Hello. I am a new diyAudio member and have just registered now. I own a pair of Beveridge 2SW-1 speakers which I bought back in '79 as store demos which was the only way I could afford them, barely, and that was a sacrifice to do so. I got a real good deal on them. Back then Harold Bev came to the store where I bought the spkrs, gave a talk and demo on his system and I met him then( and much later on called him to ask what a good dummy spkr load would be). I am still listening to these going on 45yrs. For the first 20 yrs I owned them they were 'on' almost as much as my refrigerator. I have a lot of info I can share with fellow 2SW-1 owners in future posts regarding failures, tubes to use, etc., but right now I am extremely eager to get my left channel amp back up and running. I have read the posts from cvanc, kcin, and others regarding these amps and it looks like I'm in good company.

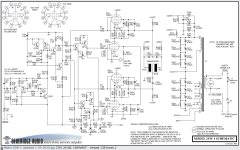

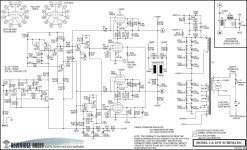

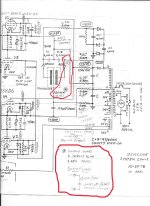

I have attached the newer redrawn amp schematic for referencing for my question(s).

The failure mode (there were other failure types in the distant past which I permanently fixed) I have from time to time is that any of three resistors in the screen/cathode circuit of the 36KD6's partially burn up which blow the fuse. They are R201, 203 and 205 which are 10K, 22K and 10K, respectively, half watt, carbon film type. In this case, R201 failed. I replaced it and powered up the amp again and I could only hear very low level lower frequency sound from the spkrs. I hooked up the other good amp to these spkrs and played fine with no issue. I opened up the bad amp and traced a 1kHz signal through the driver board to find there was no signal at the collector of Q110. There was signal at collector of Q111. So the stators (electrodes as Rick Bev calls them) were getting no audio signal and the diaphrams were. So I replaced Q110 with a suitable equivalent (BD140) which did not fix the problem. If I remember correctly, there was signal at Q106/107 collectors. So after doing some more probing with my scope the amp started to blow fuses when I would turn it on and V204 tube arc'd bigtime in the base area of the tube. Q111 collector (which has signal) is tied to grid of V204 through the 1K (910ohm in my amps) resistor. The dilemma I am having in trying to continue probing is that in order to see the signal at the Q110/111 xistors, the HV has to be connected so there is feedback present through R1 and R3 at the bases of Q108/109. I confirmed this by disconnecting the HV on the good amp and seeing there was no signal at the collectors of these xistors when HV is disabled Back in the mid 90's I bought and built the softstart circuit boards which Ron Welborne (Welborne Labs) sold and installed them right over the main pwr xformers using 3 nylon stand-offs. They still work and are preserving the main xformers. Something I will try tomorow is to bring the mains voltage up very slowly with my variac and see if V204 will live and not blow a fuse so I can continue to check for signal at Q110/111 collectors. Measuring input and output voltages on the driver bd, up to the Q110/111 collectors, I calculated 28dB voltage gain.

If anyone has any suggestions/ideas to try please pass them on. Thanks much!

I have attached the newer redrawn amp schematic for referencing for my question(s).

The failure mode (there were other failure types in the distant past which I permanently fixed) I have from time to time is that any of three resistors in the screen/cathode circuit of the 36KD6's partially burn up which blow the fuse. They are R201, 203 and 205 which are 10K, 22K and 10K, respectively, half watt, carbon film type. In this case, R201 failed. I replaced it and powered up the amp again and I could only hear very low level lower frequency sound from the spkrs. I hooked up the other good amp to these spkrs and played fine with no issue. I opened up the bad amp and traced a 1kHz signal through the driver board to find there was no signal at the collector of Q110. There was signal at collector of Q111. So the stators (electrodes as Rick Bev calls them) were getting no audio signal and the diaphrams were. So I replaced Q110 with a suitable equivalent (BD140) which did not fix the problem. If I remember correctly, there was signal at Q106/107 collectors. So after doing some more probing with my scope the amp started to blow fuses when I would turn it on and V204 tube arc'd bigtime in the base area of the tube. Q111 collector (which has signal) is tied to grid of V204 through the 1K (910ohm in my amps) resistor. The dilemma I am having in trying to continue probing is that in order to see the signal at the Q110/111 xistors, the HV has to be connected so there is feedback present through R1 and R3 at the bases of Q108/109. I confirmed this by disconnecting the HV on the good amp and seeing there was no signal at the collectors of these xistors when HV is disabled Back in the mid 90's I bought and built the softstart circuit boards which Ron Welborne (Welborne Labs) sold and installed them right over the main pwr xformers using 3 nylon stand-offs. They still work and are preserving the main xformers. Something I will try tomorow is to bring the mains voltage up very slowly with my variac and see if V204 will live and not blow a fuse so I can continue to check for signal at Q110/111 collectors. Measuring input and output voltages on the driver bd, up to the Q110/111 collectors, I calculated 28dB voltage gain.

If anyone has any suggestions/ideas to try please pass them on. Thanks much!

Attachments

Simple stuff first.

Do you have all of your voltages ? Is there an ac component on them?

I would check the varistors and the 47mfd caps for shorts and diodes for open.

Are your tube sockets clean and tight no carbon tracking - board is clean.

You should prove the low level circuit board works in both amps swapping boards is not that big of a deal.

Do you have all your heater voltages stable over time

If you pull the tubes do you blow fuses? Can you raise voltage slowly and monitor current.

Are you able to test for leakage across the the windings in the transformer with a megger? Honestly there is not a lot there. If all the checks above are positive statically then I would suspect your transformer.

Q110/111 Side note- the BD140 should work although the beta is higher than the original Toshiba S1376

I found that the closest sub was the the Motorola MPS-U56 Vce80v or the bigger brother MPS-U57 Vce100v -in fact in some very early documentation on the the schematic from Beveridge he notes the MPS-U56 as the Q110/Q111 transistor.

Both these Motorola transistors are correct pinout EBC of the original and both of them are discontinued... they still exist out there though.

Modern available equivalent from Central Semiconductor is the CEN-U57 - Central seems to take old designs and resurrect them- the CEN-U57 is an exact copy of the Motorola MPS-U57---fyi and as resource for others if ever required.

Good luck

Do you have all of your voltages ? Is there an ac component on them?

I would check the varistors and the 47mfd caps for shorts and diodes for open.

Are your tube sockets clean and tight no carbon tracking - board is clean.

You should prove the low level circuit board works in both amps swapping boards is not that big of a deal.

Do you have all your heater voltages stable over time

If you pull the tubes do you blow fuses? Can you raise voltage slowly and monitor current.

Are you able to test for leakage across the the windings in the transformer with a megger? Honestly there is not a lot there. If all the checks above are positive statically then I would suspect your transformer.

Q110/111 Side note- the BD140 should work although the beta is higher than the original Toshiba S1376

I found that the closest sub was the the Motorola MPS-U56 Vce80v or the bigger brother MPS-U57 Vce100v -in fact in some very early documentation on the the schematic from Beveridge he notes the MPS-U56 as the Q110/Q111 transistor.

Both these Motorola transistors are correct pinout EBC of the original and both of them are discontinued... they still exist out there though.

Modern available equivalent from Central Semiconductor is the CEN-U57 - Central seems to take old designs and resurrect them- the CEN-U57 is an exact copy of the Motorola MPS-U57---fyi and as resource for others if ever required.

