That's an impressive collection of panel shapes.As usual I pressed subit instead of preview.

Here's a photo of some of my panels.

Creating thinner panels

I believe someone asked a few pages back about cutting styrofoam through its thickness. I've done it once, and it works with a hot wire.

You need some nichrome wire and a suitable power supply (I used a multi-voltage Laptop dc supply). There are calculators online to get the correct voltage for the wire gauge you use - I can provide details if anyone needs it.

My setup was jury-rigged but still worked quite well. I was not prepared for the extent of expansion which occurred in the wire when hot. I cut a 600x1200x30 XPS panel into a 10mm and 20mm piece.

If you want good results, you need constant tension on the wire, and next time I would hang a weight from the wire after it passes over the terminal. Also, you need to keep a constant pressure on the panel as it passes the wire, otherwise the wire droops and creates striations across the panel. Ideally you would use gravity for this as well - eg a steeply sloping flat surface (eg a good long aluminium ladder) and some extra weighs to gravity-feed the panel into the wire.

I believe someone asked a few pages back about cutting styrofoam through its thickness. I've done it once, and it works with a hot wire.

You need some nichrome wire and a suitable power supply (I used a multi-voltage Laptop dc supply). There are calculators online to get the correct voltage for the wire gauge you use - I can provide details if anyone needs it.

My setup was jury-rigged but still worked quite well. I was not prepared for the extent of expansion which occurred in the wire when hot. I cut a 600x1200x30 XPS panel into a 10mm and 20mm piece.

If you want good results, you need constant tension on the wire, and next time I would hang a weight from the wire after it passes over the terminal. Also, you need to keep a constant pressure on the panel as it passes the wire, otherwise the wire droops and creates striations across the panel. Ideally you would use gravity for this as well - eg a steeply sloping flat surface (eg a good long aluminium ladder) and some extra weighs to gravity-feed the panel into the wire.

Simon.

I only had a 10mm x400mm square hd grade(whatever that is?) Panel .

But you should get pretty good HF and LF if the exciter is up to it.

Ziggy liked this material , I think his panels were 8ftx4ft ,it's a shame you will not see all of his posts as he deleted himself in a rage at one point.

Did you order extra panels to experiment with ?

If so I'd always recommend trying the standard panel first so that you can compare with a coated panel.

The higher density might not need the pva coating ,it probably would be better,but it's always better to check,and be sure ,for your own peace of mind.

It is what I would do.

Steve.

I only had a 10mm x400mm square hd grade(whatever that is?) Panel .

But you should get pretty good HF and LF if the exciter is up to it.

Ziggy liked this material , I think his panels were 8ftx4ft ,it's a shame you will not see all of his posts as he deleted himself in a rage at one point.

Did you order extra panels to experiment with ?

If so I'd always recommend trying the standard panel first so that you can compare with a coated panel.

The higher density might not need the pva coating ,it probably would be better,but it's always better to check,and be sure ,for your own peace of mind.

It is what I would do.

Steve.

Jamu.

The idea in my mind was that if the panel was quite good ,but not good enough,I might come back to it at a later date if I had any new ideas.

And also to keep track of my progress.

To make sure I was not just fooling myself that I was improving things.

It is a lot easier ,cheaper and quicker To do tests on small panels ,than a six foot monster.

Steve.

The idea in my mind was that if the panel was quite good ,but not good enough,I might come back to it at a later date if I had any new ideas.

And also to keep track of my progress.

To make sure I was not just fooling myself that I was improving things.

It is a lot easier ,cheaper and quicker To do tests on small panels ,than a six foot monster.

Steve.

I'm surprised I haven't seen many polyurethane foam core builds. Coming from an architectural background, I found it natural to experiment with KAPA boards, and these are made of polyurethane foam, they come with and without sheets of paper film on each side. The material is able to absorb shock and recover its shape quickly, lightweight, though stiff. As far as I know, stiffer than polystyrene. The only downside is that they are a bit expensive compared to XPS or EPS boards.

My DML speakers consist of two 420mm x 700mm x 10mm sheets of KAPA, on the backside I've added a 10mm balsa frame, this improved lower frequencies a bit. As for exciters I have a Dayton Audio DAEX32U-4 and DAEX32EP-4 in series on each panel. They sound so amazing, mids and highs are perfect in my opinion. I recently added a small 3" sub to the setup, which I have close to my desktop, this was the cherry on top. I'm just perplexed by how good they sound.

I would consider much bigger panels in the future, this would presumably give a much better lower frequency response. The same ratio, but 630mm x 1050mm, maybe even larger. And though I like having the speakers standing on the floor, I should probably hang them. With the current legs, they just start dancing around on the floor at high volume, lol.

My DML speakers consist of two 420mm x 700mm x 10mm sheets of KAPA, on the backside I've added a 10mm balsa frame, this improved lower frequencies a bit. As for exciters I have a Dayton Audio DAEX32U-4 and DAEX32EP-4 in series on each panel. They sound so amazing, mids and highs are perfect in my opinion. I recently added a small 3" sub to the setup, which I have close to my desktop, this was the cherry on top. I'm just perplexed by how good they sound.

I would consider much bigger panels in the future, this would presumably give a much better lower frequency response. The same ratio, but 630mm x 1050mm, maybe even larger. And though I like having the speakers standing on the floor, I should probably hang them. With the current legs, they just start dancing around on the floor at high volume, lol.

Attachments

Last edited:

I'm surprised I haven't seen many polyurethane foam core builds. Coming from an architectural background, I found it natural to experiment with KAPA boards, and these are made of polyurethane foam, they come with and without sheets of paper film on each side. The material is able to absorb shock and recover its shape quickly, lightweight, though stiff. As far as I know, stiffer than polystyrene. The only downside is that they are a bit expensive compared to XPS or EPS boards.

My DML speakers consist of two 420mm x 700mm x 10mm sheets of KAPA, on the backside I've added a 10mm balsa frame, this improved lower frequencies a bit. As for exciters I have a Dayton Audio DAEX32U-4 and DAEX32EP-4 in series on each panel. They sound so amazing, mids and highs are perfect in my opinion. I recently added a small 3" sub to the setup, which I have close to my desktop, this was the cherry on top. I'm just perplexed by how good they sound.

I would consider much bigger panels in the future, this would presumably give a much better lower frequency response. The same ratio, but 630mm x 1050mm, maybe even larger. And though I like having the speakers standing on the floor, I should probably hang them. With the current legs, they just start dancing around on the floor at high volume, lol.

Very neat construction! How did you do the curved corners, and how are they attached to the sides? I looked at a polyurethane product, seems to be very highly damped, and the product I saw was too thick. It did occur to me that it might be worthwhile to try a free-form speaker with extra-wide kitchen foil and expanding PU foam in a can. You would have to build a mould to support it initially, but I think it would work. You could play with variable thickness, extra long panels, insetting a stiffer window for the exciter for better hf etc.

Last edited:

Foamcore Is a very heavily damped material and is akin to a midrange unit,the highs are severely suppressed.

I improved the performance by removing the paper coating ,you then basically have an xps board

You can get the foamcore from hobby craft in the UK petty cheaply.

This panel pops up now and again over the years .

There are far better panel materials out there ,but the sound is ok for a midrange unit.

Steve.

I improved the performance by removing the paper coating ,you then basically have an xps board

You can get the foamcore from hobby craft in the UK petty cheaply.

This panel pops up now and again over the years .

There are far better panel materials out there ,but the sound is ok for a midrange unit.

Steve.

As usual I pressed subit instead of preview.

Here's a photo of some of my panels.

Maybe this juncture is a good time to summarise what you've learnt. No doubt you've mentioned them earlier, but the forum is LONG! Looks like we've had some similar ideas. Your leftmost large board with the wedges cut out opposite the exciter - I found this to be worthwhile to prevent first reflection resonances (except I used a deeper cusp). I notice you've tried circular shape with the exciter offset from the centre - this seems a reasonable way to get a range of lengths to the fist reflection for a smoother midrange, but I suppose the lows suffered, and it still has bilateral symmetry. I also notice some experiments where a metal dome is mounted in the panel, presumably with exciter behind to help with hf. I did one rough experiment like this but it was an abject failure. How did it go for you?

Looks like an artists workshop. Get some paints and start another adventure...🙂

Last edited:

Steve

Thanks for the suggestions. Yes, Ziggy's passing was such a shame. He seems to have had a Road to Damascus conversion re HD EPS panels. I'll try careful sanding and a little bit of diluted PVA around the exciter attachment point first (Monacor 3/7 + 4/9 placement). My second OB/DML integrated prototype is slowly taking shape in my head.

Reading back though the old Audiocircle posts as well as these there seems to be an awful lot of information buried which then gets recycled and repeated. If I get a fit of writing enthusiasm, I may create a blog which tries to distil the key issues and provide key links - for my benefit as much as anybody else's.

I have one sheet of PVAed 70 grade EPS left but will stump up for 10 sheets of the 10mm UHG EPS from Mr Polystyrene. Certainly the 40 x 35 bit of 70 grade went to 20khz very easily with EQ despite my dodgy exciter. I think I've got some 25mm very high grade EPS knocking around too.

Every time I've tried to add a spine to support the exciter, I've not been pleased with the results - spurious rattles, buzzing, unnecessary vibrations, pressure on the exciter etc. etc. Simple but well thought through design seems to be the way forward.

BTW, a friend of mine is an acoustics engineer with Rolls Royce. Many years, he met one of the pioneers of using exciter technology in aircraft. I believe it had something to do with noise cancellation, but I may be wrong. But my friend certainly described the results as 'stunning'.

Cheers

Simon

Thanks for the suggestions. Yes, Ziggy's passing was such a shame. He seems to have had a Road to Damascus conversion re HD EPS panels. I'll try careful sanding and a little bit of diluted PVA around the exciter attachment point first (Monacor 3/7 + 4/9 placement). My second OB/DML integrated prototype is slowly taking shape in my head.

Reading back though the old Audiocircle posts as well as these there seems to be an awful lot of information buried which then gets recycled and repeated. If I get a fit of writing enthusiasm, I may create a blog which tries to distil the key issues and provide key links - for my benefit as much as anybody else's.

I have one sheet of PVAed 70 grade EPS left but will stump up for 10 sheets of the 10mm UHG EPS from Mr Polystyrene. Certainly the 40 x 35 bit of 70 grade went to 20khz very easily with EQ despite my dodgy exciter. I think I've got some 25mm very high grade EPS knocking around too.

Every time I've tried to add a spine to support the exciter, I've not been pleased with the results - spurious rattles, buzzing, unnecessary vibrations, pressure on the exciter etc. etc. Simple but well thought through design seems to be the way forward.

BTW, a friend of mine is an acoustics engineer with Rolls Royce. Many years, he met one of the pioneers of using exciter technology in aircraft. I believe it had something to do with noise cancellation, but I may be wrong. But my friend certainly described the results as 'stunning'.

Cheers

Simon

Hi simon.

Please be aware that the hard surface on eps,and xps will make the heavily thinned pva try to run off .

ziggy never got around to pva his large panel,so I have no idea of what the outcome would have been?

Colorations in a very large panel especially near field will be more obvious , but far field less obvious.

You would be listening to the surface more if you were close up to the large panel.

A bit like being too close to a very large tv or cinema screen.

My wife is in London today so i might get around to applying epoxy resin to some 5mm xps I have in the loft.

It would be interesting to see how the epoxy strengthening effects the performance and sound .

Tech ingredients also used thin fiberglass in their strengthening of 25mm xps but I'm only going to use the epoxy, hopefully without cracking?

Steve.

Please be aware that the hard surface on eps,and xps will make the heavily thinned pva try to run off .

ziggy never got around to pva his large panel,so I have no idea of what the outcome would have been?

Colorations in a very large panel especially near field will be more obvious , but far field less obvious.

You would be listening to the surface more if you were close up to the large panel.

A bit like being too close to a very large tv or cinema screen.

My wife is in London today so i might get around to applying epoxy resin to some 5mm xps I have in the loft.

It would be interesting to see how the epoxy strengthening effects the performance and sound .

Tech ingredients also used thin fiberglass in their strengthening of 25mm xps but I'm only going to use the epoxy, hopefully without cracking?

Steve.

As usual I pressed subit instead of preview.

Here's a photo of some of my panels.

Have you classified them and labeled them in FR? That would be nice. 😀

I can only speak about my own experience, but I've had success with open baffle bass. However, you need a room that will take it. Otherwise I'd probably go for a sealed box design with maybe a 12 inch driver. This was certainly the late, great Siegfried Linkwitz preference.

My main room audio system is a traditional 2-way pair, "8 mid-woof + dome.

tweeter.

I will add an NHT 12" sub-bass in a sealed box, so Siegfried's preferences should be followed.

Simon and pway,the problem with these forums is that the good stuff gets lost among the bad especially with a forum that is so large.

It does get a bit repetitive having to constantly repeat the same things over and over again.

But it is the nature of the beast.

Yes the noise cancelling experiments on helicopters and aircraft led to NXT.

When I first heard my first dml panels ,I also thought they were amazing ,but it didn't take long before I started to notice the problems.

Steve.

It does get a bit repetitive having to constantly repeat the same things over and over again.

But it is the nature of the beast.

Yes the noise cancelling experiments on helicopters and aircraft led to NXT.

When I first heard my first dml panels ,I also thought they were amazing ,but it didn't take long before I started to notice the problems.

Steve.

I like the 'idea' of full range drivers, especially with the ability to avoid crossovers in the all-important midrange area. I'm also not a huge fan of using power and performance sapping crossover components if I can help it.

However, I also like large scale orchestral works and these can move a lot of air. This leads one to two possibilities: a large full-ranger, or a smaller full-ranger plus bass support for say up to 300hz.

However, this then gives is issues with (a) treble extension and (b) treble beaming.

I was looking for a solution that (a) avoided crossovers in the midrange (b) gave clean bass (c) avoided treble beaming (d) gave sufficient treble extension (e) gave a bit of flexibility in seating position.

As well as moving enough clean air in the bass department, I also like 'air', treble extension and a soundstage that falls behind the speakers as well as offering height.

In my experience of trying many speakers and DIY speaker projects (usually dismal failures), and becoming tired of the typical 'point and squirt' delivery of traditional boxed speakers, I have found that Open Baffle bass together with medium sized DML panels have been the only speakers that have delivered the most of what I like.

I look at it in the same way that one would look at a live performance. Sound emanates from all directions with many reflections from the venue. My OB bass plus DML approach gets me closer to what I might experience at a concert in way that no other speakers have done for me to date.

I should stress that I am on a very limited budget. I have heard amazing systems at hifi shows but at prices that are quite eyewatering.

This is very interesting. I also have the same feeling as you about having one single speaker that can cover as many octaves as possible in a flat way, particularly in the mid frequencies our ear is so sensitive too.

Once I followed the idea that a 6.5" mid-bass could do that. But a friend of mine, that makes speakers and knows a lot more than me, due to infinite tests and measurements he made with regular "piston" speakers, to call them somehow, he convinced me that you should that with an 8" mid-bass driver, designed properly.

This 2-way box he designs I have been living with for more than 30 years. And except for the very low bass which an 8" can't get too, the low bass it plays is of remarkable quality, and leaves the 300Hz-4K mid frequencies to one driver.

But the principle of a wide and full range speaker still occupies my mind. As I came to a situation where I needed such a thing in a small package, the DMLs caught my attention. The bedroom where the system is, linked to my TV, will not allow me to go too low. It's a 4m x 3m room, so how low can I aspire to get to? 80Hz perhaps?

I found a used Philips speaker very cheaply, full range tuned box. 5" full range speaker that lacks lower frequencies. That's what I considered to replace with the DML, perhaps adding a bandpass sub box under the bed, to take care of bass. That bass box would work for both systems: 5" and DML.

Last edited:

I've found the 5mm xps in the loft.

It is 60cm x86cm .

I think I will only coat around the exciter area first , maybe going all the way across ?

I think zenker mentioned something about this, which I thought was interesting?

Basically I'm just going to mix some epoxy and see how far it stretches?

As thin a coat as possible.

I'll have to do one side at a time, trying not to make a mess 😱

Steve.

It is 60cm x86cm .

I think I will only coat around the exciter area first , maybe going all the way across ?

I think zenker mentioned something about this, which I thought was interesting?

Basically I'm just going to mix some epoxy and see how far it stretches?

As thin a coat as possible.

I'll have to do one side at a time, trying not to make a mess 😱

Steve.

Attachments

I also thought they were amazing ,but it didn't take long before I started to notice the problems.

Steve.

I think the biggest issues, is peoples expectations in general.

I never would expect wonders from DML, but that doesn't mean one could make interesting but mostly creative ideas an products with them.

They are pretty reasonable from around 150Hz up to about maybe 2-4kHz.

(can stretch that here and there).

I would never use a DML fullrange.

For the highs, just use a small little tweeter, plenty of choices available these days that are very discrete.

Combine that with a couple of mini subs (which is better in general anyway), and you will have a nice system.

Very neat construction! How did you do the curved corners, and how are they attached to the sides? I looked at a polyurethane product, seems to be very highly damped, and the product I saw was too thick. It did occur to me that it might be worthwhile to try a free-form speaker with extra-wide kitchen foil and expanding PU foam in a can. You would have to build a mould to support it initially, but I think it would work. You could play with variable thickness, extra long panels, insetting a stiffer window for the exciter for better hf etc.

Thanks, I really like them too 😀 I assume your question about the curved corners is referring to the balsa frame? What I did was I just cut them out of a 10mm thick sheet of balsa that was wide enough to cover the corner. the balsa is glued directly onto the board with wood glue, while the legs (laser cut 8mm plywood) are attached to the balsa at four points on each side with pieces of eps foam, they are quite loose though, but at least they stand. On the other speaker I just used 3mm thick double sided foam tape. Moulding seems interesting, creates lots of possibilities for sure.

Foamcore Is a very heavily damped material and is akin to a midrange unit,the highs are severely suppressed.

I improved the performance by removing the paper coating ,you then basically have an xps board

You can get the foamcore from hobby craft in the UK petty cheaply.

This panel pops up now and again over the years .

There are far better panel materials out there ,but the sound is ok for a midrange unit.

Steve.

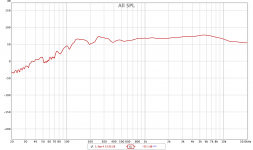

I'm not really sure how heavy the highs are damped. I would say the highs sound pretty good to me. I would assume the material performs differently on different frequencies, no? Maybe the dampening effect is more affecting lower frequencies? I did a measurement (don't have a particularly good mic, so take it with a grain of salt) there is indeed some dampening/reduction in dB between 5kHz and 20kHz. but I'm not sure how much the material is responsible for this, both of my drivers does have this property on the manufacturer's data sheets, the DAEX32EP-4 Thruster is better at mids than the DAEX32U-4 Ultra though.

The cyan is the DML speakers only, while magenta includes my tiny sub. The red is with the paper removed from the front side, seems like it did improve the performance overall, did smooth the response at around 1kHz, but there's a dip at 55Hz.

I would love to try some other material too though, been a while since I've read through this thread, but I'm particularly interested in trying out wood. Balsa end grain seems hard to get by and expensive. But maybe it's a bit more affordable if I produce them myself. I'm imagining a thin veneer sandwich with balsa core. Wondering also if it would be worth testing sheets of balsa that are not endgrain.

Attachments

Last edited:

I'll have to do one side at a time, trying not to make a mess 😱

Good luck with that. It gives me the creeps how messy my results might be with epoxy.

Carlmart.

I'm afraid it hasn't gone to plan as usual,I made the coating too thick,so have tried to drag it across the panel,should have used a roller!

If I had spread the epoxy thinly with the scraper in the beginning when it was more pliable it would maybe have been better?

Well it's all part of the learning process😀

Steve.

I'm afraid it hasn't gone to plan as usual,I made the coating too thick,so have tried to drag it across the panel,should have used a roller!

If I had spread the epoxy thinly with the scraper in the beginning when it was more pliable it would maybe have been better?

Well it's all part of the learning process😀

Steve.

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker