sklimek said:Good article from 'The Analog Dept.' on an Teres acrylic platter lead shot upgrade and bearing install:

http://www.theanalogdept.com/teres_platter_upgrade.htm

They're using threaded brass plugs to seal off the 'shot'. I'm hopin' to email Fran as well before I go to a CNC mill to get a fix on his 'flywheel' idea for sealing the shot, mass and stability.

Stan

You can also use for convenience brass freeze plugs and just

to install

to installFound some time to work on my Teres project. I got very nice lead weight from work. They are over stock, we crumble under them, so why not use some of them

I used a hole saw and cut away lead cylinder. Here the work in progress.

I used a hole saw and cut away lead cylinder. Here the work in progress.

Attachments

The plinth weights 3.7Kg. So to I can add between 40% (1.5Kg) to 60% (2.2Kg) to it. I'll probably end cutting my weights in half to get 0.3Kg each. Then I'll need 8 leads weights installed equidistant to the bearing in a circle pattern.

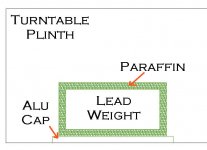

I'll drill hole, 1/8 countersink to install an aluminium sealing cap. I'll cut slices from an aluminium bar to build the cap. I'll mount the lead weight into the cavity using paraffin filling. This way, the lead won't migrate to much into the plinth's wood. Here an ACAD drawing showing how it can be done.

I'll drill hole, 1/8 countersink to install an aluminium sealing cap. I'll cut slices from an aluminium bar to build the cap. I'll mount the lead weight into the cavity using paraffin filling. This way, the lead won't migrate to much into the plinth's wood. Here an ACAD drawing showing how it can be done.

Attachments

Gorgeous stand acoustat!

Algar-emi - you know that the original teres uses lead shot rather than solid lead billet, right? I know that shot can be hard to get, but I really think you would be better off with a lose material, like lead shot that can absorb vibrations. With the lead weights as you have it you will get the extra weight, inertia etc, but not the vibration dampening.

Another material that is much easier to get and you could try it out is some shot blasting material. It is made from slag from the copper industry and is very cheap and most likely available from where shot/sand blasters get their supplies. Its quite fine and black material - I am using it in a lenco plith thats currently underway here. You could drill out your holes a little deeper and add some of that material first and then the lead billet for more weight after and then the alu cap.

Fran

Algar-emi - you know that the original teres uses lead shot rather than solid lead billet, right? I know that shot can be hard to get, but I really think you would be better off with a lose material, like lead shot that can absorb vibrations. With the lead weights as you have it you will get the extra weight, inertia etc, but not the vibration dampening.

Another material that is much easier to get and you could try it out is some shot blasting material. It is made from slag from the copper industry and is very cheap and most likely available from where shot/sand blasters get their supplies. Its quite fine and black material - I am using it in a lenco plith thats currently underway here. You could drill out your holes a little deeper and add some of that material first and then the lead billet for more weight after and then the alu cap.

Fran

I'm afraid that silicone will affect the plinth's vernish finish. I remembered, when I built my house, that the silicone smell of the bathroom prevented the guys from vernishing the floors. Silicone vapour can produce fish eye defect into the vernish finish. This is why, I'll try to stay away from silicone with the table.

Algar_emi said:I'm afraid that silicone will affect the plinth's vernish finish. I remembered, when I built my house, that the silicone smell of the bathroom prevented the guys from vernishing the floors. Silicone vapour can produce fish eye defect into the vernish finish. This is why, I'll try to stay away from silicone with the table.

If silicone gets on the wood, it will affect the finish. The smell (acetic acid, aka vinegar) is harmless.

As far as I know, Teres is pretty particular about the lead shot, I think it must be no. 8 or no. 9 shot.

Now in reality, the inertia plays an important role, but I would add in some kind of damping if you can. Even sand around the lead would work....

Silicone will affect some finishes, most notably cellulose based sprays - it will fight and you get orange peel finish. If you are oiling the wood, or using an oil based varnish you must likely will get away with it.

Fran

Now in reality, the inertia plays an important role, but I would add in some kind of damping if you can. Even sand around the lead would work....

Silicone will affect some finishes, most notably cellulose based sprays - it will fight and you get orange peel finish. If you are oiling the wood, or using an oil based varnish you must likely will get away with it.

Fran

OK, I accept the out-gasing of silicone caulk being a problem to finishes and the nose. I had assumed there would be time allowed for the evaporation to run its course...I guess that's a comment on the pace at which I work... There are other materials which fall into the category of "sealants" which remain flexible and would provide damping.

Exterior grade sealants:

http://www.bestmaterials.com/SearchResult.aspx?CategoryID=748

Self-leveling sealants:

http://www.bestmaterials.com/SearchResult.aspx?CategoryID=969

Exterior grade sealants:

http://www.bestmaterials.com/SearchResult.aspx?CategoryID=748

Self-leveling sealants:

http://www.bestmaterials.com/SearchResult.aspx?CategoryID=969

I was also waiting for a set of rabetting bit to install the lead into my Teres plinth and Santa was there to provide it  . I know I paid for it anyway but, it's Christmas. I want to cap the hole with an aluminium plug and the rabetting bit will be perfect to cut a 1/8" bigger hole than the lead hole.

. I know I paid for it anyway but, it's Christmas. I want to cap the hole with an aluminium plug and the rabetting bit will be perfect to cut a 1/8" bigger hole than the lead hole.

. I know I paid for it anyway but, it's Christmas. I want to cap the hole with an aluminium plug and the rabetting bit will be perfect to cut a 1/8" bigger hole than the lead hole.

. I know I paid for it anyway but, it's Christmas. I want to cap the hole with an aluminium plug and the rabetting bit will be perfect to cut a 1/8" bigger hole than the lead hole.Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- My DIY Teres Turntable