Good luck

Last edited:

Holy crap an original owner!

(bows respectfully)

Yeah let's get you going. First off let me make sure I understand - you are losing the bleeder resistor from all three screen supplies? That's a very strange failure.

I've split rectifiers wide open and had the electrolytics go off like a steam whistle and fill the room with smoke. But all three of my bleeders remain original. I'm struggling to come up with an electrical fault to cause bleeder failure. I suspect heat from your tubes.

In my opinion one of the most important modifications you can make is to move all 3 screen supplies to the rear side of the board where it is far cooler. I did this years ago and no failures since. But I did not replace my bleeders and they still reside on the hot side. I guess I should check 'em ":^)

At the end of the day it's a bleeder and I think you could cut all three completely out and the amp would run the same.

For replacement parts a 1N4007 is fine. The hole spacing on the board for the electrolytic is 5mm and I increased both voltage and value as far as lead spacing would allow. Mine are 270uF at 160V but the value isn't magical.

You will not see audio at the output transistor collectors until after the totem pole is up and running. If there is no feedback from the totem pole (via the 7.5Meg resistor) these collectors just sit slammed to the negative rail. As tubes warm up and loop gain grows these settle to the -30 to -35 Volt DC range.

Keep us posted, we need photos so send them when you can.

(bows respectfully)

Yeah let's get you going. First off let me make sure I understand - you are losing the bleeder resistor from all three screen supplies? That's a very strange failure.

I've split rectifiers wide open and had the electrolytics go off like a steam whistle and fill the room with smoke. But all three of my bleeders remain original. I'm struggling to come up with an electrical fault to cause bleeder failure. I suspect heat from your tubes.

In my opinion one of the most important modifications you can make is to move all 3 screen supplies to the rear side of the board where it is far cooler. I did this years ago and no failures since. But I did not replace my bleeders and they still reside on the hot side. I guess I should check 'em ":^)

At the end of the day it's a bleeder and I think you could cut all three completely out and the amp would run the same.

For replacement parts a 1N4007 is fine. The hole spacing on the board for the electrolytic is 5mm and I increased both voltage and value as far as lead spacing would allow. Mine are 270uF at 160V but the value isn't magical.

You will not see audio at the output transistor collectors until after the totem pole is up and running. If there is no feedback from the totem pole (via the 7.5Meg resistor) these collectors just sit slammed to the negative rail. As tubes warm up and loop gain grows these settle to the -30 to -35 Volt DC range.

Keep us posted, we need photos so send them when you can.

I finally got around to sharing my results of my efforts to get my Bev amp back up and running.

I had gotten some new 'lytic caps several months ago to recap my Hickok 752A tester which I got a couple years ago and finally did so and then checked the tester's calibration. It was designed for 115V line voltage but of course we now have 120V. The calibration numbers were for the most part ok. Some were off some but close enough to use the tester. I should have done this first back when the amp went kaput so I could test the tubes then. Duh.

At any rate, I hit paydirt when I tested the amp's tubes and found out that one of the tubes had a short (leakage switch position 4 on my tester). Ah hah. Also, two of the other tubes had very low Gm's (2250 and 2850). The 36KD6 shoud have a Gm of at least 3600. Fortunately I keep a spare set of tubes on hand for this situation. I just bought two more on eBay. Between the one good one that came from the amp and the three I replaced, the four tubes measured between 10200 and 11200. I replaced the burned out pilot LED which is lit via the softstart board. I brought the amp up slowly on my variac and low and behold, I saw the 1kHz signal at the collectors of Q110/Q111 once again. I was SOOOO happy! I then connected the amp to 120V directly w/o the variac to see if it would turn on without blowing anything. No problems. I did all the troubleshooting using the dummy load Harold Bev told me to use when I called him 40yrs ago (i.e., a 1.2K/10watt in series with .0047uF/6kV) which I used several times in the past. The BD140 xistors worked fine. As it turned out, the original xistors were ok after I took them out and did the 5-point xistor test on them with my DVM and reviewed how to do this (it's been a long time). I decided to leave the BD140s in. I bought new varistors and put them in both amps. I read that they do wear out and knowing mine were 45yrs old I wanted new parts. The two that came out of the bad amp were slightly cracked on both sides of the disc. I read an article on how to test test them which I should try doing.

Before I got to this point I had tested to see if the amp would blow fuses without the tubes in their sockets which it didn't of course and checked voltages around the tube pins and they looked ok. I also checked the sockets for cleanliness and pin tightness and very sparingly used some Deoxit to clean them and a dental tool to tighten pins that I could reach. I checked the 47uF caps (50uF/250V in my amps) on my cap checker at 250V for leakage- none. Diodes checked out.

kcin & cvanc per your comments, not too long after I bought the speakers, I found I was blowing the 47uf/63V screen caps, 1N4004 screen diodes. After I got a copy of the hand-drawn schematic from the audio dealer when I bought my Bevs which was like pulling teeth, the dealer told me to change out the 1n4004 diodes with 1n4007's with the 1000V PIV rating. I also changed the 47uf/63V caps to Mallory 50uF/250V. I never had any problems with these parts thereafter, BUT I did with the bleeder resistors These caps being much larger axial leaded types I soldered onto the bottom side of board.

Something I did not mention, when I first opened up the amps to replace blown parts and compare the parts used against the original schematic I noticed the bleeder, R201 was 22K and stator/diaphram resistors are 2.2M. I see on the new redrawn schematic (1/20), the note says some amps had 1M

resistors and some had 2.2M for R206-R210. So I presume this is ok. After the amp failure occured I changed R201 to 10K. Up to this time, any one of the bleeder resistors would burn up typically after long listening periods. cvanc, I would not remove the bleeders because you will blow a fuse or a tube(s) in the process. My amp failure is proof. Right when it failed I replaced the fuse and switched amp back on and got strange sounds out of the stat panels then quickly turned off the amp. I'm fairly sure that's when I shorted out the tube. So now that I have made the resistor change and changed out the tubes I'll see how long the bleeders last and will let you know how that goes. I used metal oxide 2% flameproof types.

Over the years my favorite tube to use are GE's. I've tried Philips, RCA's, Westinghouse, and Sylvania's. The Philips I tried many years ago and their plates got cherry red. When replaced with others, all was well. The Sylvania's were OK but the GE compactrons have the shortest height and I get the most mileage out of them.. All the other tubes are taller and cause the tube cap wires to be quite taught when connected.

cvanc, are you saying to move the screen resistors 10K/22K (R201,203, &205), 1n4007 diodes, varistors, 2.2K/2watt resistors and maybe the 470pF to bottom side of board? I can see doing this for the 2.2K/2W resistors and varistors since this resistor touches the tube socket and the varistor is right below it. These resistors look discolored but still measure good. I'm still learning how a mu stage works and have some understanding of it but not enough. Can you explain how the diode, bleeder resistor and 'lytic cap, varistor and 2.2K plate/cathode work in the circuit? Thanks. I measured the dc voltage at the 7.5M resistor at the base of Q108 driver without the tubes in and got -13.5V. I have an old Heath VTVM (works fine and is calibrated) and HV probe and want to measure the voltages around the tubes with the tubes inserted but was a bit afraid because of the voltages involved and possibly blowing a tube(s). What voltages should I get with tubes in? What voltage is measured on the tube side of the 7.5M after full power-up? As you said, I don't see the signal at the Q110/Q111 collectors on the scope until after ~2-3 sec. Must I use my VTVM probe (high resistance) to measure the -30V to -35VDC or can I use my DVM?

kcin, You mentioned that the original Q110/111 xistors were Toshiba's. How did you know this? In my amps these parts are green colored with no markings on them. In the original hand-written schematic from RAM (R. Modjeski), all it says is that it is an 80V/1watt part. That's it. No mention of the

MPS-U56. So I found the BD140, an 80V Vce/Vcb, 1.25W part with similar hFE..

