Aagas, easy composites sell loose CF strands, graphite powder and CF milled powder, which can be added to expoy, see below:Steve -

On holiday with rain and now a mild case of Covid, I started entertaining myself watching odd YouTube videos.

To my mind, both of these videos essentially describe homemade composites.

One advocating cotton and super glue the other graphite and super glue.

In the graphite focused video, the graphite itself serves as a structure for these DIY composites.

One can readily purchase graphite powder. Pretty cheap.

From other research I understand that graphite can increase the working time of super glue, but probably not sufficiently so to coat anything, but a small panel.

Also, super glue outgases toxic fumes when one works with it.

This has me wondering....

Why not add graphite to PVA in coating various types of panels (e.g., balsa, EPS, 3mm plywood)?

The PVA should bond the graphite particles together.

The graphite should provide the molecular structure and a harder and stronger surface.

While not a home made carbon fiber composite sheet/fabric, this approach could provide many of the benefits of such sheets, while remaining, thinner, lighter, easier to work, and less expensive.

It might even prove better for DML purposes than trying to laminate carbon fiber sheets or cloth to a lightweight core material.

Could produce a cool black DML.

Another possible structural fiber one could try:

Also available readily in a number of forms, e.g., Keratin fibers.

Probably not as strong a graphite, but easily available keratin fibers have a larger size (especially in length) than powdered graphite.

Not home in my workshop so I can't try these idea, but I thought them worth sharing.

Back to YouTube surfacing ;-)

P.S. I may have a source for carbon fibers used to make carbon fiber sheets, cloth, and composites. I haven't found it readily available the the general public, but I know someone in the industry. I'll keep the tread posted.

https://www.easycomposites.co.uk/filler-powders-and-additives

I would like to hear a sound clip/video.

here are two examples. Recorded using an iphone. The speakers in the video are my latest project. They are actually a hybrid of DML and piston.

However they sound the same (above 250 Hz) as the speakers I showed in the previous post. The panel is built in the same way.

@Sandasnickaren

Lovely!

Would you like to talk about your latest project? That is, what's behind the panel, and so on...

Lovely!

Would you like to talk about your latest project? That is, what's behind the panel, and so on...

Sandasnickaren.

Ha ha I love it, nothing like a bit of heavy metal to get things moving ✌️

Have you listened to my du hast recordings.

Your panels in the wall ideas has reminded me of an idea I was thinking of trying.

G A Briggs describes using a cone speaker in a box but mounting it so the driver has a gap between the driver and panel.

The gap acts as a port to drive the bass and mimics a free edged cone but without the low frequency resonance of the free edged cone.

This gives a sort of open baffle sound .

I did this with a 8" cone many years ago and it sounded very nice.

I wonder if mounting a driver or panel in such a way in a wall would also work ?

Steve.

Ha ha I love it, nothing like a bit of heavy metal to get things moving ✌️

Have you listened to my du hast recordings.

Your panels in the wall ideas has reminded me of an idea I was thinking of trying.

G A Briggs describes using a cone speaker in a box but mounting it so the driver has a gap between the driver and panel.

The gap acts as a port to drive the bass and mimics a free edged cone but without the low frequency resonance of the free edged cone.

This gives a sort of open baffle sound .

I did this with a 8" cone many years ago and it sounded very nice.

I wonder if mounting a driver or panel in such a way in a wall would also work ?

Steve.

The question is "end grain balsa" in 1.5 or 2mm. Have you found some? Boards 10cm by 1m in different thickness are quite aesy to find.Looks like Aliexpress has. Hope it helps.

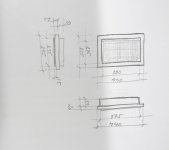

I can easily get 1.5-2mm balsa sheets, but I’m struggling to find end grain sheets at this thickness. See attached pic.The question is "end grain balsa" in 1.5 or 2mm. Have you found some? Boards 10cm by 1m in different thickness are quite aesy to find.

Thanks

Attachments

Sandasnickaren’s speakers sounded great, so maybe not worth the hassle trying to source end grain and just use standard sheets glued together, as Sandasnickaren has done. 👍I can easily get 1.5-2mm balsa sheets, but I’m struggling to find end grain sheets at this thickness. See attached pic.

Thanks

No direct link with DML but might be interesting for all DYIer : screw head repair around 10s and later the molding technique. I found also the smoke suspect!Steve -

On holiday with rain and now a mild case of Covid, I started entertaining myself watching odd YouTube videos.

.../...

Also, super glue outgases toxic fumes when one works with it.

@Sandasnickaren and others...

If you want the image you insert sized to the amount you like, just click on the inserted image, and pull from the bottom right corner. When you click on the inserted image there'd be 4 bold squares at each end. The image can be pulled to size from any of them.

