Slowly there’s progress. I finally have two prototypes for stereo listening and they sound VERY promising. The phantom mid, the way they chisel the singer in the middle is uncanny. That’s why I’m posting the picture, everybody stopping by was convinced that the black / yellow / blue speaker in the middle was on (which of course it isn’t). Also the way one can hear for example reverb tails and other micro details is really really good. The crossover is still just on axis measurements -> REW auto eq -> LR filters. So there’s a lot to improve.

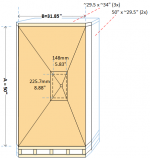

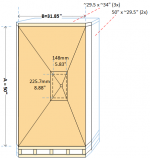

And there were a few issues to overcome. The biggest one is the vibrating of the waveguide itself. Without any treatment the colouring in the lower mids is really strong. With two layers of bitumen & aluminum it’s ok, but I’m not sure more than two layers in the front chamber of the woofers is a good idea so I kept it at two. I hope the epoxy coating that is planned in the future will help even more with rigidity. Also the small enclosure had to be modified for the woofers to even fit (bad planning). In case of the 6RS140 the basket and in case of the 6FE100 the magnet sticks out 'into the wall', in both cases I had to file / sand / route off some of the enclosure. I used 18mm baltic ply, but even with 15mm the basket / magnet would be too big. The pieces of wood for the 4-hole driver to screw into are glued with epoxy and that works really well.

As to drivers, which the damping in place the difference between the 6FE100 and the 6RS140 becomes quite obvious, unfortunately not in favour of the 6FE100. I’ve also tried different compression drivers and for now am sticking with the Faital HF108R. The Celestial 1730 sounds as it always does for me, very detailed, open and sparkly, but ultimately fatiguing. The ‘cheap’ Peerless that gets recommended some times just sounds terrible, basically broken to my ears, maybe that’s what it was (brand new though). The BMS 4538 sounds fantastic and with all the benefits one would expect from a small driver, but I don’t really trust it at 1300Hz even with a 4th order high pass. But I’ll spend more time with it, would be great if it works.

And there were a few issues to overcome. The biggest one is the vibrating of the waveguide itself. Without any treatment the colouring in the lower mids is really strong. With two layers of bitumen & aluminum it’s ok, but I’m not sure more than two layers in the front chamber of the woofers is a good idea so I kept it at two. I hope the epoxy coating that is planned in the future will help even more with rigidity. Also the small enclosure had to be modified for the woofers to even fit (bad planning). In case of the 6RS140 the basket and in case of the 6FE100 the magnet sticks out 'into the wall', in both cases I had to file / sand / route off some of the enclosure. I used 18mm baltic ply, but even with 15mm the basket / magnet would be too big. The pieces of wood for the 4-hole driver to screw into are glued with epoxy and that works really well.

As to drivers, which the damping in place the difference between the 6FE100 and the 6RS140 becomes quite obvious, unfortunately not in favour of the 6FE100. I’ve also tried different compression drivers and for now am sticking with the Faital HF108R. The Celestial 1730 sounds as it always does for me, very detailed, open and sparkly, but ultimately fatiguing. The ‘cheap’ Peerless that gets recommended some times just sounds terrible, basically broken to my ears, maybe that’s what it was (brand new though). The BMS 4538 sounds fantastic and with all the benefits one would expect from a small driver, but I don’t really trust it at 1300Hz even with a 4th order high pass. But I’ll spend more time with it, would be great if it works.

Attachments

I use the BMS 4538 in the same horn, crossing at 1250 hz LR 4. order, no problem even at high volumes, at least for home use. I have measured the distortion in REW with high levels, the mic was 3 meters away and the driver was behaving well distortion wise. Nice smooth driver at a fair price.

Thanks for chiming in, that's good to know. Out of curiosity, any more details about your setup you could share?

I skipped the basses because the horizontal polar pattern collapses anyway at around 700 hz in that waveguide. So I'm experimenting with a larger separate horn/waveguide with constant directivity down 200 hz for the bass, to sit below the 3d printet horn. You will not get the point source feeling all the way down, with that solution, but I think the controlled directivity is more important. And in the end I'll use DRC Designer to give me a nice step response, so the timing between the horns will be correct.

In my other all out Behemoth synergy horn, i used Bill Waslo's other 3d design (thanks for that 🙂) for the start of the horn and extended the sides with mdf boards, so it measured 140 x 90 cm. It has directivity down to 100 hz and uses the same drivers as the smaller horn, but with a 15" pa bass added.

In my other all out Behemoth synergy horn, i used Bill Waslo's other 3d design (thanks for that 🙂) for the start of the horn and extended the sides with mdf boards, so it measured 140 x 90 cm. It has directivity down to 100 hz and uses the same drivers as the smaller horn, but with a 15" pa bass added.

Last edited:

Did you take them into a speaker graveyard and torture chamber to scare them 🙂

Attachments

Last edited:

Did you take them into a speaker graveyard and torture chamber to scare them

Nice one 🙂

Some very impressive work done here. I have to take a crack at making one of these.

I have a few different ideas on using a different horn profile. Might be useful. Might be time to talk with the Gurus 🙂

I have a few different ideas on using a different horn profile. Might be useful. Might be time to talk with the Gurus 🙂

For these kind of horns unity/synergy/multi entrance horn I think constant directivity horns work the best. Either oblate spherical horns or conical (straight sided) horns with a roll-out of the mouth using a tractrix profile.

I skipped the basses because the horizontal polar pattern collapses anyway at around 700 hz in that waveguide. So I'm experimenting with a larger separate horn/waveguide with constant directivity down 200 hz for the bass, to sit below the 3d printet horn. You will not get the point source feeling all the way down, with that solution, but I think the controlled directivity is more important. And in the end I'll use DRC Designer to give me a nice step response, so the timing between the horns will be correct.

In my other all out Behemoth synergy horn, i used Bill Waslo's other 3d design (thanks for that 🙂) for the start of the horn and extended the sides with mdf boards, so it measured 140 x 90 cm. It has directivity down to 100 hz and uses the same drivers as the smaller horn, but with a 15" pa bass added.

View attachment 994889

Nice! And I see what you're saying, but for me the point source character is almost the most important aspect about this speaker. Can you point me to Bill's "other 3d design"? I think I missed that.

Did you take them into a speaker graveyard and torture chamber to scare them 🙂

Hehe, speaks for the audio quality that they even enjoyed spending time in the torture chamber!

Can' t remember where I saw it, but have some pics and also the STL file somewhere on one of my pc's. Let me know if you want it.

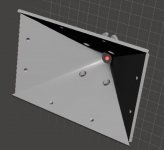

Here is the 3d start of the horn, it looks quite similar to the waveguide in this thread, but without the round over at the mouth.

The idea is that you can extent the horn as much as you want.

work in progress

Here is the 3d start of the horn, it looks quite similar to the waveguide in this thread, but without the round over at the mouth.

The idea is that you can extent the horn as much as you want.

work in progress

Oh, this is amazing! I had the same (obviously not very original) idea, but utterly failed at altering the STL I used into something like this. It looks like the throat goes straight to conical without any transition, but then the pictures are quite small and my eyes might be fooling me. But if you could send the STL my way, I'd be very happy.

Regardless of the size of the horn, this would certainly lead to a more sturdy version than printing the entire thing.

Regardless of the size of the horn, this would certainly lead to a more sturdy version than printing the entire thing.

I think the throat is OS style and then goes conical after that. The horn performs very well and works as intended. I will look for the STL file and send it to you.

You will find it all here

Index of /SynergyDIY/StubV6

And Bill's explanation on what the transition is here

3D printed 3-way Unity waveguide home audio speaker

Index of /SynergyDIY/StubV6

And Bill's explanation on what the transition is here

3D printed 3-way Unity waveguide home audio speaker

For these kind of horns unity/synergy/multi entrance horn I think constant directivity horns work the best. Either oblate spherical horns or conical (straight sided) horns with a roll-out of the mouth using a tractrix profile.

I do not like the sound of conical horns. I have been designing and building horns off and on since 1993. Built many different types of horns. Listened to many as well.

The LeCleach profile has always sounded very natural to me.

I would do it in wood if I made one. Bending wood id not so difficult for me as I was trained as a Cabinet Maker and worked in that for many years.

You are right.

And no they were not terminated properly. I didn't know enough to do this back then.

And no they were not terminated properly. I didn't know enough to do this back then.

I do not like the sound of conical horns. I have been designing and building horns off and on since 1993. Built many different types of horns. Listened to many as well.

The LeCleach profile has always sounded very natural to me.

I would do it in wood if I made one. Bending wood id not so difficult for me as I was trained as a Cabinet Maker and worked in that for many years.

Then you probably don't like most unity/synergy horns, as most of them seem to be more or less conical. All Danley's horn are conical, with af little mouth transition. Also the 3d horn in this thread goes almost conical after the throat OS transition, it actually looks a lot like SEOS horn. Where the walls meet they are rounded.

The horn stub is straight conical after the OS mouth transition. Wallmeetings in the start of the horn is slightly rounded, after there is a hard angle. For all it's worth🙂

You will find it all here

Index of /SynergyDIY/StubV6

And Bill's explanation on what the transition is here

3D printed 3-way Unity waveguide home audio speaker

thanks!

- Home

- Loudspeakers

- Multi-Way

- 3D printed 3-way Unity waveguide home audio speaker