Sorry, not with transformer sets - was looking at another version. Went back to edit but missed the 30-minute time window.The current schematic in PNG and a PDF version with suggested transformer sets.

All transformers are available from Sowter.

To get the S&B TX102 stepped attenuators I have used one has to buy the Baby Classic Pre Amplifier from Music First, a snip at £1500 GBP excluding VAT (n.b. irony). S&B won't sell the transformers on their own (unless anyone knows different?).

There are other ways to do the volume control, note however that I have the TX102 wired in +6db mode for 2x gain.

My next choice would be the Sowter 1035 Attenuator with 6 dB Gain and Balance control. 48 dB in 2 dB steps plus 4 x 0.5 dB primary balance taps. Note I have not tried them myself, for £182.67 times two reasons!

Heatsinks

Just as a note: This is the smallest sized heatsink needed for a single channel PP power stage, with a bias of about 750mA per MOSFET:

ABL Components 177AB2000B

https://uk.rs-online.com/web/p/heatsinks/9033107/

Corrugated fins, &c. are a little better but this is the base point for an amp build.

Just as a note: This is the smallest sized heatsink needed for a single channel PP power stage, with a bias of about 750mA per MOSFET:

ABL Components 177AB2000B

https://uk.rs-online.com/web/p/heatsinks/9033107/

Corrugated fins, &c. are a little better but this is the base point for an amp build.

Hi,

Depletion MOSFETs with self biasing or standard MOSFETs with separate bias?

Please note that the Zeus 75 is the Power Stage, and you will also need a Line Driver.

You can use the headphone output if it will drive low impedance headphones, you may not get full volume though. However, it would get you going.

Are you intending to us analogue sources, or only digital?

If only digital you can dispense with the stepped attenuator and use the digital volume control in the disc/media-player. As an example with our Oppo most Blu-Rays play at about 80, and DVDs at about 90; where 100 is maximum volume.

This depends on your speakers, size of listing room, type of music, and a lot of other factors so may not be suitable in all cases.

Hope this helps.

Depletion MOSFETs with self biasing or standard MOSFETs with separate bias?

Please note that the Zeus 75 is the Power Stage, and you will also need a Line Driver.

You can use the headphone output if it will drive low impedance headphones, you may not get full volume though. However, it would get you going.

Are you intending to us analogue sources, or only digital?

If only digital you can dispense with the stepped attenuator and use the digital volume control in the disc/media-player. As an example with our Oppo most Blu-Rays play at about 80, and DVDs at about 90; where 100 is maximum volume.

This depends on your speakers, size of listing room, type of music, and a lot of other factors so may not be suitable in all cases.

Hope this helps.

Dear Susan!

Could you tell me what is the resistance of your T3 input transformer"s secondary winding?

Happy New Year!

Tyimo

Hi Tyimo,

Thanks, and for you too

Each secondary DC resistance is 77.5Ω, so 155Ω in total across the two.

Best New Year Wishes,

Susan.

Last edited:

Zeus 75 Transformers

Transformers from Sowter:

A: With Volume control:

TRANSFORMER ATTENUATORS

#1 = 1035 Attenuator

B: Without local Volume control:

PRE AMP INPUT TRANSFORMERS

#1 = 9063 Input 1CT:2+2

C: Main Transformer Set

Replacement transformers for classic valve tube amps. Page 3

#2 = 9940 Line Driver (used SE 1:2 step-up)

#3 = 8160 with 50% mumetal core

#4 = 9840 Output Transformer

Hi there,

Is there an updated bill of materials somewhere? I'm looking to build the Zeus 75 Power Amplifier.

Transformers from Sowter:

A: With Volume control:

TRANSFORMER ATTENUATORS

#1 = 1035 Attenuator

B: Without local Volume control:

PRE AMP INPUT TRANSFORMERS

#1 = 9063 Input 1CT:2+2

C: Main Transformer Set

Replacement transformers for classic valve tube amps. Page 3

#2 = 9940 Line Driver (used SE 1:2 step-up)

#3 = 8160 with 50% mumetal core

#4 = 9840 Output Transformer

Thanks a lot Susan, this seems to be an amazing project.

