I don't have experience with center channels. We watch a lot of video content (blue-rays and netflix streaming) with just my normal 2-channel system.

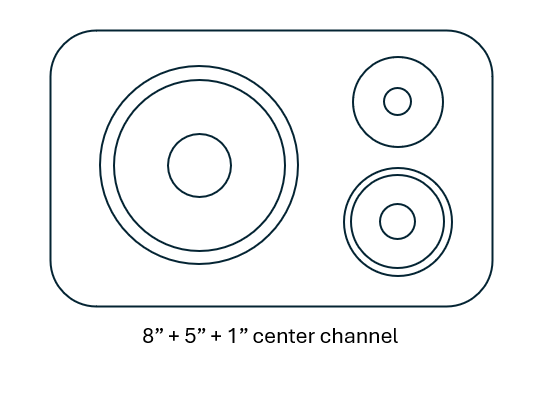

I have contemplated making a center channel, something with this kind of configuration:

Again, I have no experience with center channels, and no experience with multi-channel systems such as 5.1, 7.1, atmos, etc... I enjoy movies just fine with a standard 2-channel stereo system.

I have contemplated making a center channel, something with this kind of configuration:

Again, I have no experience with center channels, and no experience with multi-channel systems such as 5.1, 7.1, atmos, etc... I enjoy movies just fine with a standard 2-channel stereo system.

Hi,

For best results speakers should always be in-line(more or less) and vertical.

Otherwise dispersion off-axis left/right will have unnatural and not pleasant to listen response.

I suggest you take a program to simulate that.

There is one BoxSim made by Visaton, it also takes into account driver placement and listening angles.

Regards

For best results speakers should always be in-line(more or less) and vertical.

Otherwise dispersion off-axis left/right will have unnatural and not pleasant to listen response.

I suggest you take a program to simulate that.

There is one BoxSim made by Visaton, it also takes into account driver placement and listening angles.

Regards

With a crossover from woofer to mid of 400 Hz or less, the two drivers will be within 1/3 wavelength of each other. Horizontal dispersion will be affected only to a minor degree.

This sort of configuration is common to center channels in HT applications... especially because it tends to fit under or above a screen.

This sort of configuration is common to center channels in HT applications... especially because it tends to fit under or above a screen.

I have another question before i order drivers.

I'm tossing up between the waveguide/non waveguide tweeter.

I realise this decision will affect the whole design of my speaker and the front baffle setup.

In regards to this then, if i use a non waveguide tweeter, would i be best to put the 12" driver in the side of the cabinet

and have a skinnier and deeper speaker?

If i use a waveguide tweeter, i could possibly look at a wider shallower cabinet, more like Zaphs Sb12.3.

If there a general best practice in this regard?

Also i do like the look of @PKAudio 's project as you mentioned. He's done a nice job there.

https://www.diyaudio.com/community/...iesma-t34b-in-wg-18we-32w.365836/post-6777874

Thanks heaps, so close to hitting buy now on these drivers!

I'm tossing up between the waveguide/non waveguide tweeter.

I realise this decision will affect the whole design of my speaker and the front baffle setup.

In regards to this then, if i use a non waveguide tweeter, would i be best to put the 12" driver in the side of the cabinet

and have a skinnier and deeper speaker?

If i use a waveguide tweeter, i could possibly look at a wider shallower cabinet, more like Zaphs Sb12.3.

If there a general best practice in this regard?

Also i do like the look of @PKAudio 's project as you mentioned. He's done a nice job there.

https://www.diyaudio.com/community/...iesma-t34b-in-wg-18we-32w.365836/post-6777874

Thanks heaps, so close to hitting buy now on these drivers!

Hi,

1) I tested side placement of a woofer long time ago. IMO unless cross over point is low(e.g 100 Hz or so) it's not a good idea because of different directions. Also keep in mind that drivers must behave in a consistent manner to each other not only at crossing point but maybe +/- one octave from it.

2) I think if you plan to use cross over at 2k or so wave guide is important mainly for attempting to reduce distortion from tweeter.

There is a collection with lots of tests of various drivers at https://hificompass.com/en . You can check there which tweeters are possibly better for your pass band.

Regards

1) I tested side placement of a woofer long time ago. IMO unless cross over point is low(e.g 100 Hz or so) it's not a good idea because of different directions. Also keep in mind that drivers must behave in a consistent manner to each other not only at crossing point but maybe +/- one octave from it.

2) I think if you plan to use cross over at 2k or so wave guide is important mainly for attempting to reduce distortion from tweeter.

There is a collection with lots of tests of various drivers at https://hificompass.com/en . You can check there which tweeters are possibly better for your pass band.

Regards

Thanks for that Bazukaz,

I'll aim to keep all drivers on the front then, i'll just play with some different designs.

Would you aim for either the waveguide or non waveguide version of the same tweeter?

Also keep in mind I am thinking i might not build a centre channel to match these speakers, whether that makes any difference.

Thanks again

I'll aim to keep all drivers on the front then, i'll just play with some different designs.

Would you aim for either the waveguide or non waveguide version of the same tweeter?

Also keep in mind I am thinking i might not build a centre channel to match these speakers, whether that makes any difference.

Thanks again

It is not easy to come up with a design that incorporates a 12" woofer on the baffle, and also incorporates a minimum sized baffle around the tweeter. A tall trapezoid, perhaps. Or a two-box design. It is also possible to make the baffle very wide so that both the mid and the tweeter are presented with an infinite baffle. in other words, the transition from 2pi to 4pi happens well below the mid-tweeter crossover. Something on the order of 50+ cm wide.

Hi again,Thanks for that Bazukaz,

I'll aim to keep all drivers on the front then, i'll just play with some different designs.

Would you aim for either the waveguide or non waveguide version of the same tweeter?

Also keep in mind I am thinking i might not build a centre channel to match these speakers, whether that makes any difference.

Thanks again

The wave guide acts like partially a horn, boosting efficiency at some frequency spectrum.

I recall testing one aluminium tweeter without and with wave guide attached. The wave guide was made by manufacturer and matched to it.

IMO wave guide made it blend better with the woofer, so I would consider a wave guide version, perhaps.

Of course not every wave guide is made the same so if you can find measurement data and compare it's the best.

Regards

With a CNC router, you could probably profile a 15" wide cabinet such that the baffle around the tweeter was pretty minimal. With that equipment, you have a lot of options.

Got a nice surprise in the post today. See attached pic.

Drivers are all ordered and coming mid next week. I'll start a build thread once i get started. Still working on cabinet design at the moment.

The more i look at @PKAudio design the more i like it.

Drivers are all ordered and coming mid next week. I'll start a build thread once i get started. Still working on cabinet design at the moment.

The more i look at @PKAudio design the more i like it.

Attachments

Yes I always thought it looked great, probably the best way to make a very low diffraction cabinet that is wide enough for a large woofer. This challenge is one of the reasons we see so many speakers that use a stack of 7" or 8" woofers rather than a single 10" or 12"... Managing the tweeter is much less complicated when the baffle is only 8" wide.

In your situation, with your superman router, you could vary the radius of the baffle edge from ~20 mm around the woofer to gradually increase to ~120 mm radius near the tweeter, and the result is that the tweeter will have a very minimal flat baffle area. This is a key component of good directivity performance through the crossover region.

If you decide to go with a waveguide, I recommend the Satori TW29BNWG as a turn-key option. Very nice aluminum waveguide combined with an excellent tweeter. You can also use the TW29TXN tweeter and install a waveguide. @augerpro has several designs which you can have 3D-printed. I should mention that Javad Shadzi offers an aluminum waveguide for the TW29TXN tweeter which he developed for his Helios TX project. You can contact him through his facebook page.

Be careful when handling the Hypex amp boards. It is very easy to ESD them and damage the components. In fact I would handle them as little as possible until you are ready to install them.

j.

In your situation, with your superman router, you could vary the radius of the baffle edge from ~20 mm around the woofer to gradually increase to ~120 mm radius near the tweeter, and the result is that the tweeter will have a very minimal flat baffle area. This is a key component of good directivity performance through the crossover region.

If you decide to go with a waveguide, I recommend the Satori TW29BNWG as a turn-key option. Very nice aluminum waveguide combined with an excellent tweeter. You can also use the TW29TXN tweeter and install a waveguide. @augerpro has several designs which you can have 3D-printed. I should mention that Javad Shadzi offers an aluminum waveguide for the TW29TXN tweeter which he developed for his Helios TX project. You can contact him through his facebook page.

Be careful when handling the Hypex amp boards. It is very easy to ESD them and damage the components. In fact I would handle them as little as possible until you are ready to install them.

j.

Thanks for the info,

I ended up ordering the beryllium tweeter, TW29BN-B. So i'll just adjust the baffle to make things work.

Thanks for the heads up on handling the boards, i'm not going to mount the boards inside the cabinets, i'm going to mount them in their on enclosure and hang them on the back. That way if i experiment in the future i can easily take them off to use them elsewhere.

Cant wait to get started. The hardest part now is modelling the radius on that baffle edge so i can send it out to the router. Have to touch up on my modelling skills now lol.

I ended up ordering the beryllium tweeter, TW29BN-B. So i'll just adjust the baffle to make things work.

Thanks for the heads up on handling the boards, i'm not going to mount the boards inside the cabinets, i'm going to mount them in their on enclosure and hang them on the back. That way if i experiment in the future i can easily take them off to use them elsewhere.

Cant wait to get started. The hardest part now is modelling the radius on that baffle edge so i can send it out to the router. Have to touch up on my modelling skills now lol.

@hifijim

Hi,

I was going to shoot you a PM to chase some advice but figured it could be a handy reference for anyone so i'll just ask some questions here.

Basically i'd like some advice on the process for me from here on.

All the drivers arrived today so i've got everything i need to get started. I also already had a DATS V2 & Umik-1.

I know roughly the crossovers i'll be aiming for based on your build, but what do I do from here?

Eg. Do i need to measure each driver in DATS, then do some measurements on each driver in REW?

If so, do i measure in my big room where the speakers will be, or i've got a 3mx3m room in the shed will full insulation to all walls/ceiling/carpet floor, so its a nicely dampened room, would that be better?

In the mean time i'm going to slap together some rough testing cabinets based on sizing from Winisd/Your build.

Any guidance from here would be great.

Thanks heaps

Hi,

I was going to shoot you a PM to chase some advice but figured it could be a handy reference for anyone so i'll just ask some questions here.

Basically i'd like some advice on the process for me from here on.

All the drivers arrived today so i've got everything i need to get started. I also already had a DATS V2 & Umik-1.

I know roughly the crossovers i'll be aiming for based on your build, but what do I do from here?

Eg. Do i need to measure each driver in DATS, then do some measurements on each driver in REW?

If so, do i measure in my big room where the speakers will be, or i've got a 3mx3m room in the shed will full insulation to all walls/ceiling/carpet floor, so its a nicely dampened room, would that be better?

In the mean time i'm going to slap together some rough testing cabinets based on sizing from Winisd/Your build.

Any guidance from here would be great.

Thanks heaps

First advice would be to read Kimmo Saunisto's measuring tutorial for REW and VituixCAD. For me this was first way to start measurements from "for dummies" to more advanced level...You don't have to use these programs of course, but it is nice overview of important things...

--->>>

And this is also good place to start....

--->>>

And this is also good place to start....

Keep in mind that these Hypex amplifiers only hold 50W of power for long periods of time (according to their own datasheets, NC 252MP).

This is a thermal limitation of the PSU.

I used to work quite a bit with these amplifiers.

Or in other words, adequate cooling is highly advised!!

This is a thermal limitation of the PSU.

I used to work quite a bit with these amplifiers.

Or in other words, adequate cooling is highly advised!!

So just to review, and to make sure we all know the starting point:

Woofer: SB34NRXL75-8

Mid: MW16TX-4 (or did you get the TX-8?)

Tweeter: TW29BN-B

Amp/DSP: Hypex FA253

Sealed box design

Is this correct?

The next stage is to design the baffle. This includes the size and shape, the location and spacing of the drivers, the the edge radius or bevel. This part of the design is very influential in the final directivity index from 500 Hz up, in fact I would say it is the dominant factor.

First step is to design a preliminary test baffle for the mid+tweeter. You can use the Vcad diffraction tool to simulate the response of a driver in a baffle. This tool assumes the driver is a perfect flat piston with a sensitivity of 0 dB. By loading each driver's diffraction simulation into the main crossover sim, you can model the complete system. The goal at this point is to make sure that this combination of driver spacing and geometries will yield acceptable performance with a plausible, reasonable crossover filter.

Next you should build a test box for the mid+tweeter. Perform a full set of horizontal polar measurements on the two drivers, and compare this to the simulation. The data you gather will be used in the next stage of refining your design. This step also allows you to get practiced at making these measurements, as it is easy to make errors.

It is possible to use the Hypex amp as your test amp for making measurements. But I found it is more convenient and less complicated to use a separate amp. A small class D 2-channel amp works well, you only need about 10W. I also find that a collection of test leads with alligator clips is very helpful.

I recommend a good basic XLR mic and a good basic USB audio interface. You don't need anything too fancy, I used a $100 Behringer UMC202HD for many years.

Woofer: SB34NRXL75-8

Mid: MW16TX-4 (or did you get the TX-8?)

Tweeter: TW29BN-B

Amp/DSP: Hypex FA253

Sealed box design

Is this correct?

The next stage is to design the baffle. This includes the size and shape, the location and spacing of the drivers, the the edge radius or bevel. This part of the design is very influential in the final directivity index from 500 Hz up, in fact I would say it is the dominant factor.

First step is to design a preliminary test baffle for the mid+tweeter. You can use the Vcad diffraction tool to simulate the response of a driver in a baffle. This tool assumes the driver is a perfect flat piston with a sensitivity of 0 dB. By loading each driver's diffraction simulation into the main crossover sim, you can model the complete system. The goal at this point is to make sure that this combination of driver spacing and geometries will yield acceptable performance with a plausible, reasonable crossover filter.

Next you should build a test box for the mid+tweeter. Perform a full set of horizontal polar measurements on the two drivers, and compare this to the simulation. The data you gather will be used in the next stage of refining your design. This step also allows you to get practiced at making these measurements, as it is easy to make errors.

It is possible to use the Hypex amp as your test amp for making measurements. But I found it is more convenient and less complicated to use a separate amp. A small class D 2-channel amp works well, you only need about 10W. I also find that a collection of test leads with alligator clips is very helpful.

The UMMik-1 is a USB mic I believe? To my knowledge, you cannot use a USB mic to get polar response data. Given the quality and expense of the drivers and hypex amps, and given the effort you will put into this project, you owe yourself the best possible design. Polar response data is 100% crucial in simulating and measuring the power response, the early reflections, and the other "power and DI" parameters.I also already had a DATS V2 & Umik-1.

I recommend a good basic XLR mic and a good basic USB audio interface. You don't need anything too fancy, I used a $100 Behringer UMC202HD for many years.

I use the analog output of my preamp (RCA jacks) to go into the Hypex, and the preamp controls the volume. Your plan sounds like it will work fine.How have you got your audio source setup for the Hypex amps?

Eg. In my scenario, i'll be running them from my Denon X3800h to control volume etc, i assume i just use the preout on the amp to the Hypex.

I would set a base volume on the hypex then use the normal volume control on the Denon?

Hi,@hifijim

Hi,

Eg. Do i need to measure each driver in DATS, then do some measurements on each driver in REW?

If so, do i measure in my big room where the speakers will be, or i've got a 3mx3m room in the shed will full insulation to all walls/ceiling/carpet floor, so its a nicely dampened room, would that be better?

In the mean time i'm going to slap together some rough testing cabinets based on sizing from Winisd/Your build.

If steady signal measurements are done then nice +/-1 dB frequency response of good drivers can suddenly become +/- 10 dB in a typical room : ).

A gated impulse response measurement with time window can improve a lot on this but low frequencies will be cut out.

Similar problem appears if room has treated walls but the treatment is only really effective where it's thickness is half the wave length or so.

This means with low frequencies it's a lot more tricky and results should be taken with a crystal of salt. I am using Arta a lot and love this powerful and simple to use tool.

Regards.

Hi again,

Yes those drivers are correct, Tweeter and Mid are both 4 ohm. Speaker will be sealed, Hypex FA253.

I've done my preliminary baffle design, same principal as @PKAudio design as i really like the look.

Preliminary pic attached.

In general it seems to get the tweeter and mid as close together as possible, so i've worked on that.

I did some reading on the mid to bass spacing and it was to be max 1/4 wavelength, so i've worked on that too.

(hope my terminology is correct here, correct me if i'm wrong)

I modeled up the MW16TX-4 in WinISD, a Q of .7 works out to 9Litres, the driver displaces about .5L and i was going to have the mid and tweeter together in a test box so i just added .1L for some tweeter displacement. So 9.6L internal volume.

I made a box to suit, routed the driver mounting on the CNC and fitted the drivers. It was just a rectangular box just for testing, no fancy baffle yet.

I had a play in the hypex software, managed to work out how to get the high and low passes going.

As a first test, i was pretty blown away by the sound quality.

Obviously its far from what it will sound like, but it can only get better from here.

Yes the Umik-1 is a usb mic.

Thanks I'll chase up the parts you mentioned.

In the mean time, should I get the CNC to create the front baffle and mount it to the front of my current box and put the drivers in it, so when i do measure it will be an accurate reflection of the final baffle design?

That will give me something to work on while i wait for the new parts.

Thanks again! Really appreciate everyone's time and advice

Yes those drivers are correct, Tweeter and Mid are both 4 ohm. Speaker will be sealed, Hypex FA253.

I've done my preliminary baffle design, same principal as @PKAudio design as i really like the look.

Preliminary pic attached.

In general it seems to get the tweeter and mid as close together as possible, so i've worked on that.

I did some reading on the mid to bass spacing and it was to be max 1/4 wavelength, so i've worked on that too.

(hope my terminology is correct here, correct me if i'm wrong)

I modeled up the MW16TX-4 in WinISD, a Q of .7 works out to 9Litres, the driver displaces about .5L and i was going to have the mid and tweeter together in a test box so i just added .1L for some tweeter displacement. So 9.6L internal volume.

I made a box to suit, routed the driver mounting on the CNC and fitted the drivers. It was just a rectangular box just for testing, no fancy baffle yet.

I had a play in the hypex software, managed to work out how to get the high and low passes going.

As a first test, i was pretty blown away by the sound quality.

Obviously its far from what it will sound like, but it can only get better from here.

Yes the Umik-1 is a usb mic.

Thanks I'll chase up the parts you mentioned.

In the mean time, should I get the CNC to create the front baffle and mount it to the front of my current box and put the drivers in it, so when i do measure it will be an accurate reflection of the final baffle design?

That will give me something to work on while i wait for the new parts.

Thanks again! Really appreciate everyone's time and advice

Attachments

Well, to produce large roundovers you will need very thick baffle, 60 - 80 mm, which is also good support for drivers. Or to construct it in some other way. Thiel was doing that for years and they did it well. For the first test you can construct similar baffle from some residuals and make roundovers from XPS, everybody is doing that to confirm that imagined shape has expected properties. It's a pity if you loose hours and hours of CNC work and some nice woods or plywood and then you need to change roundovers or something because measurements didn't go as expected....

But generally, you will not miss with shape you sketched...

On picture is my test front baffle, 60 mm thick, made from residual OSB and MDF. If measurements and sound will be OK I will do final baffle from 3 layer real maple wood...tear drop shape which will continue to the side walls to have nicely rounded speaker without to big disturbances...

But generally, you will not miss with shape you sketched...

On picture is my test front baffle, 60 mm thick, made from residual OSB and MDF. If measurements and sound will be OK I will do final baffle from 3 layer real maple wood...tear drop shape which will continue to the side walls to have nicely rounded speaker without to big disturbances...

For Ellips I did not use roundovers with large Radius. I use elliptical "roundovers", it works well, looks good, and it does not require too thick baffle. For Ellips the baffle was 50mm thick.

- Home

- Loudspeakers

- Multi-Way

- SB Acoustics 3 way active build - Advice