Steve,I had a little accident with my eps panel, which I will fix with a 50x50 mix of pva, no problem.

but in the meantime I'm using this canvas panel with just an exciter attached, I have now added a little back brace to support the exciter weight.

the canvas is too loose , it flaps around like a sail in the wind, I have tried soaking the canvas in water and a 50x50 mix of pva but it is still too loose.

the frame is not adjustable so I have either got to undo the canvas and re-stretch it or maybe expand the frame joints somehow ?

I think the printed front surface has a plastic coating ,which sounds ok so far, but adding pva is not an option.

even in this condition the panel has a good response down to about 130hz ,with a very natural sound,but more can be done I think.

if not using full range, I am coming around to thinking that the ply is not needed on canvas.

This panel needs more testing ,the smaller panel doesn't seem to affect the overall sound, I just want to get a little bit more Life into the sound.

At the moment I'm trying to do this without affecting the front picture, but may eventually have to add a dome ?

But I have a few ideas.

Steve.

Usually there are two pieces of wood in a triangle shape at each inner corner of the frame. I don't see them. With those pieces of wood you can adjust the tension. without I don't see how it is possible. If you don't have those parts, there may be the slots to introduce them. Any piece of wood in a triangle shape of the right thickness might work. Eat some ice creams to keep the stick ;-). Sometime is it provided in a small plastic bag with the canvas.

Christian

Hmm... depend on the wood you chose for the plywood. For birch yes probably, for poplar not. The fact to have a very little bend standing on it is not a criteria. The goal is to keep a certain stiffness to aerial mass. If the panel is too stiff, you'll need more surface to reach the low frequencies.It's not as light as it should be because the air spaces in the very thin foam yet it's still less dense than most plywoods and about 4-10 times as stiff. I attached it to 1" thick hard XPS foam... it's slightly heavier per square foot but not much, and I can stand on it with very little bend, which is in no way comparable to the foam.

I understand why you said the surface is not a problem! It might a chance to have such a surface with heavy of thick material to mitigate the role of the back wall.Oops, left out the pictures...

The only good thing is that wall is thin wood paneling that's been painted and doesn't bounce sounds as badly as drywall. The downside is the guest bedroom behind it gets a lot of sound even though there is a closet there. That said, I do plan to do some wall treatments. I might even cut out the panel behind the speakers and stuff the space with mineral wool or even real wool. I want to be sure of my setup before I start cutting holes in the wall though.I understand why you said the surface is not a problem! It might a chance to have such a surface with heavy of thick material to mitigate the role of the back wall.

I don't know why so many here hate on CF so much. It doesn't really seem to be logic so much as just hating on an expensive material or maybe hating on Tectonic.

I think the benefit of carbon is that you can make something really stiff in proportion to weight.The only good thing is that wall is thin wood paneling that's been painted and doesn't bounce sounds as badly as drywall. The downside is the guest bedroom behind it gets a lot of sound even though there is a closet there. That said, I do plan to do some wall treatments. I might even cut out the panel behind the speakers and stuff the space with mineral wool or even real wool. I want to be sure of my setup before I start cutting holes in the wall though.

I don't know why so many here hate on CF so much. It doesn't really seem to be logic so much as just hating on an expensive material or maybe hating on Tectonic.

Yes, a DML wants a material that is stiff enough but as light as possible, so carbon is good. But how stiff is stiff enough?

After you have enough stiffness, everything you add is making the panel harder to drive.

I think the panel you got have 0.5mm thick carbon on each side. 1mm total carbon plate is extremely stiff. Just the resin used to bind the fibres would probably be stiff enough in that thickness. It might be great for some type of constructions, but seems to be much stiffer than optimal for a DML plate.

At least when experimenting with the printed plates, it seemed like the thinner skin the better, and there I got down to 0.1mm per skin. Don't think carbon needs to be any thicker.

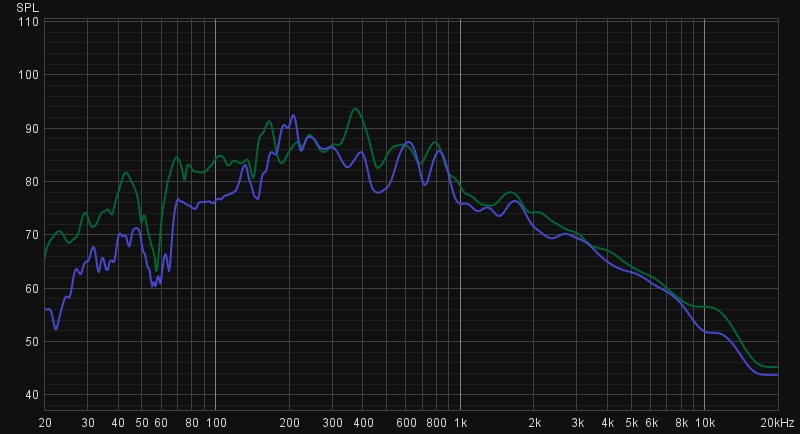

Here are graphs for the 500x330x25mm Neopor (green) and Styropor (blue) plates:

I tried running the tests from my laptop, but got the same bass dropoff I saw with the printed plates. Both the EPS and printed plates does reproduce the bass, but for some reason when measuring on my laptop everything is highpassed even if I hear the low end in the sweep. So instead I ran it from my desktop, and now see the sub bass as well.

