Hello , I will be building an enclosure of internal dimension of 6.25X7.375X32 inches. Based on Vikash calculator, the first standing waves are at 214, 1009, 917Hz.

The speaker will be crossed around 750Hz, so the most problematic standing wave is 214, 427...

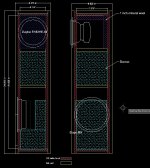

The walls of the enclosure are made of 5/8mdf + 1/2 Birch plywood glued together. See pictures.

It is a Passive radiator tuned box. 1 Single P-R.

The internal dimensions are rather small so how can i brace and stuff tis enclosure to eliminate the room modes. There is not much room to add damping material.

My second concern is the vibration of the P-R, i purposely put it near the floor to maximize the coupling and reduce vibrations. Based on your experience, would the vibration be sufficiently large to affect the sound. I can add a second P-R on the other side.

I am trying to avoid trial and errors as much as possible.

Your suggestions would be most welcome.

Thank you

The speaker will be crossed around 750Hz, so the most problematic standing wave is 214, 427...

The walls of the enclosure are made of 5/8mdf + 1/2 Birch plywood glued together. See pictures.

It is a Passive radiator tuned box. 1 Single P-R.

The internal dimensions are rather small so how can i brace and stuff tis enclosure to eliminate the room modes. There is not much room to add damping material.

My second concern is the vibration of the P-R, i purposely put it near the floor to maximize the coupling and reduce vibrations. Based on your experience, would the vibration be sufficiently large to affect the sound. I can add a second P-R on the other side.

I am trying to avoid trial and errors as much as possible.

Your suggestions would be most welcome.

Thank you

Attachments

how can i brace and stuff tis enclosure to eliminate the room modes

Those will affect internal modes, room modes not at all.

dave

The 214hz will almost certainly be strong. I've had good success using dacron batting because it isn't terrible dense and you can place it between the driver and port. In cases like yours I've placed 8" in the bottom and center of the box. The center is the most important place. This should effectively damp the pipe resonance with minimal impact on PR output. Since you need to brace, use them to create an area for the batting to sit on in the center.

Yeah, mixing up the gabbling, noted. TksThose will affect internal modes, room modes not at all.

dave

Hello Augerpro,

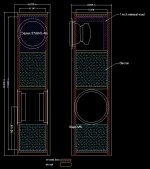

Thanks for the advise. One thing not shown is the back of the P-R needs an addional inch for cone movement. See attached the result. I must move the P-R up to be able to fill an equivalent volume of dacron.

Will the vibration be an issue with the P-R. . There will be approx. 200grams attached to the P-R.

I also have mineral wool bats that i could use.

Thank you again for your insight on this.

Thanks for the advise. One thing not shown is the back of the P-R needs an addional inch for cone movement. See attached the result. I must move the P-R up to be able to fill an equivalent volume of dacron.

Will the vibration be an issue with the P-R. . There will be approx. 200grams attached to the P-R.

I also have mineral wool bats that i could use.

Thank you again for your insight on this.

Attachments

You can leave space around the PR. Or move the batting to the top and leave some space around woofer. Or move your PR, at these frequencies I doubt moving it 8" up will make a difference. Might be better to have it 1/3 from the bottom for performance. The center batting is the most important anyway.

I don't know much about how much weight it takes before PR movement gets too wild. But a lot of people will pair them to balance forces to prevent that issue.

I don't know much about how much weight it takes before PR movement gets too wild. But a lot of people will pair them to balance forces to prevent that issue.

.....or mass load them with a removable heavy weight, though at only 200 gr/0.44 lbs I'm guessing the speakers are heavy enough as is or only need a small decorative potted plant/whatever perched on top at worst.

I think this design is going to act as a MLTL, not as a pure reflex. No options to move both units more to the center and closer to each other?

FYI/FWIW/IME it takes at least 36" to get any useful vent length reduction for a given vent area or larger area for a given length, but it was my preferred internal height for small cabs mainly because the driver loading benefited from placing at pipe odd harmonics when the vent was at the bottom/down firing.

Wow, lot of info.

The PR is changed to 1/3 from bottom. If i understand correctly, there is less unwanted noise at this level so less noise coming out of the PR.

I will plan an opposite P-R that i can add later if there is vibration on top of the box where the tweeter will be sitting. (Already have 4 PR but one is enough for the E180, kind of overkill on P-R displacement if i put 2 per cabinet. Also, there is no chance of gluing the panel on the wrong side this way. 🙂

Moving up the PR gives 6 inch of batting at the bottom, so i am in the ballpark from augerpro proposed solution.

I will go with this. Thank you for your time and all your suggestions. It is really appreciated.

Have a great summer.

Michel Arbour

The PR is changed to 1/3 from bottom. If i understand correctly, there is less unwanted noise at this level so less noise coming out of the PR.

I will plan an opposite P-R that i can add later if there is vibration on top of the box where the tweeter will be sitting. (Already have 4 PR but one is enough for the E180, kind of overkill on P-R displacement if i put 2 per cabinet. Also, there is no chance of gluing the panel on the wrong side this way. 🙂

Moving up the PR gives 6 inch of batting at the bottom, so i am in the ballpark from augerpro proposed solution.

I will go with this. Thank you for your time and all your suggestions. It is really appreciated.

Have a great summer.

Michel Arbour

Attachments

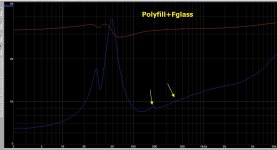

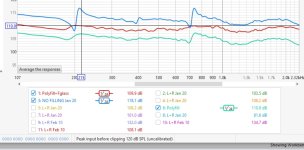

Hello, here's the results :

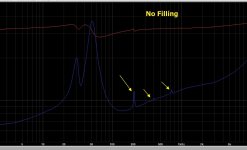

No stuffing,

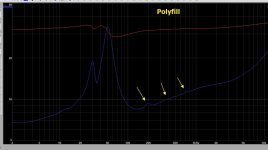

Polyfill at 178g/sqft in the P-R and middles cavities and 102g/sqft behind driver

Polyfill at 178g/sqft in the P-R and middle cavities and 3inch fiberglass behind driver. (For the fiberglass, i compressed 5inch loose F-B to 3 inch)

The 200hz resonance remains the same with and without the fiberglass at approx. 2db.

The 400hz resonance is negligible

The fiberglass behind the driver tool care of the 800Hz small resonance. This one was annoying because it was at the xover point.

Thank you for your support and have a great week-end.

No stuffing,

Polyfill at 178g/sqft in the P-R and middles cavities and 102g/sqft behind driver

Polyfill at 178g/sqft in the P-R and middle cavities and 3inch fiberglass behind driver. (For the fiberglass, i compressed 5inch loose F-B to 3 inch)

The 200hz resonance remains the same with and without the fiberglass at approx. 2db.

The 400hz resonance is negligible

The fiberglass behind the driver tool care of the 800Hz small resonance. This one was annoying because it was at the xover point.

Thank you for your support and have a great week-end.

Attachments

- Home

- Loudspeakers

- Multi-Way

- Advice on bracing and standing wave elimination