Hello Nigel

To be honest not bothered about solder resist or silk screening .. plus I have my own PCB fabricator at min cost

but thanks for the heads up

all the best

I did an update pcb to the Maplin mosfet amp a couple of years back.

I changed the transistors for easy to get modern types.

The original sometimes had problems with hum so I decoupled the front end.

I added CCS on front end and made current mirror two transistors instead of transistor and diode.

It sounded very good.

An externally hosted image should be here but it was not working when we last tested it.

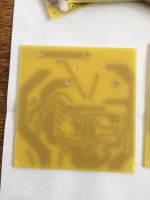

Here's mine. Must have made it getting on for 20 years ago.

I made my first Maplin mosfet amp in 1981.

It was built for a mobile disco but wasn't loud enough.

So I bought the Maplin disco amplifier which was 225WRMS into 4 ohms.

A couple of years back I spotted a Maplin mosfet kit on ebay which hadn't been built. So I bought it and built it up, worked great. I maybe should have kept it unbuilt for the rarity ?

Fired up my amp pictured in post #101 and it still works fine. I think I still have a few unbuilt kits in the depths of my workshop, maybe I'll make them up. It never fails to surprise me that such a simple circuit gives such good performance with pretty low distortion.

Hello

Exactly my thoughts ... nice little retro project, easy to make and can bridge if needed, make a couple of monoblocks with big power supply

results nice deep bass easy to repair and mod .. and with decent heatsink / cooling will take loads of abuse.

Also the 1st amplifier that I made in my youth that actually worked - still pleases me today. hence why I made the PCB with supporting gerber files

best regards

Fired up my amp pictured in post #101 and it still works fine. I think I still have a few unbuilt kits in the depths of my workshop, maybe I'll make them up. It never fails to surprise me that such a simple circuit gives such good performance with pretty low distortion.

Hello Chalky .. if you find those unbuilt kits I would pay a good price for them

Hello Nigel

To be honest not bothered about solder resist or silk screening .. plus I have my own PCB fabricator at min cost

but thanks for the heads up

all the best

Nigel .. do you still sell the PCB's ?

Last edited:

Copper shows up fingerprints after a few months, tinned doesn't. Soldermask will also prevent these cosmetic issues and help protect from oxidation over the years. Commercial PCBs are always tinned/wave soldered or gold-plated in my experience, and only the cheapest avoid soldermask.Also do I keep tinned the tracks or keep bare copper .. just wondered forum members thoughts

as bare copper you could use any solder that you are happy with ?

best regards

With very fine tin layer the tracks change from silver coloured to brick-red over the years as the tin atoms diffuse into the copper track. Hot dipped tin (or wave-soldered) will stay silver (well, greyish)

Nigel .. do you still sell the PCB's ?

I just made 10, sold 9 on and kept one for myself.

Copper shows up fingerprints after a few months, tinned doesn't. Soldermask will also prevent these cosmetic issues and help protect from oxidation over the years. Commercial PCBs are always tinned/wave soldered or gold-plated in my experience, and only the cheapest avoid soldermask.

With very fine tin layer the tracks change from silver coloured to brick-red over the years as the tin atoms diffuse into the copper track. Hot dipped tin (or wave-soldered) will stay silver (well, greyish)

HASL is common now (hot air solder levelling.)

- Home

- Amplifiers

- Solid State

- Maplin MosFET Amplifier Ga28f construction thread