They are measured at different positions in the room, so that might account for some differences between the individual plates, especially the different peaks and valleys in the bass to low mid. I can't say I notice the louder bass on the Neopor when listening, and that doesn't seem like a room mode since it is consistent over a large range, so a bit confusing to me.

Otherwise the response is similar to what I get with the printed plates. The same HF slope, but a bit smoother curve overall, which I'm guessing is mostly down to the larger dimensions.

But efficiency is really much better.

I will print another plate with the carbon fibre filament and my updated settings, and record that from my desktop as well to have a comparison. While distortion looks good for the styrofoam plates, much lower than my Tannoys for example, the printed carbon plate had the lowest distortion I have measured so far, so might still be interesting.

I tried running the tests from my laptop, but got the same bass dropoff I saw with the printed plates. Both the EPS and printed plates does reproduce the bass, but for some reason when measuring on my laptop everything is highpassed even if I hear the low end in the sweep. So instead I ran it from my desktop, and now see the sub bass as well.

They are measured at different positions in the room, so that might account for some differences between the individual plates, especially the different peaks and valleys in the bass to low mid. I can't say I notice the louder bass on the Neopor when listening, and that doesn't seem like a room mode since it is consistent over a large range, so a bit confusing to me.

Otherwise the response is similar to what I get with the printed plates. The same HF slope, but a bit smoother curve overall, which I'm guessing is mostly down to the larger dimensions.

But efficiency is really much better.

I will print another plate with the carbon fibre filament and my updated settings, and record that from my desktop as well to have a comparison. While distortion looks good for the styrofoam plates, much lower than my Tannoys for example, the printed carbon plate had the lowest distortion I have measured so far, so might still be interesting.

Leob.

Your measurements don't make much sense to me ?

Bog standard 25mm eps should be pretty flat to about 10k

So 10db down by 2k and 30db down by 10k ?

You can't be measuring correctly or there is something wrong with the exciter of mounting ?

your other measurements also have similar heavy roll off also ?

This cannot be a coincidence

they should not have similar measurements.

Steve.

Your measurements don't make much sense to me ?

Bog standard 25mm eps should be pretty flat to about 10k

So 10db down by 2k and 30db down by 10k ?

You can't be measuring correctly or there is something wrong with the exciter of mounting ?

your other measurements also have similar heavy roll off also ?

This cannot be a coincidence

they should not have similar measurements.

Steve.

Narenaud.

It is not a question of hating cf, I have never used c.f. as it is so expensive.

Cf was never designed to be a dml panel, so there is no reason for it to be any better than any other panel material, no matter what the cost.

I do get the impression though ,that my very cheap to make panels , which I have specially built to be a dml panel ,are are not taken seriously because they are too cheap!

I'm sure if I made a diamond encrusted dml panel for £10000 everyone would be salivating over it , no matter how it sounded.

It is not a question of hating cf, I have never used c.f. as it is so expensive.

Cf was never designed to be a dml panel, so there is no reason for it to be any better than any other panel material, no matter what the cost.

I do get the impression though ,that my very cheap to make panels , which I have specially built to be a dml panel ,are are not taken seriously because they are too cheap!

I'm sure if I made a diamond encrusted dml panel for £10000 everyone would be salivating over it , no matter how it sounded.

Hello LeobHere are graphs for the 500x330x25mm Neopor (green) and Styropor (blue) plates:

View attachment 1036999

I tried running the tests from my laptop, but got the same bass dropoff I saw with the printed plates. Both the EPS and printed plates does reproduce the bass, but for some reason when measuring on my laptop everything is highpassed even if I hear the low end in the sweep. So instead I ran it from my desktop, and now see the sub bass as well.

They are measured at different positions in the room, so that might account for some differences between the individual plates, especially the different peaks and valleys in the bass to low mid. I can't say I notice the louder bass on the Neopor when listening, and that doesn't seem like a room mode since it is consistent over a large range, so a bit confusing to me.

Otherwise the response is similar to what I get with the printed plates. The same HF slope, but a bit smoother curve overall, which I'm guessing is mostly down to the larger dimensions.

But efficiency is really much better.

I will print another plate with the carbon fibre filament and my updated settings, and record that from my desktop as well to have a comparison. While distortion looks good for the styrofoam plates, much lower than my Tannoys for example, the printed carbon plate had the lowest distortion I have measured so far, so might still be interesting.

Strange... With EPS, strange that your 10k level is 30dB below the "main level". To have the 4k/5k 10dB below the 300/800Hz area seems common but not 20dB with a slope like if some high pass filter was acting.

Your 3D printing panels are completely new so it was difficult to say but here it is really

Come back to #4903 or #4651 (where I introduced the spectral contamination) There are more typical FR :

- a bass area which is a bit "insulated" from the rest of FR due to the 1st mode. Often lower than the 300/800Hz level

- a kind of hole in the 100/300Hz area

- a 300Hz to 2/3kHz "main area" possibly with some humps

- a drop off 4/5kHz

- a HF hump

Under which OS do you work? Your FR remind me some tests I made under Android where I was unable to disconnect the voice filter the system adds automatically on the recorder app.

Christian

PS : going down the posts, I see Steve is saying about the same...

+ @NaRenaudNarenaud.

It is not a question of hating cf, I have never used c.f. as it is so expensive.

Cf was never designed to be a dml panel, so there is no reason for it to be any better than any other panel material, no matter what the cost.

I do get the impression though ,that my very cheap to make panels , which I have specially built to be a dml panel ,are are not taken seriously because they are too cheap!

I'm sure if I made a diamond encrusted dml panel for £10000 everyone would be salivating over it , no matter how it sounded.

I would say it about in the same way. CF by its technique and cost has probably less feedback. Among them some not so good results, some good on fully custom panels (Veleric CF+balsa). The material you use is not among the popular one.

DML is not a question of finding the stiffer material. It is the art of mastering the vibrations of a plate where the first step is the right balance stiffness to weight.

By the material you use, by the overall dimensions of your panels, your design (on very rigid panel in a larger one) you are in another area (technically speaking) than most of us.

Some Fr to speak with data?

None of these materials were "designed for DMLs". I have no problem with cheap materials... I'm using really cheap XPS right now, mated with somewhat expensive CF sandwich. I do have a problem in that my huge XPS panels are fragile. I've already had accidents and scarred them up moving them around even though Im very careful.

Structurally, CF is a composite (like wood is a composite) and that in itself has some advantages over homogenous materials. You guys cove stiffness to weight but thickness is also an issue. Using a soft foam an inch thick to achieve stiffness has it's own disadvantages. I started out with the idea of large panels, I'm not paying for giant CF so that leaves me experimenting with combined elements. So far among materials I've tried, which is admittedly very limited, it sounds really good. I think it would probably sound better if it was thinner skinned and the foam had more actual air...but I got these are a deep discount so that's ok. It also is the loudest material I've tested so far, louder than XPS project panel size.

Anyway...

I now have a really good right speaker. I did some fiddling today trying to get the left to perform more like it but didn't get very far. I will likely resort to tearing it down and rebuilding using the same design as the right. I don't think it's the sanding of the surface I did but it could be. The 1/2 inch XPS with braces seems a lot better than the 1 inch with no braces. I also thing my placement and shapes is better on right. Oh, and the 1” XPS has scoring lines. I think they are the cause of persistent rattle at high power that the right doesn't have. I squeezed some glue in there but it's not really dry yet so I don't know how much it might help...going back and getting un- scored 1/2 inch panel seems to be in my future.

Structurally, CF is a composite (like wood is a composite) and that in itself has some advantages over homogenous materials. You guys cove stiffness to weight but thickness is also an issue. Using a soft foam an inch thick to achieve stiffness has it's own disadvantages. I started out with the idea of large panels, I'm not paying for giant CF so that leaves me experimenting with combined elements. So far among materials I've tried, which is admittedly very limited, it sounds really good. I think it would probably sound better if it was thinner skinned and the foam had more actual air...but I got these are a deep discount so that's ok. It also is the loudest material I've tested so far, louder than XPS project panel size.

Anyway...

I now have a really good right speaker. I did some fiddling today trying to get the left to perform more like it but didn't get very far. I will likely resort to tearing it down and rebuilding using the same design as the right. I don't think it's the sanding of the surface I did but it could be. The 1/2 inch XPS with braces seems a lot better than the 1 inch with no braces. I also thing my placement and shapes is better on right. Oh, and the 1” XPS has scoring lines. I think they are the cause of persistent rattle at high power that the right doesn't have. I squeezed some glue in there but it's not really dry yet so I don't know how much it might help...going back and getting un- scored 1/2 inch panel seems to be in my future.

I'm starting to think it is the exciters. I will try preparing panel with PVA and gluing instead of taping the exciters to see what difference it makes. It is clear that the issue is not in the measuring chain at least. I don't get the same rolloff on my regular speakers, and the panels are clearly duller.Leob.

Your measurements don't make much sense to me ?

Bog standard 25mm eps should be pretty flat to about 10k

So 10db down by 2k and 30db down by 10k ?

You can't be measuring correctly or there is something wrong with the exciter of mounting ?

your other measurements also have similar heavy roll off also ?

This cannot be a coincidence

they should not have similar measurements.

Steve.

Listen to a bunch of tracks yesterday trying to make up my mind if I like the Neopor better then the Styropor, and I'm leaning towards the Neopor. The Styropor has a shimmery chorus kind of effect (typical of the unsanded EPS perhaps?), which does sound very nice on some material, but Neopor sounds clearer with noticeably better intelligibility.

Both my laptop and desktop run windows.I would suggest you search the reasons. A comparison with a known small full range standard loudspeaker or a tweeter alone for the HF might say if it is in the measurement chain or in the way doing the panel. As the listening results are not to bad, is it in the measurement chain?

Under which OS do you work? Your FR remind me some tests I made under Android where I was unable to disconnect the voice filter the system adds automatically on the recorder app.

Christian

PS : going down the posts, I see Steve is saying about the same...

The lack of treble is clearly audible during playback, and I think I can trust the measuring chain now. Measuring regular speakers I don't see the same slope.

I would agree with Steve. This is a plot from my 30x40 2mm plywood panels using cheap Chinese exciters. They are not free floating, so when I return from holiday, I plan to make some more panels using the same exciters to see what happens.Both my laptop and desktop run windows.

The lack of treble is clearly audible during playback, and I think I can trust the measuring chain now. Measuring regular speakers I don't see the same slope.

Nnarenaud.

It is not the thickness of the XPS that is the problem , it is the material itself.

EPS of the same thickness will vastly outperform XPS .

EPS and XPS should not be assumed to be the same .

For a better sound from XPS I have recommended applying epoxy, and maybe glass fibre,but this might be too stiff ?

I have only used 5mm XPS.

Steve.

It is not the thickness of the XPS that is the problem , it is the material itself.

EPS of the same thickness will vastly outperform XPS .

EPS and XPS should not be assumed to be the same .

For a better sound from XPS I have recommended applying epoxy, and maybe glass fibre,but this might be too stiff ?

I have only used 5mm XPS.

Steve.

Leob.

does the styropor and neopor have the same hard rough surface that crackles when scratched ,or is it quite smooth and soft ?

The hard melted styrene is not that great sounding, and needs removing.

This makes a big difference.

the neopor might have extra internal damping , this could be good or bad ?

Steve.

does the styropor and neopor have the same hard rough surface that crackles when scratched ,or is it quite smooth and soft ?

The hard melted styrene is not that great sounding, and needs removing.

This makes a big difference.

the neopor might have extra internal damping , this could be good or bad ?

Steve.

I have not sanded them yet...wanted to try them out raw first of all. But gonna sand and test with PVA as well as hide glue.Leob.

does the styropor and neopor have the same hard rough surface that crackles when scratched ,or is it quite smooth and soft ?

The hard melted styrene is not that great sounding, and needs removing.

This makes a big difference.

the neopor might have extra internal damping , this could be good or bad ?

Steve.

Weight of Neopor is 25kg/m3, so it is very similar to the EPS, but it seems a bit more dampened and sounds like it is singing along a bit less. Loudness is the same, but sound is less full, but more clear and tight. Really hard to say which I prefer in general, it really depends on the track.

This is interesting: "The graphite component of Neopor causes the heat to be reflected hundreds of times as it moves through the insulation. This significantly slows the transfer of heat, making Neopor more energy efficient than traditional EPS insulation.".I have not sanded them yet...wanted to try them out raw first of all. But gonna sand and test with PVA as well as hide glue.

Weight of Neopor is 25kg/m3, so it is very similar to the EPS, but it seems a bit more dampened and sounds like it is singing along a bit less. Loudness is the same, but sound is less full, but more clear and tight. Really hard to say which I prefer in general, it really depends on the track.

What implications this has for a DML panel is worthy of debate.

I've been keeping an eye on the DML threads for awhile. I think these speakers are amazing, have built 3 or 4 and spurred another 5 or 6 people to build them based on them hearing mine. The conversations here mostly seem to be about what's being tried to make really great speakers. Much of it is technical. I'm only a little technical. Here's my question: Is there a summary of the results of what you've found so far? What I'm hoping for is something that spells out a couple versions of DMLs in enough detail to build them AND represents a consolidation of the research that you all are doing. Kind of a "based on what we know so far do it this way or that way". Maybe the answer already exists and I just haven't discovered it. If so could you please point me to it? Keep up the great work.

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker