Quoting you -

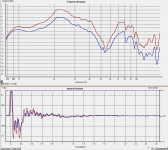

That was real data, not subjective opinion.

That's some very lossy foam, far far more than what I use. Unlike yours, I hardly see any effect at the low end of the passband.

So objectively we know that there is an effect, that's step one, given the magnitude of the effect it is hard to say that it is not audible (that much is conjecture, but given the data I am sure that it is accurate.) What is unknown is if the effect is perceived as beneficial in a controlled subjective test. A test like that would be extremely cumbersome to pull off. Hence all we can say at this point is that "the jury is still out on subjective improvements." However, as far as I know no one who has tried this has reported a negative perception. Several have reported positive effects.

So objectively we know that there is an effect, that's step one, given the magnitude of the effect it is hard to say that it is not audible (that much is conjecture, but given the data I am sure that it is accurate.) What is unknown is if the effect is perceived as beneficial in a controlled subjective test. A test like that would be extremely cumbersome to pull off. Hence all we can say at this point is that "the jury is still out on subjective improvements." However, as far as I know no one who has tried this has reported a negative perception. Several have reported positive effects.

Last edited:

Still you seem to hold the position that the foam makes an audible difference. For that you have no evidence. It's not so long ago when you admitted that yourself.

Last edited:

Yes, most probably it was far more dense than what you use. Just an experiment. Honestly, I hardly noticed a difference at the time. I haven't used it since as it gets quite expensive. Definitely it didn't harm.That's some very lossy foam, far far more than what I use. Unlike yours, I hardly see any effect at the low end of the passband.

But I probably don't listen as loud as many may be - that also can make a difference.

Last edited:

My impression is that in the case of the simulated waveguides it could be a little less difficult just because you don't have to record the sound first. It would be all artificial - the source polars, the room reflections, the head. Maybe the head would still be the weakest point.... Later in the mid-2000s I got a HEad binaural system and recorded many of my speakers and others in my sound room. On playback they were not really even close to the real thing. I think that is because I just used regular headphones and not the Head EQ'd electrostatic ones that we used at Ford. But those headphones were beyond my budget so none of this worked out for me. ...

Last edited:

Like an SB26ADC, for example. A typical hi-fi style dome tweeter. I mean, really, the only differences between a regular dome tweeter and a CD used on its backside are that the CD diaphragm is way bigger and it tends to be more rigid. Neither of them "come with" a phase plug.I agree to that. I just want to see how far I can get. I don't know what you mean by a conventional dome tweeter - I would use a regular compression driver, only from the convex side of the diaphragm.

My impression is that in the case of the simulated waveguides it could be a little less difficult just because you don't have to record the sound first. It would be all artificial - the source polars, the room reflections, the head. Maybe the head would still be the weakest point.

I've been playing around with 'Impulcifier' a bit, and it's rather promising. Basically a simplified DIY version of the smyth realizer. GitHub - jaakkopasanen/Impulcifer: Measurement and processing of binaural impulse responses for personalized surround virtualization on headphones.

I'd been thinking of using it for crossover auralization - measure the raw drivers in the cabinet in-room, and then play around with xover filters. This seems viable.

For waveguide auralization, you'd have to have a full model of the HRTF/HRIR rather than just a measurement at discrete points - this strikes me as much harder. The BACCH4MAC people seem to do head tracking in their product though, so maybe interpolating a 'good enough' full-space HRIR from discrete samples might be viable. I'd put it way into the 'non-trivial' space, though.

I think there are more convenient ways of how to present the data, like the wavelet transform (I also remember the Wigner distribution which for some reason never really catched on). Unfortunatelly these were not readily available to me at the time.In the impulse there seems to be a (minor) effect. ...

For an on-topic post, has anyone tried using Vectric V-Carve to machine the STL output of ath4 on a cnc router?. I tried my first experiment over the weekend and it kinda/sorta worked, but the finish toolpath stopped 2mm short of the bottom for some reason.

This is my first time doing anything 3d with my CNC, so it'll be a learning experience.

I also tried Estlcam, but I can't figure out any way to limit the machining to the surface of the STL so I can machine it straight into the baffle - it insists on making what amounts to a perimeter cut around the mouth.

This is my first time doing anything 3d with my CNC, so it'll be a learning experience.

I also tried Estlcam, but I can't figure out any way to limit the machining to the surface of the STL so I can machine it straight into the baffle - it insists on making what amounts to a perimeter cut around the mouth.

Sure. I'm going to start with the simulations and will see what I get for a rigid dome. If that goes well, I might well try both. Actually I still have a pair of SB26ADC at hand. I like the idea of a bigger diaphragm (and the coil) better though.Like an SB26ADC, for example. A typical hi-fi style dome tweeter. I mean, really, the only differences between a regular dome tweeter and a CD used on its backside are that the CD diaphragm is way bigger and it tends to be more rigid. Neither of them "come with" a phase plug.

Last edited:

Sure, I think it just boils down to acceptable cost and size vs distortion and LP frequency.Sure. I'm going to start with the simulations and will see what I get for a rigid dome. If that goes well, I might well try both. Actually I still have a pair of SB26ADC at hand. I like the idea of a bigger diaphragm (and the coil) better though.

For an on-topic post, has anyone tried using Vectric V-Carve to machine the STL output of ath4……….

I think the best thing is to take advantage of the Curvesimport and Surfaceimport scripts included in the application, they integrate perfectly with Fusion 360 and from it, with Manufacture you generate the gcode for machining. It must be said that * .stl files are not the best format to manipulate.

No idea about the software you have used

Un saludo

....... tested the tinyR, exported to Fusion and machining test....

BTW, how did it turn out? Would you have a photo of the finished piece? Would be nice to see it.

No, sorry, the part was not finished, it was only a test, I am still in the process of assembling the CNC, as soon as I have the machine assembled and a defined design I start manufacturing.

Very good feeling of integration with Fusion and its capabilities

Un saludo

I haven't mentioned that? I'm going for a constant directivity waveguide without HOMs, i.e. a 1P solution, at least within audio band.So I'm not really sure what exactly you're going for here, but...

But I really don't believe much that any real-world driver could allow for that.

We already know how to treat the mouth properly. Now it's time to look at the throat.

Last edited:

For an on-topic post, has anyone tried using Vectric V-Carve to machine the STL output of ath4 on a cnc router?. I tried my first experiment over the weekend and it kinda/sorta worked, but the finish toolpath stopped 2mm short of the bottom for some reason.

This is my first time doing anything 3d with my CNC, so it'll be a learning experience.

I also tried Estlcam, but I can't figure out any way to limit the machining to the surface of the STL so I can machine it straight into the baffle - it insists on making what amounts to a perimeter cut around the mouth.

I have been full time cnc-operator/programmer for the past year, but have only used Alphacam. I found a similar issue when i first processed a waveguide/baffle. Since you machine on the surface, which approaches 90 degree at the throat, presumably using a ball end router bit, in Alphacam, you must have extra (virtual) material, since the operation uses the material as a boundary.

I have used Fusion for CAD extensively, but never for CAM.

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)