Why was it it was never realized as a commercial project?

I'm most at a loss with regards to the other smaller components, the PDF doesn't quite match the description on the webpage.

I'm a total noob when it comes to such a project so I need to have things spelled out.

Why was it it was never realized as a commercial project?

I'm most at a loss with regards to the other smaller components, the PDF doesn't quite match the description on the webpage.

I'm a total noob when it comes to such a project so I need to have things spelled out.

Thanks a lot Susan, this seems to be an amazing project.

Why was it it was never realized as a commercial project?

I'm most at a loss with regards to the other smaller components, the PDF doesn't quite match the description on the webpage.

I'm a total noob when it comes to such a project so I need to have things spelled out.

The pragmatic situation is that I didn't have the finances to commercialize it.

I did have a go in the mid '90's with the 35 version but it was the new age of home cinema and THX certification and everything had to be a minimum of 100W!!! They did go on travels around the world and were demo'ed but nobody was interested.

Still don't have the finances to do so, even more difficult these days because everything is so much more expensive. Building something for oneself, even in nice commercial wall boxes as I do, is quite different to building for retail sale.

I can and do wind my own transformers, but these still take a lot of time and effort. A company like Sowter is set up to do production and they can buy their materials in large volumes, whereas I am not and I have to pay retail for my materials.

As to building, there are several different ways of configuring the system. As per the recent schematic the input attenuator is shown as a Steven & Billington TX102 whereas the Sowter is shown a bit differently in their info.

The resistors and Zener diodes shown in the schematic are needed, especially the Zeners. The Zeners protect the gates, are not normally in operation when the audio is running so should not affect the sound quality.

Power supplies are anywhere from +24V up. I typically run my preamp at +24V and the power stages at around 34V. You could use three lead-acid car/truck batteries with offline chargers should you so wish.

Thanks

Thank you Susan!i Tyimo,

Thanks, and for you too

Each secondary DC resistance is 77.5Ω, so 155Ω in total across the two.

Best New Year Wishes,

Susan.

Dear Susan!

I forgot to ask: What is the DC resistance of your T4 output transformer"s primary windings?

Greets:

Tyimo

For the quad-filar wound Zeus 75 transformer, each primary is approximately 0.65Ω for the half i.e. the DC load as seen by the MOSFET.

Best New Years Wishes,

Susan.

Yes, the previous years made the impact.

Yes, I realize it even better now in fact.

Still, it feels like I've made some kind of pact.

To agree that wine must be taken a lot and with care.

I hope you feel good, people who like this thread.

Because Ox is about peace as fast as it can.

Just like wine.

/it is just Zeussy way of Happy New Year to everyone who can accept it.

Yes, I realize it even better now in fact.

Still, it feels like I've made some kind of pact.

To agree that wine must be taken a lot and with care.

I hope you feel good, people who like this thread.

Because Ox is about peace as fast as it can.

Just like wine.

/it is just Zeussy way of Happy New Year to everyone who can accept it.

For the quad-filar wound Zeus 75 transformer, each primary is approximately 0.65Ω for the half i.e. the DC load as seen by the MOSFET.

Best New Years Wishes,

Susan.

Thank you!

Best New Years Wishes!

@Susan_Parker

Your layout is amazing, really, however have you ever considered BJT instead of MOSFET?

"The MOSFET has 3 flaws (talking about sound reproduction):

1- it is negative feedback as a pentode in the substrate to reach its linearity and this compromises the sound. Basically to have low distortion, the characteristic curves in the ACTIVE ZONE should be flat (not inclined) without having to apply any feedback. In the MOSFET this is achieved by controlling the CHANNEL MODULATION with an internal interconnection, linearizing the output (this trick is good for other applications). The sound response then depends a lot on this factor. I have solved the problem by using a transistor that is linear (see figure of the curve trace below).

2 - Another bad thing: it uses a CAPACITIVE element as driver.

The GATE has a DIELECTRIC. Unfortunately this dielectric is not decided by the amplifier designer. That is, if I were to choose a capacitor to put in series with the signal, I would choose with WHICH DIELECTRIC (which is a function of how you structured the power supplies). There the dielectric has nothing to do with the SOUND application: So the result is limiting.

