Great to have you back and thanks for sharing with us how you wind transformers using a lathe.

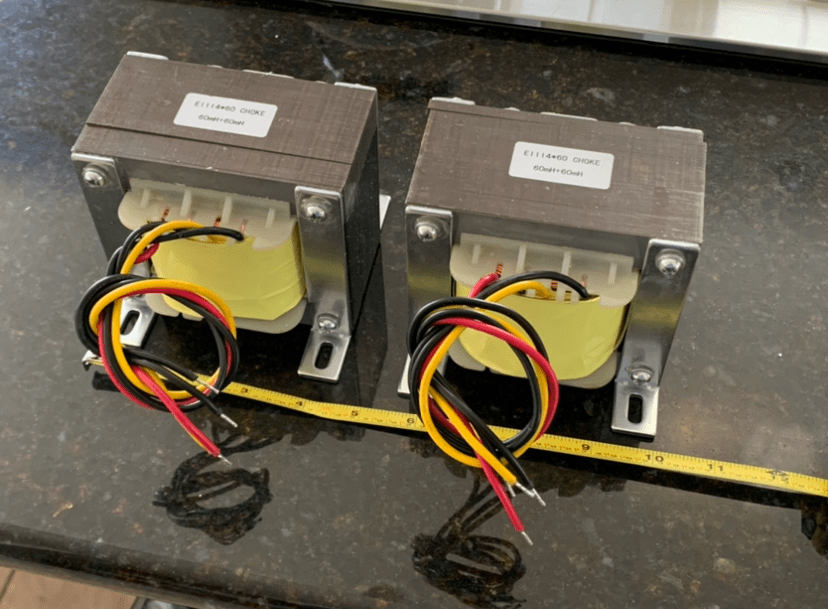

Now I sort of have an idea how these custom 60mH + 60mH bifilar wound inductors that I ordered for the SuSyLu amp were made. They are about 0.5ohm DCR per leg.

Now I sort of have an idea how these custom 60mH + 60mH bifilar wound inductors that I ordered for the SuSyLu amp were made. They are about 0.5ohm DCR per leg.

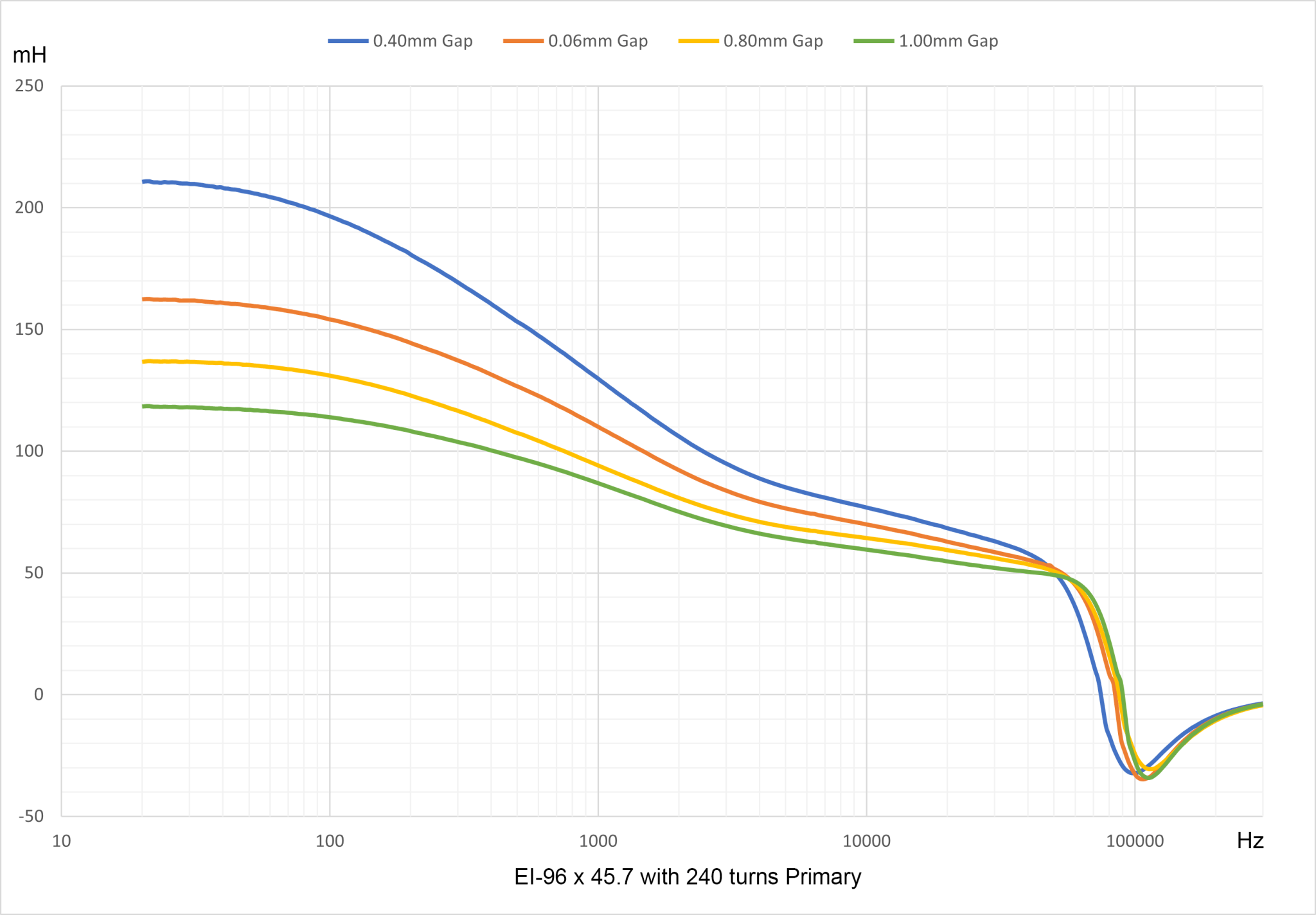

Referring to the previous post #1,737 showing the winding process, here is a plot showing core-gap versus inductance sweeps - made with a BK 891 LCR test-meter (which has a 100 ohm output impedance). With EI laminations the gap is double the paper thickness used to space the laminations.

Testing out the Single-Ended EI-96 core transformer amplifier configuration with an IXTH16N10D2 depletion MOSFET, with a ground-referenced gate so it is self-biasing with the DC resistance of the transformer primary winding.

The second device mounted at the top of the heatsink is a LT1083 linear-regulator set to +24V. Unlike Push-Pull circuits where one can be more relaxed, Single-Ended operation needs a stable and low-noise supply.

With this minimalist setup the bias is at 2.0 amps, and the 300x180x40mm heatsink is at about +50ºC or so (I can grasp it firmly for about three seconds).

