Excellent work as usual Xrk -

So it seems with the faital pros: - at 80hz - output is limited (by xmax) to about 102db,

at 90hz - 105db

Whilst with the SBAs - at 80 hz - output is limited (by thermal max) to about 107db, at 90hz - 110db.

So you can see that there really is no replacement for displacement!!

So it seems with the faital pros: - at 80hz - output is limited (by xmax) to about 102db,

at 90hz - 105db

Whilst with the SBAs - at 80 hz - output is limited (by thermal max) to about 107db, at 90hz - 110db.

So you can see that there really is no replacement for displacement!!

You are welcome.

You have summarized it correctly. I was thinking a Dayton RS225-8 might also be a nice woofer for this with 7mm xmax and similar soft suspension like SB23. Might have to run a sim - and I have these woofers already.

The XT WG is pricey here in US. They want $100 ea on Amazon - you say they are only 30 Pounds in UK?

Amazon.com: 18 Sound XT1464 High Frequency Horn: Musical Instruments

Looks like a very nice horn - coupled with a Faital Pro Nd HF146 comp driver, might actually be able to go as low as 500Hz - but look at the HD that would have plus price is $250 vs SB65 $32 price.

https://www.parts-express.com/pedocs/specs/294-1023-faitalpro-hf146-8-specifications.pdf

You have summarized it correctly. I was thinking a Dayton RS225-8 might also be a nice woofer for this with 7mm xmax and similar soft suspension like SB23. Might have to run a sim - and I have these woofers already.

The XT WG is pricey here in US. They want $100 ea on Amazon - you say they are only 30 Pounds in UK?

Amazon.com: 18 Sound XT1464 High Frequency Horn: Musical Instruments

Looks like a very nice horn - coupled with a Faital Pro Nd HF146 comp driver, might actually be able to go as low as 500Hz - but look at the HD that would have plus price is $250 vs SB65 $32 price.

https://www.parts-express.com/pedocs/specs/294-1023-faitalpro-hf146-8-specifications.pdf

Aye - just under £30!

18 Sound XT1464 Constant Coverage HF Horn (1.4 Throat)

I am very excited to get measuring with the SB65 loaded! (when ever they arrive.....)

18 Sound XT1464 Constant Coverage HF Horn (1.4 Throat)

I am very excited to get measuring with the SB65 loaded! (when ever they arrive.....)

Sometimes you can get better prices over there. That's $42 a much more reasonable price worth modifying.

Thanks sharing Akabak plots.

Would there be any demand for woofer performance that could change when frq/HD/polar measurements for XT1464/SB65WBAC25-4 is revealed.

Found SB23NRXS45-8 cost from €80-99 and 6FE100 cost from €24-40. In light of that 2x 6FE100 seems cost less than 1x SB23NRXS45-8, is it possible place 2x 6FE100 on top and 2x 6FE100 at bottom with 1x port for each driver.

Would there be any demand for woofer performance that could change when frq/HD/polar measurements for XT1464/SB65WBAC25-4 is revealed.

Found SB23NRXS45-8 cost from €80-99 and 6FE100 cost from €24-40. In light of that 2x 6FE100 seems cost less than 1x SB23NRXS45-8, is it possible place 2x 6FE100 on top and 2x 6FE100 at bottom with 1x port for each driver.

Qnty 4 x 6F100's would be even better - there probably is room to do it if an extension board is placed on horn wall and then only inner edge of driver cone is used to cover port.

OK - Finally the SB65s have arrived!!

I have spent some time trying to work out how I will be able to mount these solidly and without any air-leaks to the horn with such a tiny 'lip' to work with.

The lip is only 1mm wide and 1.5mm thick. I was going to have to cut an incredibly accurate circle in plywood then mount it perfectly centered, then somehow sandwich a compressible gasket between the two without compressing it beyond the 1mm lip so it doesn't foul the surround....didn't like the thought of that!

I therefore came to the conclusion that if I could somehow build up the driver frame with epoxy putty to form a raised gasket with a decent strength and size to sandwich a sorbothane gasket........it might work.

So here is my first attempt. It is bonded to the SB65 frame and marries perfectly to the smooth throat I routed to the horns, so hopefully will provide a diffraction free union.

Just have to make the other one. Let them fully harden. Sand them a little to neaten them up, then fit sorbothane gaskets and mount to horns.

Then......measurements begin. 😀😀😀

I have spent some time trying to work out how I will be able to mount these solidly and without any air-leaks to the horn with such a tiny 'lip' to work with.

The lip is only 1mm wide and 1.5mm thick. I was going to have to cut an incredibly accurate circle in plywood then mount it perfectly centered, then somehow sandwich a compressible gasket between the two without compressing it beyond the 1mm lip so it doesn't foul the surround....didn't like the thought of that!

I therefore came to the conclusion that if I could somehow build up the driver frame with epoxy putty to form a raised gasket with a decent strength and size to sandwich a sorbothane gasket........it might work.

So here is my first attempt. It is bonded to the SB65 frame and marries perfectly to the smooth throat I routed to the horns, so hopefully will provide a diffraction free union.

Just have to make the other one. Let them fully harden. Sand them a little to neaten them up, then fit sorbothane gaskets and mount to horns.

Then......measurements begin. 😀😀😀

Attachments

And you said X is fast! The drivers are only here for mere minutes and you've already customised them 🙂.

I better get out the popcorn and beer! 😀

How do you plan on doing the back chamber?

I better get out the popcorn and beer! 😀

How do you plan on doing the back chamber?

Nice! Check the impedance curve with the speaker, enclosure and stuffing, but without the horn.

That will show if the damping is doing the work that it needs to do. Run the free air driver impedance test first to have the "base line" to compare to. Should work nicely!

It should not show any weird new wiggles with the driver in the enclosure. But measuring it will make sure of that. All little things help. Gives you a chance to get the stuffing just right. These spheres are nice and wide around the basket. I like it!

That will show if the damping is doing the work that it needs to do. Run the free air driver impedance test first to have the "base line" to compare to. Should work nicely!

It should not show any weird new wiggles with the driver in the enclosure. But measuring it will make sure of that. All little things help. Gives you a chance to get the stuffing just right. These spheres are nice and wide around the basket. I like it!

Last edited:

Spheres can work but have a nasty bell mode. Perhaps with enough stuffing it will be fine. 3 pieces of triangular ply to make a Dagger works well and is easy to make.

Non parallel walls and act as a Woods' horn to absorb back reflections.

Nice work on expoxy frame. I found that the little 1.5mm lip seals just fine so did not mod my bezel. All that epoxy may have side benefit of reducing frame buzz or vibrations.

Re speed : I think I may have just met my match for speed builds. 😀

Non parallel walls and act as a Woods' horn to absorb back reflections.

Nice work on expoxy frame. I found that the little 1.5mm lip seals just fine so did not mod my bezel. All that epoxy may have side benefit of reducing frame buzz or vibrations.

Re speed : I think I may have just met my match for speed builds. 😀

Sphere with damping in the middle of it would not exhibit the bell mode, would it?

After all, the speaker isn't in the middle of that shape. The damping should be. Plus I'd use wool felt on the walls. But that's easy for me to say because I have it available.

After all, the speaker isn't in the middle of that shape. The damping should be. Plus I'd use wool felt on the walls. But that's easy for me to say because I have it available.

Last edited:

LOL!

Xrk - I suspect part of the reason it worked well for you, was that you used foam core as both the gasket and the mounting board - so nicer to cut accurately and no squidgy gasket to deal with!

I thought about using foam core actually after looking at your thread, but felt it would be nice to have a go at something more 'permanent'.

Also - the sorbothane has to be torqued down at the right pressure to get the best damping effect for a given frequency range, so you need a stable, wide frame to do this.

I found the sorbothane so good at driver isolation in some of my other builds that I am quite keen to utilize it again (quite measurable effects).

I know a sphere has the worse bell mode - but all my 'sphere enclosures' are divided in half with a vertical brace running back from the driver - this effectively creates two hemispheres which are surprisingly mode free. The other option would be a dagger enclosure like yours of course - funnily enough I came to similar findings as you regarding this shape.

When optimizing the sealed mid chamber for my 12MU in my three way build - I experimented with loads of enclosures and found a simple tube with a rolled stack of felt at the end - staggered to create a kinda dagger shape - was the most effective.

Xrk - I suspect part of the reason it worked well for you, was that you used foam core as both the gasket and the mounting board - so nicer to cut accurately and no squidgy gasket to deal with!

I thought about using foam core actually after looking at your thread, but felt it would be nice to have a go at something more 'permanent'.

Also - the sorbothane has to be torqued down at the right pressure to get the best damping effect for a given frequency range, so you need a stable, wide frame to do this.

I found the sorbothane so good at driver isolation in some of my other builds that I am quite keen to utilize it again (quite measurable effects).

I know a sphere has the worse bell mode - but all my 'sphere enclosures' are divided in half with a vertical brace running back from the driver - this effectively creates two hemispheres which are surprisingly mode free. The other option would be a dagger enclosure like yours of course - funnily enough I came to similar findings as you regarding this shape.

When optimizing the sealed mid chamber for my 12MU in my three way build - I experimented with loads of enclosures and found a simple tube with a rolled stack of felt at the end - staggered to create a kinda dagger shape - was the most effective.

Attachments

Wesayso - A sphere does suffer with a single overwhelming dimension (and therefore mode) - it's diameter, but you are right, this mode can be easily almost completely suppressed with a good stuffing of fiberglass!

Great idea! I see you are already an expert at minimizing parasitic effects that can muck up an otherwise perfectly good response. I am keen on trying sorbothane too.

Wesayso- absolutely! Too many people forget that. And also don't realise how good densely stuffed fibreglass is.

Xrk- the beauty with the tube and rolled felt, is, it is easy to quickly make, the tube is very rigid, and the felt not only creates the dagger absorption shape, but the felt itself absorbs some of the rear wave.

When I stuffed the tube with variable density fibreglass - loose behind driver to firmly packed at the apex of the dagger void, it sounded better than anything else I tried.

Xrk- the beauty with the tube and rolled felt, is, it is easy to quickly make, the tube is very rigid, and the felt not only creates the dagger absorption shape, but the felt itself absorbs some of the rear wave.

When I stuffed the tube with variable density fibreglass - loose behind driver to firmly packed at the apex of the dagger void, it sounded better than anything else I tried.

When I stuffed the tube with viable density fibreglass - loose behind driver to firmly packed at the apex of the dagger void, it sounded better than anything else I tried.

I found that nothing sounded as good as a Dagger stuffed with fiberglass. The spiral tapered Nautaloss was just as good reflection wise but a much larger volume. Some drivers like the 10F like a small 1.3 liter rear chamber. I could not measure any back wave coloration from the Dagger and the HD was very low. The impedance confirmed how clean it was. I really like your simple rolled felt design. Instead or concentric rolls you can cut a triangle and roll it continuously for a felt dagger. Rolled up sheet of triangular corrugated cardboard topped with a cone of felt might work too to save on cost of felt.

Last edited:

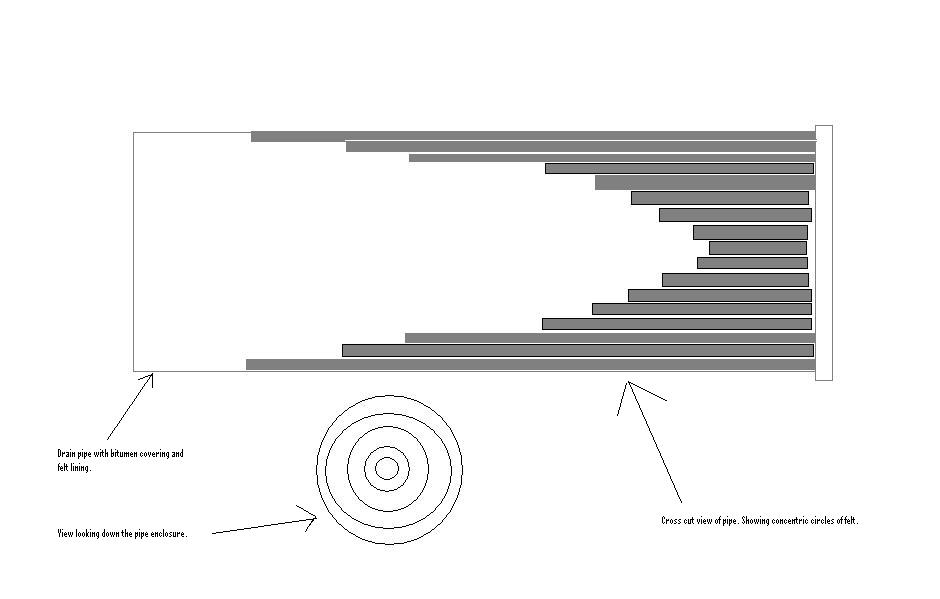

Yep - that's how I did it - a long triangle of 3mm thick wool felt, rolled up.

I also found that a stiff, rigid, plastic pipe 3mm thickness, reponded incredibly well to 4mm extensional bitumen damping.

Completely 'dead' to the knock test. Much better than similar damping techniques on 18mm MDF/Ply.

So all in all, it makes for an excellent mid/full range enclosure - particularly if it can be hidden away.

I also found that a stiff, rigid, plastic pipe 3mm thickness, reponded incredibly well to 4mm extensional bitumen damping.

Completely 'dead' to the knock test. Much better than similar damping techniques on 18mm MDF/Ply.

So all in all, it makes for an excellent mid/full range enclosure - particularly if it can be hidden away.

- Home

- Loudspeakers

- Multi-Way

- A Bookshelf Multi-Way Point-Source Horn