol.

There are lots of other stand variations that could be used on this theme to really make a DML look like just a tall thin panel with nothing driving it for a really stunning look.

Hopefully, some day I will get to try these types of ideas out when I win the lottery...

geosand

Thank you geosands, lots of great ideas. I have never tried the edges with an exciter so I have no idea how that will sound but when I have a spare exciter I will give it a go and let you know how it works. I hope you get time and resources to build yours soon.

Burnt

Burnt

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker