Don't think so. I realize the size of the box I was originally considering is already too big for easy acceptance in a typical LR. The designs you suggest are even bigger.Sounds like an Alón or Nola is what you're looking for.

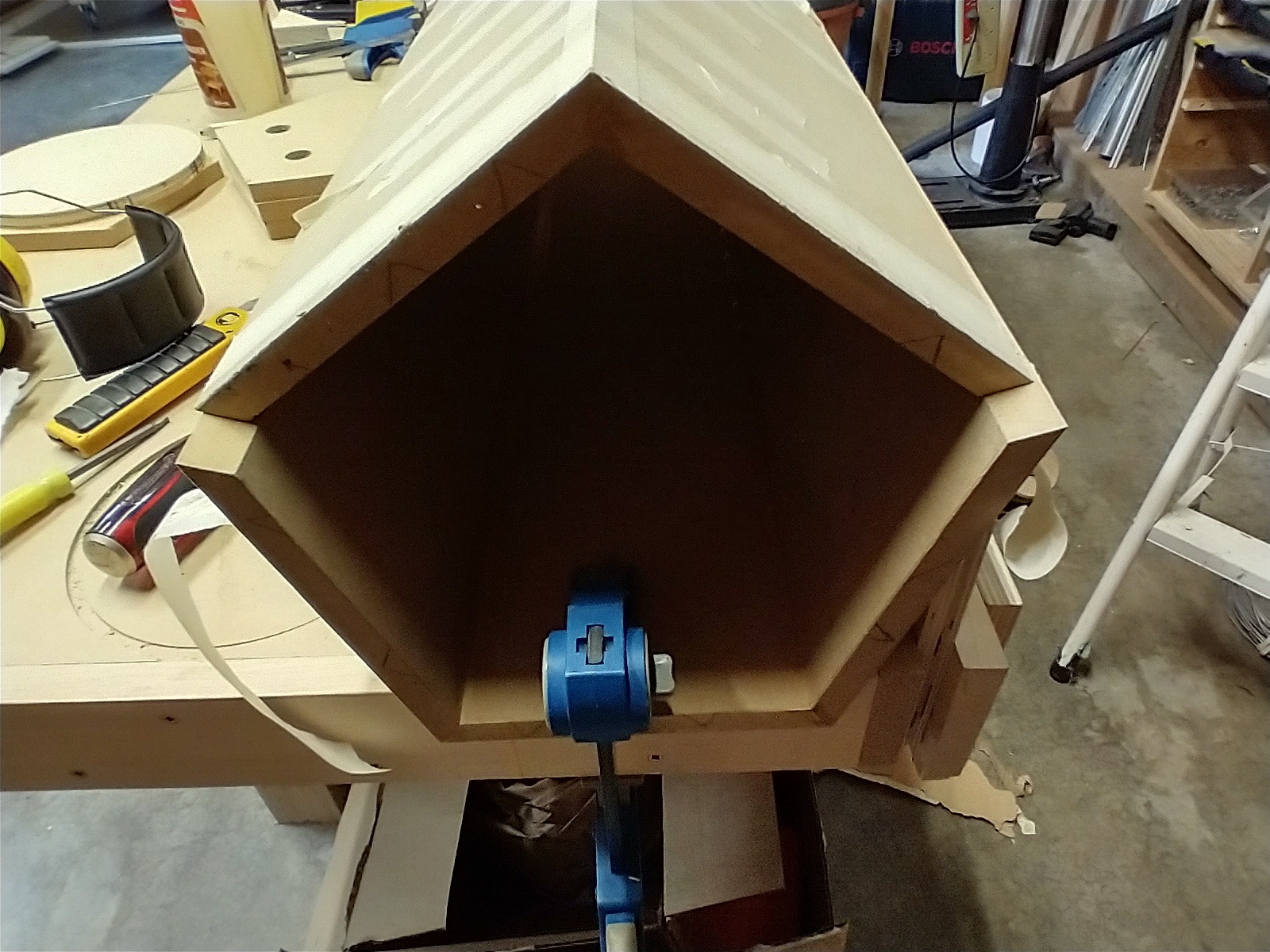

Slow progress. Any errors in angles or imperfectly straight cut are cumulative over the lengths of the 5 planks, so it's definitely not a perfect pentagon all the way up and down. Hence the ribs also need to be tweaked. Good thing I ran out of wood glue -- was starting to make too many errors today.