3- The "capacitive" GATE current (dielectric), is not as performing as the DIRECT BASE current of a BJT towards the damping of the system, because it runs at HIGH IMPEDANCE. I personally don't like high impedances."

What do you think Susan?

Your layout is amazing, really, however have you ever considered BJT instead of MOSFET?

"The MOSFET has 3 flaws (talking about sound reproduction):

1- it is negative feedback as a pentode in the substrate to reach its linearity and this compromises the sound. Basically to have low distortion, the characteristic curves in the ACTIVE ZONE should be flat (not inclined) without having to apply any feedback. In the MOSFET this is achieved by controlling the CHANNEL MODULATION with an internal interconnection, linearizing the output (this trick is good for other applications). The sound response then depends a lot on this factor. I have solved the problem by using a transistor that is linear (see figure of the curve trace below).

2 - Another bad thing: it uses a CAPACITIVE element as driver.

The GATE has a DIELECTRIC. Unfortunately this dielectric is not decided by the amplifier designer. That is, if I were to choose a capacitor to put in series with the signal, I would choose with WHICH DIELECTRIC (which is a function of how you structured the power supplies). There the dielectric has nothing to do with the SOUND application: So the result is limiting.

3- The "capacitive" GATE current (dielectric), is not as performing as the DIRECT BASE current of a BJT towards the damping of the system, because it runs at HIGH IMPEDANCE. I personally don't like high impedances."

What do you think Susan?

