Hi everyone,

I'm just in the process of updating the next iteration of my enclosure in my LS430 and noticing some modelling/real world discrepancies which I'd like to get some opinions on.

First for equipment, the system is comprised of:

- Two 12" DC Audio XLs (3" 8-layer flatwound DVC option, 2200W RMS a piece, QTS = ~0.38)

- Rockford Fosgate T1500.1BDCP (regulated at 1900W/1800W/1200W at 1/2/4 ohms respectively)

- Final impedance is wired to 1-ohm

- ~200L 4th/6th order adjustable enclosure

The enclosure is built as a series BP6 with following specs and pictures below:

- Rear chamber: 55-61L (depending on port configuration)

- Front chamber: 125-131L

- Internal ports comprise of four 46cm long PVC pipes which can be capped off to modulate internal port area (~0/45/90/135/190 square centimeters of port)

- Front port is 27cm long, with 489 square centimeters of area. In front of this there is another ~10cm of effective length having an area of ~900 square centimeters where the arm-rest recesses.

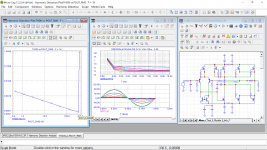

Enclosure has been modeled in Hornresp taking into account all port configurations and corresponding displacements @ 1kW RMS. Overall, the response of the box with the cabin gain is close to expected as we see in the RTAs that follow.

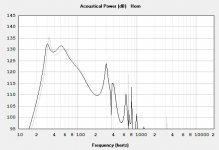

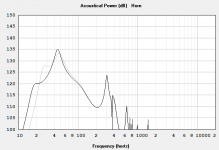

Below are Hornresp graphs which show the five different configurations:

4 ports open vs. 3 ports open

2 ports open vs. 1 port open

1 port open vs. 0 ports open (4th order mode)

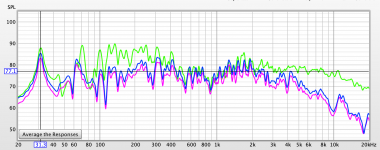

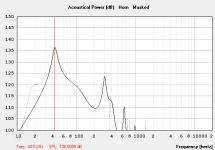

I've taking many measurements with UMIK-1 at relatively low volume (well within any limits of microphone clipping). I'm noticing an intricacy in 4th order mode as well as 1 and 2-port 6th order modes that deviates from the sims in regards to peak output. Based on modelling I'd expect it to peak harder than the next closest configurations (1-2 ports open) by ~2-4dB respectively but that does not appear to be the case. At much higher power (1000W+) I've also RTAd the vehicle with the mic outside the window (in order not clip the mic inside the vehicle) and the same discrepancy is observed.

First set of measurements are with front windows open with UMIK at headrest (probably less than <5W). Box configurations can be identified by their low-freq shelf.

Green: 4 ports

Light green: 3 ports

Orange: 2 ports

Purple: 1 port

Blue: 0 ports (4th order)

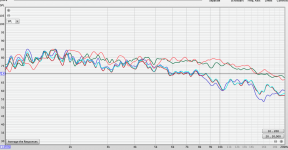

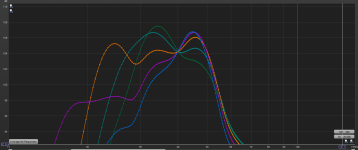

Second set of measurements are with all windows open with UMIK outside of car, ~1m away from B-pillar at same power. It's clear the car has optimal resonance mode at ~46-47Hz which is the the rough range where I'd like to target for peak SPL. The trace colors are different in this chart.

Green: 4 ports

Orange: 3 ports

Purple: 2 ports

Dark green: 1 ports

Red: 0 ports

For anybody wondering on why I want it to peak harder, it's to optimize this enclosure in these port configurations for SPL competition. I like having the modularity to switch port configurations on the fly for when I daily drive and when I want to compete. For reference before I got the UMIK, for competition I set it up as a 4th order and on the first go it did a 146.1 @ 42Hz on a Termlab at around 1kW of power. Now with the UMIK, I now have more insight into what's going on and I'm wondering if 4th order may not be optimal regard to SPL.

Was hoping to get some insight as to why this might be happening.

In terms of some factors:

- I don't believe that it's port compression as this relative behavior happens at low volumes. Furthermore, even at ~2kW there is no audible noise from the port.

- Could it be impedance being drastically difference in 4th?

- As this is done at low power I doubt I am seeing large-signal driver effects relating to BL-change vs. excursion as the drivers are barely moving when taking these measurements.

- For sealing up the ports, I am using slip-on 3" PVC test caps (very elastic). They don't leak but I do know that they are thin enough to resonate but I'm doubting this is significant.

- Could there any issues with the bracing/port supports/ports causing some tuning effect inside the box (only thing I've considered is just their displacement)?

(or is measuring and calculating way more complex than expected?

(or is measuring and calculating way more complex than expected?