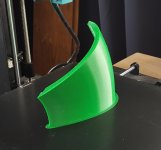

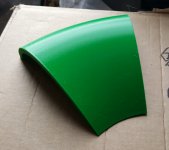

Keep us updated 🙂Well well, I stand corrected. It seems to be possible to print the 180deg petal after all.

To fit it on the print bed is one thing, the other is to reach the desired quality. The bigger piece it is, the harder it gets, as it tends to warp and so it may be dificult to assemble. At least this is typical for the hobby printers, without heated chambers, etc. I don't know how good is your printer.

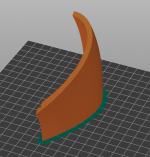

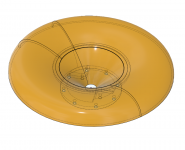

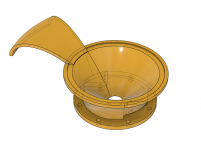

No ribs, no supports. I think this is the way to go with the petals -

Attachments

Last edited:

It's not perfect but seems practical enough -

(This is PETG + 20% infill and it's pretty dead, I don't see an issue regarding damping at all.)

(This is PETG + 20% infill and it's pretty dead, I don't see an issue regarding damping at all.)

Attachments

Last edited:

How long it takes to print a petal like that? i dont have a 3d printer but might get one for these 🙂 unless the printing time isnt too much for the current living arrangement.

A lot of putty and sanding and then spraying color? Just a typical job for compound 3D printed objects...

I'm not decided yet about the final material. PETG has nice mechanical properties but it may be a little more difficult to print than PLA. I probably won't try ABS at all.

I'm not decided yet about the final material. PETG has nice mechanical properties but it may be a little more difficult to print than PLA. I probably won't try ABS at all.

Last edited:

PETg is brittle. I prefer softer PLA, TPU 65D and PP. There is no standard for comparing different resins for acoustic cabinets so I only use knock test - more or less ringing, high or low pitch this is what can I hear. Which is better? I'm confused.

It must have been something else than PETG 🙂

So far I have best experience with natural filaments (i.e. "transparent", without any pigments) - that's what I would use for a "production run".

BTW, I use "PrintWithSmile" PETG filaments - by far the best I came across.

So far I have best experience with natural filaments (i.e. "transparent", without any pigments) - that's what I would use for a "production run".

BTW, I use "PrintWithSmile" PETG filaments - by far the best I came across.

Last edited:

Will investigate resins and cabinet construction soon when finish pellet extruder. Alu chassis or printed chassis and exotic wood shell.

I have no idea what you talk about, Jacek.

I tried PLA now, it's virtually perfect. For some reason I don't like supports, it seems I can't fine tune it to be easily removable on bigger prints, so it's a no-support design altogether (again). I'm quite curious about the price from a print shop for this. Some of them use quite high-tech stuff.

I tried PLA now, it's virtually perfect. For some reason I don't like supports, it seems I can't fine tune it to be easily removable on bigger prints, so it's a no-support design altogether (again). I'm quite curious about the price from a print shop for this. Some of them use quite high-tech stuff.

Attachments

Last edited:

I like PLA for perfect surface. Print shop prices - I've asked in China for Iwata 300 and they ask 1300$ per horn 🙂

don't like supports ...

It seems to me that the supports would be beneficial to the end product.

The way I printed the first petal the slicer decided there needs to be plenty of support.

I had no problems removing those.

Second petal in the printer as we speak...

I had no problems removing those.

Second petal in the printer as we speak...

We probably mean different supports. I mean those required during the print so that the filament does not hang in the air - those are removed afterwards. You probably mean some structural supports for the object itself. But those typically require the first kind of supports as well. For me it's not easy to print complex shapes, I don't have printer for that. There are printers capable of printing in two materials, one of which can serve as a support that's dissolvable later, which must be awesome. I could imagine designing pretty complex structures then, but not so with a basic DIY printer... This is the art of the possible.It seems to me that the supports would be beneficial to the end product.

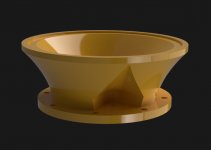

I can imagine adding ribs to the petals, making it easier to fix them together.

Like this (on both sides), maybe even bigger and in the middle as well -

And, I would add, plugs (not sure this is the right word) to ensure exact alignment.

(The ribs also add robustness, and make everything stiffer, fighting resonances.)

Do you think you might release this version with step built in? I would like to give that a try to see how it joins together.No ribs, no supports. I think this is the way to go with the petals -

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)