any interest for a 3" cast acrylic platter...

I am trying to find out what interest there might be for a machined 3” cast acrylic platter for your diy turntable.

You can obtain 12 X 12 X 3” cast acrylic ‘squares’ from Mc Masters –

http://www.diyaudio.com/forums/showthread.php?postid=1342996#post1342996

The Teres bearing and its machined dimensions is available: http://www.teresaudio.com/bearing.html and diy member woodturner-fran has mentioned on this site a few xlnt suggestions for the lead shot application:

http://www.diyaudio.com/forums/showthread.php?postid=1343230#post1343230

CNC milling machine seems to be the way to go here and there lies my dilemma; I have no experience talking the talk and making the correct decisions to have one produced for myself.

What I am wondering is if there would be enough members out there that would like to see a 3” acrylic platter for their project and if there is someone who is CNC milling savvy. Perhaps the person who undertakes the milling part of this or orchestrated the production could be rewarded somehow; perhaps all the other participants could chip in for his platter, as well of course the milling charge.

I would think that since there is such a large cost involved here that all members would purchase their platter individually and then send to the correct person who either has a milling machine or who would take it upon themselves to deliver it to the shop.

Any ideas? Thoughts??

Stan

I am trying to find out what interest there might be for a machined 3” cast acrylic platter for your diy turntable.

You can obtain 12 X 12 X 3” cast acrylic ‘squares’ from Mc Masters –

http://www.diyaudio.com/forums/showthread.php?postid=1342996#post1342996

The Teres bearing and its machined dimensions is available: http://www.teresaudio.com/bearing.html and diy member woodturner-fran has mentioned on this site a few xlnt suggestions for the lead shot application:

http://www.diyaudio.com/forums/showthread.php?postid=1343230#post1343230

CNC milling machine seems to be the way to go here and there lies my dilemma; I have no experience talking the talk and making the correct decisions to have one produced for myself.

What I am wondering is if there would be enough members out there that would like to see a 3” acrylic platter for their project and if there is someone who is CNC milling savvy. Perhaps the person who undertakes the milling part of this or orchestrated the production could be rewarded somehow; perhaps all the other participants could chip in for his platter, as well of course the milling charge.

I would think that since there is such a large cost involved here that all members would purchase their platter individually and then send to the correct person who either has a milling machine or who would take it upon themselves to deliver it to the shop.

Any ideas? Thoughts??

Stan

Attachments

If you are going to get acrylic machined I understand that diamond tools result in the best finish.

I can't see why you'd get it milled rather than turned, all the important features are concentric so having it turned will be both cheaper and more accurate.

For $80 you can buy a 40mm platter from DIY HiFi supply. Stack two and hey presto, a 3" platter. Getting the centre re-bored to suit a different bearing doesn't sound expensive. Add an intermediate layer of stainless steel or similar and call it a superplatter. Seems to me to be cheaper, easier and probably more functional.

I can't see why you'd get it milled rather than turned, all the important features are concentric so having it turned will be both cheaper and more accurate.

For $80 you can buy a 40mm platter from DIY HiFi supply. Stack two and hey presto, a 3" platter. Getting the centre re-bored to suit a different bearing doesn't sound expensive. Add an intermediate layer of stainless steel or similar and call it a superplatter. Seems to me to be cheaper, easier and probably more functional.

Mark Kelly said:If you are going to get acrylic machined I understand that diamond tools result in the best finish.

I can't see why you'd get it milled rather than turned, all the important features are concentric so having it turned will be both cheaper and more accurate.

For $80 you can buy a 40mm platter from DIY HiFi supply. Stack two and hey presto, a 3" platter. Getting the centre re-bored to suit a different bearing doesn't sound expensive. Add an intermediate layer of stainless steel or similar and call it a superplatter. Seems to me to be cheaper, easier and probably more functional.

Hi Mark, I mentioned CNC from an earlier suggestion: http://www.diyaudio.com/forums/showthread.php?postid=1343005#post1343005

How the platter is created is fine by me, your idea of two 40mm acrylic platters sandwiched w/ stainless S. or brass would make quite a beautiful platter as well, thanks.

It was just an idea, YMMV etc etc.

That being said, if any Aussie DIYer wants to try this I have two DIY HiFi supply 40 mm platters on hand which I don't want any more. They are available for the cost of shipping which should only be a few bucks in VIC or NSW. I have a single DIY HiFi supply bearing which you can have as well but I don't think much of it.

That being said, if any Aussie DIYer wants to try this I have two DIY HiFi supply 40 mm platters on hand which I don't want any more. They are available for the cost of shipping which should only be a few bucks in VIC or NSW. I have a single DIY HiFi supply bearing which you can have as well but I don't think much of it.

Mark Kelly said:It was just an idea, YMMV etc etc.

That being said, if any Aussie DIYer wants to try this I have two DIY HiFi supply 40 mm platters on hand which I don't want any more. They are available for the cost of shipping which should only be a few bucks in VIC or NSW. I have a single DIY HiFi supply bearing which you can have as well but I don't think much of it.

Hi Mark.

If you still have those platters I will gladly like to purchase them.

PS I tried using you email here on this site, but it is decactivated.

Regards

George.

Mark Kelly said:It was just an idea, YMMV etc etc.

That being said, if any Aussie DIYer wants to try this I have two DIY HiFi supply 40 mm platters on hand which I don't want any more. They are available for the cost of shipping which should only be a few bucks in VIC or NSW. I have a single DIY HiFi supply bearing which you can have as well but I don't think much of it.

Did you create this yourself, and pics?

No they were used for a prototype for a new turntable architecture I'm working on.

An externally hosted image should be here but it was not working when we last tested it.

My version :

http://www.vinylengine.com/phpBB2/album_pic.php?pic_id=4136

Platter is from Scheu , European counterpart of Teres , string driven by Maxon DC-motor. Tonearm is a heavily modified Rega RB300 with a Grado Platinum Wood.

Plinth is birch plywood with lead-shot fillings.

Bouquet

http://www.vinylengine.com/phpBB2/album_pic.php?pic_id=4136

Platter is from Scheu , European counterpart of Teres , string driven by Maxon DC-motor. Tonearm is a heavily modified Rega RB300 with a Grado Platinum Wood.

Plinth is birch plywood with lead-shot fillings.

Bouquet

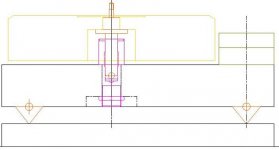

And the modified RB300

The adjustment on the left is for lowering the armpivot , so adjusting VTA , the grabs-crew on the right to lock the arm in place.

The downforce spring is removed , it's adjusted now with the counterweight.

This counterweight is replaced now with a wooden one ( african blackwood ) with lead inserts to dampen resonances.

It does make a noticable difference in the favor of the wooden counterweight.

Bouquet

The adjustment on the left is for lowering the armpivot , so adjusting VTA , the grabs-crew on the right to lock the arm in place.

The downforce spring is removed , it's adjusted now with the counterweight.

This counterweight is replaced now with a wooden one ( african blackwood ) with lead inserts to dampen resonances.

It does make a noticable difference in the favor of the wooden counterweight.

Bouquet

Attachments

Bouquet, I find your (and similar) designs very interesting indeed. I too have worked on turntable design for many years but have investigated very different routes to your self. In truth, I cannot criticise any of your design because I have not built any similiar components. My own design is different in almost every aspect; I use an AC motor, a very light but stiff chassis, a metal platter, a minimal contact mat, a suspended sub-chassis design, a combination of low and high mass chassis and a magnetic bearing.

It would be very interesting, but not in an adversarial sense, to compare our turntables as they are so diametrically opposed in so many conceptual ways. Often (myself included) a designer builds a conceptual hypothesis and investigates towards or around those thought processes. It has taken me 20 or so years to arrive at the point I am now at without experimenting in wildly different areas, or going off at severely different tangents.

It would be very interesting, but not in an adversarial sense, to compare our turntables as they are so diametrically opposed in so many conceptual ways. Often (myself included) a designer builds a conceptual hypothesis and investigates towards or around those thought processes. It has taken me 20 or so years to arrive at the point I am now at without experimenting in wildly different areas, or going off at severely different tangents.

An externally hosted image should be here but it was not working when we last tested it.

Great tables all.

They look great. I may be able to help out with 2 43 mm platters, as part of a group buy platter that I am (or have) organized.

just waiting (finally on a quote and samples...). Non polished platters. May be able to get them with just a 1/4" pilot hole in them too.

look for "any interest for acrylic platter group buy?" in GB forum

stew

They look great. I may be able to help out with 2 43 mm platters, as part of a group buy platter that I am (or have) organized.

just waiting (finally on a quote and samples...). Non polished platters. May be able to get them with just a 1/4" pilot hole in them too.

look for "any interest for acrylic platter group buy?" in GB forum

stew

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- My DIY Teres Turntable