I beleive Speaker Exchange wanted the complete assembly with midrange installed. At that point I got concerned with shipping. A guy would need to build a wood box to properly mount the assembly to ensure safe transport. That is certainly the easy route. I was exposed to a vast expanse of information as shown in this thread by pursuing the DIY method. For that I am grateful and glad I went that route even if results (I obviously compromised in my execution) could be better going the Speaker Exchange route.

So it ultimately depends on if SE is giving you just the tweeter for you to mount or if they are going to fit the tweeter into the existing sub assembly.

You were bang on... I asked some more questions and they do want the whole assembly. I think they have little interest in rewinding the tweeter, if that's even possible. Here's what they wrote:

"It would depend on what parts we have that fit. We may be able to change out the diaphragm, if not, we would change out the tweeter dome/magnet assembly to something comparable. We do advise on doing these in pairs to have a matched set. We would need to receive the complete HF/MF module from you."

I'm going to plan on doing what you did but am going to investigate the 3D printing option as I have some friends who do it and I've been considering buying one for sometime. Alternatively, I have the woodworking skills to do so.

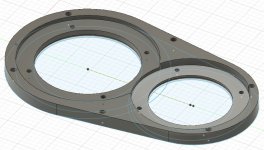

For those interested, I've created a digital model for 3D printing based on the SEAS 27TBFC driver. Fits perfectly and aligns with the original screw holes. Given the changed dimensions of the tweeter I'm not sure I can build the recess for the grill in. I may end up designing a grill specific to the mid, since the new tweeter has it already built in. I haven't figured out how to share a photo on here yet. Since the prototype worked I'll likely get another printed and put the speakers into action.

Lastly I've sent the original tweeter to a specialist who is hopeful he can repair. Either way these speakers will be singing sooner than later.

Lastly I've sent the original tweeter to a specialist who is hopeful he can repair. Either way these speakers will be singing sooner than later.

That's some nice work. Congratulations!

Would it be worth your effort to make extras to sell ?

Or maybe simply sell the 3D Printing File?

FWIW, one generally gets smoother response when drivers don't "see" or encounter hard edges ( such as will happen when the drivers are deeply counter-sunk ). Measurable diffraction effects result.

From what I see, all that can be ameliorated/controlled by the inclusion of some gasketing between the drivers and the cutout/inset .

So that rendering is the back side. The drivers are reverse mounted. The front edges where they meet the drivers are filleted (rounded) for that very reason. I should have done a front rendering... Maybe I'll open the model later today.

Re: selling it... I can't imagine there's a huge target audience. I'm happy to share it. If people feel so inclined to 'pay' something I'd prefer they do a small donation to their local food bank.

Re: selling it... I can't imagine there's a huge target audience. I'm happy to share it. If people feel so inclined to 'pay' something I'd prefer they do a small donation to their local food bank.

I actually haven't used them yet. The prototype baffle just came off the printer around 6pm. I only had 1 printed to test fit. I suspect the cab may need to be modified slightly due to the larger SEAS tweeter that had to be shifted 3mm down.

I'll get a second one printed this week (not my 3D printer). and then do a proper test. That said, I'm hesitant to modify the cab until I know if the original tweeter can be repaired or not.

I'll get a second one printed this week (not my 3D printer). and then do a proper test. That said, I'm hesitant to modify the cab until I know if the original tweeter can be repaired or not.

Low Power Amps for Veritas 1.8

I have owned a pair of Veritas 1.8 for 20 years. For all those years, I have always used low wattage amps. First Conrad Johnson MV52, LP70s, Classic 60se, BAT VK55, and now Pass Labs XA25 without any problems.

Usually a blown tweeter is a symptom of something else ... and with both blown at the same time I'm pretty sure you need to be looking at your amplifier...

I had a rough time finding specs for these speakers but they appear to be rated for "80 to 250 watts"... Now what those numbers mean is that if your amp is below 80 watts per channel you are likely to overdrive your amplifier before you reach a reasonably loud SPL. If your amp is over 250 watts, you risk overheating the speaker voice coils with too much current.

Clipping is an amplifier overdrive that, even at low frequencies, will kill your tweeters pretty quickly. The reason this happens is that the amplifier is clipping off the tops and bottoms of the musical wave form, creating something like square waves. Square waves carry a ton of harmonic content that reaches way way up into the higher frequencies... which can overheat and burn out a tweeter.

When I was doing audio service in customer's homes/studios, roughly a fifth of my calls were for blown tweeters.