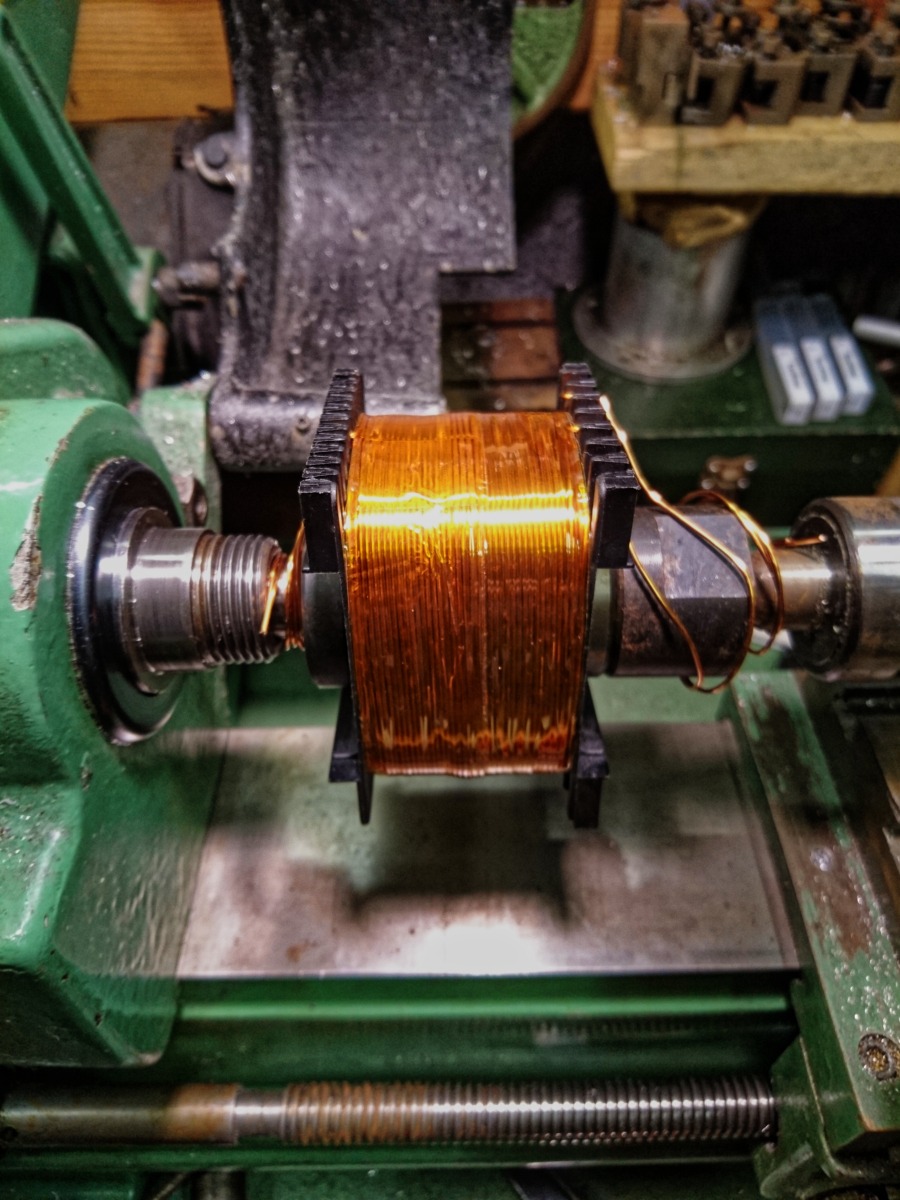

I am reminded that I have not posted here for a while...

