The center to center spacing is sub-optimum which is one of the reasons I am interested in a horn with a lower cutoff, that and perhaps a fairly healthy dose.

The system is 3 way HF above 8kHz is handled by Fostex T825..

Like Pano suggested, moving the woofer closer to the horn should solve your ctc problem. You should measure where the woofer transitions to 90 degree radiation. That is the place to put the crossoverbecause the horn also has 90 deg dispersion. My crossover to a JBl2226 is around 750 hz. Trying to go lower is not necessarily going to sound better but a smooth handoff from one driver to the other will sound audibly better in my experience.

Edit: by smooth handoff I mean matching the directivity. I’m sure your crossover is good in terms of phase overlap.

Last edited:

Unfortunately as I have explained previously moving the woofers isn't an option, I would have to build new cabinets and need to live with what I've got.

Well the 500Hz experiment is over, I can't put my finger on what I did not like about running the 2380A to 500Hz but I could not get it sound as good as it did at 700Hz. There were some imaging problems, transient response and the tonal balance I could not get right despite a lot of fiddling with the DSP. Measurements did not tell any story - should have been OK.

Currently running at 600Hz and reduced the midrange drive by 2dB and re-equalized everything again. This sounds somewhat more cohesive, and the other issues are improved as well.

I am not sure about the 2380A horn, and have been offered a pair of JBL 2390 which I am going to try as a sanity check. (I doubt I will like them but I will have something to compare against.)

Does anyone know anything about the Francis Ibre 2 inch horn ?

Ibre 2 – A.L.G. Audio-Design

Or the Kinoshita ?

Well the 500Hz experiment is over, I can't put my finger on what I did not like about running the 2380A to 500Hz but I could not get it sound as good as it did at 700Hz. There were some imaging problems, transient response and the tonal balance I could not get right despite a lot of fiddling with the DSP. Measurements did not tell any story - should have been OK.

Currently running at 600Hz and reduced the midrange drive by 2dB and re-equalized everything again. This sounds somewhat more cohesive, and the other issues are improved as well.

I am not sure about the 2380A horn, and have been offered a pair of JBL 2390 which I am going to try as a sanity check. (I doubt I will like them but I will have something to compare against.)

Does anyone know anything about the Francis Ibre 2 inch horn ?

Ibre 2 – A.L.G. Audio-Design

Or the Kinoshita ?

Kevin, I can send you my spare 2445 driver if you can get a second one. You should give them a try before giving up on the 2380.

Greatly appreciate the offer, I did have a pair of 2445 at one point in time. I believe the Radian is better overall, but have never done a direct comparison. The 2445 is common here. (I still have OEM diaphragms for the 2445 here in fact.)

I am wondering about damping the horn bell in particular. I've discovered that floor leveling compound contains sand and a resin that sets up hard and rigid.. Don't know how that would work.. Have you damped yours and if so how?

This system is so complicated there are other possibilities that there are things I could/should have done differently. Thinking power amplification here. You know what they say about hindsight.

😀

I am wondering about damping the horn bell in particular. I've discovered that floor leveling compound contains sand and a resin that sets up hard and rigid.. Don't know how that would work.. Have you damped yours and if so how?

This system is so complicated there are other possibilities that there are things I could/should have done differently. Thinking power amplification here. You know what they say about hindsight.

😀

Last edited:

Rigid damping is probably not a good idea (unless very thick.) Something that stays elastic would be better - and has historically been used to good effect

A soft termination of the horn mouth also has sonic benefits. I've used terry cloth, lambs wool, foam and felt. Mr. Iwata used slats on his bass horns.

A soft termination of the horn mouth also has sonic benefits. I've used terry cloth, lambs wool, foam and felt. Mr. Iwata used slats on his bass horns.

A soft termination of the horn mouth also has sonic benefits. I've used terry cloth, lambs wool, foam and felt

I’ve done that. Felt.

dave

Does anyone know anything about the Francis Ibre 2 inch horn ?

