Using a closed back factory mid driver will limit the frequency they can reach down to and with the increase in the number of somewhat affordable CD's that can get to the same frequency on their own I struggle to see why anyone would choose that route unless they already had drivers from another project.

There is plenty of evidence that the ports cause changes to the polar and diffraction and that placing them closer to the throat to cross higher to the CD makes that progressively worse.

I made some simulations of a conical horn and the same horn with a secondary flare at double the main horn wall angle and it was actually much better than I thought it would be when terminated in an infinite baffle. There was no effort made to smooth the join between the CD exit and the Square entrance which I think is why there was still high frequency ripple.

Depending on how much effect the ports have on an Ath style horn it may well not be worth the extra construction difficulty if a MEH is wanted.

There is plenty of evidence that the ports cause changes to the polar and diffraction and that placing them closer to the throat to cross higher to the CD makes that progressively worse.

I made some simulations of a conical horn and the same horn with a secondary flare at double the main horn wall angle and it was actually much better than I thought it would be when terminated in an infinite baffle. There was no effort made to smooth the join between the CD exit and the Square entrance which I think is why there was still high frequency ripple.

Depending on how much effect the ports have on an Ath style horn it may well not be worth the extra construction difficulty if a MEH is wanted.

As I understand, for true synergy only conical profile is in consideration because the flare rate continuously changing from high at throat to lower toward the mouth.

Every frequency range has optimal flare rate so drivers are distributed along profile considering not only distance between them but flare rate as well.

Those last designs here are closest to hyperbolic profile.

Though from impedance plots is visible that some of them has short conical entry.

But always can be MEH

Every frequency range has optimal flare rate so drivers are distributed along profile considering not only distance between them but flare rate as well.

Those last designs here are closest to hyperbolic profile.

Though from impedance plots is visible that some of them has short conical entry.

But always can be MEH

I think the tradeoff is with HF pattern control re the throat diameter of 1” or even .75” CDs being used with a co-entrant horn. A closed back driver is of course not a requirement in this scenario but it helps where a standalone axisymmetrical waveguide is desired.

As far as the HF-1440 is concerned, I was considering using slot loaded woofers on either side (flanking the standalone waveguide) as a way to low the directivity even further. It’s still just an idea.

As far as the HF-1440 is concerned, I was considering using slot loaded woofers on either side (flanking the standalone waveguide) as a way to low the directivity even further. It’s still just an idea.

Last edited:

I'm not sure that is a trade worth making, beaming above 10K vs disruption of pattern control and diffraction further down.

I have a 1" CD and 2" drivers that were bough for exactly this scenario, they are still in the boxes, maybe one day I will build them and find out.

I have had a very similar idea for the HF1440, not completely worked out or properly simulated yet either.

I have a 1" CD and 2" drivers that were bough for exactly this scenario, they are still in the boxes, maybe one day I will build them and find out.

I have had a very similar idea for the HF1440, not completely worked out or properly simulated yet either.

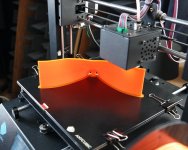

I'm really not experienced in 3D printing so what surprised me is that all the small surface glitches are virtually the same on both prints, which means this is actually determined by the slicer settings rather than by some random aberations. That would mean that the printer itself is capable to print it even better, which is encouraging. Right now it's printing the same with a different filament and 0.3 mm layer (it was 0.2 mm before - obviously an overkill).

Attachments

If one would make the mesh separating the 2 sides of a 3D printed WG (like the one above by mabat) reasonably "open", I wonder if a WG would keep its shape if one poured gypsum into it? Probably would need som air vents to not create air bubbles preventing the gypsum to completely saturate the inside mesh structure. I envision that one uses it as after the a cured pour, i.e. like a sandwich structure.

//

//

Last edited:

I guess you could easily make the wall separation larger and the infill density lower (and perhaps the walls thicker, which may not be necessary). Maybe not gypsum but something else with a lower viscosity.

After some own experiments and old experiences from others, it seems gypsum is a very nice material to use for these kind of applications. Is your hesitation for gypsum a "mechanical" aspect like how it pours or is it the finished state that you hesitate about? If it is the pouring I think one could make a few holes on strategic places which, once the gypsum starts to come out, indicating invasion, one could plug. The typical mixture for casting is still quite "milky" flowing.

//

//

TNT - I can't imagine how gypsum could be "poured" into this. Certainly not into what I have here - the gaps would have to much larger.

OK, not for this particular dimensions of thickness and mesh but maybe it could be a way of creating really stiff, dampened WGs if one allowed for pouring. The nice thing is that a 3D print would incorporate a reinforcement.

//

//

Trying to get Ath runing on my OS X comp after installing Wine as suggested above.. I get...

Jo-Mac-Pro:~ MacPro$ wine

Usage: wine PROGRAM [ARGUMENTS...] Run the specified program

wine --help Display this help and exit

wine --version Output version information and exit

Jo-Mac-Pro:~ MacPro$ wine cmd

Microsoft Windows 6.1.7601

Z:\Volumes\Home\Users\MacPro>

Z:\Volumes\Home\Users\MacPro\Applications\Ath>dir

wine: Read access denied for device L"\\??\\Z:", FS volume label and serial are not available.

Volume in drive Z has no label.

Volume Serial Number is 0000-0000

Directory of Z:\Volumes\Home\Users\MacPro\Applications\Ath

2/16/2021 11:00 AM <DIR> .

2/16/2021 11:09 AM <DIR> ..

1/12/2021 7:21 AM 135 ath.cfg

1/16/2021 8:23 PM 527,360 ath.exe

1/16/2021 8:31 PM <DIR> demos

1/16/2021 8:32 PM <DIR> doc

1/16/2021 8:30 PM <DIR> lib

1/16/2021 8:31 PM <DIR> misc

2 files 527,495 bytes

6 directories 54,083,899,392 bytes free

Z:\Volumes\Home\UsZ:\Volumes\Home\Users\MacPro\Applications\Ath>Z:\Volumes\Home\Users\MacPro\Applications\Ath\ath.exe

Can't recognize 'Z:\Volumes\Home\Users\MacPro\Applications\Ath' as an internal or external command, or batch script.

Z:\Volumes\Home\Users\MacPro\Applications\Ath>

A hint anyone?

//

Jo-Mac-Pro:~ MacPro$ wine

Usage: wine PROGRAM [ARGUMENTS...] Run the specified program

wine --help Display this help and exit

wine --version Output version information and exit

Jo-Mac-Pro:~ MacPro$ wine cmd

Microsoft Windows 6.1.7601

Z:\Volumes\Home\Users\MacPro>

Z:\Volumes\Home\Users\MacPro\Applications\Ath>dir

wine: Read access denied for device L"\\??\\Z:", FS volume label and serial are not available.

Volume in drive Z has no label.

Volume Serial Number is 0000-0000

Directory of Z:\Volumes\Home\Users\MacPro\Applications\Ath

2/16/2021 11:00 AM <DIR> .

2/16/2021 11:09 AM <DIR> ..

1/12/2021 7:21 AM 135 ath.cfg

1/16/2021 8:23 PM 527,360 ath.exe

1/16/2021 8:31 PM <DIR> demos

1/16/2021 8:32 PM <DIR> doc

1/16/2021 8:30 PM <DIR> lib

1/16/2021 8:31 PM <DIR> misc

2 files 527,495 bytes

6 directories 54,083,899,392 bytes free

Z:\Volumes\Home\UsZ:\Volumes\Home\Users\MacPro\Applications\Ath>Z:\Volumes\Home\Users\MacPro\Applications\Ath\ath.exe

Can't recognize 'Z:\Volumes\Home\Users\MacPro\Applications\Ath' as an internal or external command, or batch script.

Z:\Volumes\Home\Users\MacPro\Applications\Ath>

A hint anyone?

//

Last edited:

Did you ever go anywhere with the SB 2" I sent the profile for.

//

Measures...

//

Attachments

Using a mold, it would be possible to pour epoxy in it.

I don't know which or any epoxy would have favorable properties. But with some polishing it would be possible to make a transparent horn. That'd make a large horn less obtrusive in a living room.

I imagine making the housing of woofers with plexiglass. That would make some awesome looking speakers in my opinion. At least the most transparent sounding speaker (couldn't help myself 🙄)

I don't know which or any epoxy would have favorable properties. But with some polishing it would be possible to make a transparent horn. That'd make a large horn less obtrusive in a living room.

I imagine making the housing of woofers with plexiglass. That would make some awesome looking speakers in my opinion. At least the most transparent sounding speaker (couldn't help myself 🙄)

The glitches shown in the 3D print look like beginnings of layers - you could place the seam to a certain place by choosing "aligned" instead of "random" or "closest". Then, there would be only one seam line. Also, the retraction settings could be tuned a bit. I had the best results with PrusaSlicer and Slic3r being second best. I was not able to make good quality in Cura.

Depending on how much effect the ports have on an Ath style horn it may well not be worth the extra construction difficulty if a MEH is wanted.

I'm thinking a ported MEH would probably be better than a ported conical like my SH50. I have a BMS 4594HE which should be good down to 400-600hz, which gets rid of the mids and it's close proximity to the throat.

I think I'm going to go with a Tritonia style horn for easier woofer mounting.

I have lots to learn but this experiment is exciting 🙂

Attachments

As far as the HF-1440 is concerned, I was considering using slot loaded woofers on either side (flanking the standalone waveguide) as a way to low the directivity even further. It’s still just an idea.

Can you expand on this a little?

Using a mold, it would be possible to pour epoxy in it.

I don't know which or any epoxy would have favorable properties.

Most form of epoxy get very hot during cure, so melting the waveguide could be an issue. Polyurethane does not get hot.

That's still my plan: Acoustic Horn Design – The Easy Way (Ath4)Using a mold, it would be possible to pour epoxy in it.

I don't know which or any epoxy would have favorable properties. But with some polishing it would be possible to make a transparent horn. That'd make a large horn less obtrusive in a living room.

Fortunately, the transparent epoxy doesn't get hot (not even warm - at least the one I have at hand) but cures very very slowly, typically (which also helps the bubbles to get out).

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)