The simple answer... you need more power.

Really, the solution is that you need a more powerful amplifier so that you aren't clipping it. Alternatively... turn down the volume.

I have owned a pair of Veritas 1.8 for 20 years. For all those years, I have always used low wattage amps. First Conrad Johnson MV52, LP70s, Classic 60se, BAT VK55, and now Pass Labs XA25 without any problems.

That looks really good. Looks like a good solution. If there is a way to email/attach that data file I would make use of it and have a local shop print me off a pair. Would make my replacement look much more refined.

I think a guy could make his own steel mesh grill for the midrange. Would need to create a circular form by cutting a hole in some 3/4" plywood and then press the steel mesh into it to create a raised mesh grill. Just need to figure out a way to attach the grill to that faceplate you created.

You probably modified the cabinet already. The terminals for the tweeter are on too large of a diameter to fit the cutout in the cabinet so I took a rotary tool with a bit that is used for cutting wood and cut a notch in the cabinet to clear each terminal. Only had to cut in about 1/4" and 1/2" long for each terminal. The rotary tool I thought would make the least amount of saw dust to keep things clean.

I think a guy could make his own steel mesh grill for the midrange. Would need to create a circular form by cutting a hole in some 3/4" plywood and then press the steel mesh into it to create a raised mesh grill. Just need to figure out a way to attach the grill to that faceplate you created.

You probably modified the cabinet already. The terminals for the tweeter are on too large of a diameter to fit the cutout in the cabinet so I took a rotary tool with a bit that is used for cutting wood and cut a notch in the cabinet to clear each terminal. Only had to cut in about 1/4" and 1/2" long for each terminal. The rotary tool I thought would make the least amount of saw dust to keep things clean.

Endervox sent me the panels he made and I got them installed. Everything worked pretty well. Had ground out the cabinet for clearance for the terminals of the tweeter and then had to grind out a little more of the cutout in speaker cabinet for tweeter to move about a 1/4" lower to fit the new panel and also fit into the cabinet. Used some 8/32 bolts and nuts to mount tweeter to panel and tapped the midrange for 8/32 bolts also - the original is metric thread and I didn't want to hunt around for longer bolts in metric and the 8/32 was not much different so not much removed with rethreading.

The plastic is a little soft. Some washers under the bolt heads would have been a good idea in hindsight. Couldn't find black hardware where I was looking so just painted some bolts. Never thought ahead enough to paint some washers.

The plastic is a little soft. Some washers under the bolt heads would have been a good idea in hindsight. Couldn't find black hardware where I was looking so just painted some bolts. Never thought ahead enough to paint some washers.

Attachments

Reviving this thread because I have a pair of 1.8s here that are supposed to have good tweeters (I haven't listened to them yet but they are likely in good shape). I've read through everything so far, and there are a lot of awesome contributions toward the cause.

It doesn't look like there is data for the original tweeters. I'll need hand holding, and it will take some elapsed time (lots of other irons in the fire) but would it be valuable to capture some performance data from one/both of the tweeters?

I'm pretty new to REW. I have a Dayton Audio measurement mic (EMM-6 iirc) handy, and a pair of soundproofing panels if they would be useful. My interface currently is a DBX 386 mic preamp with spdif/aes output, which I'm sure isn't ideal but also doesn't totally suck I could probably borrow a Focusrite Scarlett 6i6 gen 2 once I get the hang of things.

I could probably borrow a Focusrite Scarlett 6i6 gen 2 once I get the hang of things.

Comments appreciated.

It doesn't look like there is data for the original tweeters. I'll need hand holding, and it will take some elapsed time (lots of other irons in the fire) but would it be valuable to capture some performance data from one/both of the tweeters?

I'm pretty new to REW. I have a Dayton Audio measurement mic (EMM-6 iirc) handy, and a pair of soundproofing panels if they would be useful. My interface currently is a DBX 386 mic preamp with spdif/aes output, which I'm sure isn't ideal but also doesn't totally suck

Comments appreciated.

@rockies914

I think, an impedance curve for a good ( raw ) tweeter would be most useful ( you'll need to measure it without the crossover in place ).

REW can make impedance measurements if you build it's recommended jig.

I think, an impedance curve for a good ( raw ) tweeter would be most useful ( you'll need to measure it without the crossover in place ).

REW can make impedance measurements if you build it's recommended jig.

- Home

- Loudspeakers

- Multi-Way

- Energy Veritas 1.8 tweeters quit