Late 50's / early 60's VW Beetles had the battery under the rear seat on the passenger side. Makes for a hot seat when the sagging seat springs touch the top of the battery.

We had a VW Squareback when I was growing up, some idiot at a Sears auto center sold us a battery that was too tall... Luckily it was discovered without the entire car burning.

I have had good luck with Moog Cargo Coils for added capacity for many cars. Or the rubber spring boosters that occupy the space between a coil work pretty good too. Some of those can raise the car as well if that’s the objective. Or maybe it’s just to maintain a normal ride height with a large subwoofer cabinet.

My project will involve a dual 10" subwoofer in a box that was made specifically for this car as it will clear the two strut towers and the rear parcel shelf with a centimeter to spare on each side.

I'm not 100% sure on the second part and that is re-making a second dual 8" subwoofer in the same size of cabinet. The cost might be too great as the drivers are expensive but we will have to see what my finances are like for the rest of 2018.

I'm not 100% sure on the second part and that is re-making a second dual 8" subwoofer in the same size of cabinet. The cost might be too great as the drivers are expensive but we will have to see what my finances are like for the rest of 2018.

I received the 8 meters of 35mm2 cable yesterday. Today I figured out an interesting method of drilling some extra holes without having to get underneath the car to look at the area where I'm drilling into. I simply went down and stuck my middle finger through the existing aircon AC drain hole and then pulled my middle finger out and measured where the holes should be roughly. and also at the same time checked the area around where I'm going to make the holes to make sure that they were free of obstacles.

I then put a small 2mm pilot hole into the metal using a step drill then reconfirmed where its going to come out on the other side with my finger again. I made sure that where I was putting the holes there wasn't going to be any obstacles on the other side, but it did come close on the 10 o'clock position hole that I made.

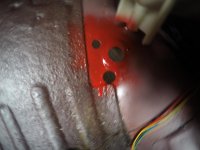

In the attached pictures you can see the original existing ac drain hole which is about 22-24mm wide, but you can also see the first hole that I made at about the 6-7 o'clock position, this hole is 20mm wide, I've ordered some cable grommets for this size hole.

Also in the attached pictures you can see a second hole at about the 10 O'Clock position in reference to the original AC drain hole. this hole is 14mm wide, the reason why this one is so small is because just above it and to the left there are what I suspect to be either fuel lines/brake lines or a bracket to hold the steering rack in place.

I've also ordered some 13mm inner diameter plastic conduit on ebay, that will take a while to arrive.

I've also sprayed the new holes with some high temp paint that I had lying around.

I did the best I could considering but as far as I'm concerned it turned out good, really good. Now I can route two 35mm SQ cables for the front amp and the rear subwoofer amp as well as a 6mm SQ cable for ham radio use and coax.

I then put a small 2mm pilot hole into the metal using a step drill then reconfirmed where its going to come out on the other side with my finger again. I made sure that where I was putting the holes there wasn't going to be any obstacles on the other side, but it did come close on the 10 o'clock position hole that I made.

In the attached pictures you can see the original existing ac drain hole which is about 22-24mm wide, but you can also see the first hole that I made at about the 6-7 o'clock position, this hole is 20mm wide, I've ordered some cable grommets for this size hole.

Also in the attached pictures you can see a second hole at about the 10 O'Clock position in reference to the original AC drain hole. this hole is 14mm wide, the reason why this one is so small is because just above it and to the left there are what I suspect to be either fuel lines/brake lines or a bracket to hold the steering rack in place.

I've also ordered some 13mm inner diameter plastic conduit on ebay, that will take a while to arrive.

I've also sprayed the new holes with some high temp paint that I had lying around.

I did the best I could considering but as far as I'm concerned it turned out good, really good. Now I can route two 35mm SQ cables for the front amp and the rear subwoofer amp as well as a 6mm SQ cable for ham radio use and coax.

Attachments

The world's first car in outer space and the world's first fully functioning car audio system in outer space.

I'm sure that there was a quite deliberate dose of irony in doing that

Tony.

Oh, I think Elon was just having one of his whimsical moments - and he's probably on the short list for the new roadster anyway?

The most impressive part of this was probably that it was a successful launch on first attempt of the most powerful lift rocket since Saturn V, and that two of the boosters managed to land unscathed on the pad. Who else has managed that?

The most impressive part of this was probably that it was a successful launch on first attempt of the most powerful lift rocket since Saturn V, and that two of the boosters managed to land unscathed on the pad. Who else has managed that?

Last edited:

I noticed that Ford is releasing an all aluminium body Ford F-Series trucks now.

Don't worry. its a ford. it will still find a way to rust.

I just found shitloads of rust on my Ford Au Falcon and I will be getting rid of it once I drain the tank of gas. They never sealed the seams up at the factory and they always design the seams where they will either collect water or be exposed to a high moisture environment. so whenever one large major body panel meets another and needs to be welded together you will find them rusting to the point that the entire weld seam will crumble in your hands and you won't have a car that holds together anymore.

On mine there is a rubber gasket which runs the entire left hand side of the windscreen on the passengers side (Aust passengers), I lifted up that gasket because I noticed some bubbling at the edge of the gasket and the entire god damn metal seam was rusting away, to the point that there isn't any metal there to do a repair on even if I could repair it which I can't because its a structural point and I would need to do too much to make it strong enough to hold the body together!

Don't worry. its a ford. it will still find a way to rust.

I just found shitloads of rust on my Ford Au Falcon and I will be getting rid of it once I drain the tank of gas. They never sealed the seams up at the factory and they always design the seams where they will either collect water or be exposed to a high moisture environment. so whenever one large major body panel meets another and needs to be welded together you will find them rusting to the point that the entire weld seam will crumble in your hands and you won't have a car that holds together anymore.

On mine there is a rubber gasket which runs the entire left hand side of the windscreen on the passengers side (Aust passengers), I lifted up that gasket because I noticed some bubbling at the edge of the gasket and the entire god damn metal seam was rusting away, to the point that there isn't any metal there to do a repair on even if I could repair it which I can't because its a structural point and I would need to do too much to make it strong enough to hold the body together!

Last edited:

Fords used to be quite bad for rusting in the UK too.

In the last 20 years they seem to be a lot better.

I have had 10 year old Fords that had no rust on the bodywork.

My current Ford Mondeo has electric hand brake and soft start etc.

It will be interesting to see how long it is before they go wrong.

Its already been in to have the battery changed after 2 years from new.

In the last 20 years they seem to be a lot better.

I have had 10 year old Fords that had no rust on the bodywork.

My current Ford Mondeo has electric hand brake and soft start etc.

It will be interesting to see how long it is before they go wrong.

Its already been in to have the battery changed after 2 years from new.

Audi (since the mid 80's) and VW (since the mid 90's) have galvanized panels, don't seem to rust much at all. I'm sure a few other marques are doing it by now. I have seen mid 2000's mazdas(ford) that are still pretty bad as far as rust-through goes. I rented a 2017 nissan altima with 15k miles that had rust at a seam on the back door

Hondas seem better than they used to be...but rust is all part of planned obsolescence that gets you to buy new.

Hondas seem better than they used to be...but rust is all part of planned obsolescence that gets you to buy new.

My favourite lady a young Liz Hurley.

An externally hosted image should be here but it was not working when we last tested it.

That design had the "odd fire" crankshaft, essentially a V8 with two cylinders missing. The "even fire" 231 CI design had the offset ground crank such that a cylinder fired every 120 degrees.

I never had a Buick 198 but did play with a turbocharged 231 in my Camaro for a while before it found its final home in a friends Chevy Monza. My turbo 2.2L Dodge would still beat his Monza on the dragstrip and the autocross course.

Another fun car I had was a 1962 Oldsmibile Starfire. It had a factory turbocharged aluminum 215 CI Buick V8. The ugly old car sure surprised a few muscle car owners at the dragstrip.

That engine was too far ahead of its time for GM (didn't sell well), so they sold the design and all the tooling to British Leyland where it resurfaced as the Rover 3.5L V8 that powered everything from Land Rovers to the Triumph TR8. More than a few "TR8's" were DIYed in the US from TR7's and old Buick parts. Some even got modern Land Rover fuel injection.

I never had a Buick 198 but did play with a turbocharged 231 in my Camaro for a while before it found its final home in a friends Chevy Monza. My turbo 2.2L Dodge would still beat his Monza on the dragstrip and the autocross course.

Another fun car I had was a 1962 Oldsmibile Starfire. It had a factory turbocharged aluminum 215 CI Buick V8. The ugly old car sure surprised a few muscle car owners at the dragstrip.

That engine was too far ahead of its time for GM (didn't sell well), so they sold the design and all the tooling to British Leyland where it resurfaced as the Rover 3.5L V8 that powered everything from Land Rovers to the Triumph TR8. More than a few "TR8's" were DIYed in the US from TR7's and old Buick parts. Some even got modern Land Rover fuel injection.

- Home

- Member Areas

- The Lounge

- The car thread