I was able to preserve my HV xformer by adding the Welborne Labs softstart board which I mentioned in my post which you can see in the photo I attached. It is sitting over the HV xformer. I added it back in the mid 90s. Without it I'm doubtful the xformer would have made it this long (knock on wood).

My current ambition and dream is to convert the Bev amps' SE inputs to balanced. I have a schematic which I got from a white paper (c '93) by Alan Kimmel who you may know from Welborne Labs days. He designed circuits for Ron W, including the softstart circuit I put in my Bevs. The white paper talks about mu stage circuits for pramps and the benefits of constant current sources which is I guess old news now. In part of the paper he shows a differential circuit using a pair of 12ax7's driving a pair of pentodes (my choice, 12gn7's with lowest outpt Z). Or the better option is to use the 12ax7 differential pair to drive a pair of 6DJ8's which drive a pair of n channel mosfet source followers which have the lowest output Z and maximum voltage swing. This board would replace the Bev SS driver board and would be connected to my Levinson 390S CD processor which has it's own preamp with switchable balanced ouputs. I measured and calculated the voltage gain of the Bev board to be 28dB so this must be maintained. I hope to buy at some point, a used Marchand Electronics XM126 fully tubed (12ax7s) balanced IN/OUT Low/Hi-pass output crossover which you can get with either 2nd, 3rd or 4th order filters. I opt for the 4th order filters. The unit has both balanced and SE inputs and outputs. So I can use the balanced I/Os for my cd player and the SE I/Os for the other program sources. The Bev amp's built in coax cable would be moved to the swfr amp board's input, deleting the Bev X/O board. The subwfr level control would be replaced with an XLR input conntr to input the tube balanced I/O driver board. You may have heard of Dan Curcio of Curcio Audio who does Bev amp repairs and will convert your 2SW-1 or 2 amps to balanced inputs for at last check, > or = $3K. I've read about the conversion of these amps and using the Levinson's balanced outputs in it's Stereophile review and the sonic difference is night and day.

And finally, a note on the late RAM- may he RIP. I saw a post on Audiokarma from some years ago in which he stated he did not design the 2SW-1 & 2 amps. I found that strange because at the bottom of all the schematics ('stat panel amp, X/O and subwoofer boards) are his initials. I thought to myself, why would Harold Bev hire an engineer to check over another engineer's design? If he didn't design it why are his initials on the schematics? He was a young engineer at the time and didn't come to Bev, I believe, until after the original Model 2 two-panel system (?). I don't mean anything derogatory towards him. He became well known after that. I had him rebuild 3 of my panels and bought preamp tubes from him over the years. I think he did not want to speak to the design errors found in the tube circuit by customers and tried to pass it off.

That's it. I think I covered everything and got it off my chest.

Sorry for my insanely long post and all my questions. Your inputs are greatly appreciated!

Thanks.

I had gotten some new 'lytic caps several months ago to recap my Hickok 752A tester which I got a couple years ago and finally did so and then checked the tester's calibration. It was designed for 115V line voltage but of course we now have 120V. The calibration numbers were for the most part ok. Some were off some but close enough to use the tester. I should have done this first back when the amp went kaput so I could test the tubes then. Duh.

At any rate, I hit paydirt when I tested the amp's tubes and found out that one of the tubes had a short (leakage switch position 4 on my tester). Ah hah. Also, two of the other tubes had very low Gm's (2250 and 2850). The 36KD6 shoud have a Gm of at least 3600. Fortunately I keep a spare set of tubes on hand for this situation. I just bought two more on eBay. Between the one good one that came from the amp and the three I replaced, the four tubes measured between 10200 and 11200. I replaced the burned out pilot LED which is lit via the softstart board. I brought the amp up slowly on my variac and low and behold, I saw the 1kHz signal at the collectors of Q110/Q111 once again. I was SOOOO happy! I then connected the amp to 120V directly w/o the variac to see if it would turn on without blowing anything. No problems. I did all the troubleshooting using the dummy load Harold Bev told me to use when I called him 40yrs ago (i.e., a 1.2K/10watt in series with .0047uF/6kV) which I used several times in the past. The BD140 xistors worked fine. As it turned out, the original xistors were ok after I took them out and did the 5-point xistor test on them with my DVM and reviewed how to do this (it's been a long time). I decided to leave the BD140s in. I bought new varistors and put them in both amps. I read that they do wear out and knowing mine were 45yrs old I wanted new parts. The two that came out of the bad amp were slightly cracked on both sides of the disc. I read an article on how to test test them which I should try doing.

Before I got to this point I had tested to see if the amp would blow fuses without the tubes in their sockets which it didn't of course and checked voltages around the tube pins and they looked ok. I also checked the sockets for cleanliness and pin tightness and very sparingly used some Deoxit to clean them and a dental tool to tighten pins that I could reach. I checked the 47uF caps (50uF/250V in my amps) on my cap checker at 250V for leakage- none. Diodes checked out.

kcin & cvanc per your comments, not too long after I bought the speakers, I found I was blowing the 47uf/63V screen caps, 1N4004 screen diodes. After I got a copy of the hand-drawn schematic from the audio dealer when I bought my Bevs which was like pulling teeth, the dealer told me to change out the 1n4004 diodes with 1n4007's with the 1000V PIV rating. I also changed the 47uf/63V caps to Mallory 50uF/250V. I never had any problems with these parts thereafter, BUT I did with the bleeder resistors These caps being much larger axial leaded types I soldered onto the bottom side of board.

Something I did not mention, when I first opened up the amps to replace blown parts and compare the parts used against the original schematic I noticed the bleeder, R201 was 22K and stator/diaphram resistors are 2.2M. I see on the new redrawn schematic (1/20), the note says some amps had 1M

resistors and some had 2.2M for R206-R210. So I presume this is ok. After the amp failure occured I changed R201 to 10K. Up to this time, any one of the bleeder resistors would burn up typically after long listening periods. cvanc, I would not remove the bleeders because you will blow a fuse or a tube(s) in the process. My amp failure is proof. Right when it failed I replaced the fuse and switched amp back on and got strange sounds out of the stat panels then quickly turned off the amp. I'm fairly sure that's when I shorted out the tube. So now that I have made the resistor change and changed out the tubes I'll see how long the bleeders last and will let you know how that goes. I used metal oxide 2% flameproof types.

Over the years my favorite tube to use are GE's. I've tried Philips, RCA's, Westinghouse, and Sylvania's. The Philips I tried many years ago and their plates got cherry red. When replaced with others, all was well. The Sylvania's were OK but the GE compactrons have the shortest height and I get the most mileage out of them.. All the other tubes are taller and cause the tube cap wires to be quite taught when connected.

cvanc, are you saying to move the screen resistors 10K/22K (R201,203, &205), 1n4007 diodes, varistors, 2.2K/2watt resistors and maybe the 470pF to bottom side of board? I can see doing this for the 2.2K/2W resistors and varistors since this resistor touches the tube socket and the varistor is right below it. These resistors look discolored but still measure good. I'm still learning how a mu stage works and have some understanding of it but not enough. Can you explain how the diode, bleeder resistor and 'lytic cap, varistor and 2.2K plate/cathode work in the circuit? Thanks. I measured the dc voltage at the 7.5M resistor at the base of Q108 driver without the tubes in and got -13.5V. I have an old Heath VTVM (works fine and is calibrated) and HV probe and want to measure the voltages around the tubes with the tubes inserted but was a bit afraid because of the voltages involved and possibly blowing a tube(s). What voltages should I get with tubes in? What voltage is measured on the tube side of the 7.5M after full power-up? As you said, I don't see the signal at the Q110/Q111 collectors on the scope until after ~2-3 sec. Must I use my VTVM probe (high resistance) to measure the -30V to -35VDC or can I use my DVM?

kcin, You mentioned that the original Q110/111 xistors were Toshiba's. How did you know this? In my amps these parts are green colored with no markings on them. In the original hand-written schematic from RAM (R. Modjeski), all it says is that it is an 80V/1watt part. That's it. No mention of the

MPS-U56. So I found the BD140, an 80V Vce/Vcb, 1.25W part with similar hFE..

I was able to preserve my HV xformer by adding the Welborne Labs softstart board which I mentioned in my post which you can see in the photo I attached. It is sitting over the HV xformer. I added it back in the mid 90s. Without it I'm doubtful the xformer would have made it this long (knock on wood).

My current ambition and dream is to convert the Bev amps' SE inputs to balanced. I have a schematic which I got from a white paper (c '93) by Alan Kimmel who you may know from Welborne Labs days. He designed circuits for Ron W, including the softstart circuit I put in my Bevs. The white paper talks about mu stage circuits for pramps and the benefits of constant current sources which is I guess old news now. In part of the paper he shows a differential circuit using a pair of 12ax7's driving a pair of pentodes (my choice, 12gn7's with lowest outpt Z). Or the better option is to use the 12ax7 differential pair to drive a pair of 6DJ8's which drive a pair of n channel mosfet source followers which have the lowest output Z and maximum voltage swing. This board would replace the Bev SS driver board and would be connected to my Levinson 390S CD processor which has it's own preamp with switchable balanced ouputs. I measured and calculated the voltage gain of the Bev board to be 28dB so this must be maintained. I hope to buy at some point, a used Marchand Electronics XM126 fully tubed (12ax7s) balanced IN/OUT Low/Hi-pass output crossover which you can get with either 2nd, 3rd or 4th order filters. I opt for the 4th order filters. The unit has both balanced and SE inputs and outputs. So I can use the balanced I/Os for my cd player and the SE I/Os for the other program sources. The Bev amp's built in coax cable would be moved to the swfr amp board's input, deleting the Bev X/O board. The subwfr level control would be replaced with an XLR input conntr to input the tube balanced I/O driver board. You may have heard of Dan Curcio of Curcio Audio who does Bev amp repairs and will convert your 2SW-1 or 2 amps to balanced inputs for at last check, > or = $3K. I've read about the conversion of these amps and using the Levinson's balanced outputs in it's Stereophile review and the sonic difference is night and day.

And finally, a note on the late RAM- may he RIP. I saw a post on Audiokarma from some years ago in which he stated he did not design the 2SW-1 & 2 amps. I found that strange because at the bottom of all the schematics ('stat panel amp, X/O and subwoofer boards) are his initials. I thought to myself, why would Harold Bev hire an engineer to check over another engineer's design? If he didn't design it why are his initials on the schematics? He was a young engineer at the time and didn't come to Bev, I believe, until after the original Model 2 two-panel system (?). I don't mean anything derogatory towards him. He became well known after that. I had him rebuild 3 of my panels and bought preamp tubes from him over the years. I think he did not want to speak to the design errors found in the tube circuit by customers and tried to pass it off.

That's it. I think I covered everything and got it off my chest.

Sorry for my insanely long post and all my questions. Your inputs are greatly appreciated!

Thanks.

Attachments

OK... here's what I suggest.

Post a picture of what you plan to measure your kilovolts with, OK? You sure your tools are safe for this work?

It is cheap and easy to sweep a couple circuit areas with known fresh parts and I recommend you do so as your next step. Plus it's the perfect opportunity to relocate all of these parts to the back side of the board where it is enormously cooler.

I think you should rebuild the "mid-point" of both totem poles including the screen supplies. You want better grade parts in there anyway, just get it behind you now.

Remove the 3 electrolytics you've added on the back and replace with ones that stand up, you will then have all the space you need. Photo gives the idea but does not show my current parts.

Post a picture of what you plan to measure your kilovolts with, OK? You sure your tools are safe for this work?

It is cheap and easy to sweep a couple circuit areas with known fresh parts and I recommend you do so as your next step. Plus it's the perfect opportunity to relocate all of these parts to the back side of the board where it is enormously cooler.

I think you should rebuild the "mid-point" of both totem poles including the screen supplies. You want better grade parts in there anyway, just get it behind you now.

Remove the 3 electrolytics you've added on the back and replace with ones that stand up, you will then have all the space you need. Photo gives the idea but does not show my current parts.

Attachments

Other hints:

It's not hard to un-install the main board from the chassis and so much easier to work on when it's out. Get out the sandpaper & clean all the grounding points to the frame while you have access.

Also, perfect time to deal with your tube sockets. At a minimum you need to clean & tighten with some D5 and dental tools. It's NBD to tighten these up if you can just get to them!

My thoughts on specific components:

2.2K totem pole resistor - I'd love to find a 2W metal film for here but I have the usual metal oxides in mine, nothing special

The original varistor is still available and my advice is do not stray

The 470pF cap - I've got 1600V Wima PP films

Electrolytic - Lead spacing of 5mm fits the board perfectly

Screen rectifier - A 1N4007 here is fine

It's not hard to un-install the main board from the chassis and so much easier to work on when it's out. Get out the sandpaper & clean all the grounding points to the frame while you have access.

Also, perfect time to deal with your tube sockets. At a minimum you need to clean & tighten with some D5 and dental tools. It's NBD to tighten these up if you can just get to them!

My thoughts on specific components:

2.2K totem pole resistor - I'd love to find a 2W metal film for here but I have the usual metal oxides in mine, nothing special

The original varistor is still available and my advice is do not stray

The 470pF cap - I've got 1600V Wima PP films

Electrolytic - Lead spacing of 5mm fits the board perfectly

Screen rectifier - A 1N4007 here is fine

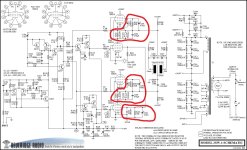

My screen resistors are 47k not 10k ...as in the diagram attached. I also have the 2.2M isolating resistors not 1M .

On the Toshiba S1376 output transistors... my boards came with them and my observations on many other boards show that they are original.

On one of the hand drawn Bev amp schematics it is noted that the outputs are MPS U56. The MPS U57 is a sister device with 100v CE rating.

Current Transistor that is the same pinout and rating is the Central Semiconductor CEN-U57.

On RAM.. I had spoken to Roger, he definitely did not design these amps but certainly was involved in their production and the crossover boards.

On the Toshiba S1376 output transistors... my boards came with them and my observations on many other boards show that they are original.

On one of the hand drawn Bev amp schematics it is noted that the outputs are MPS U56. The MPS U57 is a sister device with 100v CE rating.

Current Transistor that is the same pinout and rating is the Central Semiconductor CEN-U57.

