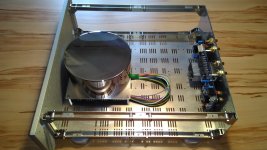

... added bottom. fits exactly. puuuh 😎

That looks professional !

Nice work Astx !!

After breaking a couple of 3mm hand taps, I now drill a 90 hole of the right size in a thick flat piece of wood in a drill press and use that as a jig for hand tapping.

Important to get the correct size drilled in the Aluminium too.

Haven't broken a hand tap for years. The hole in the wood keeps the tap vertical.

Important to get the correct size drilled in the Aluminium too.

Haven't broken a hand tap for years. The hole in the wood keeps the tap vertical.

I use a base drill and then,after drilling,a hand tool for tapping.

Yes isn't an easy way for 90 degree angle perfect tapping.

I had an accident once with a broken tap.The lesson was learned

Tapping oil and one movement forward one reverse is just fine.

This trick,using wood as vertical driver looks interesting.

Tapping oil and one movement forward one reverse is just fine.

This trick,using wood as vertical driver looks interesting.

I have only broken one tap in the few decades I have been working with aluminium, in lots of different grades.

I often drill by hand on my knees with the Al lying on a bit of hardboard.

I usually tap with the Al lying on my knees while I am seated at the work bench.

I always use vegetable oil. (Olive, sunflower, rapeseed, whatever is in the kitchen is fine).

I don't use any guides.

I must be stupid, or very sensitive.

I often drill by hand on my knees with the Al lying on a bit of hardboard.

I usually tap with the Al lying on my knees while I am seated at the work bench.

I always use vegetable oil. (Olive, sunflower, rapeseed, whatever is in the kitchen is fine).

I don't use any guides.

I must be stupid, or very sensitive.

Last edited:

... or plenty of luck! 😉...

I must be stupid, or very sensitive.

After breaking a couple of 3mm hand taps, I now drill a 90 hole of the right size in a thick flat piece of wood in a drill press and use that as a jig for hand tapping...

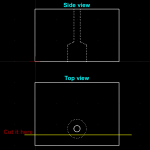

Something like this?

My screw tap needs room for the swarf. Maybe designing the wood-helper with a bigger, short hole from bottom and cut it to have room for the swarf/chips. As a side effect you can see what happens ...

BR, Toni

Attachments

Some of my taps push the swarf forwards. These self clearing types may not need backing off to break the swarf.

Are these intended for machine tapping?

What are they called?

Are these intended for machine tapping?

What are they called?

Some of my taps push the swarf forwards. These self clearing types may not need backing off to break the swarf.

Are these intended for machine tapping?

What are they called?

I think you are talking about spiral helix taps. They perform better when machine driven.

...in post 2503 (second picture) you can see three swarf spirals ...

These taping drill types are for machine and hand tapping and are more universal. You can tap aluminium as well as stainless steel. Also good for through hole and blind hole tapping. No need of backing off to break the swarf!

These taping drill types are for machine and hand tapping and are more universal. You can tap aluminium as well as stainless steel. Also good for through hole and blind hole tapping. No need of backing off to break the swarf!

Last edited:

Some of my taps push the swarf forwards....

What are they called?

"Spiral point" taps push the swarf forward, usually for thru holes.

Not to be confused with "spiral flute" taps, what JWilhem has described and Toni linked, that lift the swarf back.

Best wishes

David

Last edited:

...I now drill a 90 hole...in a thick flat piece of wood

I just use like this, only a bit heavier.

Best wishes

David

Copied from Wikipedia.

Attachments

Last edited:

Mine's just a simple hole drilled to fit the tap snugly.Something like this?

My screw tap needs room for the swarf. Maybe designing the wood-helper with a bigger, short hole from bottom and cut it to have room for the swarf/chips. As a side effect you can see what happens ...

Of course your correct size drilled hole needs to be vertical too so best done in a drill press.

If you haven't got a drill press, find a friend with one and drill a couple of vertical holes in scrap plywood. One to fit your correct size drill and the other to fit your tap.

And thimios advice about using oil (any type) and "one turn (or less) in, one turn out" to break the swarf is important too.

That and with my 2 pieces of scrap wood, you can hand drill and tap (with crappy T handle taps) very quickly in Aluminium heatsinks.

...and "one turn (or less) in, one turn out" to break the swarf is important too.

Now, where's the proceeding in this procedure?

Best regards!

"one turn (or less) in, one turn out" to break the swarf is important too.

This only applies to conventional straight flute taps. it's actually counterproductive with spiral flute taps as the main advantage is to remove the chip through the top in a single piece.

This only applies to conventional straight flute taps. it's actually counterproductive with spiral flute taps as the main advantage is to remove the chip through the top in a single piece.

Yes i have spiral flute taps only.

- Home

- Amplifiers

- Solid State

- 2stageEF high performance class AB power amp / 200W8R / 400W4R