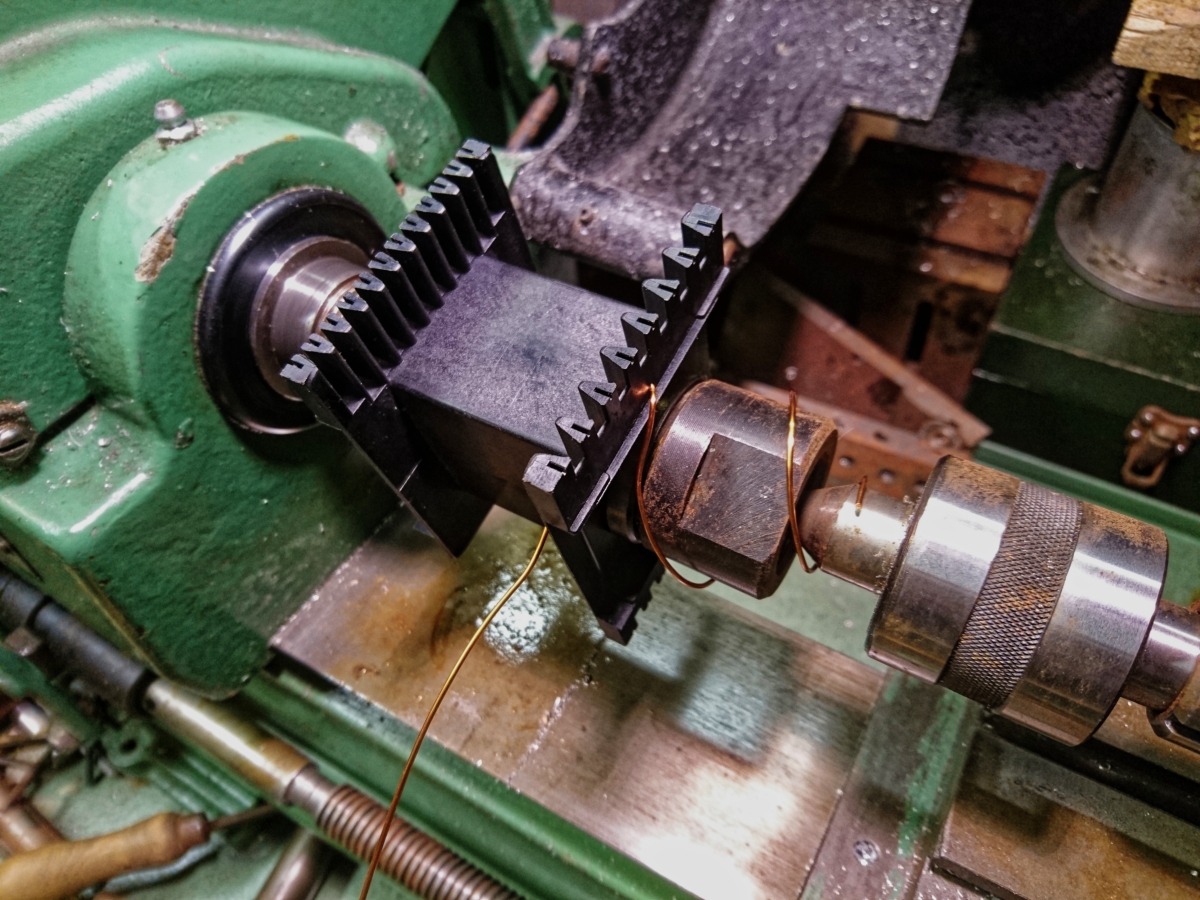

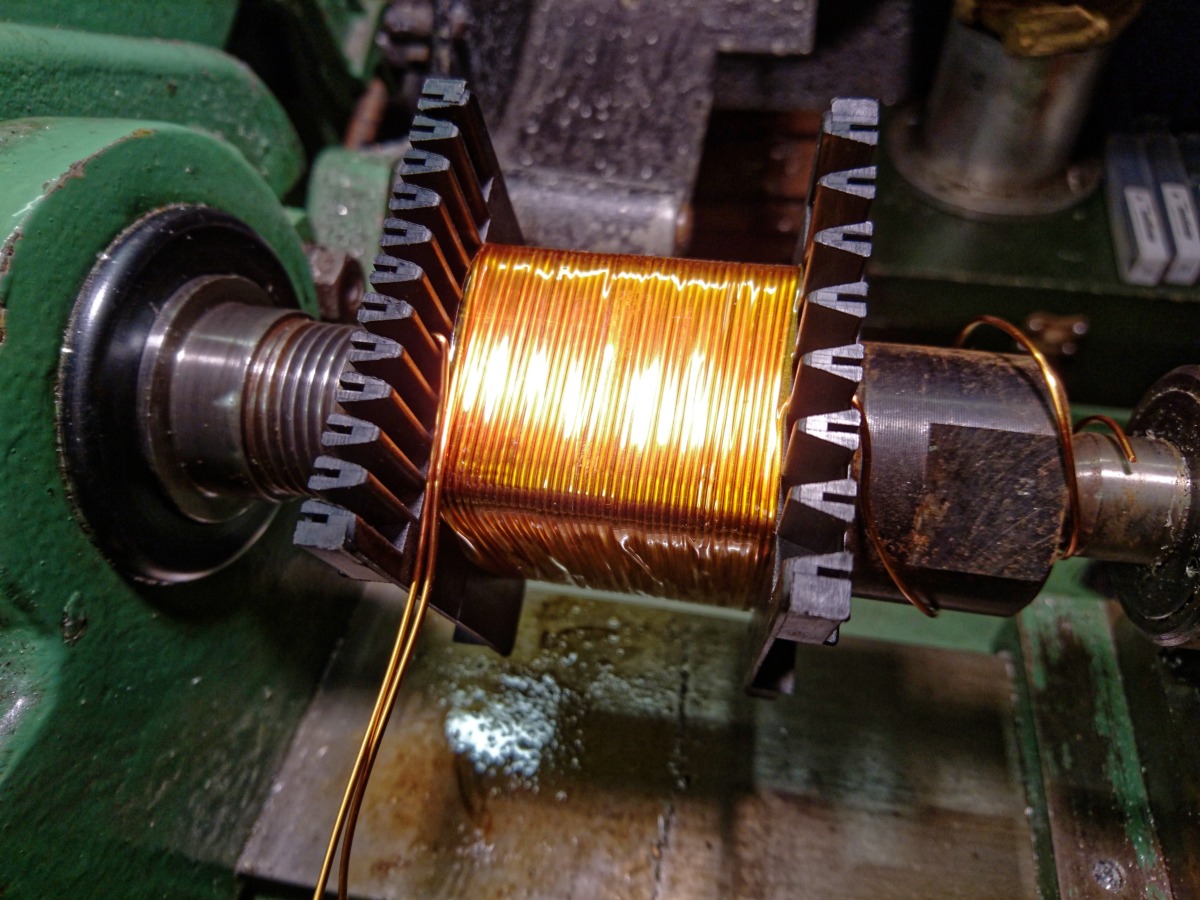

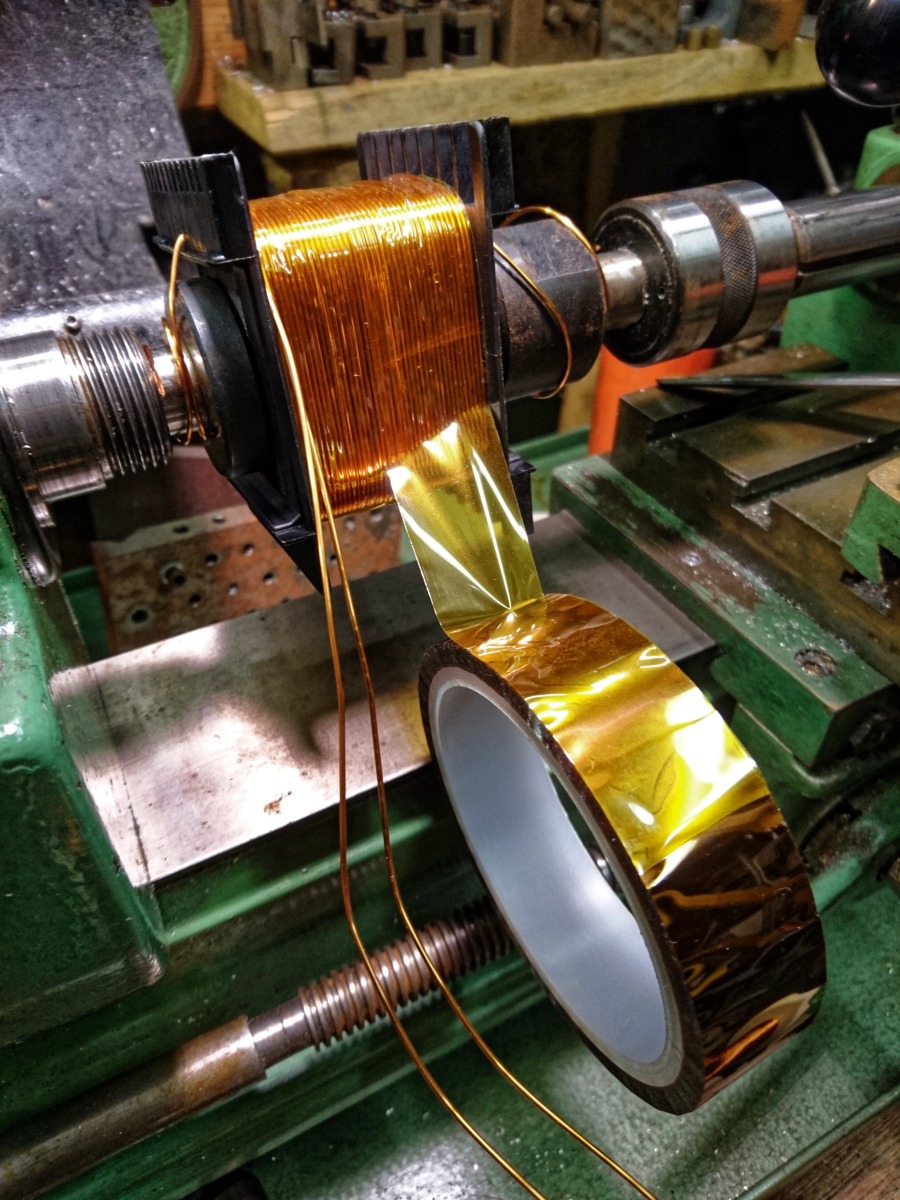

So here are some pics of me hand winding a single-ended 1.5 to 1 output transformer with 1.0mm magnet-wire on my lathe.

First and last layers are primary only, the eight intermediate layers are bifilar wound.

Winding setup.

Ready to start.

First layer wound...

Dynamic bifilar-winding method, with bio-feedback tensioning and traverse.

Applying Kapton tape per layer

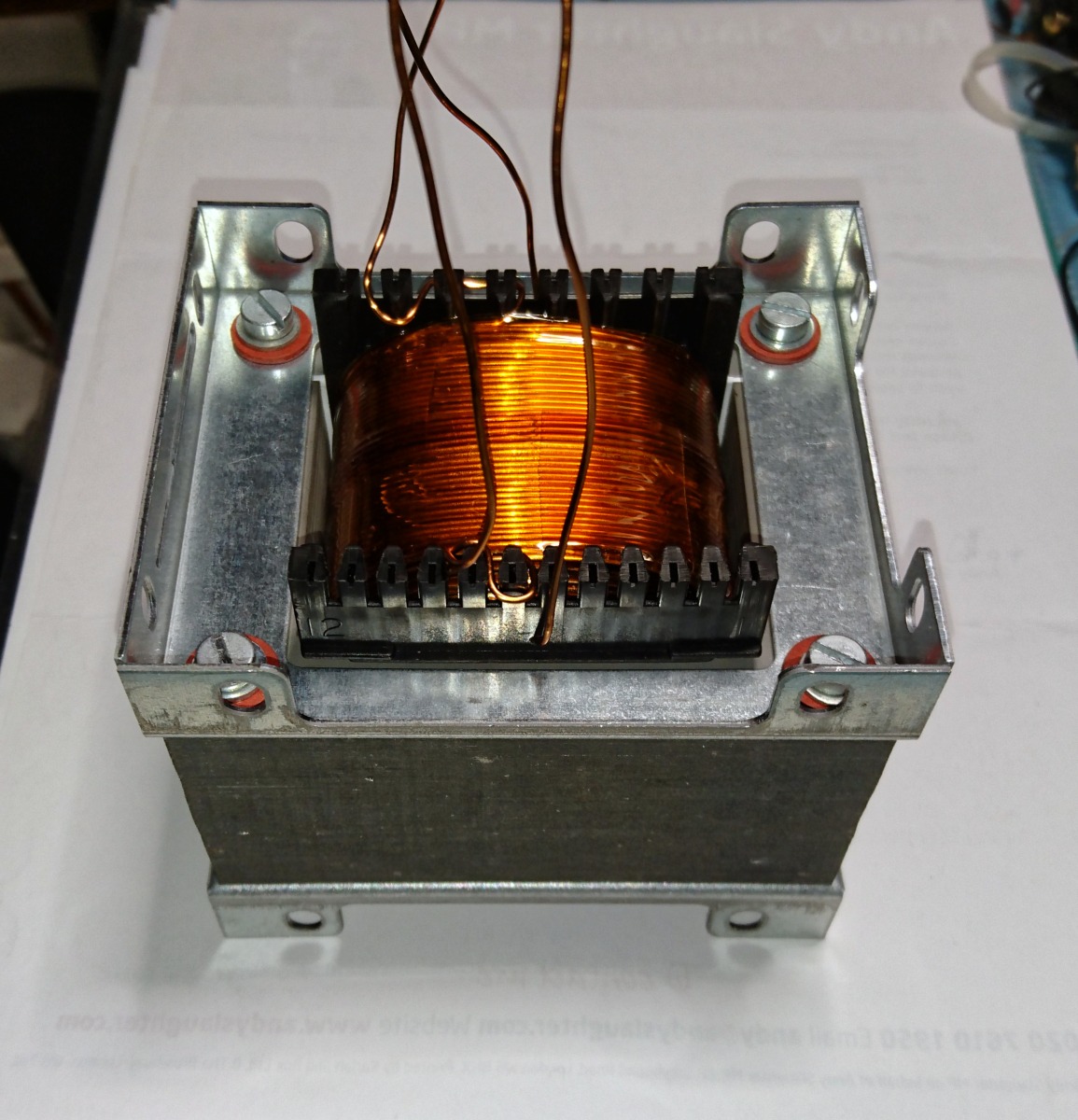

Finished winding. The slight bump in the middle is from the overlap in the Kapton tape I have put on each layer.

Finished transformer.

So here are some pics of me hand winding a single-ended 1.5 to 1 output transformer with 1.0mm magnet-wire on my lathe.

First and last layers are primary only, the eight intermediate layers are bifilar wound.

Winding setup.

Ready to start.

First layer wound...

Dynamic bifilar-winding method, with bio-feedback tensioning and traverse.

Applying Kapton tape per layer

Finished winding. The slight bump in the middle is from the overlap in the Kapton tape I have put on each layer.

Finished transformer.

- Home

- Amplifiers

- Solid State

- Zero Feedback Impedance Amplifiers