If you want the image you insert sized to the amount you like, just click on the inserted image, and pull from the bottom right corner. When you click on the inserted image there'd be 4 bold squares at each end. The image can be pulled to size from any of them.

Also worth considering is the density of balsa that can vary between 60 to 250 kg per kubik meter. I have used the ligthest I could find which was roughly 100kg/m3.Sandasnickaren’s speakers sounded great, so maybe not worth the hassle trying to source end grain and just use standard sheets glued together, as Sandasnickaren has done. 👍

I’ve considered making an endgrain core (I do have the equipment to do it). It would be intresting to see/hear if it makes a difference. Maybe later on.

What was the weight of the panel without the carbon film cover? Or, with the carbon film cover?Also worth considering is the density of balsa that can vary between 60 to 250 kg per kubik meter. I have used the ligthest I could find which was roughly 100kg/m3.

I’ve considered making an endgrain core (I do have the equipment to do it). It would be intresting to see/hear if it makes a difference. Maybe later on.

As requested,@Sandasnickaren

Lovely!

Would you like to talk about your latest project? That is, what's behind the panel, and so on...

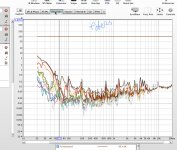

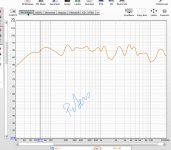

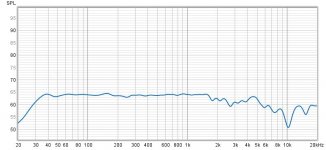

These are designed to be in a closed box or in-wall. I call them hybrid as they operate both as DML and piston. The size is roughly the same as an 15 inch driver ie SD 912 cm2,but the moving mass is only 60g and the BL 29 Tm. Xmax 10mm p-p.

There is a ”regular ” foam surround I made from 1 mm EVA foam. It’s U shaped.

I’m using 6 exciters to drive the panel.

’Frequency range when mounted in-wall is 30-20000 Hz. It’s most likely possible to push them down to 20 with a bit of eq.

measurements from 1m and nearfield few cm.

Attachments

-

8B45D5FD-2025-479F-82FA-1C32098D480B.jpeg367.8 KB · Views: 275

8B45D5FD-2025-479F-82FA-1C32098D480B.jpeg367.8 KB · Views: 275 -

E488AA13-C126-465C-A57F-9EA70B97583D.jpeg400.4 KB · Views: 286

E488AA13-C126-465C-A57F-9EA70B97583D.jpeg400.4 KB · Views: 286 -

B655389B-6557-4FA6-9EC8-382AB2CEF23C.jpeg351.3 KB · Views: 298

B655389B-6557-4FA6-9EC8-382AB2CEF23C.jpeg351.3 KB · Views: 298 -

A9CCA20B-2C7F-4845-862B-7F89D12320BC.jpeg362.8 KB · Views: 255

A9CCA20B-2C7F-4845-862B-7F89D12320BC.jpeg362.8 KB · Views: 255 -

129F77DE-9074-44C6-A30F-4A32C39F528F.jpeg67.7 KB · Views: 284

129F77DE-9074-44C6-A30F-4A32C39F528F.jpeg67.7 KB · Views: 284

Can you give the dimensions of the box, length and breadth of the panel? How are the drivers connected?As requested,

These are designed to be in a closed box or in-wall. I call them hybrid as they operate both as DML and piston. The size is roughly the same as an 15 inch driver ie SD 912 cm2,but the moving mass is only 60g and the BL 29 Tm. Xmax 10mm p-p.

There is a ”regular ” foam surround I made from 1 mm EVA foam. It’s U shaped.

I’m using 6 exciters to drive the panel.

’Frequency range when mounted in-wall is 30-20000 Hz. It’s most likely possible to push them down to 20 with a bit of eq.

measurements from 1m and nearfield few cm.

balsa 10gWhat was the weight of the panel without the carbon film cover? Or, with the carbon film cover?

CF 8 g per side

in total 26g

I just checked, 10g is 2 A4 printer paper. 26g is just 5 A4 paper. Is your 2nd project panel that light too?balsa 10g

CF 8 g per side

in total 26g

Last edited:

You've 6 drivers. Are you using a crossover?View attachment 1126716

The voicecoilformer is glued to the panel.

Hat was the finished weight of the panel? Thanksbalsa 10g

CF 8 g per side

in total 26g

No, same signal to all six drivers.You've 6 drivers. Are you using a crossover?

So, the lightness of the panel is the most important factor, other than how it is made - a composite. Both Gobel and Herger were talking about very light composite panels. Actually they are featherlight. @Sandasnickaren's panel is lighter than Gobel's. Thanks pal, I'm going to read both Gobel's and Herger's patents very carefully. You've done a superb job of proving it! 🙂

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker