Thanks Allen, how does this relate to the actual final sound? And although my goal was to see if this could be a stand alone (as in no subs needed) build, which direction would be easier to blend to subs?

I find the same in experience, so I should go for the lowest tuning possible for this design and maybe tie in the subs super low (if needed) ………the music i listen to blues/country/rock doesnt really have much content (if any) below 30hz

I’m considering making a remove able panel of the port section for tuning it to the room…..probably a good idea?

Big box means it can be tuned low with a short vent. You should be fine with most shapes, rectangular like Scot does with the Pensils, but I am a fan of the semicircular one in the Hawking Memorial Monolith.1) Is the shallow (1”) depth what reduces resonance?

dave

In other words equalising. You'll get the same result whether you do it electronically or by mechanical mistuning.I’m considering making a remove able panel of the port section for tuning it to the room

Compensating bass in a room is usually about location, because this relates to the fundamental problem. (It is also why multiple subs are able to do what they do.)

Allen my room is setup so that the speakers must go in one position only +/- maybe a few inches, so being able to change it up a little at the source might not be a bad thing? Plus i’m a master craftsman….. theres nothing I can’t build, quite unlike designing the alphabet boxes…..theres no hope for me there! 😉

GM……ya still with me?

GM……ya still with me?

If your mains are fixed in location you can diversify, virtually, by way of overlapping subs.

Yes equalising is an option, however you won't be able to do much about dips in the response, you can't equalise them significantly when they are modal. Also it kind of limits you to sitting in the one spot.

Yes equalising is an option, however you won't be able to do much about dips in the response, you can't equalise them significantly when they are modal. Also it kind of limits you to sitting in the one spot.

The sims are with 0.75"/1.8-9 cm, but 1" is an inaudible difference.Ok, seeing as you have real world (sim to build) experience with HR i will definitely take your word for that, and is exactly what information i’m after.

Questions arise still about the port……

1) Is the shallow (1”) depth what reduces resonance?

2) Is one (8” vs 5”) better than the other regarding resonance, and would a ‘in between’ say 6.5” be a good compromise?

3) If this is how I imagine it, just a hole in the baffle (I usually use 1” ply for baffle so no problem there) can one use grill cloth over it or will that alter it too much?

4) Is port shape critical to the design, or can the round hole be changed to rectangular if it keeps the same area?

One thing i do know is that dimensional accuracy is critical to a mltl build, so if once we boil it down could i get you to list critical dimensions as Matt did?

I applaud your patience! 😎

edit; Is this design basically the same as the old altec,jbl,etc. with just holes in the baffle? I’d always wondered how that was possible.

Depends on the room mode's impact on its response and where the speakers are, so the 5" could either be filling in a room null or adding to its peak or somewhere in-between or back them into a corner and it will make the red even more 'boomy', though both will be rolled off, lowered in frequency due to the corner's parabolic horn loading assuming the floor/wall is parallel, otherwise it's conical; so of course an in-between tuning just changes all this a little bit one way or another and down this low I seriously doubt you'd notice any difference in a typical musical, action playback, though maybe in some really low tuned instrument solos such as Tuba, (contra) bassoon, drums, etc., or parts of a concert piano concerto or full on orchestra with these latter three being my main 'frames of reference' and of course if experienced in a proper concert hall somewhere near/at the front row center, all the better.

Right, just like in the good ol' days when cabs were big, tuned ~40-100 Hz depending on driver size, intended app, allowing baffle thickness vents with Av = Sd being the normal limit.

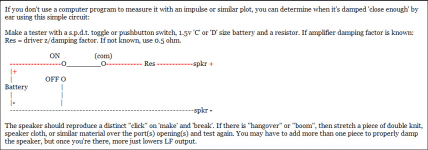

Yes, and if wanting to roll off and/or 'tighten' up its transient response, recommend critically damping the vent with the click test first as it usually is all the tweak that's needed IME (barring certain types of EQ, room mode issues) and at the very least you'll have the best of both vented and sealed with a 'heart attack fast' transient response in the lower octaves up to its upper mass corner (Fhm = 2*Fs/Qts') where T/S theory peters out with the driver design setting its higher BW performance.

[Qts']: [Qts] + any added series resistance [Rs]: http://www.mh-audio.nl/Calculators/newqts.html

Thanks, I view this as a respite from reality and being a type 'A' personality, enjoy educating (some say 'preaching').

Attachments

Last edited:

Appreciate it GM, (and everyone else helping)

<“enjoy educating”> welcome to special ed ! 😛

This is quite difficult for me as there are very few things in life I don’t grasp, i’ve intentionally avoided computers as something i’d “never need” and now finding myself in a position where in order to do something I‘m interested in, being at their mercy is……..aggravating/frustrating to say the least. My near term goals are to put a little more effort into figuring out how not to be such a compu-idiot……. but that’s something for the winter month (January) 🙂

Back to the meat and potatoes……..i‘ve got all the dimensions to build your version Except for the port height, if you could pass that along. And after figuring out the volume it seems as though you already subtracted for drivers and horn?

As far as stuffing goes…..<“Damping is standard BR, sealed QL = 7, so basically lined or lightly stuffed down to just above the vent.”> would a layer of something like 6“ rockwool against the back panel down to ‘just above the vent’ suffice for a start?

I like tight ‘heart attack fast’ transients, i’m not familiar with the term ‘upper mass corner’ but will look it up, I’m assuming the red (8”) version will be more accepting to vent damping? And in this application does the grill cloth matter whether its across the inside or outside of port?

Another thing crossed my mind, does the wiring (series vs parallel) of the two woofers make any difference for these parameters? My plan is parallel.

I’d heard of the ‘click test’ and will definitely implement it here…..thanks for the excerpt.

Would there be enough difference between your design and Matt’s to build them both? My original goal was to build several versions and see which is best……..i have enough to do the GM, Matt, and a sealed w/sub version.

<“enjoy educating”> welcome to special ed ! 😛

This is quite difficult for me as there are very few things in life I don’t grasp, i’ve intentionally avoided computers as something i’d “never need” and now finding myself in a position where in order to do something I‘m interested in, being at their mercy is……..aggravating/frustrating to say the least. My near term goals are to put a little more effort into figuring out how not to be such a compu-idiot……. but that’s something for the winter month (January) 🙂

Back to the meat and potatoes……..i‘ve got all the dimensions to build your version Except for the port height, if you could pass that along. And after figuring out the volume it seems as though you already subtracted for drivers and horn?

As far as stuffing goes…..<“Damping is standard BR, sealed QL = 7, so basically lined or lightly stuffed down to just above the vent.”> would a layer of something like 6“ rockwool against the back panel down to ‘just above the vent’ suffice for a start?

I like tight ‘heart attack fast’ transients, i’m not familiar with the term ‘upper mass corner’ but will look it up, I’m assuming the red (8”) version will be more accepting to vent damping? And in this application does the grill cloth matter whether its across the inside or outside of port?

Another thing crossed my mind, does the wiring (series vs parallel) of the two woofers make any difference for these parameters? My plan is parallel.

I’d heard of the ‘click test’ and will definitely implement it here…..thanks for the excerpt.

Would there be enough difference between your design and Matt’s to build them both? My original goal was to build several versions and see which is best……..i have enough to do the GM, Matt, and a sealed w/sub version.

Last edited:

Before I had computer simulations I'd use a hand calculator, pencil and paper. I'd spend a weekend plotting the effect of various filters on a driver's response and plotting it on graph paper. I'd measure them using a signal generator, oscilloscope, multimeter and sound level meter.

The first simulator I had was one that I wrote myself to automate the process, so I guess the computer is helpful but not essential.

The first simulator I had was one that I wrote myself to automate the process, so I guess the computer is helpful but not essential.

Lol, I thought I was saying the opposite. In any case I expect you will find all the help you need here to slide into it 😉

I have a binder with lots of hand calls— I did have an HP11 — but were for my all torn PA. What Allen did was harder

dave

dave

I need you back from reality GM ! 😉

Outstanding questions are……

1) port location for the 32 Hz (8” port/red) tuning? From what i gather this dimension is critical.

2) Here’s what i’ve got for final dimensions (red, 8”) 12.5”X18.5”X57.5” I.D. = 217.9 L > 213 L (after subtracting drivers/horn displacement) 16” driver CTC / 38“ tweeter HT ………..correct?

3) lined/lightly stuffed from top down to just above port……..i suppose experimentation?

4) For critically damping the vent……is barrier over inside or outside better (or doesn’t matter)?

5) Does driver wiring (series vs parallel) matter to these parameters?

Thats enough to get me started

Thanks again,

Bob

Outstanding questions are……

1) port location for the 32 Hz (8” port/red) tuning? From what i gather this dimension is critical.

2) Here’s what i’ve got for final dimensions (red, 8”) 12.5”X18.5”X57.5” I.D. = 217.9 L > 213 L (after subtracting drivers/horn displacement) 16” driver CTC / 38“ tweeter HT ………..correct?

3) lined/lightly stuffed from top down to just above port……..i suppose experimentation?

4) For critically damping the vent……is barrier over inside or outside better (or doesn’t matter)?

5) Does driver wiring (series vs parallel) matter to these parameters?

Thats enough to get me started

Thanks again,

Bob

Sorry, but I need to put this on hold because I've been trying to keep up when apparently not alert enough and ATM not even sure I've been answering correctly nor up to the task ATM. 🙁

Wow, sorry GM………I hope my over enthusiasm didn‘t stress you out! Certainly wasn’t my intention 🙂

Wife is going back to the mountains for 2 wks over thanksgiving was the what for on the hastiness, wanted to cobble something while she was gone…….reckon i’ll start on Matt’s version and see how that plays out.

Hopefully we can get back to it in the future 😎

Wife is going back to the mountains for 2 wks over thanksgiving was the what for on the hastiness, wanted to cobble something while she was gone…….reckon i’ll start on Matt’s version and see how that plays out.

Hopefully we can get back to it in the future 😎

My near term goals are to put a little more effort into figuring out how not to be such a compu-idiot…….

Except for the port height, if you could pass that along. And after figuring out the volume it seems as though you already subtracted for drivers and horn?

As far as stuffing goes…..<“Damping is standard BR, sealed QL = 7, so basically lined or lightly stuffed down to just above the vent.”> would a layer of something like 6“ rockwool against the back panel down to ‘just above the vent’ suffice for a start?

I like tight ‘heart attack fast’ transients, i’m not familiar with the term ‘upper mass corner’ but will look it up, I’m assuming the red (8”) version will be more accepting to vent damping? And in this application does the grill cloth matter whether its across the inside or outside of port?

Another thing crossed my mind, does the wiring (series vs parallel) of the two woofers make any difference for these parameters? My plan is parallel.

I’d heard of the ‘click test’ and will definitely implement it here…..thanks for the excerpt.

Would there be enough difference between your design and Matt’s to build them both? My original goal was to build several versions and see which is best……..i have enough to do the GM, Matt, and a sealed w/sub version.

You're welcome!

I'm nearly one, have only learned just enough to get by to do my hobbies, shop online, etc..

8.5" up from the bottom.

Actually, I don't bother till the cab is small enough to make an audible difference, so technically no, though my design routines all have an ample fudge factor to increase acoustic efficiency.

6" rockwool is way too much except for sealed IME; 1" heat/AC duct board has always been my choice, especially since back then I could get a garbage bag full of scrap whenever I needed it and in the rare cases I needed more, just layered/stacked on more to 'taste'. 'Lightly stuffed' is if you use one of the popular fiberfils or similar.

Any vent can be critically damped/whatever on the outside, though never tried on the inside other general light stuffing the cab, but guessing it would work also.

The only place I recall learning about Fhm in technical detail is in this AES doc that Altec copied to me ~ at the time.

Series/parallel has no impact on box design, just electrical sensitivity, though better to parallel as it will draw less current = less VC heat rise/thermal power distortion.

If interested enough in DIY audio, then having the means to make multiple cab alignments for comparisons is a good plan; you wouldn't believe the number of box/TL/horn alignments I cobbled together to create some (barely) usable 'rules-of-thumb' (ROT) since I couldn't do the higher math required.

Nowadays we've advanced to the point where for the most part we don't need to know much of anything to create a usable starting point or 'spot on' IF we have sufficient listening/'feeling' experience to meet our performance goals.

- Home

- Loudspeakers

- Multi-Way

- 10” MTM design help