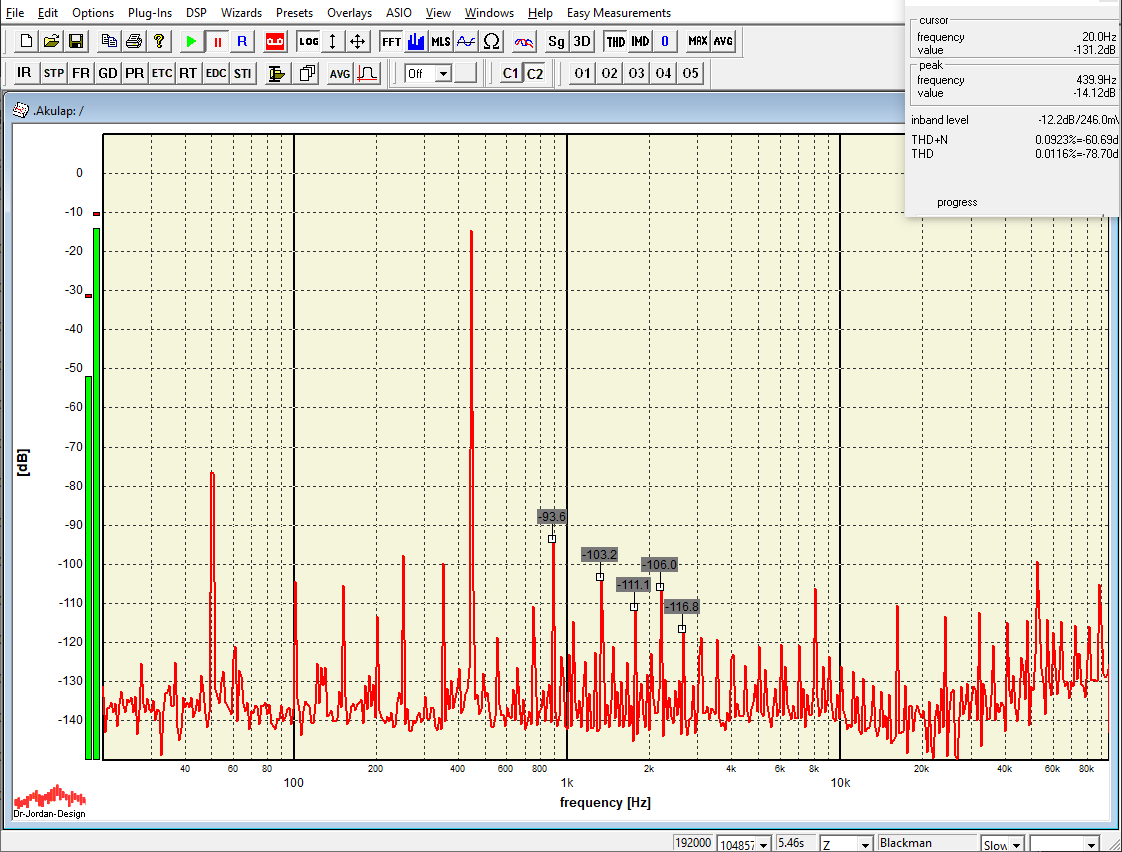

The depletion MOSFET is been driven directly from the output of the Audio Analyser, to get a measurement of the basic output-stage characteristics.

The second device mounted at the top of the heatsink is a LT1083 linear-regulator set to +24V. Unlike Push-Pull circuits where one can be more relaxed, Single-Ended operation needs a stable and low-noise supply.

With this minimalist setup the bias is at 2.0 amps, and the 300x180x40mm heatsink is at about +50ºC or so (I can grasp it firmly for about three seconds).

The depletion MOSFET is been driven directly from the output of the Audio Analyser, to get a measurement of the basic output-stage characteristics.

Distortion at 440Hz into 16ohm load. WinAudioMLS software doing a one million point FFT, with Moto M2 USB audio-interface.

Note the 3rd is the important figure, not the 2nd. It's about -89db down from the fundament, which is c. 0.004%

Note the 3rd is the important figure, not the 2nd. It's about -89db down from the fundament, which is c. 0.004%

