I’m not afraid to think out loud and very happy to be corrected and learn. If this is not acceptable in this forum I apologise.

Thinking out loud is what happens way too often here; this way most of the time threads get polluted for no reason.

thanks for the reply, reason i asked is, i believe the high frequency end can be helped somewhat....Hi Tony,

Firstly and most importantly, the Kapton tape is to ensure each layer maintains tension whilst the next layer is wound, as this is hand wound and hand tensioned.

The Kapton tape also helps to give a "flat" layer to wind the next row on (okay, with a bit of a bump). I was using the Kapton tape I had to hand.

The magnet wire is 1.0mm diameter, to run at 2 amps. For this size core I can't get enough turns on a heaver gauge wire.

Additionally, skin-effect comes into play.

fwiw, the McIntosh 270 opts did not have anything in between coils, just the sheer thickness of insulation in the magnet wires used...

now the cat is out of the bag....When I wind transformers I usually finish each layer with a strip of paper (grocery bags...) covered in wet epoxy glue. Once the glue has set, the previous layer is secured and there's a nice flat surface to wind the next layer on. It does steal a bit of the winding space though.

i once proposed in another thread to get the smallest 120/220 variac one can find, makes a nice tvc....It's my concept of "wire with gain".

Schematic is the complete audio-path for one channel, features a minimal number of components and NO capacitors.

View attachment 1173222

This method is quite messy and the results are not always pretty but it works rather well. The windings become mechanically rigid and I've tested one such transformer i na tube circuit with peak voltages around 1kV without problems. Probably more than one layer of paper between the primary and secondary sections in that transformer, though. The paper I use is ~0,12mm thick, if my memory serves.

in my builds, just paper and scotch tapes in between layers, i used onion skinned bond papers...

These multi-filar wound transformers are not the same beasts as the valve/tube amp transformers.thanks for the reply, reason i asked is, i believe the high frequency end can be helped somewhat....

fwiw, the McIntosh 270 opts did not have anything in between coils, just the sheer thickness of insulation in the magnet wires used...

Because of the totally interleaved nature of the windings, the PP output stage (T4 and MOSFETS) itself goes up beyond a MHz and becomes limited more by RF impedance load mismatching and the bandwidth of the MOSFETS. I think that is probably high enough.

The bandwidth "bottleneck" for the power-stage is the T3 step-up, depending on the construction.

As drawn, the audio-path does 20Hz to 200kHz.

200kHz is an impressive number for any amp and quite marvellous for a topology based on step-up transformers.

T1 is a +6dB (max) gain/attenuator; Rterm1 provides a flat impedance to the audio-signal source. Unterminated the audio levels would change with frequency and there would be a peak at the top end from resonance (it's an inductor thing).Does it break down like this?

T1: volume control; unsure how it affects input impedance, differential to single ended conversion. Unsure of the role of Rterm1.

T2: pre-gain stage of x2(?); going from single ended to differential; the is a source follower so it has less than unity gain, it’s more of a high input impedance/low-output impedance thingy? They provide current gain? Is that the point!?

< is something intended to be connected between T2 and T3?>

T3: single ended to differential to drive push pull output stage; gain of 10.

T4: driven by source follower again; gain of -4?!

I clearly don’t get it 😂

T2 is SE to Balanced, as you correctly identify. Yes, it's all about current gain with transformers.

The two parts are separated: The volume/line-driver sits next to the source, and the power stage can sit right next to the loudspeakers they are driving. This saves many thousands of $$$ for exotic speaker cables. The two are connected with 100 ohm twinax cable (Belden 9207) i.e. the space between the two halves, not flimsy phono or mic cables. And yes, this DOES make an audible difference.

T3 is balanced input, a single phase to dual phase splitter. It has an effective gain of 5.

T4 is a balanced gain of 0.5 (0.45ish as a follower).

The point to note is that everything here is ground-referenced, BUT T2 and T4 self-generate their own imaginary negative power rails when compared for example to a conventional solid-state amplifier with a pair of output devices and positive and negative power supply rails. Which is where the confusion comes as to the the gains. Basically if one configures T4 as single ended transformer by swapping the second primary leg to be in the same phase as the first which maintains the same overall winding ratios, one gets the same gains.

If you look at the big EI162 transformer in post #1,746 this is what is happening. Small transformer on the right T3 is configured to give 2 in-phase signals which drive 2 MOSFETs in-phase onto two primary windings in-phase. The use of two 1.0mm magnet wires wound as a pair improves bandwidth (skin-effect current is smaller) as well as hand-winding ability. The larger magnet wire diameters get very difficult to manage very quickly over 1.25 mm or so.

In summary, T3 and T4 can be configured to operate as either SE or PP using the same transformers and same winding ratios, to give the same output levels. This could even be implemented as a multi-pole switch for test-comparison purposes (with power removed). The resultant volume from either mode should be the same, so would side-step one of the issues when doing conventional A/B comparisons.

Hope this helps 🙂

For the SE output transformers there is a good reason to consider some kind of epoxy filling whilst winding, as the 2A biasing turns them into audible tweeters due to the varying magnetic field vibrating the copper-wire.This method is quite messy and the results are not always pretty but it works rather well. The windings become mechanically rigid and I've tested one such transformer i na tube circuit with peak voltages around 1kV without problems. Probably more than one layer of paper between the primary and secondary sections in that transformer, though. The paper I use is ~0,12mm thick, if my memory serves.

Once hidden in a box, probably okay, but with the EI96 transformers it was quite noticeable on the bench 12 or so inches away from my ear when testing into a resistive load.

I didn't do this as it becomes too messy when hand winding without a lot of setup-prep. I have a peristaltic pump, which I could use as and when I am machine-winding these coils. Again, something that needs a lot of setup, which isn't always time-effective when prototyping ones and twos for one's own use.

Applying glue or varnish on the windings is probably very beneficial in bifilar transformers where there is a significant DC potential between the wires. Who knows how long the enamel will last if the wires can rub against each other.

I am always happy to answer questions when they help explain my concepts. I may not always be able to answer in detail or immediately.I’m not afraid to think out loud and very happy to be corrected and learn. If this is not acceptable in this forum I apologise.

Also of course it is good to read through some of the back posts, although I would admit for this particular thread there are rather a lot of them given that this thread has been running for nearly 20 years!.

I would say that the encouragement over the years from people interested in this thread has been hugely helpful, and I very much doubt I would have progressed my ideas nearly as far were it not for all the awesome people here and their posts.

Finally having got M$ Frontpage web-design software working again on my Win10 PC I intend to make a BIG effort over the next weeks to do something about my website, so hopefully that would help with some of the basic-questions too.

Please note that I don't always get time of an evening during the week to get to my personal computer and see/answer emails, and the posting messages can slip out of sight a bit too easily.

Hi Susan, output transformers for mosfets are indeed different from tubes since we are talking higher plate resistances with tubes compared with mosfets that had very low dynamic resistances, i made an opt for the 6c33 with windings similar to yours and still good results, just sayin'.....

I just ordered some nice bobbins with solder tags from Italy to rewind my transformers. They work fine as they are but during the first power up I had them miswired and got a phone call from a drunk friend at the worst possible moment, when I came back the transformers were very hot and since then I don't fully trust the wire insulation...🙄

I am fascinated by this thread. This design is very zen indeed and so close to Physics.

At the same time, I have no trust in myself to identify, source and even less build the very special transformers required.

At the same time, I have no trust in myself to identify, source and even less build the very special transformers required.

Magnet wire insulation should be good for 200C, at which point things would be smoking!I just ordered some nice bobbins with solder tags from Italy to rewind my transformers. They work fine as they are but during the first power up I had them miswired and got a phone call from a drunk friend at the worst possible moment, when I came back the transformers were very hot and since then I don't fully trust the wire insulation...🙄

For an output transformer, probably okay. A quick test would be to check the inductance of each winding. Similar length windings should all measure about the same. But it is a thing and I agree with your caution. These amps get left on for extended periods of time and one doesn't want to take risks.

If it's a mains power transformer, definitely good to be cautious.

The wire insulation is probably ok, but the incident still bothers me a bit and the questionable state of the transformers is a major reason why the project hasn't moved on from the prototype stage yet. I also did a bit of a sloppy job when winding them, hopefully the MkII version will be a bit tidier with properly layered windings.

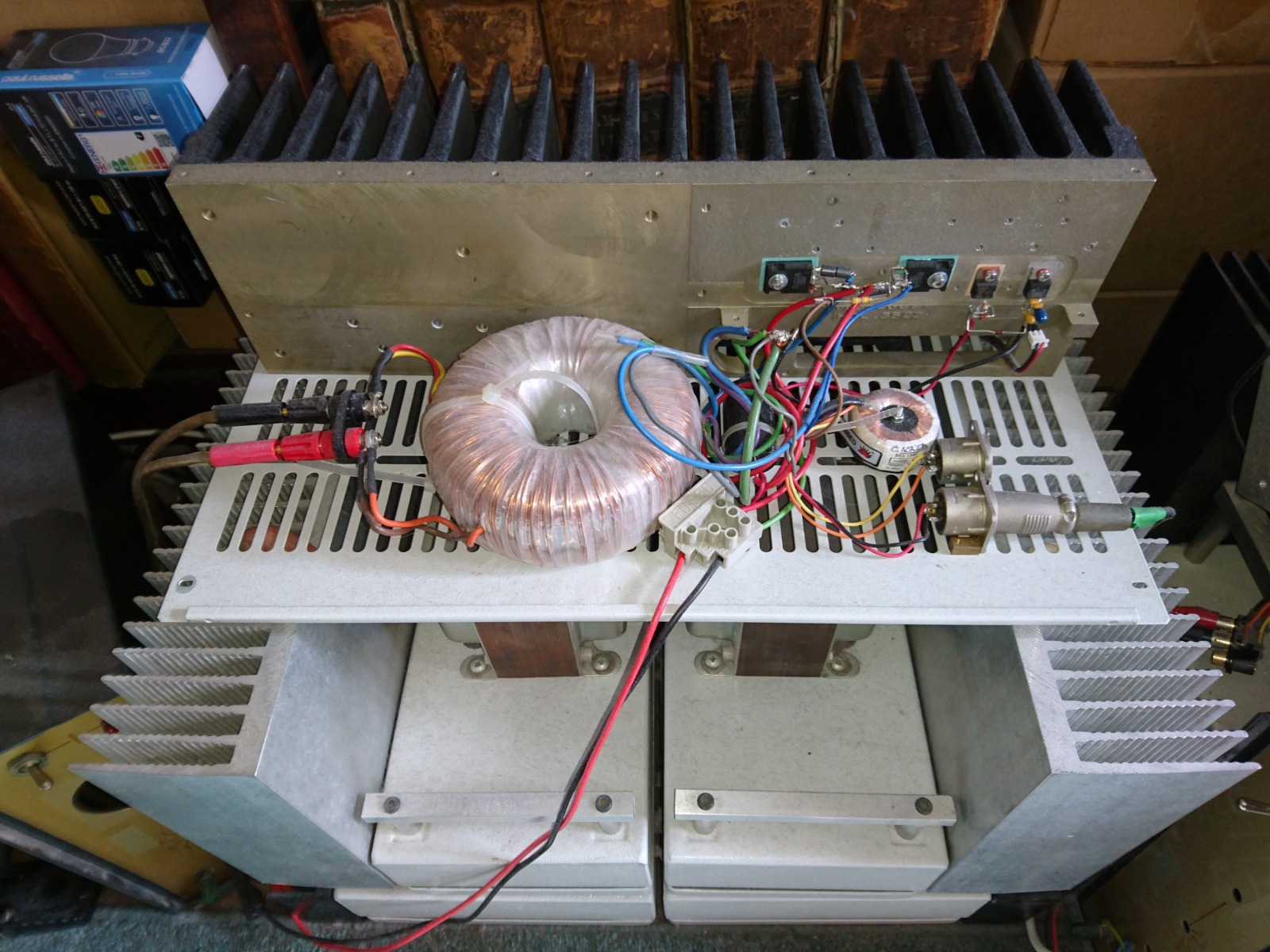

This is the bass-amp with my fully hand-wound toroid output transformer, PP and auto-biased with a pair of depletion MOSFETs, driving my SP150 bass-speaker as part of our 5.1 setup.

It's perched on top of the main Zeus-75 amps, lifted off their heatsinks with some pebbles from a beach in Devon.

The two smaller TO-220 parts are to provide +5V to a 12V fan mounted underneath the rear of the bass-amps wide heatsink as the heatsink otherwise gets a tad too warm. The slow speed of the fan is barely audible when standing over the amp, and inaudible in use when sitting on the sofa.

It's perched on top of the main Zeus-75 amps, lifted off their heatsinks with some pebbles from a beach in Devon.

The two smaller TO-220 parts are to provide +5V to a 12V fan mounted underneath the rear of the bass-amps wide heatsink as the heatsink otherwise gets a tad too warm. The slow speed of the fan is barely audible when standing over the amp, and inaudible in use when sitting on the sofa.

- Home

- Amplifiers

- Solid State

- Zero Feedback Impedance Amplifiers