First glued 2 + 3 planks. The 36 degree mitre edges are taped edge to edge on the underside before glue is applied, then folded till the seam closes. I am keeping fingers crossed the extra strap of painter's tape across the open ends keeps enough pressure on to keep the seams perfectly closed till the glue sets.

That's an extra 3/4" plate glued & screwed in place. For secure mounting of the tweeter/diffusion tube bracket.

First glued 2 + 3 planks. The 36 degree mitre edges are taped edge to edge on the underside before glue is applied, then folded till the seam closes. I am keeping fingers crossed the extra strap of painter's tape across the open ends keeps enough pressure on to keep the seams perfectly closed till the glue sets.

That's an extra 3/4" plate glued & screwed in place. For secure mounting of the tweeter/diffusion tube bracket.

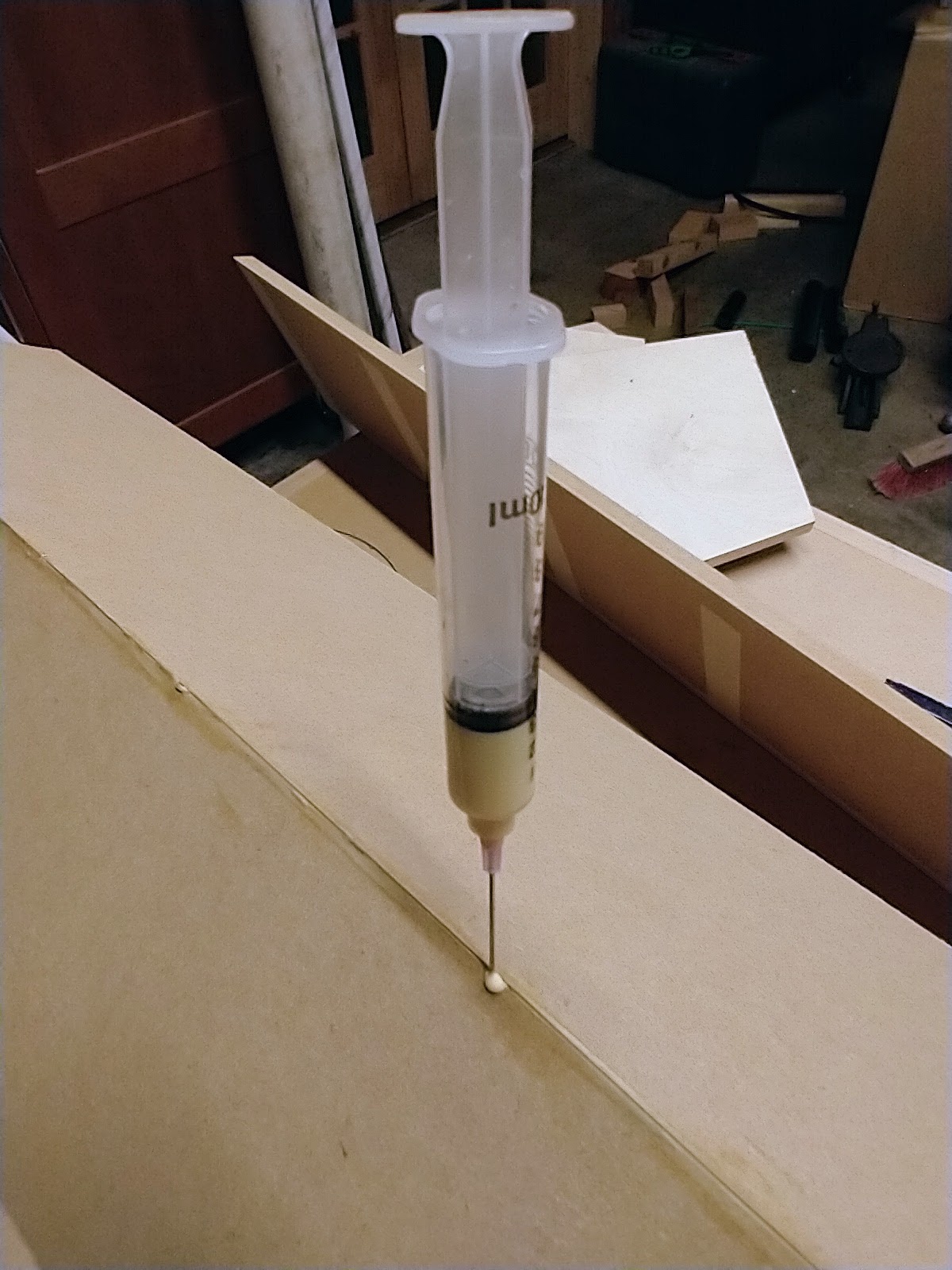

The glue-up of the first tube turned out workable but not great. I didn't get enough pressure on the 2 long glue seams between the 2-panel and 3-panel parts, so in one patch there's about an 8" long gap where light comes through. Looks like maybe a 0.3mm gap. 🙁 I'll try filling it with slightly watered down wood glue from the outside, using maybe a hypodermic syringe or similar. If I can reach it, I will hit it from the inside too, then add gobs of thicker glue or silicone to ensure a good seal. Mechanical integrity is OK, though, with the 5 ribs for the 30" long tube.

Knuckle-rapping produces a primary peak at 1200 Hz and a secondary one at 650 Hz. Lower than I'd like, but at least the main resonance is mostly well above the active range of the bass driver. It has to be less resonant than a PVC pipe, though, right?!

There's only one baffle layer, with an oversized hole for the driver. Another baffle extending out to cover the ends of the 5 boards will be bolted to the top, with a sealant gasket to ensure airtightness. This will allow changes in driver/baffle if needed or desired. If these SEAS drivers don't work out well, I have on hand Vifa/Peerless neodymium drivers -- NE180 & NE225 -- as well as the old Peerless 8" SLS which might be shoehorned in. And Satori 6.5"s. Not sure if rebating the driver is necessary -- the baffle is only marginally larger than the driver. It would be just for cosmetics.

The space between the bottom plate (which has a large hole like the rest of the inner ribs) and the rib above it is about 8" -- deliberately a bit more spacing than the 6-7" of the rest, Not sure if that's quite enough for a small custom plate amp... or whether it's worth trying to get one in there. I took delivery of a used Dayton KABD-4100 8-ch DSP amp, and it's tiny & would fit, but I suspect cooling could be an issue for extended high output. Anyway, the space is there if I want to cut a hole out of the back panel. A second solid bottom plate will go in after the box is stuffed with acoustic damping.

Knuckle-rapping produces a primary peak at 1200 Hz and a secondary one at 650 Hz. Lower than I'd like, but at least the main resonance is mostly well above the active range of the bass driver. It has to be less resonant than a PVC pipe, though, right?!

There's only one baffle layer, with an oversized hole for the driver. Another baffle extending out to cover the ends of the 5 boards will be bolted to the top, with a sealant gasket to ensure airtightness. This will allow changes in driver/baffle if needed or desired. If these SEAS drivers don't work out well, I have on hand Vifa/Peerless neodymium drivers -- NE180 & NE225 -- as well as the old Peerless 8" SLS which might be shoehorned in. And Satori 6.5"s. Not sure if rebating the driver is necessary -- the baffle is only marginally larger than the driver. It would be just for cosmetics.

The space between the bottom plate (which has a large hole like the rest of the inner ribs) and the rib above it is about 8" -- deliberately a bit more spacing than the 6-7" of the rest, Not sure if that's quite enough for a small custom plate amp... or whether it's worth trying to get one in there. I took delivery of a used Dayton KABD-4100 8-ch DSP amp, and it's tiny & would fit, but I suspect cooling could be an issue for extended high output. Anyway, the space is there if I want to cut a hole out of the back panel. A second solid bottom plate will go in after the box is stuffed with acoustic damping.

Attachments

Last edited:

Bargain of the summer for me: two 10-ml syringes + three 1.2mm hypodermic needles from a local drugstore for CA$1.80 tax included.

It worked ok. The needle was too thick to push into the crack, but the syringe allowed me to put a tiny bead along the crack, into which the glue flowed over time. I repeated twice, and the seam looks decently filled with glue now.

A thinner needle was available but I didn't think the glue would flow through it well. Might try one another time -- at 15 cents each...

Meanwhile I'm pondering whether to try a GRS/B&G Neo 8 planar magnetic tweeter instead of the cone full range.

It worked ok. The needle was too thick to push into the crack, but the syringe allowed me to put a tiny bead along the crack, into which the glue flowed over time. I repeated twice, and the seam looks decently filled with glue now.

A thinner needle was available but I didn't think the glue would flow through it well. Might try one another time -- at 15 cents each...

Meanwhile I'm pondering whether to try a GRS/B&G Neo 8 planar magnetic tweeter instead of the cone full range.

Juhazi prefers them re this discussion of Klippel testing by Erin. But mounting it will be fussy.

EFD has lots of different style tips with Luer fittings (plenty of knock-offs on the market at lower prices also). They have some with thin flexible tubes at the end, which sometime help getting into narrow gaps. Their more typical ones are tapered, which produces less flow resistance than a straight tip. I've pushed everything from wood glue to acrylic solvent cements through them (you want all plastic plungers if dealing with solvents - the rubber ones can turn to goo).

Last edited:

In the LXMini department, you might consider my variant described in this thread. It replaces the tall tube with a sealed box of equal volume while replicating other dimensions. Endless details are in the blog linked in the first post. I'd be happy to share drawings for router templates or laser/CNC.

Thanks for the offer! I examined your build before & admire it. 👍In the LXMini department, you might consider my variant described in this thread. It replaces the tall tube with a sealed box of equal volume while replicating other dimensions. Endless details are in the blog linked in the first post. I'd be happy to share drawings for router templates or laser/CNC.

At this point, one pentagon tube is glued up, and the 2nd is in process, so I'll finish them. I want the floor standing config, which is easier -- no stands to deal with. And I like the look of the pentagon tower. Next time around, if there is one, unless I have a eureka about how to do all this carpentry better manually, I'll get all the parts CNC cut so fit & assembly is not such a PITA. And use 12 or 15mm BB plywood so it starts out more rigid, and the dust isn't so damn fine as the MDF.

So you're referring to the needles that can fit a standard medical syringe, I presume?EFD has lots of different style tips with Luer fittings (plenty of knock-offs on the market at lower prices also). They have some with thin flexible tubes at the end, which sometime help getting into narrow gaps. Their more typical ones are tapered, which produces less flow resistance than a straight tip. I've pushed everything from wood glue to acrylic solvent cements through them (you want all plastic plungers if dealing with solvents - the rubber ones can turn to goo).

Yes. The Luer-Lok version is the one typically used for dispensing and filtering chemistries, and it's also used on medical equipment. There's a Luer-Slip as well, but it's obviously less secure.

I'm sure there are cheaper ones out there, but this was easy to find in a quick search.

https://www.coleparmer.com/i/cole-parmer-disposable-syringes-luer-lok-20-ml-100-pk/1291503

https://www.nordson.com/en/products/efd-products/dispense-tips-and-needles

A cheap tapered assortment from one of the Amazonians

https://www.amazon.com/Plastic-Tapered-Dispenser-Dispensing-Applicator/dp/B09V7Y1QZX/

I'm sure there are cheaper ones out there, but this was easy to find in a quick search.

https://www.coleparmer.com/i/cole-parmer-disposable-syringes-luer-lok-20-ml-100-pk/1291503

https://www.nordson.com/en/products/efd-products/dispense-tips-and-needles

A cheap tapered assortment from one of the Amazonians

https://www.amazon.com/Plastic-Tapered-Dispenser-Dispensing-Applicator/dp/B09V7Y1QZX/

Some thought led to a way to mount the NEO8 that's much easier than the original full range cone driver & tube in the original LXmini.

There were lots of angled offcuts from all the pentagon shaped ring/rib supports, and some were just the right thickness to make simple brackets to fit flush with the flange on a GRS NEO8. Unlike the B&G NEO8s which were held together with rivets, the GRS variants have removable screws & nuts, which opens up more holes for mounting. Also, once a couple of those screws & nuts nearest the bottom are removed, that section of the flange is flat, which makes it much simpler to mount the brackets.

A 5 degree tilt back was incorporated in view of the narrow vertical directivity of these planars. This should help a bit when listeners are standing.

It should be easy to mount this on the pentagon tower. I'll experiment with diffusion on the back side when I get to that stage.

The 2nd pentagon bass box is being glued up now. It came together a bit easier than the first one, without any gaps in the seams. (Maybe I'm learning on the job. 😏) It has a total of 6 ribs compared to 5 on the first one. I'm curious to see how much higher the panel resonances go. And whether the difference between the two boxes will be audible when playing music. I kind of doubt it, but worth finding out.

There were lots of angled offcuts from all the pentagon shaped ring/rib supports, and some were just the right thickness to make simple brackets to fit flush with the flange on a GRS NEO8. Unlike the B&G NEO8s which were held together with rivets, the GRS variants have removable screws & nuts, which opens up more holes for mounting. Also, once a couple of those screws & nuts nearest the bottom are removed, that section of the flange is flat, which makes it much simpler to mount the brackets.

A 5 degree tilt back was incorporated in view of the narrow vertical directivity of these planars. This should help a bit when listeners are standing.

It should be easy to mount this on the pentagon tower. I'll experiment with diffusion on the back side when I get to that stage.

The 2nd pentagon bass box is being glued up now. It came together a bit easier than the first one, without any gaps in the seams. (Maybe I'm learning on the job. 😏) It has a total of 6 ribs compared to 5 on the first one. I'm curious to see how much higher the panel resonances go. And whether the difference between the two boxes will be audible when playing music. I kind of doubt it, but worth finding out.

Probably at least as good. PVC is very stiff (good for reducing radiation off of the surface) but not as dissipative as MDF. With regard to reflection from the bottom back to the driver, Linkwitz claimed that dense packing with polyfill makes the pipe behave like an infinite transmission line. Worth a try! And with the extra volume you have room for some surface treatment.It has to be less resonant than a PVC pipe, though, right?!

Last edited:

I felt the neo8 didn't quite have enough top end with out EQ, so I never opted for using them as a tweeter.

I did however use them as tweeters in my car where I had full EQing power over them.

I did however use them as tweeters in my car where I had full EQing power over them.

??? Minidsp 2x4 HD is integral to LXmini so tweaking PEQ to boost top end is trivial.I felt the neo8 didn't quite have enough top end with out EQ, so I never opted for using them as a tweeter.

Having played with the Seas & ScanSpeak 10cm full ranges, I know the Neo8 has better transparency & detail. IMHO, the main issues using it here are...

1. Integration with bass driver

2. Directivity -- not the same as 3" cone driver; definitely less impeded towards the rear

But the Neo8 is not the final choice, just the first tweeter to be tried because the mounting is a lot less fiddly than the cone driver in 3" pipe -- didn't have such pipe on hand anyway. Getting some scraps from a neighbor today.

Hopefully, my friend with the champaign flute Lxmini will be willing to bring them over for comparison when my pair is ready.

Sure, stiff, but with tendency to high frequency ringing, based on my experience with 2" & 4" diameter PVC tubes. Just knock on any length with your ear at one end and you can hear that ringing at multiple frequencies. Granted when the ends are terminated, this should be much reduced.Probably at least as good. PVC is very stiff (good for reducing radiation off of the surface) but not as dissipative as MDF. With regard to reflection from the bottom back to the driver, Linkwitz claimed that dense packing with polyfill makes the pipe behave like an infinite transmission line. Worth a try! And with the extra volume you have room for some surface treatment.

I don't buy the infinite transmission line story. I think it would have to be a lot longer for that degree of absorption. WRT the bottom, I'm considering a conical diffuser down there. Like what Joseph Crowe did with 3D printing. I think I could come up with something that has a similar effect from all the angled wood scraps from cutting those pentagon ribs.

Last edited:

More build shots.

A simple MDF base plate. The MDF came from a DIY sub I retired a while ago -- hence the black paint.

Baffle consideration below -- 15mm BB ply, last cut not made yet. Driver hole not cut either, but wanted to see how the brackets for the NEO3 look/fit. Can only be positioned at the end of the bass driver cone. If it needs to be positioned over the back half of the cone like in the original LXmini, some changes have to be made.

What's the consensus among LXmini users? Is the tweeter positioning over the bass driver critical or just a quirk of SL's thinking at the time?

A simple MDF base plate. The MDF came from a DIY sub I retired a while ago -- hence the black paint.

Baffle consideration below -- 15mm BB ply, last cut not made yet. Driver hole not cut either, but wanted to see how the brackets for the NEO3 look/fit. Can only be positioned at the end of the bass driver cone. If it needs to be positioned over the back half of the cone like in the original LXmini, some changes have to be made.

What's the consensus among LXmini users? Is the tweeter positioning over the bass driver critical or just a quirk of SL's thinking at the time?

Last edited:

I don't buy the infinite transmission line story. I think it would have to be a lot longer for that degree of absorption.

Yes, that was always my feeling from the moment I first read about it (especially given the fact that it's polyester), but the end result seems to contradict the scepticism, for example here:

https://www.erinsaudiocorner.com/loudspeakers/linkwitz_lx_mini/

Low/mid frequency response is exemplary, particularly given the dimensions.

Linkwitz' intent was that in the crossover region the fullrange/tweeter and mid-base sum to a cardioid directivity pattern. Straight on, and at a decent listening distance, a time delay should compensate. Maybe the effect at wider angles is more of a question.What's the consensus among LXmini users? Is the tweeter positioning over the bass driver critical or just a quirk of SL's thinking at the time?

Got one speaker going 90 minutes ago. Went through rapid FR measurements, quick manual driver EQ, then 1st order Butterworth crossover at 850 Hz. High pass at that point follows natural fall-off slope of Neo8. No mechanical diffusion filter for Neo8. It already sounds excellent! No more time; more later.

A dense piece of foam was stuffed into the bottom of the box to minimize reflections back to the driver. The rest was stuffed with about 10 oz of polyfill. 14G copper wiring for woofer & 18G for tweeter, run through separate holes drilled in ribs. Single exit hole near bottom of back plate; a 4-pole Speakon connector will go there. I left the back pointed end of the top baffle in place for now because I'm not certain about the best mounting for the Neo8. It's simply glued on with double side tape right now.

A dense piece of foam was stuffed into the bottom of the box to minimize reflections back to the driver. The rest was stuffed with about 10 oz of polyfill. 14G copper wiring for woofer & 18G for tweeter, run through separate holes drilled in ribs. Single exit hole near bottom of back plate; a 4-pole Speakon connector will go there. I left the back pointed end of the top baffle in place for now because I'm not certain about the best mounting for the Neo8. It's simply glued on with double side tape right now.

Attachments

- Home

- Loudspeakers

- Multi-Way

- A “Good Enough” OB/Sealed Hybrid for “Everyman”?