Ibre 2 – A.L.G. Audio-Design

Or the Kinoshita ?

I'm wondering the same thing about these designs. Not that I've tried too hard, but I haven't come across much info on the development of the Iwata. I've have seen the very impressive measurements here.

I'm in the same boat as several others here, considering Yuichi, TAD, Iwata, et al for as low (of an uncompromised) cross as possible. I'm with camplo...one would think CAD routing/3d printing type fabrication would be a more accessible option than it seems to currently be with these devices.

I wish my skillet allowed me to be of some meaningful assistace to this effort! I do know that Joseph Crowe makes prepared CAD plans for the Yuichi and some others available for purchase at a very reasonable cost. His is the only effort in this regard I'm aware of.

Hi,

Tad and Kinoshita share the same roots, Kinoshita's being evolution of the TAD design. There is some variation for Kinoshita's afaik the later(?) design being infinite baffle oriented ( for studio use inwall, with some lowering of cutoff freq iirc).

Kinoshita's have the fins used.

Docali iirc, use a tad clone with a 1,4" and custom adapters with great results ( measured) and mitigate issues of 2", Marco Gea is the guy to ask about different Tad/Kino version and implementation as passive filter used were not simple for what i've seen.

For the Kino i've seen heard they were x around 480hz ( Rm7) or 640hz ( Rm4). Difference come from different behavior of direct driver used and layout.

Tad around 640hz.

Dsp could sure help to find an optimum filter here.

Tad and Kinoshita share the same roots, Kinoshita's being evolution of the TAD design. There is some variation for Kinoshita's afaik the later(?) design being infinite baffle oriented ( for studio use inwall, with some lowering of cutoff freq iirc).

Kinoshita's have the fins used.

Docali iirc, use a tad clone with a 1,4" and custom adapters with great results ( measured) and mitigate issues of 2", Marco Gea is the guy to ask about different Tad/Kino version and implementation as passive filter used were not simple for what i've seen.

For the Kino i've seen heard they were x around 480hz ( Rm7) or 640hz ( Rm4). Difference come from different behavior of direct driver used and layout.

Tad around 640hz.

Dsp could sure help to find an optimum filter here.

Docali iirc, use a tad clone with a 1,4" and custom adapters with great results ( measured) and mitigate issues of 2"

Hi,

this was not me 😛

I have an 18s ND4015Be attached with my custom brass adapter to the TH4001 horn. All passive solution. This is no problem with this combo.

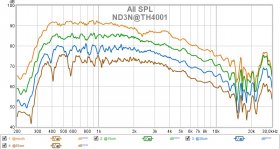

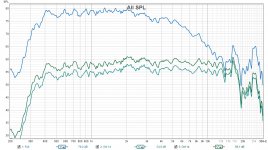

Some time ago I got my first results with a test setup using an autoformer. The following frequency response was the result of using only 4 parts. The AF itself, a resistor in series after the AF to the driver and a resonant circuit in of cap/coil in parallel to the AF:

The measurement is uncalibrated and show some room reflections. But the driver has plenty of headroom to pull it down to the level of the woofer. Nearly no further correction needed with 4 passive components and more than 5 octaves.

Docali that is a rather remarkable result. Are the lower two plots the left and right after your passive circuit? The factory frequency response of the ND4015Be looks like a typical 1.5" driver, it's not anywhere near as flat as what you show here.

Yes, that is amazingly good. Far better than I can achieve with 2 inch drivers without EQ. I achieved better unequalized results using 2420 on a 2392 horn to the best of my recollection something close +/-2dB from 500Hz - 8kHz at a meter.. (This was more than a decade ago so I no longer have any details unfortunately.)

Greatly appreciate the offer, I did have a pair of 2445 at one point in time. I believe the Radian is better overall, but have never done a direct comparison. The 2445 is common here. (I still have OEM diaphragms for the 2445 here in fact.)

I am wondering about damping the horn bell in particular. I've discovered that floor leveling compound contains sand and a resin that sets up hard and rigid.. Don't know how that would work.. Have you damped yours and if so how?

This system is so complicated there are other possibilities that there are things I could/should have done differently. Thinking power amplification here. You know what they say about hindsight.

😀

Yeah, the 2445s are common.

The 2380 horns I have are original JBL, made of very thick plastic or fiberglass or something. They are not like the newer, thinner, plastiky JBL horns. I don't find them to be resonant or needing any damping.

I downloaded Dirac yesterday and used it through JRiver. Have some observations to share, but maybe I'll do it at a later time so as to not divert attention from the discussion above.

Docali that is a rather remarkable result. Are the lower two plots the left and right after your passive circuit? The factory frequency response of the ND4015Be looks like a typical 1.5" driver, it's not anywhere near as flat as what you show here.

I should have explaining a little bit more. The blue line is the raw frequency response about 30 cm from mouth which is about 70cm from sound origin. So we will see a little bit more LF decrease if the mic would have been at 1m but not so much. The two green lines were different passive sets of the mentioned 4 components.

I already showed my own ND4015Be measurements here nad I cannot understand the quite bad results in VC magazine. Although these were done with an 1.5" to 2" adapter. I know the factory adapter and would not use it for HiFi. They never showed tests results for this driver in really good horn that loads low. The TH4001 is an extraordinary good horn. Maybe the flare version (Yuichi) are even better but I have no experience.

My 2380A are older JBL as well and are made of a structural polymer, they came off of a cinema speaker system some years ago.

I would be interested in your observations on Dirac3.

I have decided I am going to wait a while. I haven't received responses from any of the makers I contacted. (I have not contacted ALG yet, but seems the most likely choice)

I would be interested in your observations on Dirac3.

I have decided I am going to wait a while. I haven't received responses from any of the makers I contacted. (I have not contacted ALG yet, but seems the most likely choice)

Joseph Crowe makes prepared CAD plans for the Yuichi

CAD plans are fairly easy. Getting them converted into the 2 STL files needed to 3D print them (you need a BIG 3D printer), or CNC files is the hard part.

If you have access to either and can convert the dxf, 7 pieces per horn (2 halves + the vanes) and away you go.

Can’t currently get at the picture of the file.

dave

Attachments

These were done on a CNC as 2 pieces (plus fins):

They might be convinced to make more.

dave

These pictures weren't displaying for me last night for some reason. Very nicely done.

CAD plans are fairly easy. Getting them converted into the 2 STL files needed to 3D print them (you need a BIG 3D printer), or CNC files is the hard part.

If you have access to either and can convert the dxf, 7 pieces per horn (2 halves + the vanes) and away you go.

Can’t currently get at the picture of the file.

dave

Can you tell me more about the hard part? i.e., does the difficulty lie in accurately separating the single CAD file into multiple discreet CNC/printing plans, or the filetype conversion itself.... or both? Really appreciate your input. I'm in an area with relatively cheap and accessible fabrication options.

So depending on how hard the hard part is, I may be willing to give it a go.

Also would love to hear the Yuichi replacement horn on the Altec 604-8gs.

These pictures weren't displaying for me last night for some reason.

I let a domain expire.

dave

Can you tell me more about the hard part? i.e., does the difficulty lie in accurately separating the single CAD file into multiple discreet CNC/printing plans, or the filetype conversion itself.... or both? Really appreciate your input. I'm in an area with relatively cheap and accessible fabrication options.

I’d only be guessing. Never done it. The plan can be sliced for sheet material, but the intention was that one use a CNC with sufficient z to be able to do it in 2 halves, and then sandwich everything together.

The fins would need to be lifted out or left in and CNCed in place.

The CNC guy should know what to do for their machine.

It could also be sliced into pieces small enuff to print on whatever 3D printer is available.

Attention would ned to be made to accomodate finishing.

dave

- Home

- Loudspeakers

- Multi-Way

- Looking at Yuichi A-290 or TAD TH-4001 Clones: Makers