As a point of clarification since I am not that familiar with the Klippel implementation, does he do the measurements in a cylindrical data set? If so, then this has different functions than spherical and those details would have to be worked out. The Weinreich approach uses a spherical data set.

If so, then this has different functions than spherical and those details would have to be worked out.

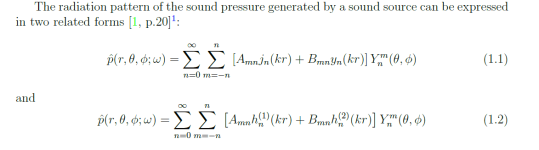

NTK's code uses these functions:

The 'r' is present in these functions and are thus used when 'fitting' the coefficients. Why do we need different functions?

Here is a figure made with his code where the 'measurements' were taken resulting in a cylindrical data set (with cap). The sound pressure is then re-evaluated at the two planes.

Yes they do with a top and bottom layerAs a point of clarification since I am not that familiar with the Klippel implementation, does he do the measurements in a cylindrical data set?

I suppose you are saying that the points need not be at a constant r because that is in the equation. I would agree with that, except that I am not sure of the double sphere reflection elimination works correctly in that case. The surfaces are not of a constant separable surface and may not be spatially uncorrelated, which might be required for the modes to all be orthogonal. I am not sure, but it would concern me. It could be a small error, or maybe not.

Thinking more about this and I can see problems and maybe a better solution. If any r can be used in the equations, i.e. one does not to be on a surface of constant r, then one could use a square box. A flat panel scanner (easy to make) could simply be rotated into the six positions necessary. That may (or may not) be easier to assemble.

But, I am seriously concerned that one needs to be on a constant coordinate surface for all this to work.

But, I am seriously concerned that one needs to be on a constant coordinate surface for all this to work.

That's a significant development.

Then I would make a square scanning array of mics, either as individual mics or a moving single mic and move this array to six sides. Much simpler than a full 360 unit. Bottom would be unique because of the support of the DUT.

Then I would make a square scanning array of mics, either as individual mics or a moving single mic and move this array to six sides. Much simpler than a full 360 unit. Bottom would be unique because of the support of the DUT.

“A novel method for measuring acoustic radiation fields of subwoofers based on non-free-field aspheric measurements”

I haven’t found an accessible copy of this paper. if someone has a link, please pass it along! I’d be interested in the details of their method.

Thanks,

Few

I haven’t found an accessible copy of this paper. if someone has a link, please pass it along! I’d be interested in the details of their method.

Thanks,

Few

In my old man's brain, I can imagine that since the polar pattern terms do not depend on r, then why should the r matter at all as long as you know, or can calculate what that r is. Spherical this is trivial because r is a constant, but that's not a necessity.

https://www.diyaudio.com/community/...r-on-a-shoestring.318151/page-31#post-7131533“A novel method for measuring acoustic radiation fields of subwoofers based on non-free-field aspheric measurements”

I haven’t found an accessible copy of this paper. if someone has a link, please pass it along! I’d be interested in the details of their method.

Thanks,

Few

In my old man's brain, I can imagine that since the polar pattern terms do not depend on r, then why should the r matter at all as long as you know, or can calculate what that r is. Spherical this is trivial because r is a constant, but that's not a necessity.

Are you saying that r doesn't need to be constant, just known?

So let me ask a question. To get a known distance when machining with a CNC milling machine as an example, you use a position sensor. A know distance from the machine table and set your tool tip distance.

Can we not do the same thing? A know distance from the DUT gets entered and then the software can start from a know position. It could be as simple as a measured stick placed between the mic and the DUT. And then you have an absolute reference.

Useful? Or superfluous?

Can we not do the same thing? A know distance from the DUT gets entered and then the software can start from a know position. It could be as simple as a measured stick placed between the mic and the DUT. And then you have an absolute reference.

Useful? Or superfluous?

The "r" in the equations is the distance to a fixed origin, it is not necessarily the distance to the DUT. The origin should be inside the DUT, but again I don't see that as a requirement.

It's so obvious to me now, in hindsight: We know from Green's theorem that if I know the field variable and it's gradient on any closed surface then I know its solution everywhere. This is the basis of BEM as well as many other concepts such as the Green's function. We get the pressure on the surface and then the gradient from a second surface and we have the complete solution. Any closed surface will do with the origin anywhere inside this surface.

It's so obvious to me now, in hindsight: We know from Green's theorem that if I know the field variable and it's gradient on any closed surface then I know its solution everywhere. This is the basis of BEM as well as many other concepts such as the Green's function. We get the pressure on the surface and then the gradient from a second surface and we have the complete solution. Any closed surface will do with the origin anywhere inside this surface.

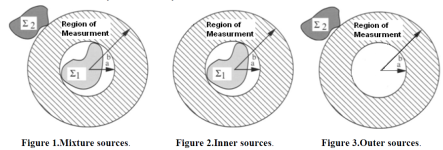

Yes, any (set of 2) closed surface in free space with only sources inside and outside of the (set of) surfaces:

But not limited to circles as in the image above.

I started typing a hole story that that might mean that everywhere one could place a mic would be free space as sound sources and reflectors need to be physical things and thus prevent a microphone from being placed there. But I guess you don't want to be in a space 'affected by diffraction', like around a corner. But I think that is only a theoretical limitation; just don't place a mic there.

But not limited to circles as in the image above.

I started typing a hole story that that might mean that everywhere one could place a mic would be free space as sound sources and reflectors need to be physical things and thus prevent a microphone from being placed there. But I guess you don't want to be in a space 'affected by diffraction', like around a corner. But I think that is only a theoretical limitation; just don't place a mic there.

And closed surfaces means no shortcuts like scanning only the half-space in front of the speaker, correct? It would be nice to ignore the space behind the speaker for quick-and-dirty measurements, but am I right when concluding that‘s not an option because it would prevent field separation? The same reasoning implies you can’t ignore the round caps at the top and bottom of the two cylinders (if cylinders are the selected surfaces), correct?

Reading a bit on both REW and on the Speakertester Pro manual I see a physical measurement is not exactly needed. A chirp and a time of flight calculation seems to be enough. I'm guessing temperature humidity and barometric pressure being the variables, but those constraints should not make for massive differences in the speed of sound in a moderate environment.So let me ask a question. To get a known distance when machining with a CNC milling machine as an example, you use a position sensor. A know distance from the machine table and set your tool tip distance.

Can we not do the same thing? A know distance from the DUT gets entered and then the software can start from a know position. It could be as simple as a measured stick placed between the mic and the DUT. And then you have an absolute reference.

Useful? Or superfluous?

Erin's video on using the Klippel device shows an initial homing relative to a physical reference point. He just jogged the mic by eye to put it over a pointer in a known location, so it seems straightforward enough. That seems like the best bet to me. I'd be worried about ambiguities slipping in if time of flight were relied on. I'm saying this with zero real-world experience with a scanner, of course!

Few

Few

- Home

- Design & Build

- Software Tools

- Klippel Near Field Scanner on a Shoestring