Were those prices from Solen?

Yes Solen, but I just checked and that driver is now $326. Cdn

🙂

Correct.The statement "In hypex horns, m increases monotonically from throat to mouth." (where m = flare rate) does not apply to hyperbolic-exponential horns that have a T flare parameter value greater than 1.

But in practical terms, the vast majority of hypex horns are designed to have T < 1, to increase loading at Fc vs. pure exponential (T = 1).

A hypex horn with T > 1 would have the opposite effect, and so it is rarely pursued (to the best of my knowledge, at least).

So, my statement implicitly referred to Hypex horns with T < 1 (such as the TADs and Yuichi's, which have T = 0.7, or sometimes T = 0.6).

A hypex horn with T > 1 would have the opposite effect, and so it is rarely pursued

Except for a hyperbolic-exponential horn with T = ∞, otherwise known as a conical horn 🙂.

OK, so I will try and explain how I understand the issue here (i.e., the conditions for obtaining a "best" match between a compression driver and a horn).

0) A few definitions first. For an expanding duct of area Sx at distance x from the origin, the "flare rate" m is defined as m = 1/Sx * dSx/dx.

If the expansion of the duct is exponential (T = 1 in Salmon's equation), then m is constant throughout.

If the expansion profile is Hypex with 0 < T < 1 (to increase loading in the vicinity of the "cut-off" frequency Fc), then m increases monotonically along x.

1) We have a compression driver with an internal throat, characterised by a circular entry (at the end of the phase plug) of area S1, a circular exit of area S2, and a length L1.

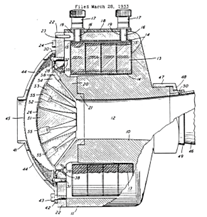

In the earliest original Western Electric 594A field-coil driver (which was the first "modern" compression driver with a sophisticated phase plug, after which ALL subsequent compression drivers have been modelled ever since), the expansion of the internal throat was actually exponential, with an Fc = 160 Hz. This value was chosen so that it could be mated to a large cinema horn of the very same expansion profile with no discontinuity at all in the flare rate.

However, it was soon realised that precisely casting an internal throat with an exact exponential expansion profile was unnecessarily costly, and that an acceptable approximation could be obtained by simply making the internal throat conical, while keeping the same S1, S2 and L.

That is because, over the first very few cm of length, a slow flare rate (i.e., low Fc) exponential is not too dissimilar from a simpler conical expansion.

From that moment on, ALL compression drivers have had a conical internal throat.

For instance, the first JBL 375 drivers were directly modelled on the WE 594A, but replaced the electromagnet with a permanent AlNiCo magnet.

The internal throat geometry was conical, with very similar (albeit not 100% identical) S1, S2 and L, i.e.: S1 = 11.3 cm2, S2 = 18.9 cm2 and L = 7.8 cm.

Using these numbers, once can thus calculate an Equivalent exponential flare rate (i.e., the flare rate that an exponentially expanding throat witht the same S1, S2 and L would have), which for the JBL 375 is m = 6.5, i.e., Fc = 180Hz.

The same calculations can be made for all other more modern compression drivers with an internal conical throat. Basically, you measure S1, S2 and L and calculate the equivalent exponential flare rate (and Fc) accordingly.

2) Starting from the geometry of the compression driver's internal throat (see 1 above), there is technically only ONE exponential horn that matches it perfectly without introducing any discontinuity in the expansion profile, and that is a horn having the exact same flare rate m.

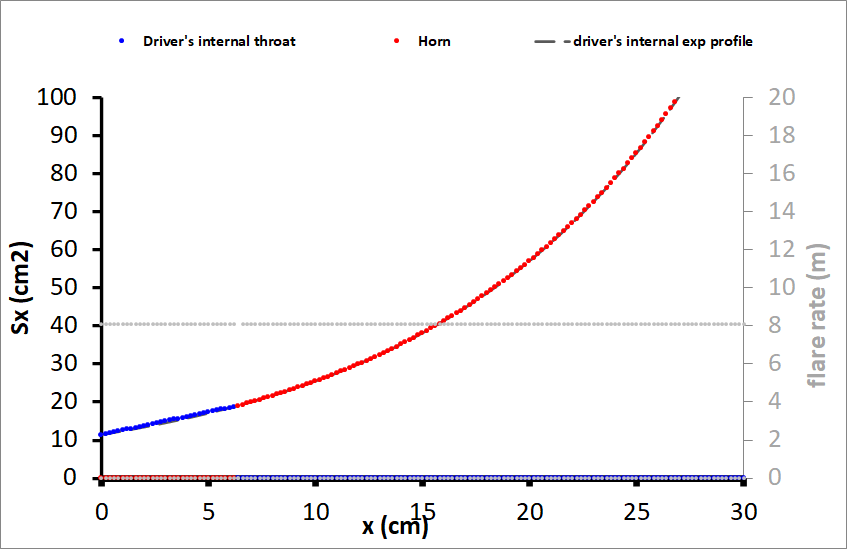

In the example below, we see plots of the expansion profile (Sx) and flare rate (m) along distance from phase plug (x), for the JBL 2450J driver.

In this particular case, the internal throat geometry has an equivalent exponential flare rate m = 8.1, and the best (only, really) matching exponential horn has the same m and Fc = 220 Hz.

If instead we opt for a hypex horn with T < 1, then m varies (increases) with distance x, and there are a number of combinations of T and Fc in Salmon's equation that lead to a flare rate m that starts out at the same value as the driver's internal equivalent exponential flare rate m.

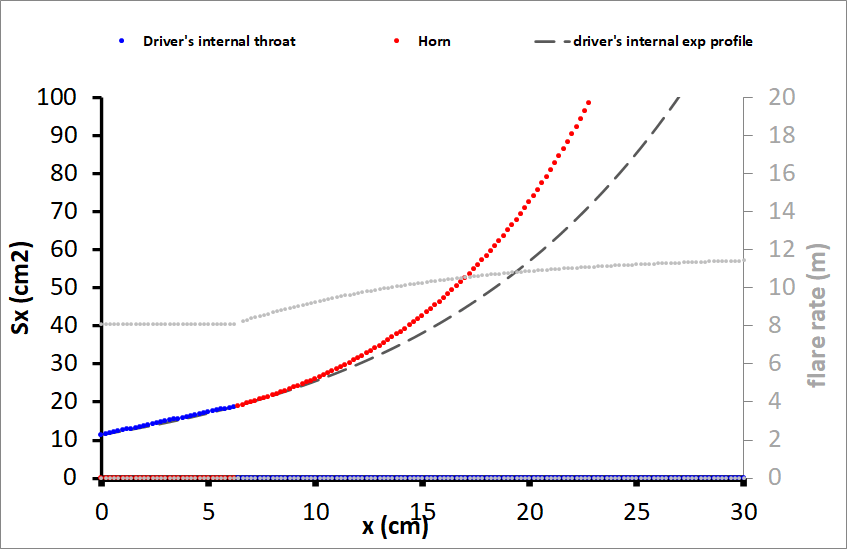

One such example is given below, once again for the JBL 2450J driver; the horn is Hypex, with Fc = 320Hz and T = 0.7 (does that ring a bell? ;-) those are the exact same parameters as the TAD TH-4001 horn!)

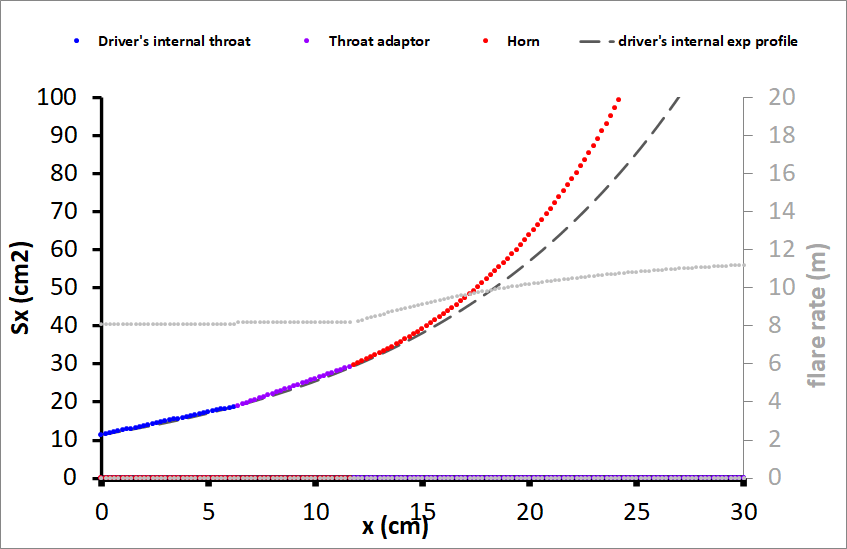

3) Now we introduce the throat adaptor. This is a necessary evil when we want to mate a driver's circular exit to a horn that has a non-circular throat. Ideally, it would be preferable to avoid the adaptor completely, and just have a horn with a round entry throat, and a smooth internal transition from circular to rectangular (if desired for directivity control) cross-section.

But in the real world, for many horns, there is in fact a throat adaptor, which has the difficult task of performing the transition from circular to rectangular cross-section, while maintaining to the best extent possible the same flare rate as that of the driver's internal throat (which, as per 2 above, also needs to match the horn's own flare rate - if the horn is exponential - or its INITIAL flare rate - if the horn is Hypex).

See below one more example, once again for the case of the JBL 2450J driver and a Hypex horn with Fc = 320Hz and T=0.7.

But in this case the horn throat is larger (S3 = 29.4 cm2, vs the driver's exit area S2 = 18.9 cm2), and between the two there is a 5.4cm-long throat adapter (the expansion of which along x is - for simplicity's sake - assumed to be linear, but for which we can also calculate an equivalent exponential flare rate, just like we did for the driver's internal throat):

OK, in a nutshell, THIS is how I see the issue of obtaining the "best" match between a compression driver and a horn.

As you see, there isn't much leeway, really. Only a very few driver & horn pairs can really work optimally (from the point of view of ensuring a smooth hand-over in terms expansion profile). All others are a bit of a kludge.

Of course, then, IN ADDITION to all of the above, there are ALSO other goals worth pursuing, such as, as already mentioned multiple times elsewhere in this thread, avoiding sharp discontinuities in terms of internal angles at the driver-adaptor and adaptor-horn joints.

I hope this helps!

Marco

P.S. the discussion above does not address the actual shape of the wavefront, which depends on the specific horn (e.g., radial horns assume cyclindrical wavefronts), and further complicates the issue of matching a driver to a horn (either directly or via a throat adaptor. See my previous post on this.

0) A few definitions first. For an expanding duct of area Sx at distance x from the origin, the "flare rate" m is defined as m = 1/Sx * dSx/dx.

If the expansion of the duct is exponential (T = 1 in Salmon's equation), then m is constant throughout.

If the expansion profile is Hypex with 0 < T < 1 (to increase loading in the vicinity of the "cut-off" frequency Fc), then m increases monotonically along x.

1) We have a compression driver with an internal throat, characterised by a circular entry (at the end of the phase plug) of area S1, a circular exit of area S2, and a length L1.

In the earliest original Western Electric 594A field-coil driver (which was the first "modern" compression driver with a sophisticated phase plug, after which ALL subsequent compression drivers have been modelled ever since), the expansion of the internal throat was actually exponential, with an Fc = 160 Hz. This value was chosen so that it could be mated to a large cinema horn of the very same expansion profile with no discontinuity at all in the flare rate.

However, it was soon realised that precisely casting an internal throat with an exact exponential expansion profile was unnecessarily costly, and that an acceptable approximation could be obtained by simply making the internal throat conical, while keeping the same S1, S2 and L.

That is because, over the first very few cm of length, a slow flare rate (i.e., low Fc) exponential is not too dissimilar from a simpler conical expansion.

From that moment on, ALL compression drivers have had a conical internal throat.

For instance, the first JBL 375 drivers were directly modelled on the WE 594A, but replaced the electromagnet with a permanent AlNiCo magnet.

The internal throat geometry was conical, with very similar (albeit not 100% identical) S1, S2 and L, i.e.: S1 = 11.3 cm2, S2 = 18.9 cm2 and L = 7.8 cm.

Using these numbers, once can thus calculate an Equivalent exponential flare rate (i.e., the flare rate that an exponentially expanding throat witht the same S1, S2 and L would have), which for the JBL 375 is m = 6.5, i.e., Fc = 180Hz.

The same calculations can be made for all other more modern compression drivers with an internal conical throat. Basically, you measure S1, S2 and L and calculate the equivalent exponential flare rate (and Fc) accordingly.

2) Starting from the geometry of the compression driver's internal throat (see 1 above), there is technically only ONE exponential horn that matches it perfectly without introducing any discontinuity in the expansion profile, and that is a horn having the exact same flare rate m.

In the example below, we see plots of the expansion profile (Sx) and flare rate (m) along distance from phase plug (x), for the JBL 2450J driver.

In this particular case, the internal throat geometry has an equivalent exponential flare rate m = 8.1, and the best (only, really) matching exponential horn has the same m and Fc = 220 Hz.

If instead we opt for a hypex horn with T < 1, then m varies (increases) with distance x, and there are a number of combinations of T and Fc in Salmon's equation that lead to a flare rate m that starts out at the same value as the driver's internal equivalent exponential flare rate m.

One such example is given below, once again for the JBL 2450J driver; the horn is Hypex, with Fc = 320Hz and T = 0.7 (does that ring a bell? ;-) those are the exact same parameters as the TAD TH-4001 horn!)

3) Now we introduce the throat adaptor. This is a necessary evil when we want to mate a driver's circular exit to a horn that has a non-circular throat. Ideally, it would be preferable to avoid the adaptor completely, and just have a horn with a round entry throat, and a smooth internal transition from circular to rectangular (if desired for directivity control) cross-section.

But in the real world, for many horns, there is in fact a throat adaptor, which has the difficult task of performing the transition from circular to rectangular cross-section, while maintaining to the best extent possible the same flare rate as that of the driver's internal throat (which, as per 2 above, also needs to match the horn's own flare rate - if the horn is exponential - or its INITIAL flare rate - if the horn is Hypex).

See below one more example, once again for the case of the JBL 2450J driver and a Hypex horn with Fc = 320Hz and T=0.7.

But in this case the horn throat is larger (S3 = 29.4 cm2, vs the driver's exit area S2 = 18.9 cm2), and between the two there is a 5.4cm-long throat adapter (the expansion of which along x is - for simplicity's sake - assumed to be linear, but for which we can also calculate an equivalent exponential flare rate, just like we did for the driver's internal throat):

OK, in a nutshell, THIS is how I see the issue of obtaining the "best" match between a compression driver and a horn.

As you see, there isn't much leeway, really. Only a very few driver & horn pairs can really work optimally (from the point of view of ensuring a smooth hand-over in terms expansion profile). All others are a bit of a kludge.

Of course, then, IN ADDITION to all of the above, there are ALSO other goals worth pursuing, such as, as already mentioned multiple times elsewhere in this thread, avoiding sharp discontinuities in terms of internal angles at the driver-adaptor and adaptor-horn joints.

I hope this helps!

Marco

P.S. the discussion above does not address the actual shape of the wavefront, which depends on the specific horn (e.g., radial horns assume cyclindrical wavefronts), and further complicates the issue of matching a driver to a horn (either directly or via a throat adaptor. See my previous post on this.

Last edited:

Let me also illustrate one example of a such a "kludge" that clearly does NOT work optimally.Only a very few driver & horn pairs can really work optimally (from the point of view of ensuring a smooth hand-over in terms expansion profile). All others are a bit of a kludge.

The Radian 950PB has a shallow internal conical throat with the following measurements:

S1 = 9.95 cm2 (circular phase plug exit with r1 =3.56 cm),

S2 = 20.43 cm2 (circular driver exit with r2 =5.1 cm),

L = 4.2 (resulting in the stated 21 degree exit angle).

These parameters lead to an internal equivalent exponential flare rate m = 17.3 (Fc = 474 Hz).

When paired with the Yuichi A-290 horn (Hypex expansion, Fc = 290Hz, T = 0.7), the following rather extreme mismatch in flare rate is the result:

Last edited:

By way of comparison / contrast, here's instead the TAD TD-4001, paired with the same Yuichi A-290:Only a very few driver & horn pairs can really work optimally (from the point of view of ensuring a smooth hand-over in terms expansion profile).

I think this analysis explains a lot of what was measured (see start of this thread).

So the way to map the differences in relation to effect would be to change the horn throat in sims until its a smooth transition then build that horn (same driver) measuring/comparing fr to the previous (existing) version?

I really have no idea but that seems logical to me.

As to matching existing hardware it seems as simple as keeping the angle copacetic……with a smooth (not stepped) transition, yes / no?

I really have no idea but that seems logical to me.

As to matching existing hardware it seems as simple as keeping the angle copacetic……with a smooth (not stepped) transition, yes / no?

Last edited:

I have a question…. is Sx defined flat or curved (3D surface)? As one approches the mouth, this makes a small difference.

I would not over-rate this issue as long as we do not have a complete mismatch between driver and horn. As rough guide I would say first off (a already mentioned by others) if the driver does not have any conical exit section it leaves the job to the horn designer if a slow or fast opening flare is intended.

Second, if any driver exit section is present then it should have a lower or equal equivalent cut-off frequency. A lower value is no problem for me. Maybe you could even add a "short plane wave tube" (resonance...) and it should work.

But the Radian drivers are somewhat strange. I had a 745Neo and it had a suspicious hole in the back cover. Asking the Radina folks it is intended to protect the diaphragm. For normal home listening levels this hole could be closed (I will not take any responsibilities about driver issues for larger levels!). So if there is a ventilation hole in the back cover/cap then close it and measure again the impedance ;-)

Second, if any driver exit section is present then it should have a lower or equal equivalent cut-off frequency. A lower value is no problem for me. Maybe you could even add a "short plane wave tube" (resonance...) and it should work.

But the Radian drivers are somewhat strange. I had a 745Neo and it had a suspicious hole in the back cover. Asking the Radina folks it is intended to protect the diaphragm. For normal home listening levels this hole could be closed (I will not take any responsibilities about driver issues for larger levels!). So if there is a ventilation hole in the back cover/cap then close it and measure again the impedance ;-)

Curved.I have a question…. is Sx defined flat or curved (3D surface)? As one approches the mouth, this makes a small difference.

In principle, Sx should be the area of the actual wavefront surface (see my previous post on this).

In practice, at short distances x from the throat, crudely assuming a flat wavefront will not lead to a large error.

But the main issue with many "modern" drivers is that the internal equivalent cut-off frequency is rather high, thereby precluding meeting this condition of yours.Second, if any driver exit section is present then it should have a lower or equal equivalent cut-off frequency. A lower value is no problem for me.

Therefore a good match between these drivers and many older/larger hypex horns designed to load well into the lower midrange isn't possible.

The 951 should be a better match as it does not have this fast opening conical exit section. Anyway I have found some older impedance shots of 745neo with ventilation hole open and closed.

red=open, blue=closed.

The 745neo was attached to SL400Hz with a way too small mouth area so ignore the double peak as it should be mostly horn related.

red=open, blue=closed.

The 745neo was attached to SL400Hz with a way too small mouth area so ignore the double peak as it should be mostly horn related.

Yes, I’m seeing that as a problem With modern drivers.

Thanks for your posts above. I will ask follow up questions after coffee

Thanks for your posts above. I will ask follow up questions after coffee

@docali Thanks, I will measure this. Something else I want to try is running this driver without back cover, like Troy (Joseph Crowe) runs other drivers. Also it would not be hard to add an extra ring to increase the volume of the rear chamber so as to stuff it with wool felt. There is room to experiment and see if the performance for home hifi use can be improved. Long to do list

This generalizing statement is misleading. There are still enough modern drivers that are appropriate in the mentioned context.But the main issue with many "modern" drivers is that the internal equivalent cut-off frequency is rather high, thereby precluding meeting this condition of yours.

Therefore a good match between these drivers and many older/larger hypex horns designed to load well into the lower midrange isn't possible.

But then take care about diaphragm alignment when you unscrew the back cover. What I found insane with the 745Neo that the screws of the back cover at the same time fixed the diaphragm! This is a no go for me. I am not sure if the larger drivers have the same issue but if you are unsure how to correctly align a diaphragm then hands off ;-)@docali Thanks, I will measure this. Something else I want to try is running this driver without back cover, like Troy (Joseph Crowe) runs other drivers. Also it would not be hard to add an extra ring to increase the volume of the rear chamber so as to stuff it with wool felt. There is room to experiment and see if the performance for home hifi use can be improved. Long to do list

Last edited:

This will dramatically decrease efficiency. But to increase the rear volume would be an interesting experiment.@docali Thanks, I will measure this. Something else I want to try is running this driver without back cover, like Troy (Joseph Crowe) runs other drivers. Also it would not be hard to add an extra ring to increase the volume of the rear chamber so as to stuff it with wool felt. There is room to experiment and see if the performance for home hifi use can be improved. Long to do list

There's a simple solution to the curvature mismatch: http://www.at-horns.eu/release/R-OSSE Waveguide rev7.pdf#page=21 (pages 21 - 27).

(Be it wall curvature or flare rate, these seem to be the same thing after all.)

(Be it wall curvature or flare rate, these seem to be the same thing after all.)

- Home

- Loudspeakers

- Multi-Way

- Matching horns to compression drivers, a discussion