Narenaud.

Elemers glue is the cheapest in the test , that's the one I'd probably choose.

Steve.

Elemers glue is the cheapest in the test , that's the one I'd probably choose.

Steve.

Narenaud.

WARNING.

There are YouTube videos of gluing two pieces of xps together using pva ,and failing to dry.

xps will seal in the moisture, xps and cf will do the same.

Steve.

WARNING.

There are YouTube videos of gluing two pieces of xps together using pva ,and failing to dry.

xps will seal in the moisture, xps and cf will do the same.

Steve.

I thought Elmer's wasn't PVA? I was interested in PVA as a coating.

I would never use Elmer's for that kind of bond. I'll start with double sided tape and if I like it then I'll epoxy it.

I would never use Elmer's for that kind of bond. I'll start with double sided tape and if I like it then I'll epoxy it.

Anyone tried hide glue or bone glue?

Reading discussions regarding soundboards in pianos it seems like they usually treat the wood with hide glue then finish with shellac. Many guitar makers swear that hide glue sounds better than PVA, causing a better acoustic coupling between parts thanks to making thinner and harder bonds. Would it being harder than PVA be an advantage or a disadvantage?

Glass temperature of styrene should be 100c, and hide glue should be kept at 60c, so should be possible to apply without melting the panel. It is a bit more work than a cold glue, but for just making a few panels I don't really care about that.

Reading discussions regarding soundboards in pianos it seems like they usually treat the wood with hide glue then finish with shellac. Many guitar makers swear that hide glue sounds better than PVA, causing a better acoustic coupling between parts thanks to making thinner and harder bonds. Would it being harder than PVA be an advantage or a disadvantage?

Glass temperature of styrene should be 100c, and hide glue should be kept at 60c, so should be possible to apply without melting the panel. It is a bit more work than a cold glue, but for just making a few panels I don't really care about that.

I'm not sure where this conversation is going (or even started!), both don't bother coating carbon composite panels with PVA. At most, it could add some weight and cut efficiency a bit. But most likely it will do nothing.I thought Elmer's wasn't PVA? I was interested in PVA as a coating.

I would never use Elmer's for that kind of bond. I'll start with double sided tape and if I like it then I'll epoxy it.

On the plus side, sanding it probably didn't do anything to hurt it. You'd have to sand into the carbon fibers pretty deep to do much damage.

Can you describe exactly what you bought? Or share a link? What size? For sure, it should be mounted with a mostly fixed perimeter, as anything should.

Eric

Here's the link again...0.5mm sikins on a 2mm foam core. They are light, but not as light as I expected, which I think is because there is a lot of resin in the foam, being spliced so thin.I'm not sure where this conversation is going (or even started!), both don't bother coating carbon composite panels with PVA. At most, it could add some weight and cut efficiency a bit. But most likely it will do nothing.

On the plus side, sanding it probably didn't do anything to hurt it. You'd have to sand into the carbon fibers pretty deep to do much damage.

Can you describe exactly what you bought? Or share a link? What size? For sure, it should be mounted with a mostly fixed perimeter, as anything should.

Eric

It seems apples to apples the unsanded panel sounds slightly better. It's not a fair test though because the one I didn't sand has an area near the middle that was a slightly dry layup and I think that makes it better. I kinda want to make my own panel just to do a dry layup.

I'm sitting here now listening to....maybe version 6? I started with a full 4x8 foot panel and realized it's too big for the wall...my ceiling is apparently only 7'11” lol ...also the space next to the TV is a tad under 4 feet so as not to argue with the giant TV mount.

My left speaker at the moment is a roughly 2 meter by one meter 1 inch XPS panel with a window cut out and the CF sandwich mounted in the hole with carpet tape. It sounds decent but it lost a little tremble vs the free panel. It has 2 exciters, one Dayton "spider" (really 4 exciters on it's own) plus a "steel balanced" also Dayton, both 8 ohm wired parallel to give 4 ohms to the amp. I put a 150htz high pass filter on ONE of the exciters thinking it would take the bass but not eliminate it and maybe blend a bit with my sub...the bass is still super strong. In certain songs it scares the hounds and rattles some decorations.

