I built this pair of speakers for my brother’s workshop/garage. He has speakers on his workbench on either side of a PC monitor, and he is often standing at the bench as well as sitting. He needs the speakers to sound good in the nearfield, as well as being able to fill the garage with music.

His current speakers are the MTM version of the Paul Carmody Overnight Sensation. He likes these speakers, but when standing at the bench, he feels the tweeter is too low (it is basically aimed at his belly). I also believe that the MTM configuration might be aiming a null at his face when standing close.

I thought that making a new pair for him might be a fun project. He had some specific requirements:

- Maximum width of the cabinet is 7”.

- Tweeter must be at least 17” above the bench.

- No paper drivers due the garage environment which has drastic changes in temperature and humidity

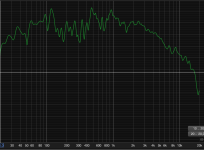

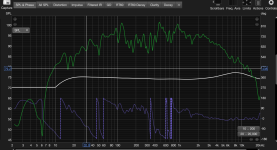

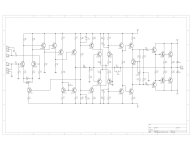

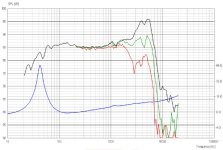

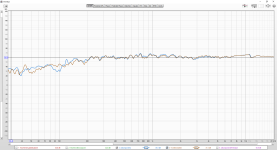

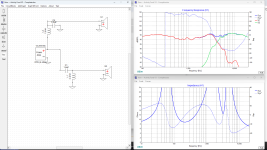

I have worked with the SB26CDC tweeter several times, and it is a great choice in the sub-$100 market. The sensitivity of 89 dB/m/2.83V is a bit low, but a small 2-way speaker is going to be low sensitivity anyway.

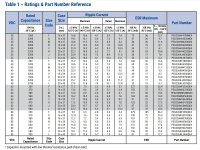

I wanted to use the SB17CAC35 woofer, but they were sold out in North America when I placed the order, so I used the very similar SB17NBAC35. I chose the 8 ohm version for two reasons. First, the Qts of the 8 ohm is more suitable to a sealed box, and second, his garage amp is an older A/V receiver, and he sometimes drives 2 pairs of speakers with it… no sense in burdening the amp with another 4 ohm speaker.

The cabinet was built from inexpensive “birch plywood” from Home Depot, labeled as made in Indonesia. I did not want to eat into my limited supply of Baltic birch, and I thought I would give this product a try. The plywood had some voids which had to be filled on the edges. It did not cut, machine, or sand as nicely as the Canadian made cabinet grade plywood I get from my hardwood lumber shop. There is no issue with the finished cabinet in terms of performance, but there was more work than necessary in working the material. In hindsight, I would have made the 30 mile trip to the lumber shop and paid $20 more for a sheet of maple or birch faced cabinet grade plywood. From now on I will stick with the Canadian stuff when I can’t get Baltic birch.

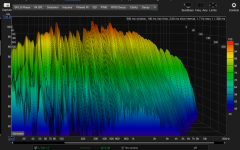

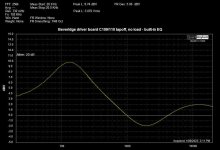

As I mentioned earlier, this is a sealed box design. That is my preference, I just prefer the quality of the bass from sealed box designs. It also reflects my own limitations as a designer. I have never been really satisfied with any vented box speaker I have ever built, and I find it very difficult to get the damping level just right so that both the bass and midrange sound correct. I have great respect for designers who can find the right combination of vent location, damping, tuning frequency, etc and arrive at a great 2-way vented box speaker. I am not one of them…

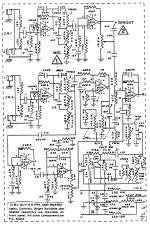

The baffle is double thick. There are three partial bulkhead braces.

The woofer is positioned at 9 13/16” from the bottom. The tweeter is positioned at 17 13/16” from the bottom. Both drivers are centered. The tweeter is recessed, but the woofer is not. The cabinet is only about ¼” wider than the woofer frame, and I did not think that a recess router cut would be successful with such a narrow edge distance.

The bevel cuts around the tweeter are at 33 degrees. The tapered bevels on the sides were made on the table saw with a wedge jig I screwed to the back of the cabinet. I selected the taper so that the bevel would begin at the point level with the top of the woofer frame. Around the tweeter, I wanted a ½” edge distance between the bevel and the tweeter recess. So, those two points set the taper angle. When I was cutting the bevel along the top, I screwed up and made the bevel deeper than I intended, so I have only about 1/8” edge distance between the top bevel and the tweeter recess, but fortunately there was no tear out or other problems. The tapered bevels below the woofer are for aesthetics only, they have no affect on the woofer directivity as far as I can tell.

The cabinets were stuffed with long fiber loose wool, well fluffed. I measured out 192 g of wool, which gives me a stuffing density of 16 g/liter, or 16 oz/ft^3.