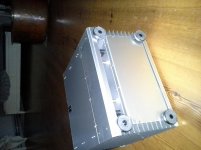

The design is mine, but the metalwork is made by pros. I did the drilling and assembly.

It is made by 1 mm alu, but I will go for 2 mm in the next one and I like to paint it with

"bmw diamond black metallic"

(1mm is too weak for this design)

/ t

It is made by 1 mm alu, but I will go for 2 mm in the next one and I like to paint it with

"bmw diamond black metallic"

(1mm is too weak for this design)

/ t

But I agree with Walter from Utrecht, is a good solution in use the 1mm aluminium, but is folded when that happen became stiffest than a similar of 4mm. The solution of the vertical connection to the 230v is a very handsome idea. And the rest of connections are not exposed and are protected by the hall space behind the amp. If you let me copy to you because I have a similar more tall than wide heatsinks making a cube. Beautiful DIY producto Señor.

You are free to do the same, of course ! that's what diy are -sharing tips and trix and helping. ;-)

In my design with these "broken" corners I had to cut of the corners of the heatsinks, but it is alu so that's not so

difficult.

In my design with these "broken" corners I had to cut of the corners of the heatsinks, but it is alu so that's not so

difficult.

Last edited:

Nice etching!

Thanks! I love to show off my etchings. 😀

(I don't know if the reference is lost in time, but "etchings" used to be a term for porn in Victorian times.)

Good work my dear😀

Thanks! About ready to take some pics of the metal work. Some drilling, tapping, sawing, filing left to do. 95% finished. I need also to plug it in and see if I let out any magic blue smoke. I plan on biasing it up and replacing those trim pots with fixed resistors. One step at a time!

Thanks! I love to show off my etchings. 😀

(I don't know if the reference is lost in time, but "etchings" used to be a term for porn in Victorian times.)

haha...I invited many girls to see mine all the time 😀

BA3 preamp

Recently finished BA3 front end, which is working nicely with a F5.

200VA, 22V trans from Antek. Regulated supply from JLM audio. K170 and J74 from Spencer. Alps 50K blue velvet pot and Mundorf Film Caps 10uf, 250V, MKP, both from partsconnexion. Case is HIFI2000.

You may not like the terminal block, but it was very handy.

Recently finished BA3 front end, which is working nicely with a F5.

200VA, 22V trans from Antek. Regulated supply from JLM audio. K170 and J74 from Spencer. Alps 50K blue velvet pot and Mundorf Film Caps 10uf, 250V, MKP, both from partsconnexion. Case is HIFI2000.

You may not like the terminal block, but it was very handy.

Attachments

Terminal blocks are just fine.

You can be assured of good contact and even clean them in the future if oxidation comes to call.

And...you can service your own gear more easily. I'm often surprised at how many times I revisit my projects for upgrades and adjustments!

You can be assured of good contact and even clean them in the future if oxidation comes to call.

And...you can service your own gear more easily. I'm often surprised at how many times I revisit my projects for upgrades and adjustments!

My F5

Hallo.

Excuse my bad english but I suppose everyone will understand me.

I finished my F5 clone built as a pair of mono amps.

The enclosure design is according to my DIY tube linestage.

I want to say thankyou to:

- First of all Nelson for sharing the circuit design. This is a great sounding amp!

- Mr. "stereoplay" for the NOS SJ74/K170 and the knobs.

- a_h for mosfets, tips and and pleasant contact.

A look inside the black building and more pics here.

F5 - My Photo Gallery

I know it´s a frequently asked question.

The heatsinks are a little bit to small. But I fished them for a couple of cents out of the bay hoping they doing their job well.

The Heatsink temperature rise up to 50 degrees C at a 20 degrees room temperature. Ventilating with the mini fans it´s 8 degrees less.

The fans are Sunon 12V Typs in serien connection driven by 13V(6,5V each).

They are whispering quiet and don´t disturb listening music even the sound is very quiet.

I greet all DIY guys´n ´girls.

Peter

Hallo.

Excuse my bad english but I suppose everyone will understand me.

I finished my F5 clone built as a pair of mono amps.

The enclosure design is according to my DIY tube linestage.

I want to say thankyou to:

- First of all Nelson for sharing the circuit design. This is a great sounding amp!

- Mr. "stereoplay" for the NOS SJ74/K170 and the knobs.

- a_h for mosfets, tips and and pleasant contact.

An externally hosted image should be here but it was not working when we last tested it.

A look inside the black building and more pics here.

F5 - My Photo Gallery

I know it´s a frequently asked question.

The heatsinks are a little bit to small. But I fished them for a couple of cents out of the bay hoping they doing their job well.

The Heatsink temperature rise up to 50 degrees C at a 20 degrees room temperature. Ventilating with the mini fans it´s 8 degrees less.

The fans are Sunon 12V Typs in serien connection driven by 13V(6,5V each).

They are whispering quiet and don´t disturb listening music even the sound is very quiet.

I greet all DIY guys´n ´girls.

Peter

- Home

- Amplifiers

- Pass Labs

- Pictures of your diy Pass amplifier