The right speaker is basically just the CF sandwich with one exciter. Most of my treble is coming from that speaker. I've mounted it several different ways, including frimly to a small built in shelf which seems to give the best overall response and really nice low midrange but the wall causes some noticable suckouts so I tilted it to try and break up the interference. I carpet taped an XPS piece similar to the size of the panel to it as extra surface and it's an improvement for sure. I think the combo cancels some modes. It also improves the bass on that panel (which still lags way behind the left panel even though the right panel has no high pass filter.

Depending on what happens to my life in the next few months I may try making my own sandwich. Just a hand layup either fiberglass I have already over XPS or maybe I'll get ambitious and do single layer spread tow CF over nomex honeycomb. I bought a roll of thin woven fiberglass with the XPS specifically in mind.

Eric.

I don't know if this was just a throw away comment.

It should be mounted with a mostly fixed perimeter, as anything should.

maybe this panel should be clamped ,to try and fix its problems.

but if a free floating panel is designed correctly in the first place ,it should not need any clamping .

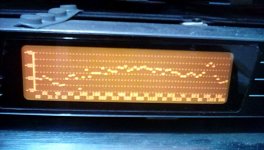

to prove my point, here is a plot of the low quality 70grade eps panel I have just put together, very simple and easy and very cheap to make.

The first picture is with The peak at about 13k .

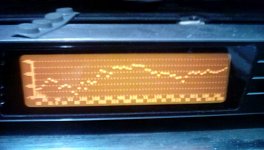

The second is with this peak sorted.

Clamping depends on the panel used and if it has a poor performance.

If I clamped this panel in any way it's sound would be totally destroyed.

All my panels are designed without clamping, except my old full range very rigidly mounted ply panel.

If it doesn't need fixing ,don't clamp it.

Steve.

I don't know if this was just a throw away comment.

It should be mounted with a mostly fixed perimeter, as anything should.

maybe this panel should be clamped ,to try and fix its problems.

but if a free floating panel is designed correctly in the first place ,it should not need any clamping .

to prove my point, here is a plot of the low quality 70grade eps panel I have just put together, very simple and easy and very cheap to make.

The first picture is with The peak at about 13k .

The second is with this peak sorted.

Clamping depends on the panel used and if it has a poor performance.

If I clamped this panel in any way it's sound would be totally destroyed.

All my panels are designed without clamping, except my old full range very rigidly mounted ply panel.

If it doesn't need fixing ,don't clamp it.

Steve.

Attachments

The web page changed a little bit since last week but the figures remain the same. I find a density of 605kg/m³. This is not light in the scale of material for DML. EPS at 30kg/m³ is very light. Plywood somewhere in 500 to 700kg/m³ (perhaps a bit more) is heavy in my opinion or at least I wouldn't go higher due to the consequence on efficiency. Acrylic is very heavy.

I had a little accident with my eps panel, which I will fix with a 50x50 mix of pva, no problem.

but in the meantime I'm using this canvas panel with just an exciter attached, I have now added a little back brace to support the exciter weight.

the canvas is too loose , it flaps around like a sail in the wind, I have tried soaking the canvas in water and a 50x50 mix of pva but it is still too loose.

the frame is not adjustable so I have either got to undo the canvas and re-stretch it or maybe expand the frame joints somehow ?

I think the printed front surface has a plastic coating ,which sounds ok so far, but adding pva is not an option.

even in this condition the panel has a good response down to about 130hz ,with a very natural sound,but more can be done I think.

if not using full range, I am coming around to thinking that the ply is not needed on canvas.

This panel needs more testing ,the smaller panel doesn't seem to affect the overall sound, I just want to get a little bit more Life into the sound.

At the moment I'm trying to do this without affecting the front picture, but may eventually have to add a dome ?

