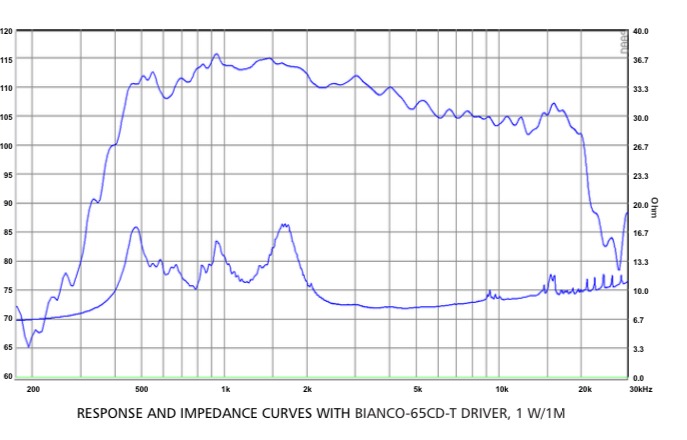

It’s interesting how close the raw response of the H280 horn with the tiny SB driver is to the datasheet:

Complete with dip at ~620 Hz and ~15 kHz. So clearly these are inherent to the horn itself, it's not super smooth overall.

Another option may be RCF HF950. Although the diffraction slot is bigger, so less room to place the woofers.

Complete with dip at ~620 Hz and ~15 kHz. So clearly these are inherent to the horn itself, it's not super smooth overall.

Another option may be RCF HF950. Although the diffraction slot is bigger, so less room to place the woofers.

Last edited:

Mine are 830883 😉Funy enough I have 4 x Peerless 6.5" 850439 lying around that I may have to use as temp mids on this build too.

I wonder if the high pressure in the woofer chamber will cause any issues within the driver because of the open pole peice on the 830883?

I don't know... maybe @xrk971 has in idea?I wonder if the high pressure in the woofer chamber will cause any issues within the driver because of the open pole peice on the 830883?

Just found these at 65 each rather than 200. Not sure if they will work horn wise but made for a 0.5 cubic foot box down to 70hz sealed.

https://www.wagneronline.com.au/sb-...speaker-drivers/audio-speakers-pa/1005261/fl/

https://www.wagneronline.com.au/sb-...speaker-drivers/audio-speakers-pa/1005261/fl/

| Order Code | SB20PFCR30-8 |

|---|---|

| Impedance | 8Ω (Re 5.0Ω) |

| Fs | 34Hz |

| Sens. | 90.5dB |

| Power | 50Wrms |

| Qms | 2.66 |

| Qes | 0.43 |

| Qts | 0.37 |

| Vas | 66.2l |

The only difference with these two seems to be the norex cone on the round unit.

The truncated unit looks to have the smoother response and the frame being 16mm narrower would make it easier to mount between the horn mouth and throat area available....

The truncated unit looks to have the smoother response and the frame being 16mm narrower would make it easier to mount between the horn mouth and throat area available....

Ok so the truncated unit just fits on the H280 horn wall, but i will have to remove a small part of the thoat rib, no big deal.

Quick and dirty calc in WinISD puts two drivers in a 300x300x450mm ID (30 Litre) box (Less approx 30% for Horn+Driver Volume) at an f3 of 71hz with only a 1db knee in the responce then it rolls off.

Hmmmm, interesting.

Quick and dirty calc in WinISD puts two drivers in a 300x300x450mm ID (30 Litre) box (Less approx 30% for Horn+Driver Volume) at an f3 of 71hz with only a 1db knee in the responce then it rolls off.

Hmmmm, interesting.

Possible, it would probably need to be printed in 4 parts and glued together..

Days of printing, rolls of material, but possible

Days of printing, rolls of material, but possible

Go for it. https://www.diyaudio.com/community/...-neile-alo-horn-by-sphericalhorns-net.390581/

Some tips

I am now working on a slightly smaller horn from 5 parts, each is designed in a way to use the available build area and an almost whole spool of filament. It should make a very solid resonance free horn. The one linked above had a problem with mouth resonance without any damping.

Some tips

- use acrylic wood putty for the seams

- using photo resin (for resin 3D printers) coat hardened by UV will improve the surface quality. Maybe ordinary two part resin would work, too - it just needs to be very thin

- 6 mm wooden dowels work better for alignment than printed interlocks, bolts and nuts are also fine.

- if you print very fast as I do, use a sharp knife to cut off the overshoots in the corners if there are any - especially on the gluing surfaces

- use construction glue in a thin layer or gel type super glue. Both are stronger than the plastic itself.

I am now working on a slightly smaller horn from 5 parts, each is designed in a way to use the available build area and an almost whole spool of filament. It should make a very solid resonance free horn. The one linked above had a problem with mouth resonance without any damping.

I wonder what one would do with the throat size for the SB driver if one were to create a fully 3D-printed horn? Should one just use a ~2" opening (equal to SD), or would it be better to squeeze it a bit and go with 1.4" as these ready-made horns use. My guess is that this will have some impact on the high-frequency dispersion?

Given the fact that for my idea the XT1464 is just a bit too large, and the other horns are way less appealing, or quite expensive (LTH142), I think a custom horn may be an interesting option.

Given the fact that for my idea the XT1464 is just a bit too large, and the other horns are way less appealing, or quite expensive (LTH142), I think a custom horn may be an interesting option.

Last edited:

I just read through your horn threads pelanj, fantastic work mate, I admire your patience and commitment to the craft.Go for it. https://www.diyaudio.com/community/...-neile-alo-horn-by-sphericalhorns-net.390581/

Some tips

- use acrylic wood putty for the seams

- using photo resin (for resin 3D printers) coat hardened by UV will improve the surface quality. Maybe ordinary two part resin would work, too - it just needs to be very thin

- 6 mm wooden dowels work better for alignment than printed interlocks, bolts and nuts are also fine.

- if you print very fast as I do, use a sharp knife to cut off the overshoots in the corners if there are any - especially on the gluing surfaces

- use construction glue in a thin layer or gel type super glue. Both are stronger than the plastic itself.

I am now working on a slightly smaller horn from 5 parts, each is designed in a way to use the available build area and an almost whole spool of filament. It should make a very solid resonance free horn. The one linked above had a problem with mouth resonance without any damping.

We just purchased a new 100k Multicam cnc at work (cnc operator as a day job) so I get the temptation to go all wood, your new birch horns look epic!

I am going to hold off for now as the current horn/driver combo is for learning and evaluation purposes mainly, I'll make most of my mistakes on these 😉

Re, 3d printing a custom horn, its definitly on the cards, I finally have my head around fusion and my Creality Ender 3 s1 Pro.

Hi, I'm about 20 pages into this awesome design collaboration and this is the only part I don't get at all. Can you point me to a resource where I can learn about this? I also can't for the life of me find what a "FAST horn" is.1. Generate minimum phase data

2. Export IR as wav file

3. Close existing data and import IR wav file

4. Apply FDW from 1 cycle to 6 cycles and look at FR behavior and phase behavior

FAST speaker not horn. Fullrange Assisted Subwoofer Technology (lately called WAW for Wideband Assisted Woofer).

Basically use a fullrange driver to cover midrange and upper treble and use a woofer to cover bass and mid bass up to circa 300Hz to 1kHz crossover point. Idea is to have most sound from fullrange for coherence and good sound stage since approximates a point source.

Basically use a fullrange driver to cover midrange and upper treble and use a woofer to cover bass and mid bass up to circa 300Hz to 1kHz crossover point. Idea is to have most sound from fullrange for coherence and good sound stage since approximates a point source.

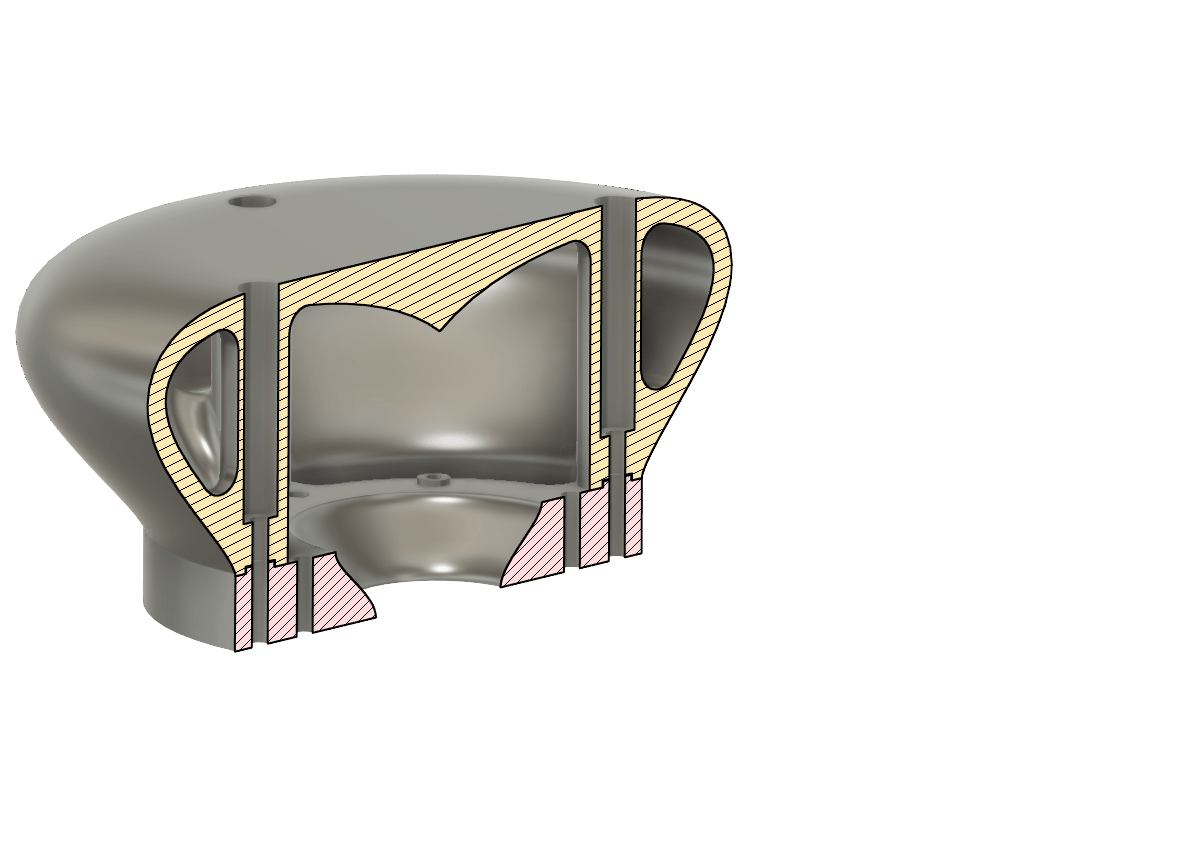

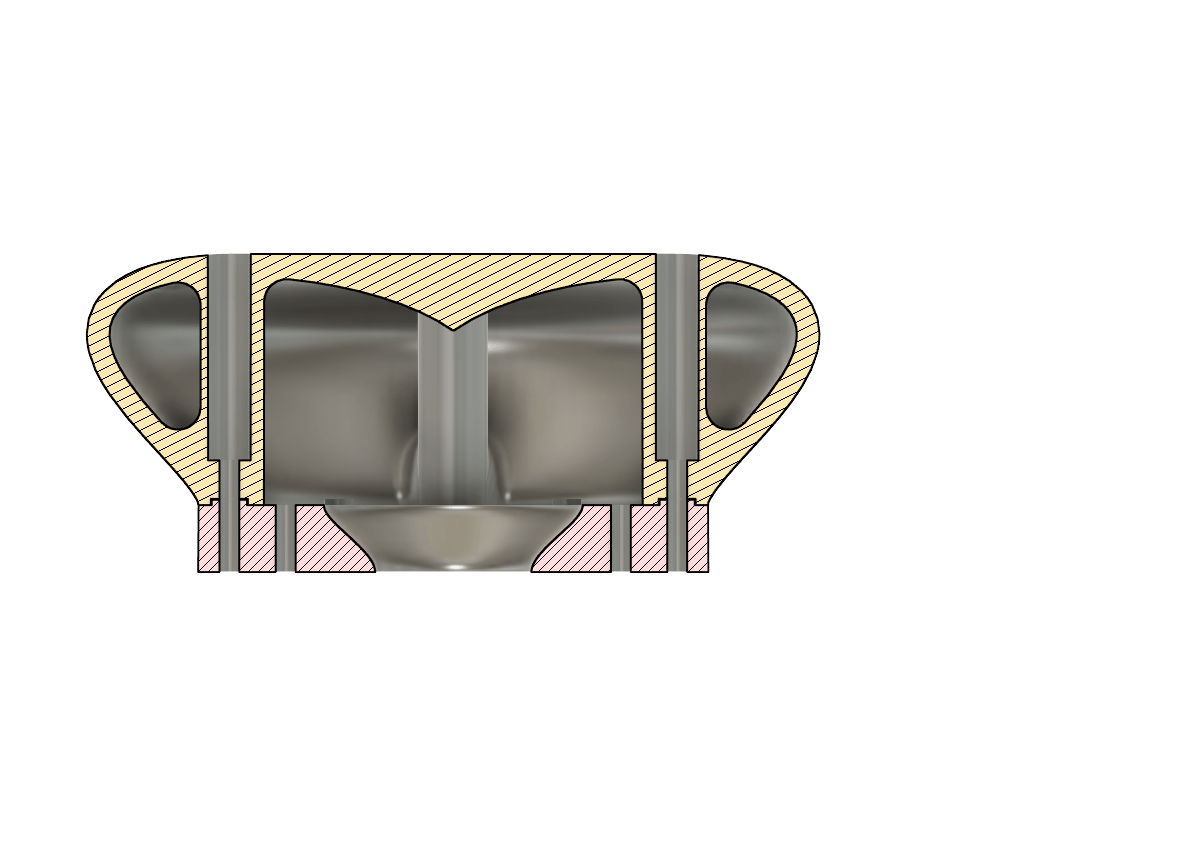

A bit of work on the rear chamber for the SB65.... Although the volume now comes in at 0.7litres which may be unnecessarily large with 500hz + XO

Superb work! Can you share the STL or STEP files for the nozzle and rear chamber?

Filling the rear chamber with white melamine foam might work well. Or plain fiberglass.

Filling the rear chamber with white melamine foam might work well. Or plain fiberglass.

If one goes for a 650 to 500 Hz x-over, one could even use a CD like SB 65CDN-T. A larger 3D printed back cover would lower the standard crossover point a bit, while also lowering distortion a bit.

I may also have a solution for the phase plugs of my my HDS drivers: I can simply add an O-ring to seal the gap. It should be flexible enough to not interfere with woofer motion. The question is still if I actually need it though?

I may also have a solution for the phase plugs of my my HDS drivers: I can simply add an O-ring to seal the gap. It should be flexible enough to not interfere with woofer motion. The question is still if I actually need it though?

Can do 😉Superb work! Can you share the STL or STEP files for the nozzle and rear chamber?

Filling the rear chamber with white melamine foam might work well. Or plain fiberglass.

A few points re these files.

1. This design is a prototype, I have not printed it yet.

2. The Tangent weight for the loft at the surround of the SB65 has been lowered from 1 to 0.5 to smooth out the shape a lot more, but may rub at full excursion, to be tested.

3. The model may not follow parametric design best practices, I am still learning, hence the prototypes, I may do a full redraw with this in mind.

4. The bolt holes are 4.5mm wide for m4 bolts.

5. The third attached file can be renamed from .txt to .f3d and should load in fusion for full editing.

Let me know if anybody needs an edit, happy to oblige.

Attachments

- Home

- Loudspeakers

- Multi-Way

- A Bookshelf Multi-Way Point-Source Horn