Do you use actual bitumen? Or the automotive stuff, usually butyl based nowadays.

I like the butyl based stuff. No nasty smells, sticks like crazy, damps very well and can take temperature changes very well, always staying elastic. I've used it a lot in my own build. The sheets with thin alu layer as well as butyl rope.

I like the butyl based stuff. No nasty smells, sticks like crazy, damps very well and can take temperature changes very well, always staying elastic. I've used it a lot in my own build. The sheets with thin alu layer as well as butyl rope.

You are absolutely right wesayso - not proper bitumen!

I like the silentcoat extra 4mm. Quite pricey - but as you say, really works well.

I like the silentcoat extra 4mm. Quite pricey - but as you say, really works well.

That's the one I use! Silent Coat 4mm, love that stuff! One of the best performers on a test over at DIYMA.

Butyl rope I got trough ebay, usually sold to seal all kinds of things on cars. I used it between my dual aluminium baffle around the drivers to create a sort of CLD effect.

Butyl rope I got trough ebay, usually sold to seal all kinds of things on cars. I used it between my dual aluminium baffle around the drivers to create a sort of CLD effect.

Attachments

Last edited:

Ooooo 'Butyl rope', that's a new one on me......might have to look into that!

The thing with extensional damping, is you need to use the right stuff and have sufficient thickness (which is dependent on what you are damping of course!)

I found with 18mm MDF you need 12mm of silent coat to get a good effect (3 layers)

so it does take up significant volume and is quite expensive - but of course a lot easier than CLD, which is a minefield in itself!!

The thing with extensional damping, is you need to use the right stuff and have sufficient thickness (which is dependent on what you are damping of course!)

I found with 18mm MDF you need 12mm of silent coat to get a good effect (3 layers)

so it does take up significant volume and is quite expensive - but of course a lot easier than CLD, which is a minefield in itself!!

The XT WG is pricey here in US. They want $100 ea on Amazon - you say they are only 30 Pounds in UK?

Just a quick heads up: This is available right now on ebay for about $135/pr, shipped. The seller is "www.speakeraddict" and I have no affiliation, but have purchased from him before.

Just a quick heads up: This is available right now on ebay for about $135/pr, shipped. The seller is "www.speakeraddict" and I have no affiliation, but have purchased from him before.

Thanks for the tip - looks like mainly they are made in Europe so getting them to US has initial cost they puts them above $45 ea.

Ooooo 'Butyl rope', that's a new one on me......might have to look into that!

The thing with extensional damping, is you need to use the right stuff and have sufficient thickness (which is dependent on what you are damping of course!)

I found with 18mm MDF you need 12mm of silent coat to get a good effect (3 layers)

so it does take up significant volume and is quite expensive - but of course a lot easier than CLD, which is a minefield in itself!!

I find thick layer of latex caulking between thin 3/16 in wood ply and 1in thick XPS foam quite dead sounding and doesn't weigh a thing.

I assume you are making measurments on the mounted SB65 as I type? Really curious how it will work out with a smooth round throat vs a square tractrix throat.

Ha ha xrk971 let his epoxy get time to fully harden, sand them, fit sorbothane gaskets, and mount to horns.

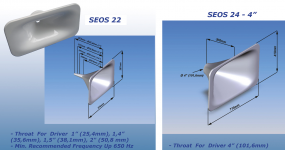

In meantime if we seek for nice round-over surfaces to improve on diffraction here a couple of SEOS type and a couple of JMLC types for higher diameter entrance. There a lot more types and possibilityes looking their website but of course they some costly until the day we can 3d print as modules - Horns by Auto-Tech.

In meantime if we seek for nice round-over surfaces to improve on diffraction here a couple of SEOS type and a couple of JMLC types for higher diameter entrance. There a lot more types and possibilityes looking their website but of course they some costly until the day we can 3d print as modules - Horns by Auto-Tech.

Attachments

LOL! hi guys! Thanks for defending me Byrtt!

In all honesty I have had a bit of a disaster. The laptop I use for REW has developed a fault so it is with the engineer at work today. I hope to get it back tomorrow. But if not tomorrow definitely Friday.

I have made the second gasket this evening - it is a little smoother now I know what I am doing!

I need to get some smaller screws than I have in stock in my garage, get some wide drainpipe from the local DIY store - so I can use my drainpipe method for rear chamber - I will pick this up tomorrow.

So. To keep me amused tonight I will do some sample port cut outs for your approval!

So I am going to cut some white paper ports.

In all honesty I have had a bit of a disaster. The laptop I use for REW has developed a fault so it is with the engineer at work today. I hope to get it back tomorrow. But if not tomorrow definitely Friday.

I have made the second gasket this evening - it is a little smoother now I know what I am doing!

I need to get some smaller screws than I have in stock in my garage, get some wide drainpipe from the local DIY store - so I can use my drainpipe method for rear chamber - I will pick this up tomorrow.

So. To keep me amused tonight I will do some sample port cut outs for your approval!

So I am going to cut some white paper ports.

30cm2 seems like a nice compromise looking at your sims to minimize diffraction and prevent port chuffing - so 3x10cm if cut in slots....

Photos to follow!

Photos to follow!

My sims with 6.5cm dia holes is same as 32 cm2 so yes 30cm2 is perfect. 10x3cm slots sounds like a good plan. Straight slots or arc'd?

My REW data Acq laptop hard disk crashed last week and I don't have it backed up. Mostly REW mdat data files from last 2 years. I need to get REW installed on another laptop. So I am in similar situation with measurements.

No pressure, just thought I had met my match with build speed 🙂

No pressure, just thought I had met my match with build speed 🙂

Hmmm. So this is with 2x10x4cm slots. For a 30cm2 per port. Seems like a lot of horn lost. The start of the slot begins 10 cm axially from the throat.

Those look like they are in too deep. The middle of the slot should be 10cm from the exit plane meaning the end of it is 5cm from exit plane. I would not make them pie shape. I think just a straight parallel wall with rounds on end looks and works best. Hotdog or wiener shape.

How are you going to be mounting the SB23's on the board to get the cone to cover to two slots? You have to look at coverage of the 8in cone and how it overlays with horn wall to come up with the positioning.

Yep already cut a piece of paper diameter of driver to check!

Plus the real thing arrives tomorrow!

Plus the real thing arrives tomorrow!

Should it end up ruin horns performance too much when holes are bored on the first horn, then with other horn you can revert to first plan but still add band pass port which will improve further ctc distance, or just use one 12" high sensitivity driver including a band pass port.

Attachments

- Home

- Loudspeakers

- Multi-Way

- A Bookshelf Multi-Way Point-Source Horn