But I have a few ideas.

Steve.

but in the meantime I'm using this canvas panel with just an exciter attached, I have now added a little back brace to support the exciter weight.

the canvas is too loose , it flaps around like a sail in the wind, I have tried soaking the canvas in water and a 50x50 mix of pva but it is still too loose.

the frame is not adjustable so I have either got to undo the canvas and re-stretch it or maybe expand the frame joints somehow ?

I think the printed front surface has a plastic coating ,which sounds ok so far, but adding pva is not an option.

even in this condition the panel has a good response down to about 130hz ,with a very natural sound,but more can be done I think.

if not using full range, I am coming around to thinking that the ply is not needed on canvas.

This panel needs more testing ,the smaller panel doesn't seem to affect the overall sound, I just want to get a little bit more Life into the sound.

At the moment I'm trying to do this without affecting the front picture, but may eventually have to add a dome ?

But I have a few ideas.

Steve.

Attachments

Just took some quick photos of the floppy art panel .

In the first picture, even in its present state ,gives a half decent response and quite good natural sound.

In the second picture I stuffed strips of foam between the frame and canvas, this tightened up the canvas a little bit and pushed the canvas away from the exciter coil, so not perfect, it did introduce a sound I didn't like ,but the response goes much lower now.

These canvas panels can be very flexible, different sizes seem to work ,with or without the ply panel, and with different size ply panels, small or large, depending on how you want to use them.

the third picture is of the larger canvas panel without the ply panel for comparison, the dip at 4k might be to do with the damage I caused to the dome ?

At the moment I am listening to these two panels with an XO at 100hz but as usual the sub goes up to 300hz.

Cymbals are sounding quite good, but the floppy canvas is causing buzzing on loud vocals.

So far they are sounding good, but as I say , I think they can be improved.

All measurements are at 30cm.

Steve.

In the first picture, even in its present state ,gives a half decent response and quite good natural sound.

In the second picture I stuffed strips of foam between the frame and canvas, this tightened up the canvas a little bit and pushed the canvas away from the exciter coil, so not perfect, it did introduce a sound I didn't like ,but the response goes much lower now.

These canvas panels can be very flexible, different sizes seem to work ,with or without the ply panel, and with different size ply panels, small or large, depending on how you want to use them.

the third picture is of the larger canvas panel without the ply panel for comparison, the dip at 4k might be to do with the damage I caused to the dome ?

At the moment I am listening to these two panels with an XO at 100hz but as usual the sub goes up to 300hz.

Cymbals are sounding quite good, but the floppy canvas is causing buzzing on loud vocals.

So far they are sounding good, but as I say , I think they can be improved.

All measurements are at 30cm.

Steve.

Attachments

It's not as light as it should be because the air spaces in the very thin foam yet it's still less dense than most plywoods and about 4-10 times as stiff. I attached it to 1" thick hard XPS foam... it's slightly heavier per square foot but not much, and I can stand on it with very little bend, which is in no way comparable to the foam.The web page changed a little bit since last week but the figures remain the same. I find a density of 605kg/m³. This is not light in the scale of material for DML. EPS at 30kg/m³ is very light. Plywood somewhere in 500 to 700kg/m³ (perhaps a bit more) is heavy in my opinion or at least I wouldn't go higher due to the consequence on efficiency. Acrylic is very heavy.

Of course this was experimental and the design changed as I was building. I realized on the second one that square alignment of the CF wasn't the best guess at leveling modes. I also realized it's probably better to put one exciter on the CF and the other on the XPS rather than both on the CF as I did the first time.

In these pictures the left panel is squared, has both exciters on the CF and is 25mm thick XPS. The left is angled, has one exciter on each material, is 12mm XPS and has some light bracing on the back made of 25mm XPS to make it a little stiffer in the long axis. The bracing is also extended to make little feet to stand on. The dimensions are slightly different. They both have a high pass filter on only on of the two exciters with 6db/octave at 150 hertz. The right speaker is noticably louder and seems to be a little stronger in the 1,000-3,000 range. Their bass peaks mostly overlap. Maybe later I'll figure out testing software and pull out my studio mic and run some curves but not this week. Going to live with them a while before making more changes. My first.impression is I'll probably end up redoing the left panel to make it more like the right.