On RAM.. I had spoken to Roger, he definitely did not design these amps but certainly was involved in their production and the crossover boards.

Attachments

cvanc,

I have some questions first.

How long have you had your Bev amps? Were they working when you bought them? If not, after you got them running again, were there failures after that and what were they? From your photo it looks like you have another FR-4 amp board (or had a new one made). Also, what is the board (?) in the lower left hand corner (modified driver board?) and the large red component connected to the board? A large capacitor perhaps.

As mention previously I cleaned the tube sockets and tightened socket pins that I could access. I may do this again after getting enough ambition to remove the board. I saw on the internet a supplier sells an exact copy of the socket used in the Bev's except it's ceramic.. It also has the same pin socket design which wears and causes loose tubes.

I use a Heath VTVM (IM-28) which accepts either of two high resistance probes which can measure the Bev voltages with no problem. One is the high resistance probe that came with it which can measure up to +/- 1500V AC/DC and then I bought a HV probe which can measure up to +/- 150kV AC/DC.

When I started blowing 1N4004 diodes not long after I bought the system the recommendation from RAM was to change them to 1N4007 which I did back then. The same diodes are in the amp today. Also I did the 47uf/63V cap change to 50uF/250V back in the early '90's. No issues with these two parts ever after that. When getting my bad amp back up and running I moved the screen resistors to the bottom side of the board and did not trim the leads off these resistors so they are extended off the board by about a half inch, keepig them cooler. This really helps if/when either of these resistors burn up allowing easy access and making removing tube(s) unnecessary. In the amp I just fixed I made these 1/2W metal oxide. So I have the 'lytic caps and screen resistors on the bottom side of board. I am leaving the diodes on the top side because they lasted for 40+ yrs and will probably last another 40. I will be long gone before that time. The only other parts I would move to the bottom would be the 2.2K/2W, varistor and maybe the ceramic 470pF, but changing it to a silver mica which is the most stable at high temp and probably would not require moving it. As I mentioned, I just put in new varistors in both amps- same exact part by the original company, Littelfuse. I can leave the 'lytic caps where they are and still move the 2.2K and varistor downside. I was considering using Solen 47uF/630V metallized PP caps which have a 0.8 mohm ESR and metal oxide resistors for the totem poles, but the Solen caps are 54mm D X 65mm L and are

$27 ea. I have 2W metal film resistors in my Audio Research line stage preamp so they should be available out there.

For clarification, when you mention 'mid-point' you mean the +1650V totem pole, correct? Also, for example, can you tell me the DC voltages you read at the suppressor, screen, and control grids of V201, quiescently (i.e., with no signal input)? What is the DC voltage measured at the speaker side of the 1M resistor (R206)? I have never measured these voltages on my amps for fear of blowing something. I always wanted to be able to see the actual audio signal as well that rides on the DC screen voltage (i.e., at R206, the side that goes to the stators (electrodes) and the signal at R210 (1M going to the diaphram). Can I safely do this after I AC-couple my scope using my X10 probe? I float my scope with a cheater wall adaptor. What kind of AC voltages do you see with a few mVs of input signal? Do the tubes produce additional gain on top of the gain present at Q110/111 collectors and if so, how much? On the 36kd6 data sheet I read that it has an amplication factor of 4. If there is gain, do you know how to calculate it? I would imagine the screen and plate resistors are part of the calculation. I tried measuring the feedback -30Vdc at the 7.5M FB resistor but only read -3V. I think this was a bad connection to my meter and I need to clip the alligator clip on the probe to the 7.5M and try it again.

I attached a marked up schematic of the output half of the amp showing how to connect the 1.2K 10W/.0047uf 6kV ceramic cap dummy load to amp. You only need one dummy load, i.e., one resistor and one cap. I connect the resistor end to the '+' red banana jack and the cap end to the black (blue on my amps) diaphram jack. I doubt that it matters if you connect resistor end to the '+', red or '-' jack, green, either polarity should work. This load works fine and I used it whenever I needed to troubleshoot.

kcin,

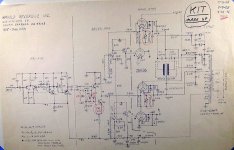

Thanks for the info and history on the Toshiba driver xistor and extra thanks for the very original Bev schematic. I searched for and could never find either one online. As I mention previously there are no markings on my green xistors and the schematic only said, "80V, 1W".

This must be the circuit for the amp that drove the original Model 2, 2-panel (as opposed to 3) speaker. I would guess then that Bev may have very well designed the original circuit. He designed tubes and defense systems for Raytheon in the Boston area before he moved to Santa Barbara. I just it weird that 'RAM' was on all the dwgs.

OK guys, THANKS for all your help & info.

I have some questions first.

How long have you had your Bev amps? Were they working when you bought them? If not, after you got them running again, were there failures after that and what were they? From your photo it looks like you have another FR-4 amp board (or had a new one made). Also, what is the board (?) in the lower left hand corner (modified driver board?) and the large red component connected to the board? A large capacitor perhaps.

As mention previously I cleaned the tube sockets and tightened socket pins that I could access. I may do this again after getting enough ambition to remove the board. I saw on the internet a supplier sells an exact copy of the socket used in the Bev's except it's ceramic.. It also has the same pin socket design which wears and causes loose tubes.

I use a Heath VTVM (IM-28) which accepts either of two high resistance probes which can measure the Bev voltages with no problem. One is the high resistance probe that came with it which can measure up to +/- 1500V AC/DC and then I bought a HV probe which can measure up to +/- 150kV AC/DC.

When I started blowing 1N4004 diodes not long after I bought the system the recommendation from RAM was to change them to 1N4007 which I did back then. The same diodes are in the amp today. Also I did the 47uf/63V cap change to 50uF/250V back in the early '90's. No issues with these two parts ever after that. When getting my bad amp back up and running I moved the screen resistors to the bottom side of the board and did not trim the leads off these resistors so they are extended off the board by about a half inch, keepig them cooler. This really helps if/when either of these resistors burn up allowing easy access and making removing tube(s) unnecessary. In the amp I just fixed I made these 1/2W metal oxide. So I have the 'lytic caps and screen resistors on the bottom side of board. I am leaving the diodes on the top side because they lasted for 40+ yrs and will probably last another 40. I will be long gone before that time. The only other parts I would move to the bottom would be the 2.2K/2W, varistor and maybe the ceramic 470pF, but changing it to a silver mica which is the most stable at high temp and probably would not require moving it. As I mentioned, I just put in new varistors in both amps- same exact part by the original company, Littelfuse. I can leave the 'lytic caps where they are and still move the 2.2K and varistor downside. I was considering using Solen 47uF/630V metallized PP caps which have a 0.8 mohm ESR and metal oxide resistors for the totem poles, but the Solen caps are 54mm D X 65mm L and are

$27 ea. I have 2W metal film resistors in my Audio Research line stage preamp so they should be available out there.

For clarification, when you mention 'mid-point' you mean the +1650V totem pole, correct? Also, for example, can you tell me the DC voltages you read at the suppressor, screen, and control grids of V201, quiescently (i.e., with no signal input)? What is the DC voltage measured at the speaker side of the 1M resistor (R206)? I have never measured these voltages on my amps for fear of blowing something. I always wanted to be able to see the actual audio signal as well that rides on the DC screen voltage (i.e., at R206, the side that goes to the stators (electrodes) and the signal at R210 (1M going to the diaphram). Can I safely do this after I AC-couple my scope using my X10 probe? I float my scope with a cheater wall adaptor. What kind of AC voltages do you see with a few mVs of input signal? Do the tubes produce additional gain on top of the gain present at Q110/111 collectors and if so, how much? On the 36kd6 data sheet I read that it has an amplication factor of 4. If there is gain, do you know how to calculate it? I would imagine the screen and plate resistors are part of the calculation. I tried measuring the feedback -30Vdc at the 7.5M FB resistor but only read -3V. I think this was a bad connection to my meter and I need to clip the alligator clip on the probe to the 7.5M and try it again.