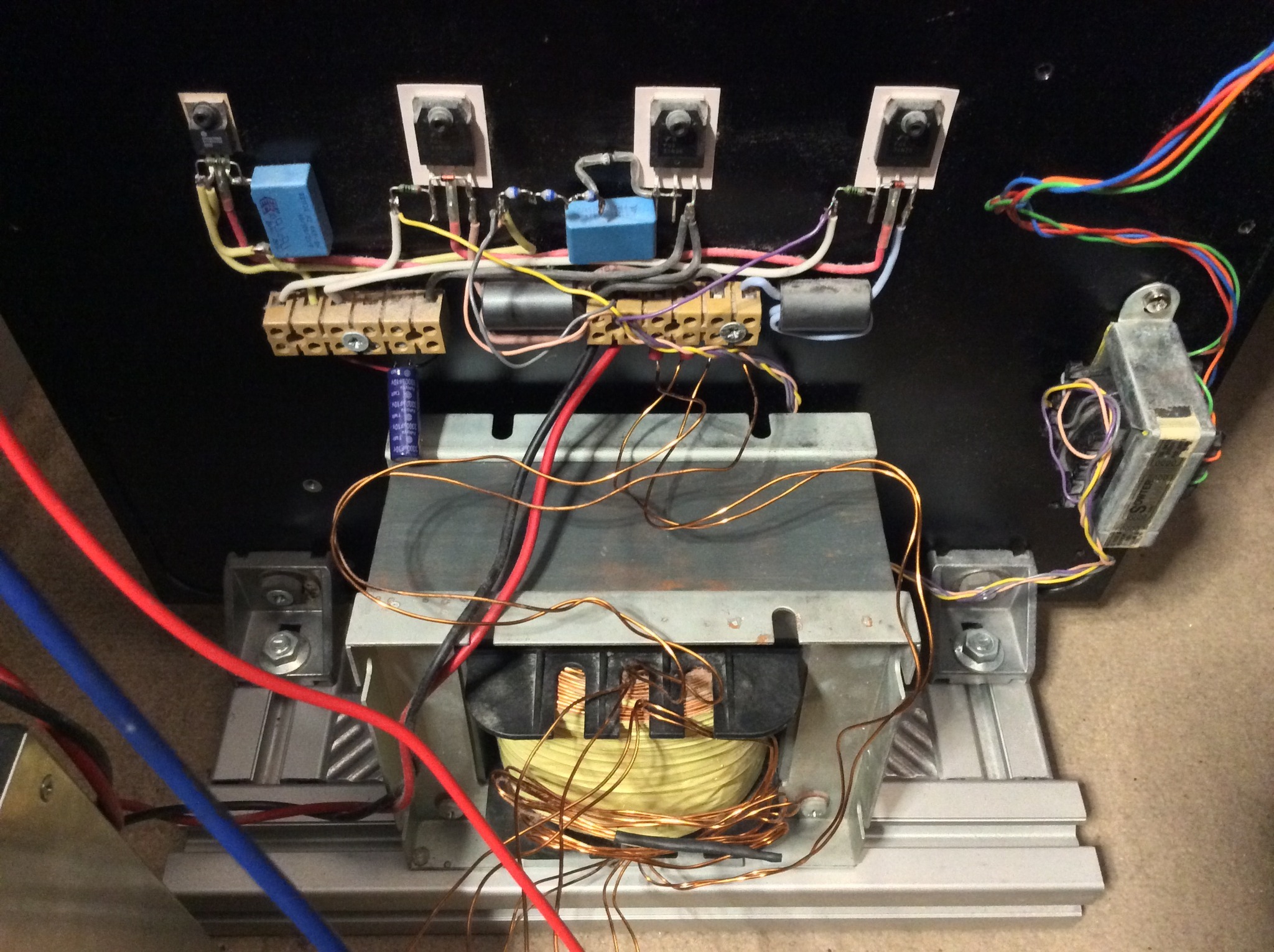

This is a bigger EI162 (UK638) sized single-ended transformer which I made c. 2005 which I have also been testing recently.

It has bi-filar wound primaries so I have one MOSFET on each winding; the third middle MOSFET is for biasing, in this case with a number of diodes to increase the voltage level.

It is very large, and heavy!

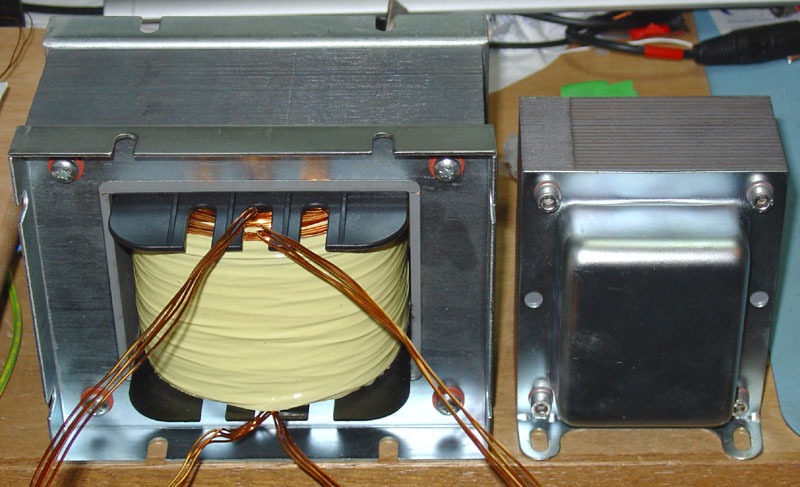

This is a size comparison of the EI162 to my normal EI120 transformers.

