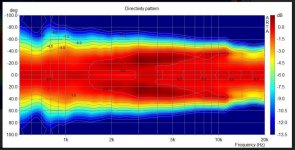

Look at the polar respons inn post 10513 under the text «sonogram storhornet», the large version. This is the best 600 Hz to 15000 Hz i have ever seen.

Is this with the JBL 2451Be or the TAD TD4003?

Attachments

Last edited:

Sure, I was reffering to metal diaphragms and the situation when the surround (suspension) and the diaphragm are from one piece of material as this situation is still very common. Also it seems to me that bending this plate near the edge must deform the whole structure, including the voice coil. I guess this holds for any material when clamped at the egde like that.

I would try to cut the suspension off the clamp and glue a foam ring between the edge and some mouting flange.

- BTW, the picture above seems to be heavily smoothed - 1/3 oct would make for a very coarse picture.

I would try to cut the suspension off the clamp and glue a foam ring between the edge and some mouting flange.

- BTW, the picture above seems to be heavily smoothed - 1/3 oct would make for a very coarse picture.

Last edited:

Sure, I was reffering to metal diaphragms and the situation when the surround (suspension) and the diaphragm are from one piece of material as this situation is still very common. Also it seems to me that bending this plate near the edge must deform the whole structure, including the voice coil. I guess this holds for any material when clamped at the egde like that.

.

Yes, the bending of the VC is also shown in Oclee-Brown's thesis (2nd pic.)

These issues probably also fuelled development of an annular diaphragm for the Axi2050.

Attachments

Last edited:

Yes, this is what I'm talking about I suppose. So my question is why to clamp the whole plate (diaphragm + suspension) at one point at the edge so it actually must be deformed for any axial motion of the voice coil? It seems to me that there must be a better way, like some elastic clamping of the whole suspension that would not require the deformation of the diaphragm but only of the suspending foam. It would get deformed anyway but to much lesser degree I suppose.

The bending (modes) are obviously related to the diaphragm material + suspension material, the combination determines the interaction.

These 2 seem well thought out, which is confirmed by Dickason's measurements:

Foam probably works well at low freqs, but I expect too much damping for hf.

These 2 seem well thought out, which is confirmed by Dickason's measurements:

Foam probably works well at low freqs, but I expect too much damping for hf.

Last edited:

A very small surround?

My solution would be an improved clone of G.T. Sound's Duraluminum diaphragm.

The Japanese produce the highest grades Aluminum (alloys and composites), but China and Russia are catching up.

My solution would be an improved clone of G.T. Sound's Duraluminum diaphragm.

The Japanese produce the highest grades Aluminum (alloys and composites), but China and Russia are catching up.

Last edited:

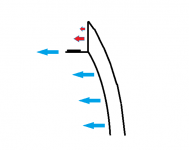

First and foremost, I would want a uniform pressure drive across the whole wall of the compression chamber, i.e. not to have any suspension in the chamber. The practical realization is another issue.

No I don't know what you mean.

- Maybe I should more precisely say that I want a uniform axial excursion across the cavity wall. In any case leaving a falling excursion towards the periphery of the chamber makes the situation a lot worse as the simulations suggest.

- Maybe I should more precisely say that I want a uniform axial excursion across the cavity wall. In any case leaving a falling excursion towards the periphery of the chamber makes the situation a lot worse as the simulations suggest.

Last edited:

Yeah, a "foam" stands for "something elastic" here. Maybe, given the dimensions and excursions involved, just a layer of a suitable permanently elastic glue could work, I don't know....Foam probably works well at low freqs, but I expect too much damping for hf.

Last edited:

Yeah, a "foam" stands for "something elastic" here. Maybe, given the dimensions and excursions involved, just a layer of a suitable permanently elastic glue could work, I don't know.

For Titanium and Aluminium diaphragms, I think Mylar/Polymer surrounds are preferred.

The all-titanium diaphragms in latest top of the line B&C drivers are mostly well behaved up to 12 sometimes even 15k.

Last edited:

Is this with the JBL 2451Be or the TAD TD4003?

JBL 2451 with Truextent

By the way, I got some really cheap tweeters which measure really awful - once I take the horn and phase plug off and measure the dome only, they are flat to 20 kHz. Some info here: Cheap compression tweeter tuning This could be a cheap test source with a convex membrane. Then it might be actually usable.

The green part is a kind of damping (material) I suppose?

I am definitely no expert in mechanics, but some (not too much) "cushioning" seems the best way to absorb (most of) the vibrational transmissions.

I am definitely no expert in mechanics, but some (not too much) "cushioning" seems the best way to absorb (most of) the vibrational transmissions.

The green part is the suspension - it would have to hold the diaphragm in place and allow for its axial motion.

The diaphram of the ND3ST looks suitable:

The diaphragm assembly is made by joining the former directly to the titanium dome on its upper bend edge. In comparison with a usual straight former joint, the driver's design assures extended frequency energy transfer for improved response linearity and unparallel reliability. This feature facilitates proper motion control of the dome in real working conditions.

The diaphragm assembly is made by joining the former directly to the titanium dome on its upper bend edge. In comparison with a usual straight former joint, the driver's design assures extended frequency energy transfer for improved response linearity and unparallel reliability. This feature facilitates proper motion control of the dome in real working conditions.

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)