Now I work on CE360, but the ST260 have STEP file available - you can modify it at will. I may do it later.Do you think you might release this version with step built in? I would like to give that a try to see how it joins together.

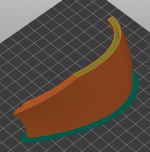

It complicates the printing at the moment. The petal thickness is currently 5 mm, which should not be a probem to connect and glue together without the ribs.The guides to connect petals seem like s good idea. Why did you remove them?

Thanks, have you built in any tolerances between the parts for glue etc. in the model you are working on?Now I work on CE360, but the ST260 have STEP file available - you can modify it at will. I may do it later.

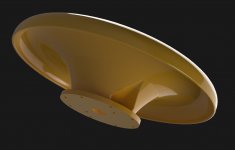

I'm not sure if buying a printer just for that pays off. You will face a lot of struggle, unless you buy a printer for 3000 EUR. I have now a quotation for a CE360 kit, printed on a professional FDM printer (Raise3D), including the dissoluble supports I mentioned (PETG + PVA), it's around 500 EUR for a two-piece set. You won't get a 3D printer capable of prints in that quality for that money, IMO.

Last edited:

You won't get a 3D printer capable of prints in that quality for that money, IMO.

Even on cheapest Anet A8 you can print very nice. It depends on speed and filament.

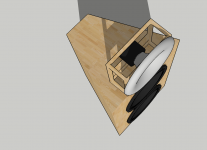

I've just realized it's plain possible to print the petal completely hollow this way and then fill it with just about anything through a drilled hole (0% infill; there's in fact no top layer, only perimeters). It can also be made a lot thicker (not shown).

Not to mention the substantial speeding up of the print and improvement on the surface quality. Well, sometimes it takes a day or two to have a bright idea..

Not to mention the substantial speeding up of the print and improvement on the surface quality. Well, sometimes it takes a day or two to have a bright idea..

Attachments

Last edited:

Keep us updated

To fit it on the print bed is one thing, the other is to reach the desired quality. The bigger piece it is, the harder it gets, as it tends to warp and so it may be dificult to assemble. At least this is typical for the hobby printers, without heated chambers, etc. I don't know how good is your printer.

Update:

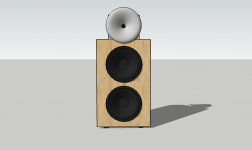

Throat and two 180deg petals printed....

Not too happy with the petals....

Tomorrow some epoxy and then Dremeling.

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)