It has bi-filar wound primaries so I have one MOSFET on each winding; the third middle MOSFET is for biasing, in this case with a number of diodes to increase the voltage level.

It is very large, and heavy!

This is a size comparison of the EI162 to my normal EI120 transformers.

Last edited:

Nice to see this thread coming back to life again.

I did some experiments with mosfets and homemade output transformers last year, though leaning more towards Hiraga's Nemesis amplifier using the mosfets as gain stages. The transformers are wound on 85VA cores, 2:1 winding ratio with a small part (20% or so, I don't remember the exact number) of the primary winding snipped off and connected between source and ground for local feedback.

I did some experiments with mosfets and homemade output transformers last year, though leaning more towards Hiraga's Nemesis amplifier using the mosfets as gain stages. The transformers are wound on 85VA cores, 2:1 winding ratio with a small part (20% or so, I don't remember the exact number) of the primary winding snipped off and connected between source and ground for local feedback.

@traderbam - Good question.

This dip is where the parasitic capacitance of the windings in conjunction with the driving impedance of the measuring instrument AC source forms a resonant point i.e. an LC filter pole at around 100,000kHz.

The main thing to consider for a single-ended transformer is the low-frequency end with the differences in inductance relative to the gap as this determines the energy storage capability of the transformer.

One needs to balance the gap needed to prevent the magnetic-core i.e. laminations saturating, to the current needed to store enough energy to operate into the desired minimum load.

This is why SE transformers get big very quickly.

This dip is where the parasitic capacitance of the windings in conjunction with the driving impedance of the measuring instrument AC source forms a resonant point i.e. an LC filter pole at around 100,000kHz.

The main thing to consider for a single-ended transformer is the low-frequency end with the differences in inductance relative to the gap as this determines the energy storage capability of the transformer.

One needs to balance the gap needed to prevent the magnetic-core i.e. laminations saturating, to the current needed to store enough energy to operate into the desired minimum load.

This is why SE transformers get big very quickly.

That explains it, thanks Susan. And yes, it is 100kHz - I misread the graph.

Hi Susan, any chance you would wind them without the kapton tapes? or none at all, since voltages involved are not that high, so using heavy formex magnet wire i believe will work, i wonder how this will stack up against the kaptons..

Hi Tony,

Firstly and most importantly, the Kapton tape is to ensure each layer maintains tension whilst the next layer is wound, as this is hand wound and hand tensioned.

The Kapton tape also helps to give a "flat" layer to wind the next row on (okay, with a bit of a bump). I was using the Kapton tape I had to hand.

The magnet wire is 1.0mm diameter, to run at 2 amps. For this size core I can't get enough turns on a heaver gauge wire.

Additionally, skin-effect comes into play.

Firstly and most importantly, the Kapton tape is to ensure each layer maintains tension whilst the next layer is wound, as this is hand wound and hand tensioned.

The Kapton tape also helps to give a "flat" layer to wind the next row on (okay, with a bit of a bump). I was using the Kapton tape I had to hand.

The magnet wire is 1.0mm diameter, to run at 2 amps. For this size core I can't get enough turns on a heaver gauge wire.

Additionally, skin-effect comes into play.

When I wind transformers I usually finish each layer with a strip of paper (grocery bags...) covered in wet epoxy glue. Once the glue has set, the previous layer is secured and there's a nice flat surface to wind the next layer on. It does steal a bit of the winding space though.

I’ve read the original post from 2004 and the schematic, but I have not yet read anything about why you would want to do this, advantages, disadvantages. That would be interesting to know I think. Forgive me if this has all ready been answered somewhere in the last few thousands posts 😅

1.SE iron amps are cool!

