Thanks for that idea - i could test it out on a tiny print to see if it works.

You may reduce the size by reducing the grid of the 3D model, without drawbacks.the Gcode file comes out too large in file size to fit on the machines memory

Thank you very much.Hi @kodomo,

Nylon easily absorbs humidity.

If you don't have already do this, you could check this steps:

- Drying the parts in an oven, maybe few hours at low temp like 50° celsius. Be aware of a potential shrinkage. Measuring the throat hourly.

- Cleaning with isopropyl alcohol

- Sanding the surfaces

- Cleaning again

- Quick drying with an hairdryer

Is the glue good, not too old ?

Are the 2 parts mixed correctly?

It's possible to pour the glue in a cup to see the quantity and mix by hand

I cleaned them with iso, resand the surfaces, cleaned and quickly dried with a heat gun.

The glue is new and I am using its own mixer. I applied and waited 24h.

Today I put them together and they seem to hold (for now). I am waiting for 24h like this and then I will put some stress on them to see/hear if anything is happening.

Attachments

I'm not sure what that means 'reducing the grid' is that a slicer specific thing? I don't see anything useful when searching for this term. I did find 'decimate' to reduce a models detail. I'll see if i can make that work.You may reduce the size by reducing the grid of the 3D model, without drawbacks.

I don't know what do you mean by "with the troath", but no, there's supposed to be a gap between the ring inserts and the flange - see Fig. 9 here: https://www.at-horns.eu/gen2-4554.htmlDoes the top phase plug come together all in one piece with the troath?

BTW, all the three parts were intended to be printed separately. I'm not sure there's any advantage in doing it otherwise.

ah ok mabat, i will try again later, i did open the file and it was already on top of it i don't know why! thanks!I don't know what do you mean by "with the troath", but no, there's supposed to be a gap between the ring inserts and the flange - see Fig. 9 here: https://www.at-horns.eu/gen2-4554.html

BTW, all the three parts were intended to be printed separately. I'm not sure there's any advantage in doing it otherwise.

Yes, sorry I did not make myself more clear, I thought you would understand. Good luck!I did find 'decimate' to reduce a models detail. I'll see if i can make that work.

I've done one! Needs more sanding and painting but it works.

Unfortunately the image is very weird with one of these and one of the wood horns on the other speaker 😀 I might try tuning it out with dirac and it would be cool to see both the wood and plastic horn on a single graph.

Unfortunately the image is very weird with one of these and one of the wood horns on the other speaker 😀 I might try tuning it out with dirac and it would be cool to see both the wood and plastic horn on a single graph.

No, but i could try that too i guess. decimating it a lot has giving me a much smaller file size - I have however almost entirely printed the 2nd horn... so i might just see if it loads on there but not actually print it.@WerTicus - did you try to increase the layer height?

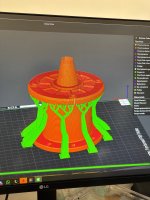

It would be pretty awesome as a single print:

no only this file , and keeps happening i don't why, i use the slicer in the bambu studioThat's funny, I've never seen that happen. Did you open all the STLs at once?

You are great!@kodomo - there's now a new version of the DF10.171K adapter available, a one-piece version.

View attachment 1425605

I will try thanks (it works) edit.try orca slicer maybe?

Last edited:

oh yeah just measured out my time alignment and the old tweeter was at 17.7cm back and the new horn has it at 4 cm back from the baffle. So that probably explains why the imagining is gone.

time align your **** folks makes a huge difference! (obviously very easy to do with the hypex plate amps)

time align your **** folks makes a huge difference! (obviously very easy to do with the hypex plate amps)

Thanks this worked the file is under 250mb and loads.... I can now buy 2kg more plastic and try a whole horn in one piece!Yes, sorry I did not make myself more clear, I thought you would understand. Good luck!

Do you realize that you will need whole new crossover filters to make it work properly? 🙂oh yeah just measured out my time alignment and the old tweeter was at 17.7cm back and the new horn has it at 4 cm back from the baffle. So that probably explains why the imagining is gone.

time align your **** folks makes a huge difference! (obviously very easy to do with the hypex plate amps)

It's not just "time alignment"...actually far from that.

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)