I attached a marked up schematic of the output half of the amp showing how to connect the 1.2K 10W/.0047uf 6kV ceramic cap dummy load to amp. You only need one dummy load, i.e., one resistor and one cap. I connect the resistor end to the '+' red banana jack and the cap end to the black (blue on my amps) diaphram jack. I doubt that it matters if you connect resistor end to the '+', red or '-' jack, green, either polarity should work. This load works fine and I used it whenever I needed to troubleshoot.

kcin,

Thanks for the info and history on the Toshiba driver xistor and extra thanks for the very original Bev schematic. I searched for and could never find either one online. As I mention previously there are no markings on my green xistors and the schematic only said, "80V, 1W".

This must be the circuit for the amp that drove the original Model 2, 2-panel (as opposed to 3) speaker. I would guess then that Bev may have very well designed the original circuit. He designed tubes and defense systems for Raytheon in the Boston area before he moved to Santa Barbara. I just it weird that 'RAM' was on all the dwgs.

OK guys, THANKS for all your help & info.

Attachments

I float my scope with a cheater wall adaptor.

Loumon, seriously that is dangerous as hell. NEVER do this.

Loumon, seriously that is dangerous as hell. NEVER do this.

Other answers;

My pair of speakers were flood damaged burned up hacked on barn finds when I got them. Nonfunctional. They had been "fixed" and "upgraded" by someone who did not know what they were doing and should never have been in there. There had been fires in both the amps and the foam in the speaker cabinet(!).

Circuit boards: The small driver boards are original but both of my large output boards are new.

Pics attached showing how tidy they first looked after the rebuild and then the progression as bigger & bigger caps got fitted. It's all quite the FrankenBev by now but it remains, more or less, the original schematic.

My pair of speakers were flood damaged burned up hacked on barn finds when I got them. Nonfunctional. They had been "fixed" and "upgraded" by someone who did not know what they were doing and should never have been in there. There had been fires in both the amps and the foam in the speaker cabinet(!).

Circuit boards: The small driver boards are original but both of my large output boards are new.

Pics attached showing how tidy they first looked after the rebuild and then the progression as bigger & bigger caps got fitted. It's all quite the FrankenBev by now but it remains, more or less, the original schematic.

I'm very aware of the dangers of using a cheater plug for my scope. When I first start troubleshooting the bad Bev amp 2-3 months ago. I thought to protect anything from failing on the driver board referencing to gnd something that shouldn't be, I used the cheater adapter since I was still getting acquainted with the board. After I probed the board where I needed to and realized the circuit is SE throughout and is just a diff amp used as a phase splitter and was ok to use the scope probe w/gnd clip. By that point I never thought to remove it. I know that's a dangerous mistake. It's been removed. When I was still working we would test car audio amps which had balanced outpts which required the use of a scope set to 'Diff' mode or use a plug adapter to float the scope otherwise the output ICs blew.

Looking at your amp's pics I see you are using 100uF caps in the totem poles. That's an additional 424uf from the stock total capacitance. Doing this significantlly increases the charging current putting a bigger strain on the tubes at turn ON, at the tube plates specifically, especially with the very high voltages involved. I was hellbent on doing this with PS filter caps in my beloved Mac MI75's when I refurbished them but after confering with some guys at another audio blog, I got talked out of doing it. Yes there would be bit more bottom end to be had, but it wasn't worth deceasing tube life for it. The amps sound great just the same. This stuff can be done with SS stuff which involve much lower voltages with no issues. Do you have a full front view of the tube board?

I was asking in last post how long you had these amps? Did you make the new amp(main) board yourself or you had it made? As I previously mentioned, I hope to start breadboarding this winter a balanced tube I/O driver board to replace the SS one, adding a toroid pwr xformer for it and PS board which will have regulated plate (hopefully) and filament supplies. Another thing I did not long after I got my Bevs was I bought a complete set of new Potter caps and Caddock hi-watt resistors to have on hand. (Or maybe just the caps).

Back in the 90's I experimented with the speakers by removing the panels from their cabinets and building frames, each frame holding 3 panels. I did this because I wanted more top end and to hear what differences there would be in the image and focus of instruments/voices from left to right. I knew I would give up the great depth the cabinets provide with their 180 deg lenses but I wanted a more up front jazz night club sound which I mostly listen to. It was worth it because I'm still listening to them that way. Now I'm thinking of turning my 2SW-1's into 2's by adding the high freq control which switches in or out either of two caps to give you +3 or +6dB more top end and then put the panels back in their cabinets to see how I like them. The cabinets are still in great shape (the grilles are starting to crumble a bit). I bought a new set from RAM back then. At that time I also re-veneered the cabinets myself which were walnut and veneered them in teak to match my Fried model T stereo subwfr. I also built a mylar stretcher to rebuild panels. Bev should have used an adhesive to glue the stators together (rather than just screw them together) after the diaphrams were stretched because after many years they loose their tension and flop-over occurs. RAM used adhesive when he rebuilt my panels the second time I sent them to him. I used 2-part epoxy which has a 30 minute set-up time to give me plenty of time to work.

When you have the time please check out my questions on my last post. Thanks.

Looking at your amp's pics I see you are using 100uF caps in the totem poles. That's an additional 424uf from the stock total capacitance. Doing this significantlly increases the charging current putting a bigger strain on the tubes at turn ON, at the tube plates specifically, especially with the very high voltages involved. I was hellbent on doing this with PS filter caps in my beloved Mac MI75's when I refurbished them but after confering with some guys at another audio blog, I got talked out of doing it. Yes there would be bit more bottom end to be had, but it wasn't worth deceasing tube life for it. The amps sound great just the same. This stuff can be done with SS stuff which involve much lower voltages with no issues. Do you have a full front view of the tube board?

I was asking in last post how long you had these amps? Did you make the new amp(main) board yourself or you had it made? As I previously mentioned, I hope to start breadboarding this winter a balanced tube I/O driver board to replace the SS one, adding a toroid pwr xformer for it and PS board which will have regulated plate (hopefully) and filament supplies. Another thing I did not long after I got my Bevs was I bought a complete set of new Potter caps and Caddock hi-watt resistors to have on hand. (Or maybe just the caps).

Back in the 90's I experimented with the speakers by removing the panels from their cabinets and building frames, each frame holding 3 panels. I did this because I wanted more top end and to hear what differences there would be in the image and focus of instruments/voices from left to right. I knew I would give up the great depth the cabinets provide with their 180 deg lenses but I wanted a more up front jazz night club sound which I mostly listen to. It was worth it because I'm still listening to them that way. Now I'm thinking of turning my 2SW-1's into 2's by adding the high freq control which switches in or out either of two caps to give you +3 or +6dB more top end and then put the panels back in their cabinets to see how I like them. The cabinets are still in great shape (the grilles are starting to crumble a bit). I bought a new set from RAM back then. At that time I also re-veneered the cabinets myself which were walnut and veneered them in teak to match my Fried model T stereo subwfr. I also built a mylar stretcher to rebuild panels. Bev should have used an adhesive to glue the stators together (rather than just screw them together) after the diaphrams were stretched because after many years they loose their tension and flop-over occurs. RAM used adhesive when he rebuilt my panels the second time I sent them to him. I used 2-part epoxy which has a 30 minute set-up time to give me plenty of time to work.

When you have the time please check out my questions on my last post. Thanks.

Dude. PICTURES! Need pictures of your cool Bev stuff. Open baffles? Your own stretcher? Don't be a tease 🤣

I've owned my pair for 5 years. The new blank boards were made by a friend of mine here in Chicago many years ago, he had a couple extra sets and I got lucky. They match the original layout.

Thanks for the Harold-approved dummy load info! This is something I did not know. For others reading I can confirm these amps will run fine on the bench with no load, a load is not mandatory, but I have plans for testing with one.

It seems to me whether your resistor is noninductive or not is a BIG deal here, I went with inductive as I want the load to ease up a little at HF.

When I say mid-point I mean between the upper & lower tubes (where the Varistor is).

Each of the 3 half-wave screen grid power supplies run off the 36V filament winding that drives their respective tube. This defines the voltage across each screen cap at about 51 Volts. Some early hand-drawn schematics have this voltage noted on them.

Of course both of the 'upper' screen supplies are elevated & sitting on +1650VDC. The single 'lower' screen supply is shared by both totem poles as they share a single filament winding.

I've owned my pair for 5 years. The new blank boards were made by a friend of mine here in Chicago many years ago, he had a couple extra sets and I got lucky. They match the original layout.

Thanks for the Harold-approved dummy load info! This is something I did not know. For others reading I can confirm these amps will run fine on the bench with no load, a load is not mandatory, but I have plans for testing with one.

It seems to me whether your resistor is noninductive or not is a BIG deal here, I went with inductive as I want the load to ease up a little at HF.

When I say mid-point I mean between the upper & lower tubes (where the Varistor is).

Each of the 3 half-wave screen grid power supplies run off the 36V filament winding that drives their respective tube. This defines the voltage across each screen cap at about 51 Volts. Some early hand-drawn schematics have this voltage noted on them.

Of course both of the 'upper' screen supplies are elevated & sitting on +1650VDC. The single 'lower' screen supply is shared by both totem poles as they share a single filament winding.

Ok let's talk inrush. Let me start at the finish and say I think it's mandatory to add inrush limiting, these don't have any. This is the single cheapest thing you can do to keep your transformer running forever.

Two things here have a strong inrush: our bank of electrolytic capacitors, but also the filaments of the vacuum tubes. Both of these currents travel thru the power transformer so both can be controlled with a restriction on the transformer primary.

I have verified the factory fuse value is much too big and can be reduced if you get inrush out of the way. Doing both of these things together - adding a IRL and simultaneously reducing the fuse value - is a kind of belt & suspenders and synergistic.

The inrush specific to the capacitors also travels thru your rectifiers, which benefit just as much from this upstream protection.

So when you say upping the size of the cap bank significantly increases the charging current you are correct but this charging current does not go thru (or even near) the tubes. Tube plates do not experience inrush, the tube filaments do.

Right now I use a 220 Ohm 2A IRL and a 2.5A type FCA fast blow fuse.

Hope this helps?

https://photos.app.goo.gl/iDmrKY9Y1ziDLmXWA

Two things here have a strong inrush: our bank of electrolytic capacitors, but also the filaments of the vacuum tubes. Both of these currents travel thru the power transformer so both can be controlled with a restriction on the transformer primary.

I have verified the factory fuse value is much too big and can be reduced if you get inrush out of the way. Doing both of these things together - adding a IRL and simultaneously reducing the fuse value - is a kind of belt & suspenders and synergistic.

The inrush specific to the capacitors also travels thru your rectifiers, which benefit just as much from this upstream protection.

So when you say upping the size of the cap bank significantly increases the charging current you are correct but this charging current does not go thru (or even near) the tubes. Tube plates do not experience inrush, the tube filaments do.

Right now I use a 220 Ohm 2A IRL and a 2.5A type FCA fast blow fuse.

Hope this helps?

https://photos.app.goo.gl/iDmrKY9Y1ziDLmXWA

OK, OK. I have attached some pics of my Bev system below, but first per your post from last Thurs. So it may be understood, Harold Bev didn't approve anything. I asked him by phone many many years (early '80s) what would be a good dummy load to use when benching a Bev amp. HE told me to use the R & C values I gave you. The 10W, 1.2K resistor I use is an inductive type and it works just fine..been using it for many years if I needed to. It really doesn't make much difference.

Referring to the new corrected schematic from '20, I have noted the 50V value on the screen caps on the very original schematic from '75. So the voltage at the top tube side (i.e., V203 cathode) where the varistor, 2.2K, and 470pF are tied together is ~1650V. (I have 2.2M isolating resistors in my amps.) What is the voltage at the other side of these components, i.e., the plate of V204 for example? What would the voltage rating of the 470pF be? Have you actually measured these voltages quiescently, with no input signal applied? I would REALLY like to see the actual audio on the diaphrams. With 1650VDC, I would be exceeding the DC limit of my scope after AC coupling it. Have you seen the audio signal at the diaphram? How can I see this?

On the topic of inrush current, I don't have to worry about that in my case because I have the softstart circuit to null this, but I don't see how, IF there is no IRL or other protection used, the tube plates would not be affected by this since the 3200V is going through only a 200 ohm resistor at the top end of totem pole. Regardless of rectifier diodes or not there would be large current surge.

On an earlier post you mentioned that you don't use load resistors when testing amps That could be very detrimental to the amps, especially if you are making power or THD measmts. They do need a load. This is especially so with SS amps. I learned that a very long time ago when I forgot to hook up my load resistors to my Mac MA6100 which has full complimentary direct-coupled outputs instead of the typical Mac output xformer (bi-filar wound) and wiped out the output xistors.

In regard to the attached pics, I will probably turn off some or all of the Bev owners with the first pic of my speaker panels sans cabinets & lenses. Back in the mid nineties I had a great curiosity as to how the panels would sound out of their cabinets and mounted in a suitable wood frame. I was longing for more top end, detail and more focus of voices and instruments from left to right. I new I would be giving up the great front to back depth. So I got some 1- 1/2" X 3/4" poplar wood pieces which is very much cheaper than oak but almost as strong and dense, some fastners/hardware and built the frame(s) you see - all for not that much $$. After finishing them and many hours of listening, my suspicions turned out to be correct. I did miss the depth of the soundstage and greater stereo field the lenses provide but desired more, more top end with more upfront, intimate in-your face sound that you get in a jazz nightclub. I do listen to classical and other music genres but mostly jazz. Listening to the panels this way, the voices and instruments are more clearly placed and the stage has a less homogenated (spelling?) sound. (The Bev acoustic lenses are actually diffraction gratings [per wave theory]...when plane wavefronts goes through a slot in a barrier, out comes 180 degree wave fronts on the other side of the barrier. I may to turn my amps into 2SW-2's by adding the switchable input caps to the output board inputs to add either 3 or 6dB at the high end. I then might put the panels back in the cabinets and listen again.