2. Secondaries are tailored for the load

3. The distortion profile of a SET.

4. It’s super cool!

2. Secondaries are tailored for the load

3. The distortion profile of a SET.

4. It’s super cool!

It's my concept of "wire with gain".

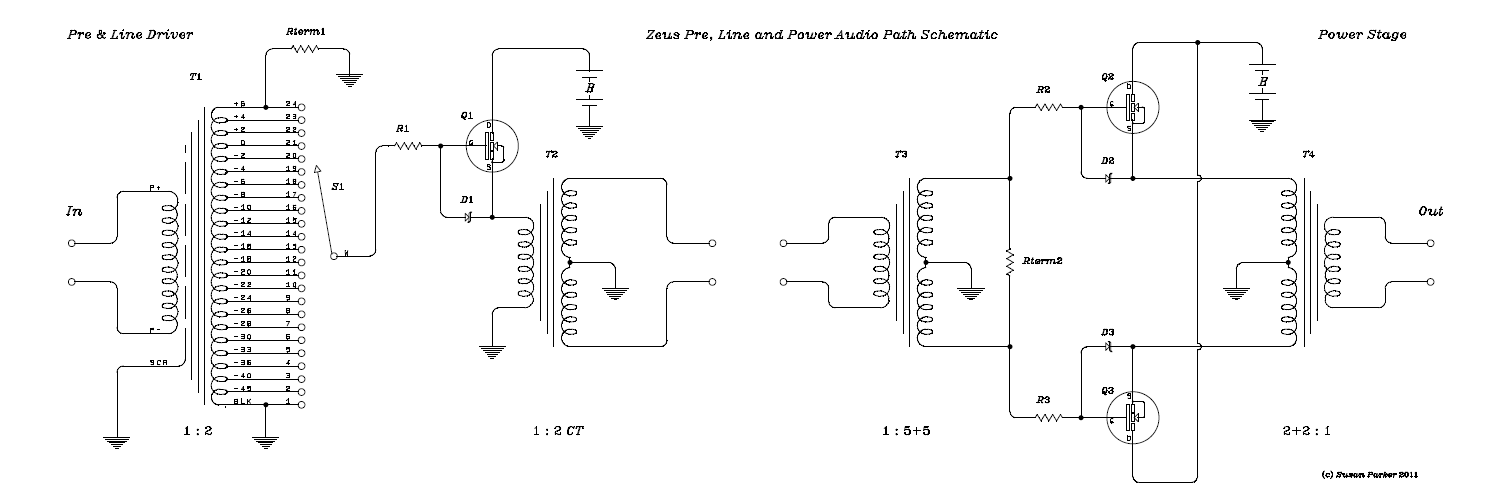

Schematic is the complete audio-path for one channel, features a minimal number of components and NO capacitors.

Schematic is the complete audio-path for one channel, features a minimal number of components and NO capacitors.

Does it break down like this?

T1: volume control; unsure how it affects input impedance, differential to single ended conversion. Unsure of the role of Rterm1.

T2: pre-gain stage of x2(?); going from single ended to differential; the is a source follower so it has less than unity gain, it’s more of a high input impedance/low-output impedance thingy? They provide current gain? Is that the point!?

< is something intended to be connected between T2 and T3?>

T3: single ended to differential to drive push pull output stage; gain of 10.

T4: driven by source follower again; gain of -4?!

I clearly don’t get it 😂

T1: volume control; unsure how it affects input impedance, differential to single ended conversion. Unsure of the role of Rterm1.

T2: pre-gain stage of x2(?); going from single ended to differential; the is a source follower so it has less than unity gain, it’s more of a high input impedance/low-output impedance thingy? They provide current gain? Is that the point!?

< is something intended to be connected between T2 and T3?>

T3: single ended to differential to drive push pull output stage; gain of 10.

T4: driven by source follower again; gain of -4?!

I clearly don’t get it 😂

- Home

- Amplifiers

- Solid State

- Zero Feedback Impedance Amplifiers