In these pictures the left panel is squared, has both exciters on the CF and is 25mm thick XPS. The left is angled, has one exciter on each material, is 12mm XPS and has some light bracing on the back made of 25mm XPS to make it a little stiffer in the long axis. The bracing is also extended to make little feet to stand on. The dimensions are slightly different. They both have a high pass filter on only on of the two exciters with 6db/octave at 150 hertz. The right speaker is noticably louder and seems to be a little stronger in the 1,000-3,000 range. Their bass peaks mostly overlap. Maybe later I'll figure out testing software and pull out my studio mic and run some curves but not this week. Going to live with them a while before making more changes. My first.impression is I'll probably end up redoing the left panel to make it more like the right.

It seems weird, but even filtering some of the bass from my DMLs..I turned the crossover on by subwoofer down to about 120 hertz and turned the power way down and this seems to be the best solution so far to level it out. Will keep playing with it.

Just got the plates from dekokopf and mounted one of the 25mm 20 kg/m³ styropor and 25mm 25 kg/m³ neopor.

No sanding or preparation, and wow, they go wide and loud with these exciters! I have done my fair share of blasting as a DJ, dancer and producer, so my threshold for what is painfully loud might be a bit higher than average. But I cannot max the amp (Ayima A08), which I actually could do safely with these exciters with other plates after applying a HPF at 150hz, because it is too loud for me to be in the room without protection.

Just taped the exciters onto unprepared panels, no sanding or gluing. Both panels do sound good, but a little bit busy and fatiguing compared to the printed and ply I tested. Will do measurements later before I attempt sanding and gluing.

No sanding or preparation, and wow, they go wide and loud with these exciters! I have done my fair share of blasting as a DJ, dancer and producer, so my threshold for what is painfully loud might be a bit higher than average. But I cannot max the amp (Ayima A08), which I actually could do safely with these exciters with other plates after applying a HPF at 150hz, because it is too loud for me to be in the room without protection.

Just taped the exciters onto unprepared panels, no sanding or gluing. Both panels do sound good, but a little bit busy and fatiguing compared to the printed and ply I tested. Will do measurements later before I attempt sanding and gluing.

Is there a way to get this stuff in USA?Just got the plates from dekokopf and mounted one of the 25mm 20 kg/m³ styropor and 25mm 25 kg/m³ neopor.

No sanding or preparation, and wow, they go wide and loud with these exciters! I have done my fair share of blasting as a DJ, dancer and producer, so my threshold for what is painfully loud might be a bit higher than average. But I cannot max the amp (Ayima A08), which I actually could do safely with these exciters with other plates after applying a HPF at 150hz, because it is too loud for me to be in the room without protection.

Just taped the exciters onto unprepared panels, no sanding or gluing. Both panels do sound good, but a little bit busy and fatiguing compared to the printed and ply I tested. Will do measurements later before I attempt sanding and gluing.

I have a gallon of the titebond in my shop so the best price is free 😉Narenaud.

Elemers glue is the cheapest in the test , that's the one I'd probably choose.

Steve.

Styropor, Neopor and Peripor are just EPS/GPS brandnames from BASF. It should be the same as any comparable EPS with the same density, apart from Neopor which is a type of product that seems uncommon in the US. First listening tests indicates that is not worth getting for the sound at least. Sounds similar to the EPS, but little less clear and loud.Is there a way to get this stuff in USA?

Problem it seems, both in the US and EU, is that it is hard to buy EPS in smaller quantities and in a suitable thickness, especially 20kg/m3 or higher quality. Dekokopf seems quite unique in being able to ship a few plates for a reasonable cost.

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker