The throat adapter was chosen based on the measurements - I believe the middle one measured the best. I don’t have any recommendations for a 3D shop. I hear Los Angeles has a lot of them. Just google it and go by price and delivery time.

If you have it printed, you could find a service that does SLS printing. High resolution and much better quality than filament printers. Not real cheap, but prices have gone down.

I've used printing services like Shapeways. I'd only print a throat adapter with a service like that. Filament printers are fine for the woofer fillers etc.

I've used printing services like Shapeways. I'd only print a throat adapter with a service like that. Filament printers are fine for the woofer fillers etc.

The throat adapter was chosen based on the measurements - I believe the middle one measured the best. I don’t have any recommendations for a 3D shop. I hear Los Angeles has a lot of them. Just google it and go by price and delivery time.

If you have it printed, you could find a service that does SLS printing. High resolution and much better quality than filament printers. Not real cheap, but prices have gone down.

I've used printing services like Shapeways. I'd only print a throat adapter with a service like that. Filament printers are fine for the woofer fillers etc.

Perfect, thank you both!

Six-Mpls

Hello everybody.

I read this thread that interested me a lot and I congratulate all the people who have contributed to this project with their skills. the pages to be read in one go are many and so I focused on the most interesting ones.

not knowing how to read the graphs, I look for a description of what these loudspeakers are and what they can do. In another forum a gentleman said the following words:

the sound is a mix of the best parts of headphones, horns, electroastatics, near-field mini-monitorse and behemoth audiophile monsters.

In the following link I found a description:

Multiple Entry Horns [MEHs]--the "Why" and their Future - Technical/Modifications - The Klipsch Audio Community

do you agree with these statements?

Not having completely clear ideas, I thought I'd ask you a list of questions if you have the desire and time to answer me. I realize that there are many and therefore they are listed in order of importance.

1) what is the difference between your loudspeakers and a normal horn combined with a compression driver?

2) since the horn does not have a straight surface how do you connect woofer and horn without causing problems?

3) because a cone driver was used instead of a compression driver for the frequencies

medium and high?

4) What is the difference between your projects that use commercial horns and those that use self-made wooden horns with straight walls? How do they compare with other similar projects?

5) how do the holes made in the horns for the woofers not cause problems with the tweeter or the full range when the mid and high frequencies are working?

6) if I understood correctly, two different horns were used:

18sound XT1464 by mr bushmeister

Faital Pro LTH142 by mr xrk971

what is the diversification of this choice due to?

7) does the upper limit of the reproducible frequency correspond to 15 Khz?

8) how much sensitivity in dB? How much SPL?

9) are these loudspeakers suitable for home listening? Can they be placed against the wall?

I am not an expert, I am not able to read graphics (only one) and I do not know how to design and build an acoustic speaker on my own.

I'm trying to understand if for me there is also the possibility of self-building this type of loudspeakers but I cannot do it without a ready-made project, that's why I ask you if anyone is willing to pass me the technical information. I think the biggest problem is what I wrote to question number 2. I understand that someone has built a carbon fiber adapter holder that solves this problem, is it for sale?.

It would be another problem for me if it is not possible to use an analog crossover filter with these speakers. In this regard, I would like to know if anyone has made a DSP filter in an open environment and I wonder if it could be good for me too.

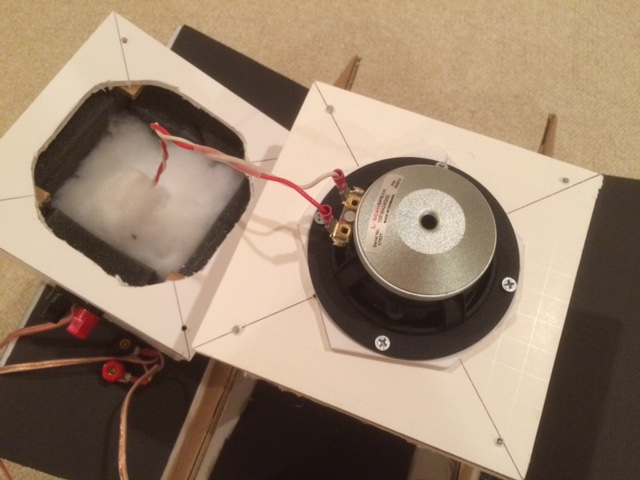

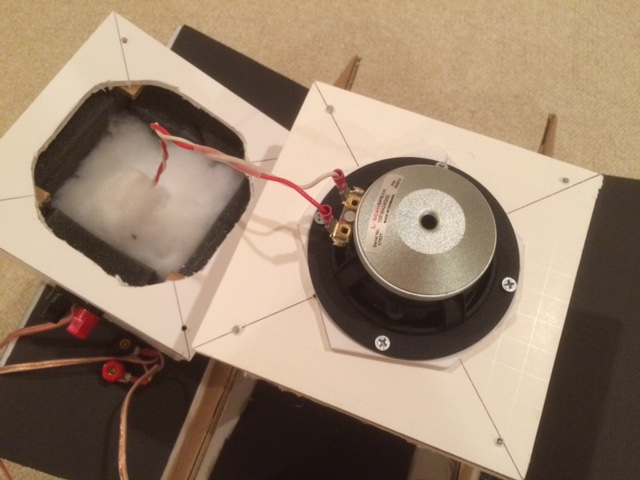

I have the KIT that you can see in the attached file, if you assure me that your loudspeaker (horn with multiple inputs) is much better, I am ready to sell my KIT.

I read this thread that interested me a lot and I congratulate all the people who have contributed to this project with their skills. the pages to be read in one go are many and so I focused on the most interesting ones.

not knowing how to read the graphs, I look for a description of what these loudspeakers are and what they can do. In another forum a gentleman said the following words:

the sound is a mix of the best parts of headphones, horns, electroastatics, near-field mini-monitorse and behemoth audiophile monsters.

In the following link I found a description:

Multiple Entry Horns [MEHs]--the "Why" and their Future - Technical/Modifications - The Klipsch Audio Community

do you agree with these statements?

Not having completely clear ideas, I thought I'd ask you a list of questions if you have the desire and time to answer me. I realize that there are many and therefore they are listed in order of importance.

1) what is the difference between your loudspeakers and a normal horn combined with a compression driver?

2) since the horn does not have a straight surface how do you connect woofer and horn without causing problems?

3) because a cone driver was used instead of a compression driver for the frequencies

medium and high?

4) What is the difference between your projects that use commercial horns and those that use self-made wooden horns with straight walls? How do they compare with other similar projects?

5) how do the holes made in the horns for the woofers not cause problems with the tweeter or the full range when the mid and high frequencies are working?

6) if I understood correctly, two different horns were used:

18sound XT1464 by mr bushmeister

Faital Pro LTH142 by mr xrk971

what is the diversification of this choice due to?

7) does the upper limit of the reproducible frequency correspond to 15 Khz?

8) how much sensitivity in dB? How much SPL?

9) are these loudspeakers suitable for home listening? Can they be placed against the wall?

I am not an expert, I am not able to read graphics (only one) and I do not know how to design and build an acoustic speaker on my own.

I'm trying to understand if for me there is also the possibility of self-building this type of loudspeakers but I cannot do it without a ready-made project, that's why I ask you if anyone is willing to pass me the technical information. I think the biggest problem is what I wrote to question number 2. I understand that someone has built a carbon fiber adapter holder that solves this problem, is it for sale?.

It would be another problem for me if it is not possible to use an analog crossover filter with these speakers. In this regard, I would like to know if anyone has made a DSP filter in an open environment and I wonder if it could be good for me too.

I have the KIT that you can see in the attached file, if you assure me that your loudspeaker (horn with multiple inputs) is much better, I am ready to sell my KIT.

Attachments

Lots of questions here. Thanks for your interest but I think you need to spend some more time reading (scanning) at least the first 30 pages to get much of what you are asking.

It is a FAST based speaker design where a full range driver is used as the tweeter. A lower crossover frequency is employed and this allows the main band for vocals and most instruments to one driver. The woofer supplements this below say 600Hz. This gives more coherence and better spatial imaging. Look in Fullrange Forum for FAST or WAW type speakers.

What’s the difference compared to CD’s? I personally don’t like the harsh sound of a CD. They sometimes have an edge to them and they like to be crossed rather high. This requires the mid injection ports to be placed close to the throat. And requires mids and woofer if you want output below 600Hz. Then it becomes a 3 way. Although some designs manage a CD with a woofer closer the throat like SynTrippi by Weltersys.

Bushmeister and myself used different waveguides as we had different ones readily available to us. They both can work well.

Why do holes not affect the waveguide? They do and it’s a trade off on how big you can make the holes.

How to get drivers to mount to curved walls? That’s in the first few pages of the thread. Use 3D printed adapter or lots of Bondo.

How to get the throat to be smooth? Lots of work and trial and error. I made at least 3 printed throat adapters and Bushmeister used Bondo contoured adapters.

That’s the basics. Hope you try it out. It’s a super sounding speaker.

It is a FAST based speaker design where a full range driver is used as the tweeter. A lower crossover frequency is employed and this allows the main band for vocals and most instruments to one driver. The woofer supplements this below say 600Hz. This gives more coherence and better spatial imaging. Look in Fullrange Forum for FAST or WAW type speakers.

What’s the difference compared to CD’s? I personally don’t like the harsh sound of a CD. They sometimes have an edge to them and they like to be crossed rather high. This requires the mid injection ports to be placed close to the throat. And requires mids and woofer if you want output below 600Hz. Then it becomes a 3 way. Although some designs manage a CD with a woofer closer the throat like SynTrippi by Weltersys.

Bushmeister and myself used different waveguides as we had different ones readily available to us. They both can work well.

Why do holes not affect the waveguide? They do and it’s a trade off on how big you can make the holes.

How to get drivers to mount to curved walls? That’s in the first few pages of the thread. Use 3D printed adapter or lots of Bondo.

How to get the throat to be smooth? Lots of work and trial and error. I made at least 3 printed throat adapters and Bushmeister used Bondo contoured adapters.

That’s the basics. Hope you try it out. It’s a super sounding speaker.

I wondered jow long it would be beforesomeone tried what Ive been doing wit the Galaxy SN5-8. I have gone a different waveguidedirection, designing my own take on a waveguide with half the flares missing...

The basic idea is to use the length of the slot, in one plan to make its beam collapse to the arc desired, while using traditional flares on the perpendicular to set the orher plane of the desired pattern...

More, later...

The basic idea is to use the length of the slot, in one plan to make its beam collapse to the arc desired, while using traditional flares on the perpendicular to set the orher plane of the desired pattern...

More, later...

thanks for the previous answers.

I read carefully up to page 125 after which I started skipping every 5 pages. I don't know the English language and I have to get help from the google translator.

I forgot an important question.

how does this speaker start at 30Hz if the frequency range for the LT142 horn is 0.5-18KHz?.

would it be a benefit if the holes were plugged with an acoustic canvas? I think the angle of attack makes a difference.

the waves arriving from the medium-high driver have the angle of incidence with respect to the surface of the holes which is close to 180 degrees. perhaps with this angle of incidence the acoustic canvas behaves like a solid wall. I hope I have explained what I mean, I leave it to you.

I read carefully up to page 125 after which I started skipping every 5 pages. I don't know the English language and I have to get help from the google translator.

I forgot an important question.

how does this speaker start at 30Hz if the frequency range for the LT142 horn is 0.5-18KHz?.

would it be a benefit if the holes were plugged with an acoustic canvas? I think the angle of attack makes a difference.

the waves arriving from the medium-high driver have the angle of incidence with respect to the surface of the holes which is close to 180 degrees. perhaps with this angle of incidence the acoustic canvas behaves like a solid wall. I hope I have explained what I mean, I leave it to you.

Acoustic grill cloth (canvas) should be transparent to audio frequencies for the most part. I am not sure how much it would help but worth a test. There’s a lot of air flow through the vents. I would not want to obstruct them with grill cloth. It can reach lower frequencies in the case of Bushemeister’s speaker via EQ in DSP. Natural sealed box woofer alignments with these drivers typically fall off around 50Hz.

What would the response without the throat adapter look like?

Could I get by using a 2" throat waveguide instead?

Could I get by using a 2" throat waveguide instead?

The throat adapter is specific to this particular driver and diameter of throat used. Sure, try your own waveguide. This was meant to inspire others to try other commercially available waveguides. There appears to be a need to provide some sort of adapter to transition the cone driver to a waveguide designed for a compression driver though unless it fits perfectly inside.

Read some plans in this thread to test a 10F in a 2 inch throat horn. Was that ever realised?

Not on this type of horn. I did try the 10F in a foam core tractrix. It sounds very nice. Better clarity and dynamics compared to a Faital 3FE22.

Presenting the Trynergy - a full range tractrix synergy.

Presenting the Trynergy - a full range tractrix synergy.

Great thread!

And some great results by the look of it.

I've been playing with Horn's for a while, no expert though.

I'm going to get some of the 18 sound horns to try with my Dh1 CDs but have been trying some conical mid horns, experimenting with different mouth terminations.

I got some 3fe25 last week and have tried them in some horns I made for the Dh1, they worked well enough to make some horns with a 60mm entry rather than 2". They seem to be loading between ~250-1700hz with 10-15db drop to higher than I can hear. That makes them almost usable to fill in between my midbass horns and tpl150h.

But I thought it might be fun to try making them MEH. I've bought a couple of 6fe100 to try, the faitalpro are very affordable in the UK and free next day delivery too. First mock up with the 6 inch drivers to a test bed horn produced awful results. Very little in the way of bass with a strongly rising response so something clearly wasn't right. I'm going to have to relearn HR to do some modelling.

Will post some data when I get home next week, but so far I'm impressed with the sound of the 3fe25 and will see how well they do with some DSP. Might try the SB drivers in the future, looks like they can manage more extension, but I notice you guys are only using them down to the same kind of frequencies as compression drivers are happy to?

Many thanks

Enzo

And some great results by the look of it.

I've been playing with Horn's for a while, no expert though.

I'm going to get some of the 18 sound horns to try with my Dh1 CDs but have been trying some conical mid horns, experimenting with different mouth terminations.

I got some 3fe25 last week and have tried them in some horns I made for the Dh1, they worked well enough to make some horns with a 60mm entry rather than 2". They seem to be loading between ~250-1700hz with 10-15db drop to higher than I can hear. That makes them almost usable to fill in between my midbass horns and tpl150h.

But I thought it might be fun to try making them MEH. I've bought a couple of 6fe100 to try, the faitalpro are very affordable in the UK and free next day delivery too. First mock up with the 6 inch drivers to a test bed horn produced awful results. Very little in the way of bass with a strongly rising response so something clearly wasn't right. I'm going to have to relearn HR to do some modelling.

Will post some data when I get home next week, but so far I'm impressed with the sound of the 3fe25 and will see how well they do with some DSP. Might try the SB drivers in the future, looks like they can manage more extension, but I notice you guys are only using them down to the same kind of frequencies as compression drivers are happy to?

Many thanks

Enzo

Nice to see interest here Enzo. 6FE100 is a nice driver. I think a large tractrix would sound good. What shape horn did you use and how big was it? You might try scaling same horn I made for 5in 5MR450 driver.

https://www.diyaudio.com/community/threads/prv-5mr450-ndy-for-fast-waw-applications.259293/page-5

https://www.diyaudio.com/community/threads/prv-5mr450-ndy-for-fast-waw-applications.259293/page-5

Horn I just made was the first section of this, if it works out I'll make the second flare.

I did make a tactrix to load a 5mn12-80, something like 24 X 12 X 15 off the top of my head, I'll try and find a link. Results didn't fit my desired use, not sure the driver worked out as well as the hype.

I like the idea of conical 2/3 of the length then tactrix, isn't the 402 reputed to be something along those lines?

Wish I'd tried it to 20k and the idea of using DSP to boost the top flat hadn't occurred to me till reading this thread, probably because I got interested in horns as a result of messing with smaller tube/valve amps.

Started reading some of these threads looking to see if I could improve on the hr940 horn on my EV Dh1 midrange (600-2k) but think I'm going to take some inspiration from yourself and go dsp'd class d amped. NOT very purist tube n horn lol.

Given my hearing stops at 14k that paudio looks tempting...

I've been really impressed with the 3fe25 though, £11 rather well spent.

Last edited:

Well its been about twelve months since the last post here so I thought I would give it a bump.

Thanks firstly to everybody who has contibuted here, I have started my second read through!

Secondly, Its harder to find or scource DIY gear over in Aus, especially at a reasonable price, but I did manage to find a decent looking CD horn locally and decided to grab two and begin the learning curve. Also grabbed the SB65's from the same shop.

https://www.wagneronline.com.au/sb-...audio-speakers-pa/horn-h280-92853/1002105/pd/

This seemed like an easy starter horn too, with the semi flat sides and low enough cost to not mind destroying one or two.

Then took some inspiration from XRK's adaptors to model this 15mm deep unit in fusion and 3d print a test unit.

The driver entry mount is 1mm bigger that the outside of the drivers surround and follows a directional loft down to the 35mm horn entry.

Printed with PLA+ and sanded to a smooth (+/- 0.1mm) transition with the horn.

I added more bolting points so the adaptor can be exactly aligned with the horn throat, bolten down, then the driver is screwed on, then the back chamber is bolted on. Also the alignment lugs between sections helps all the parts sit in the correct positions.

Printing went well and before I knew it I had a horn to test!

Im not great at testing yet and background noise was terrible so I just cranked it, using calibrated umik1 @ 1m on axis. First is just with xover, second with 10mins of minidsp PEQ play.

Sound test after EQ was decent but its hard to tell with no bass.

Next is do some better measurments including off axis and start work on the woofer section.

Cheers and all the best lads.

Thanks firstly to everybody who has contibuted here, I have started my second read through!

Secondly, Its harder to find or scource DIY gear over in Aus, especially at a reasonable price, but I did manage to find a decent looking CD horn locally and decided to grab two and begin the learning curve. Also grabbed the SB65's from the same shop.

https://www.wagneronline.com.au/sb-...audio-speakers-pa/horn-h280-92853/1002105/pd/

This seemed like an easy starter horn too, with the semi flat sides and low enough cost to not mind destroying one or two.

Then took some inspiration from XRK's adaptors to model this 15mm deep unit in fusion and 3d print a test unit.

The driver entry mount is 1mm bigger that the outside of the drivers surround and follows a directional loft down to the 35mm horn entry.

Printed with PLA+ and sanded to a smooth (+/- 0.1mm) transition with the horn.

I added more bolting points so the adaptor can be exactly aligned with the horn throat, bolten down, then the driver is screwed on, then the back chamber is bolted on. Also the alignment lugs between sections helps all the parts sit in the correct positions.

Printing went well and before I knew it I had a horn to test!

Im not great at testing yet and background noise was terrible so I just cranked it, using calibrated umik1 @ 1m on axis. First is just with xover, second with 10mins of minidsp PEQ play.

Sound test after EQ was decent but its hard to tell with no bass.

Next is do some better measurments including off axis and start work on the woofer section.

Cheers and all the best lads.

Nice work on the rear chamber 3D work! The EQ’d response looks excellent! Very low distortion and wide bandwidth. So you are also using SB65WBAC25-4 drivers?

@CooperH, that looks pretty good! I was looking at that horn as well.

Actually, I’m contemplating to build a JBL L100 “clone”. One can buy the grills and metal stand, so basically all you need is the box 😉

The XT1464 is basically a too tight fit for this. The Faital horn would work, but it’s relatively expensive, and to start, a cheap solution to prove the concept would be great. I also still have some 18cm HDS exclusive woofers (the ones with the phase plugs) around, as well as a 15” woofer to mount on the back to make it a 3-way. That should just about fit.

@CooperH, any idea where the 7xx Hz distortion peak comes from? This peak can’t be seen in other measurements.

Actually, I’m contemplating to build a JBL L100 “clone”. One can buy the grills and metal stand, so basically all you need is the box 😉

The XT1464 is basically a too tight fit for this. The Faital horn would work, but it’s relatively expensive, and to start, a cheap solution to prove the concept would be great. I also still have some 18cm HDS exclusive woofers (the ones with the phase plugs) around, as well as a 15” woofer to mount on the back to make it a 3-way. That should just about fit.

@CooperH, any idea where the 7xx Hz distortion peak comes from? This peak can’t be seen in other measurements.

Hey X, correct, it's odd looking at the little sb65 on the back of the horn but hearing so much output at the front of the horn!Nice work on the rear chamber 3D work! The EQ’d response looks excellent! Very low distortion and wide bandwidth. So you are also using SB65WBAC25-4 drivers?

Hey real.@CooperH, that looks pretty good! I was looking at that horn as well.

Actually, I’m contemplating to build a JBL L100 “clone”. One can buy the grills and metal stand, so basically all you need is the box 😉

The XT1464 is basically a too tight fit for this. The Faital horn would work, but it’s relatively expensive, and to start, a cheap solution to prove the concept would be great. I also still have some 18cm HDS exclusive woofers (the ones with the phase plugs) around, as well as a 15” woofer to mount on the back to make it a 3-way. That should just about fit.

@CooperH, any idea where the 7xx Hz distortion peak comes from? This peak can’t be seen in other measurements.

Funy enough I have 4 x Peerless 6.5" 850439 lying around that I may have to use as temp mids on this build too.

The Sb23 8" are approx $200 each here, while even the Dayton Dc200 are $95 Delivered.

I have a silly idea for a replacable mid injection assembly that I will model and share asap.

Re the 700hz distortion peak, I believe it's the upper part of the broader peak seen in others measurements, mine looks different because of the 24db xo used on both measurements.

- Home

- Loudspeakers

- Multi-Way

- A Bookshelf Multi-Way Point-Source Horn