Lastly, if you want to try rebuilding a panel, I included a pic of the roll of mylar I got several years back from CS Hyde. I see you are in Chicago and CS Hyde is in your back yard in Lake Villa, IL. With my set-up, a 100' roll will rebuild 36 panels which should last a little while, ha ha. If you desire they can put 100' of it on one roll.

https://catalog.cshyde.com/keyword/?ddlSearchType=2&keyword=48-1f-1m

Referring to the new corrected schematic from '20, I have noted the 50V value on the screen caps on the very original schematic from '75. So the voltage at the top tube side (i.e., V203 cathode) where the varistor, 2.2K, and 470pF are tied together is ~1650V. (I have 2.2M isolating resistors in my amps.) What is the voltage at the other side of these components, i.e., the plate of V204 for example? What would the voltage rating of the 470pF be? Have you actually measured these voltages quiescently, with no input signal applied? I would REALLY like to see the actual audio on the diaphrams. With 1650VDC, I would be exceeding the DC limit of my scope after AC coupling it. Have you seen the audio signal at the diaphram? How can I see this?

On the topic of inrush current, I don't have to worry about that in my case because I have the softstart circuit to null this, but I don't see how, IF there is no IRL or other protection used, the tube plates would not be affected by this since the 3200V is going through only a 200 ohm resistor at the top end of totem pole. Regardless of rectifier diodes or not there would be large current surge.

On an earlier post you mentioned that you don't use load resistors when testing amps That could be very detrimental to the amps, especially if you are making power or THD measmts. They do need a load. This is especially so with SS amps. I learned that a very long time ago when I forgot to hook up my load resistors to my Mac MA6100 which has full complimentary direct-coupled outputs instead of the typical Mac output xformer (bi-filar wound) and wiped out the output xistors.

In regard to the attached pics, I will probably turn off some or all of the Bev owners with the first pic of my speaker panels sans cabinets & lenses. Back in the mid nineties I had a great curiosity as to how the panels would sound out of their cabinets and mounted in a suitable wood frame. I was longing for more top end, detail and more focus of voices and instruments from left to right. I new I would be giving up the great front to back depth. So I got some 1- 1/2" X 3/4" poplar wood pieces which is very much cheaper than oak but almost as strong and dense, some fastners/hardware and built the frame(s) you see - all for not that much $$. After finishing them and many hours of listening, my suspicions turned out to be correct. I did miss the depth of the soundstage and greater stereo field the lenses provide but desired more, more top end with more upfront, intimate in-your face sound that you get in a jazz nightclub. I do listen to classical and other music genres but mostly jazz. Listening to the panels this way, the voices and instruments are more clearly placed and the stage has a less homogenated (spelling?) sound. (The Bev acoustic lenses are actually diffraction gratings [per wave theory]...when plane wavefronts goes through a slot in a barrier, out comes 180 degree wave fronts on the other side of the barrier. I may to turn my amps into 2SW-2's by adding the switchable input caps to the output board inputs to add either 3 or 6dB at the high end. I then might put the panels back in the cabinets and listen again.

Lastly, if you want to try rebuilding a panel, I included a pic of the roll of mylar I got several years back from CS Hyde. I see you are in Chicago and CS Hyde is in your back yard in Lake Villa, IL. With my set-up, a 100' roll will rebuild 36 panels which should last a little while, ha ha. If you desire they can put 100' of it on one roll.

https://catalog.cshyde.com/keyword/?ddlSearchType=2&keyword=48-1f-1m

Attachments

I think it's cool you got to talk with Harold. I talked once with his son Rick, in I think 2019. He was happy to hear from a fan and quite gracious but sadly the signs of age were already in place. The last I heard he was not doing well.

The dummy load was from his lips to your ears so good enough for me. I'm eager to do some bench testing with one and will grab some of the measurements you've asked for whenever I next have one on the bench.

I think your speakers are cool and hey we all just instantly learned you don't have a cat because he'd be dead by now 🤣 . You're running with three thousand volts on the outside? Warn the cleaning lady ":^)

I bet your set up goes much louder, right? I stuck a mic deep into the lens once and it was almost ten dB louder back near the transducer! The Beveridge Lens may be an acoustic miracle but it's quite inefficient.

Regarding inrush. it's true the +3200V almost immediately arrives at the top plates of the totem poles, but it doesn't do anything once it arrives. The tubes at this moment are stone cold, they can not draw any plate current at all until the filament has warmed and that's a good twenty seconds after the inrush occurs.

The Mac 6100 will happily blow itself up because it has a CROWBAR ACROSS THE OUTPUT that is one of the dumbest 'protection' ideas ever. Removing it entirely makes for a more reliable amp. It's worth buying the Doug Self book just to read him bitch about this feature ":^)

I raised my children in Lake Villa, I know it well ❤️. I'm down in the city these days.

The dummy load was from his lips to your ears so good enough for me. I'm eager to do some bench testing with one and will grab some of the measurements you've asked for whenever I next have one on the bench.

I think your speakers are cool and hey we all just instantly learned you don't have a cat because he'd be dead by now 🤣 . You're running with three thousand volts on the outside? Warn the cleaning lady ":^)

I bet your set up goes much louder, right? I stuck a mic deep into the lens once and it was almost ten dB louder back near the transducer! The Beveridge Lens may be an acoustic miracle but it's quite inefficient.

Regarding inrush. it's true the +3200V almost immediately arrives at the top plates of the totem poles, but it doesn't do anything once it arrives. The tubes at this moment are stone cold, they can not draw any plate current at all until the filament has warmed and that's a good twenty seconds after the inrush occurs.

The Mac 6100 will happily blow itself up because it has a CROWBAR ACROSS THE OUTPUT that is one of the dumbest 'protection' ideas ever. Removing it entirely makes for a more reliable amp. It's worth buying the Doug Self book just to read him bitch about this feature ":^)

I raised my children in Lake Villa, I know it well ❤️. I'm down in the city these days.

Hey looking closer at your pictures, do you have a mix of 1st and 2nd generation panels? It looks like some have the aluminum frame and some do not?

All six of mine are 2nd generation, with the words 'Black Magic' and Rick's signature molded into them. Instead of the aluminum frame they have white plastic rails on the long sides.

I have no idea about performance differences between the two versions, but for sure Rick was trying to make them easier to manufacture.

All six of mine are 2nd generation, with the words 'Black Magic' and Rick's signature molded into them. Instead of the aluminum frame they have white plastic rails on the long sides.

I have no idea about performance differences between the two versions, but for sure Rick was trying to make them easier to manufacture.

Here's my inrush measured across 40 seconds. Display is in Amps with 4A at the top of the graph. You can see the initial tall spike (the combined inrush of caps, filaments, and the transformer itself). This is followed by the filaments running alone until they warm up, then you can see the plates start to conduct about 20 seconds later.

https://photos.app.goo.gl/LMAad9UZ8QJuag9KA

https://photos.app.goo.gl/LMAad9UZ8QJuag9KA

Interesting that you have all 6 panels 2nd generation black magic.Hey looking closer at your pictures, do you have a mix of 1st and 2nd generation panels? It looks like some have the aluminum frame and some do not?

All six of mine are 2nd generation, with the words 'Black Magic' and Rick's signature molded into them. Instead of the aluminum frame they have white plastic rails on the long sides.

I have no idea about performance differences between the two versions, but for sure Rick was trying to make them easier to manufacture.

I had two of these new panels in on of my model 2, along with four old generation 1 panels. And they sound very different from each other, most significantly the black magics are much lower sensitivity

- Home

- Loudspeakers

- Planars & Exotics

- Troubleshooting Help Needed for My Bev 2SW-1 Amp