Yes I have my amp. Like Turboeatch2 said, I have two behringer Nu6000DSP.

UM15 are indeed ordered. And will be here tomorrow.

the only thing is, I didnt measure very well. In my head, the door of my cabinet were 16 inch, but thats the depth of the cabinet. I have 48inch between couche and cabinet, -24in door, I am left with 24 inch for ''free space'', remove 10inch for legs when sitting on couch, I have 14 inch left for a 15 inch driver. hahah but thats my bad. ill have to deal with the fact that door dont open fully without moving the table (same problem we have now with the 36inch round table). So ill make the table 16.5x16.5x40. reducing a bit on the internal volume.

if xmax of the driver is 19mm. is it same to make my grill 19mm deep? at 19mm would have a pet/bug screen

or is it better to have a couple of mm over the xmax ?

from winisd, with tthe smaller box ill make will not be reached. (yes, but at like 10hz, which woul dbe at -25db almost)

UM15 are indeed ordered. And will be here tomorrow.

the only thing is, I didnt measure very well. In my head, the door of my cabinet were 16 inch, but thats the depth of the cabinet. I have 48inch between couche and cabinet, -24in door, I am left with 24 inch for ''free space'', remove 10inch for legs when sitting on couch, I have 14 inch left for a 15 inch driver. hahah but thats my bad. ill have to deal with the fact that door dont open fully without moving the table (same problem we have now with the 36inch round table). So ill make the table 16.5x16.5x40. reducing a bit on the internal volume.

if xmax of the driver is 19mm. is it same to make my grill 19mm deep? at 19mm would have a pet/bug screen

or is it better to have a couple of mm over the xmax ?

from winisd, with tthe smaller box ill make will not be reached. (yes, but at like 10hz, which woul dbe at -25db almost)

If you use the sub inside your room, it is hardly possible to reach this kind of extreme excursion while living beings are there.

Second, if you have a look at the DSP settings, it has a "Peak Limiter" page. You can set a maximum voltage there. So even when you increase the input level too much, the amp's output will stay under this value.

Last there is a function "Dynamic EQ" which compresses at certain frequency. So for example you may get a maximum gain of -10dB at 20Hz, but full output of 0dB at 40 Hz. Just play with it to get an idea. You have two of these and can even limit a certain frequency, while left and right of it is not limited.

You should read a little about limiter and adjusting them to fully understand and use all parameter.

Second, if you have a look at the DSP settings, it has a "Peak Limiter" page. You can set a maximum voltage there. So even when you increase the input level too much, the amp's output will stay under this value.

Last there is a function "Dynamic EQ" which compresses at certain frequency. So for example you may get a maximum gain of -10dB at 20Hz, but full output of 0dB at 40 Hz. Just play with it to get an idea. You have two of these and can even limit a certain frequency, while left and right of it is not limited.

You should read a little about limiter and adjusting them to fully understand and use all parameter.

Just butting in here for a nano-second.

If "Fast Bass" is the one with no hangover and a fast return to rest/no ringing then there is such a thing.

But for most of us it's a storm in a teacup, due to being unable to afford these excellent drivers.

A 30Hz wave form is a 30Hz waveform etc: etc: etc>

I think the Wilson Benesch Torus infrasonic generator is a very fast low frequency speaker ( don't call it a subwoofer, they ask ) and they are not cheap for sure. The truth is that an accurate and loud enough bass speaker requires some serious BOM and R&D.

BTW- two of them toruses (tori?) have appeared on HiFiShark. One of them is in my city.... still... more than four grand.

IMHO, the idea of creating a woofer array of low displacement small drivers or sort of a mini Pipe Oh (large transmission line) is likely the DIY way to make a fast, accurate, low hangover, no ringing, low frequency driver. Done right, you ought to be able to use it with an electronic parametric crossover at worst... or a simple low pass filter at best.

Yeah.... I was afraid, after I posted my original note, that the term would resonate with some people, in a negative way.

The link in GM's post is quite good. It claims, with some cogent proofs, that it is the inductance of the voice coil that creates the phase shift... therefore the heavier (greater mass of ) the cone, the more powerful the voice coil (and more inductance) and a greater phase shift. That means that cone mass does affect the phase shift of the bass.

Last edited:

The tread starter already has an amp. Reading the thread helps if one wants to add something useful.

A very capable Class D amp with a DSP and very comfortable 2x 1000+x watt rms.

He has also ordered his two 15" chassis with a static Le of 1.3mH. The amp will not have any problems at all to move the 280gram cone "fast" enough with more than 2kW program power. 2kW are usually enough to move even a fat butt on a scooter.

Maybe not fast enough for anyone, scooter and cone...

Give it up, please.

Yes I have my amp. Like Turboeatch2 said, I have two behringer Nu6000DSP.

UM15 are indeed ordered. And will be here tomorrow.

the only thing is, I didnt measure very well. In my head, the door of my cabinet were 16 inch, but thats the depth of the cabinet. I have 48inch between couche and cabinet, -24in door, I am left with 24 inch for ''free space'', remove 10inch for legs when sitting on couch, I have 14 inch left for a 15 inch driver. hahah but thats my bad. ill have to deal with the fact that door dont open fully without moving the table (same problem we have now with the 36inch round table). So ill make the table 16.5x16.5x40. reducing a bit on the internal volume.

if xmax of the driver is 19mm. is it same to make my grill 19mm deep? at 19mm would have a pet/bug screen

or is it better to have a couple of mm over the xmax ?

from winisd, with tthe smaller box ill make will not be reached. (yes, but at like 10hz, which woul dbe at -25db almost)

So, you got a door into your 10x10 space and the woofer table is going to block it.

How big is the space behind the door? A hallway?

How about, buy a solid core door, mount the drivers on it, put the current door in storage, mount the new door, not a "swinging baffle" and use that as your subwoofer? You will have a volume behind it measured in cubic yards and it will be out of the way. You might even build a simple "box" cover for the drivers. It should have to be very deep... the only caveat being that it will have to be closed to operate.

Audiophile lore details someone who build a speaker into the wall between his living room and garage, during the weekend when his wife was gone on a trip. It doesn't say what happened when stereo came on... but the idea of building such a thing makes a lot of sense.

Was asking for my speaker grill. and wanted to know If i use 3/4 birch ply if it wouold cause problem with the excursion. So I understand that it will not cause issue.If you use the sub inside your room, it is hardly possible to reach this kind of extreme excursion while living beings are there.

Second, if you have a look at the DSP settings, it has a "Peak Limiter" page. You can set a maximum voltage there. So even when you increase the input level too much, the amp's output will stay under this value.

Last there is a function "Dynamic EQ" which compresses at certain frequency. So for example you may get a maximum gain of -10dB at 20Hz, but full output of 0dB at 40 Hz. Just play with it to get an idea. You have two of these and can even limit a certain frequency, while left and right of it is not limited.

You should read a little about limiter and adjusting them to fully understand and use all parameter.

Nah, its the tv cabinet door. cabinet is 97-98 inch wide with 4 doors. each door are 24in.So, you got a door into your 10x10 space and the woofer table is going to block it.

How big is the space behind the door? A hallway?

How about, buy a solid core door, mount the drivers on it, put the current door in storage, mount the new door, not a "swinging baffle" and use that as your subwoofer? You will have a volume behind it measured in cubic yards and it will be out of the way. You might even build a simple "box" cover for the drivers. It should have to be very deep... the only caveat being that it will have to be closed to operate.

Audiophile lore details someone who build a speaker into the wall between his living room and garage, during the weekend when his wife was gone on a trip. It doesn't say what happened when stereo came on... but the idea of building such a thing makes a lot of sense.

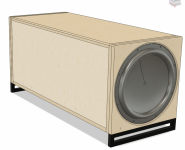

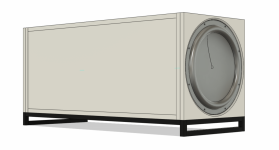

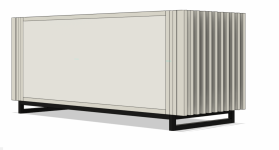

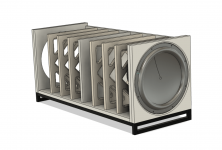

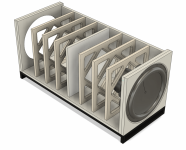

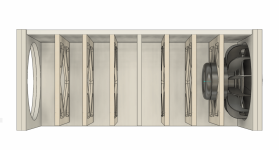

linked some screenshot or a render in this post.

https://www.diyaudio.com/community/...-a-home-theater-subwoofer.393057/post-7195669

Like I should have measure better before, but our table is a 36in roud at the moment, so will still be able to open those cabinet door more than what we can now. this house is very not that big! XD

Nah, its the tv cabinet door. cabinet is 97-98 inch wide with 4 doors. each door are 24in.

linked some screenshot or a render in this post.

https://www.diyaudio.com/community/...-a-home-theater-subwoofer.393057/post-7195669

Aaah, that's right.

You could use some bifold doors. Cut one or two of those doors in half and use a piano hinge.

Or can you sacrifice one or two of those bottom storage areas? Build the subwoofer into them? Sort of like a slide in box.

its actually a good idea to build into them, and I've been suggested this already. But like I said, house is 1000 sq feet. without a basement, nor a 2nd floor. Storage is a real estate I cannot cut on. all the bottom cabinet are already in use with AVR, PS5, Switch, security camera nvr, apple tv, ethernet switch, philips hue bridge and storage for laptop, misceanlenous wire/cable, ipad.Aaah, that's right.

You could use some bifold doors. Cut one or two of those doors in half and use a piano hinge.

Or can you sacrifice one or two of those bottom storage areas? Build the subwoofer into them? Sort of like a slide in box.

i'll have to check about piano hinge. Its ikea cabinet, and its high gloss, if I cut the door, i'm scared itll show.

i'll figure this out when its built! haha.

im 3d printing a 1:10 subwoofer prototype as we speak just for the kick.

its actually a good idea to build into them, and I've been suggested this already. But like I said, house is 1000 sq feet. without a basement, nor a 2nd floor. Storage is a real estate I cannot cut on. all the bottom cabinet are already in use with AVR, PS5, Switch, security camera nvr, apple tv, ethernet switch, philips hue bridge and storage for laptop, misceanlenous wire/cable, ipad.

i'll have to check about piano hinge. Its ikea cabinet, and its high gloss, if I cut the door, i'm scared itll show.

i'll figure this out when its built! haha.

im 3d printing a 1:10 subwoofer prototype as we speak just for the kick.

Build a narrower coffee table with drawers and use that for the missing storage when you make the slide in woofer cabinets for the storage.

That may depend on what kind of EQ you are running, how much power, what frequency, etc. Xmax is not normally a hard limit. It's an indication of the linear range of the driver. Xmech or Xdamage is the physical limit of the suspension, and on some drivers it can be significantly larger.Was asking for my speaker grill. and wanted to know If i use 3/4 birch ply if it wouold cause problem with the excursion. So I understand that it will not cause issue.

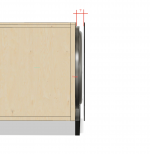

I'm also not clear on where your 19 mm of grille depth is starting. The flange of the driver and the surround both may protrude beyond the baffle depending on how the driver is mounted. Sorry if you already dealt with this earlier. The thread is getting long, so it's hard to keep track of everything.

yeah, its getting long. No worries. I didnt think I would have 10 page of reply when starting this thread haha.That may depend on what kind of EQ you are running, how much power, what frequency, etc. Xmax is not normally a hard limit. It's an indication of the linear range of the driver. Xmech or Xdamage is the physical limit of the suspension, and on some drivers it can be significantly larger.

I'm also not clear on where your 19 mm of grille depth is starting. The flange of the driver and the surround both may protrude beyond the baffle depending on how the driver is mounted. Sorry if you already dealt with this earlier. The thread is getting long, so it's hard to keep track of everything.

In the past, the box had double baffle, but from previous comment, this is not required (since there will be bracing).

so the I had the woofer on the first baffle, and I had a second 0.75in plywood on top of the first.

So basically, my question is, what is the 'safe' distance for a grill to be (from flange, baffle, or anything else)

I'll probably recess the driver like 6 mm in the 0.75in plywood.

From Dayton audio tech sheet, the flange thickness isnt spec'ed.

Attachments

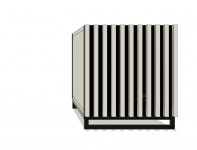

Updating on the ''gril'' design: as in the screenshot, the woofer is recessed in the second baffle (outermost).

One 3/4 plywood is added for distance from driver. Bug/pet screen, or maybe laser cut acrylic. than 'slat' for aesthetic.

Last Screenshot is without the grill...

One 3/4 plywood is added for distance from driver. Bug/pet screen, or maybe laser cut acrylic. than 'slat' for aesthetic.

Last Screenshot is without the grill...

Attachments

I'd be making it to clear X-Max plus 50%.

My opinion about expanded metal lath/mesh remains the same tho

My opinion about expanded metal lath/mesh remains the same tho

This is a good plan! Me n' others have converted sliding and/or hinged panel closet doors to slat/vented with Winter clothing to act as bass traps.You could use some bifold doors.

I know the divider is not 45,If you build a divider, just do not make it in a 90° angle, but something from 25-45°. That way the sound does not get reflected as a straight wave, which fits exactly one wavelength, leading to a strong resonance, By the way, inside bracing has some sound wave diffusing properties too.

This is something I do if it is possible, just to make a good design better. It is no "must do", as the usual sub woofer theoretically does not emit high frequency which will fit between the walls. Anyway, it can not do any harm, is usually no extra cost and can reduce harmonics.

With DIYS you can do what the industry ignores, mostly to cut cost's at any corner.

Maximum level from your speakers largely depends on the low cut they get. Usually 80 Hz, you may lift that to 100 Hz without any negative effect.

Calculate the level by the sensitivity and the max power they are build for. Like 86dB 1 watt/ 1 meter equals 96dB with 10W and 106dB driven by 100W.

If you cut them at 100Hz with 12 dB/Oct or steeper, in practice you should be able to hear very loud.

Anyway, the usual AVR will not deliver much watt if you use all channels. The impressive 120W per channel may be reduced to 5x 40W, even less if you have 8 Ohm speaker. You sure do not want to drive your main, center and surround speaker into clipping! A weak AVR will reduce the headroom, which may make the amp sound stressed.

If we talk stereo HIFI, a sub woofer reduces load on main speaker and main amp, which leads to much better sound. With the average AVR this relieve is already included in the design, as it has no power hungry sub frequency amp stage build in.

I was quite surprised when I replaced my Onkyo TX-NR818 AVR with a Denon X-4100W.

The Onkyo put 48.5 lb on the scale, the Denon is a 28 lb featherweight in comparison.

I'm under the impression the Onkyo had more “slam” with the same speakers.

I have planed to beef up the Denon with some external amps anyway...

But how’s that for bracing?

Attachments

That cabinet looks really good.

Calculating costs, I think you shoud use stripes of wood, as otherwise you would have a lot of waste. On the other hand, you could use cheap particle board for the braces, which would not matter cost wise. The strength of plywood on such braces is overestimated. Particle board even has better inner damping properties, it's acoustic is more "dead". You can do the cut outs with a good hacksaw free hand. Might be too expensive to have so many meters CNC'd.

I would go for ply on the outside and particle for the inner parts, even when the wood was for free. MDF is fine, too. The divider can be particle board as well and 16mm are OK, because it does not see any pressure if both drivers get the same level. The wheight sums up....

The divider, as I told you, does not have to be angled, it is just a "nice to have" if it fits the design.

Calculating costs, I think you shoud use stripes of wood, as otherwise you would have a lot of waste. On the other hand, you could use cheap particle board for the braces, which would not matter cost wise. The strength of plywood on such braces is overestimated. Particle board even has better inner damping properties, it's acoustic is more "dead". You can do the cut outs with a good hacksaw free hand. Might be too expensive to have so many meters CNC'd.

I would go for ply on the outside and particle for the inner parts, even when the wood was for free. MDF is fine, too. The divider can be particle board as well and 16mm are OK, because it does not see any pressure if both drivers get the same level. The wheight sums up....

The divider, as I told you, does not have to be angled, it is just a "nice to have" if it fits the design.

Mmm.That cabinet looks really good.

Calculating costs, I think you shoud use stripes of wood, as otherwise you would have a lot of waste. On the other hand, you could use cheap particle board for the braces, which would not matter cost wise. The strength of plywood on such braces is overestimated. Particle board even has better inner damping properties, it's acoustic is more "dead". You can do the cut outs with a good hacksaw free hand. Might be too expensive to have so many meters CNC'd.

I would go for ply on the outside and particle for the inner parts, even when the wood was for free. MDF is fine, too. The divider can be particle board as well and 16mm are OK, because it does not see any pressure if both drivers get the same level. The wheight sums up....

The divider, as I told you, does not have to be angled, it is just a "nice to have" if it fits the design.

Made me think.

If I wanted to have that kind of bracing, I could like you said cut strip of wood and glue them, then get the router in there with a template. 🤓🤔( I have acces to a laser cutter, so I could make an acrylic template, then batched them out using the router. But it won’t cut through 1/2, 3/4 plywood, nor 3/4 mdf)

Will have to check if I have mdf on hand.

3/4 birch plywood is insane in my area. 150$ for a 4x8 sheet.

That’s good to k ow about the other material. What you mean by particle board?

Meaning OSB or melamine?

Edit: okay, just check the mdf price.

I can have 3 sheet of 4x 8 for the price of 1 birch plywood.

I think I’ll make the outermost shell (all sides, 1 baffle) and inner most baffle and brace will be in mdf. I’ll save 100$

This is particle board.

Even as it is cheap, it is a very good material for speaker cabinets. Maybe the best. It is the cheapest panel, made from wood left over and glue. So in HIFI peoples "more expensive is always better" mindset this can not be a perfect material...

You can make an instrument out of ply wood, in fact guitars are made from it, "sounding" = resonating well. Particle board is the opposite. you won't get any nice sound out of it. For a very simple explanation, sound energy has to jump randomly from different size particle to particle, from dense to not so dense, turning sound into heat. Contains a lot of air, too.

Con: You can easily damage it at corners and edges. Carpenters hate it, as you have to hide it from sight. Painting it is a PITA.

MDF is harder, producing a more metallic sound. Quite heavy, too. It is much better for producing good looking objects. So any wood worker will tell you to use it for speaker cabinets, even as it may sound worse. Carpenters convenience product. Sales people are not objective.

If you want something robust, that may get wet and bumped around, birch ply wood construction is best, so you make a good PA speaker from it. A little resonance does not bother anyone.

OSB is a very special stuff. I don't like it in cabinet construction, it even isn't that cheap any more. Maybe for a workshop speaker.

See, I'm in Germany. wood prices have gone crazy in the last few years. You 150$ 3/8 -4' by 8' panel would cost me Euro 250, in questionable quality, not usable for living room use without additional veneer. I would be happy to get it so "cheap".

- Home

- Loudspeakers

- Subwoofers

- Need help designing a home theater subwoofer