That doesn't make it correct.

And anyways that paper is so out-of-date that it is not of much relevance when one now has waveguide with virtually no resonances. It is very misleading to quote analysis of devices that we know are bad, and why, in a thread where we have devices that don't have any of those problems. Let's move on from where we are now, not where we were decades ago.

Here I partly agree.

1. I think Holland and Newell have much the same views as you about horns

2. With that in mind, it's obvious that by using mabat's ATH4 tool it is possible to make better waveguides than their own EX-2. However, it goes too far to suggest that your OSWG and their waveguide are worlds apart.

Attachments

Last edited:

How about these? S400 White — Buchardt Audio

They get great reviews. I see potential problem with diffraction on the sharp edges, but the WG is supposed to be matched to the mid-woofer and there is a passive radiator in the back. They are not that expensive either.

They get great reviews. I see potential problem with diffraction on the sharp edges, but the WG is supposed to be matched to the mid-woofer and there is a passive radiator in the back. They are not that expensive either.

Attachments

I think Holland and Newell have much the same views as you about horns

From what I know, I think that is largely correct.

Resonances must be avoided in the passband. Compression chamber resonances will be on the high end of the pass band, as will diaphragm resonances. Hence they are of less concern to me. But the waveguides are big and the potential resonances in them fall well within the passband and right in the middle of our ears maximum sensitivity. They must be controlled.

One of the things that I like most about the use of foam in a waveguide is how it dampens all modes - even ones in the compression chamber and perhaps the diaphragm itself. since it adds considerable damping over an air filled cavity. I think that this is highly overlooked as anyone who has tried foam will attest.

The biggest difference between the OWSG and the EX-2 is in the throat area, which, I assume you will find significant.

Newell and Holland have included loading characteristics in their design, not that it matters much with a shallow horn (like theirs).

Newell and Holland have included loading characteristics in their design, not that it matters much with a shallow horn (like theirs).

See the measurements (made on Klippel NFS, which is a dream): Buchardt S400 Speaker Review | Audio Science Review (ASR) ForumHow about these? S400 White — Buchardt Audio

I know of better speakers. And worse.

How about these? S400 White — Buchardt Audio

They get great reviews. I see potential problem with diffraction on the sharp edges, but the WG is supposed to be matched to the mid-woofer and there is a passive radiator in the back. They are not that expensive either.

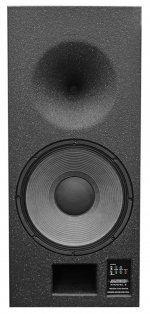

Or turn this one upside down? 😀

Attachments

Last edited:

One of the things that I like most about the use of foam in a waveguide is how it dampens all modes - even ones in the compression chamber and perhaps the diaphragm itself. since it adds considerable damping over an air filled cavity. I think that this is highly overlooked as anyone who has tried foam will attest.

Foam works wonders in diffraction slots, but I have to admit I am not fond of the looks of a big sponge in my (future?) waveguides.

I like the looks - waveguide plus woofer. Maybe a bit too small. I have too many speakers anyway. CNC'd waveguide with 10"-12" woofer in a glossy paint is my ultimate DIY goal, that is why I follow this thread with interest.

Foam works wonders in diffraction slots, but I have to admit I am not fond of the looks of a big sponge in my (future?) waveguides.

Fashion before form!!

Can we use small OS waveguide instead of wideband driver in center off spherical cap shaded array?

Attachments

Last edited:

Thank you for responding, I read the part you quoted from Tom as saying a bigger wave guide reduced the effect and level falls with distance (which really shouldn't need to be said) so now I'm confused as what he really meant, either way mabat has shown the value of good mouth termination in his simulations.I'm not going to critique the entire text but this line is clearly wrong

The pressure declines as the wave moves out, but the circumference also increases at the same rate - half the pressure over twice the length, etc. This will yield the exact same level of mouth diffraction in the far field no matter what distance along the device the mouth is at. Only a mouth flare will reduce this diffraction, again no matter how long the device is.

That's just the one that jumped out to me at first.

How about these? S400 White — Buchardt Audio

They get great reviews. I see potential problem with diffraction on the sharp edges, but the WG is supposed to be matched to the mid-woofer and there is a passive radiator in the back. They are not that expensive either.

Here is a review of them using a Klippel Near Field Scanner and ANSI/CTA 2034-A, “Standard Method of Measurement for In-Home Loudspeakers" which one can download for free. Worth a read as it represents the SOTA on loudspeaker measurements.

Buchardt S400 Speaker Review | Audio Science Review (ASR) Forum

Fashion before form!!

Considering waveguides made by using mabat's tool minimize most edge-related issues, wouldn't a small piece of foam in the throat suffice?

Last edited:

I suppose that with a careful tailoring of the material you could do that. I just found something that works with materials I could get many decades ago. Getting the foam period was hard enough back then, but someone who actually had a range of material specs, that was far more difficult. But I went through a large range of material specs until I found the best optimum that was available.

Meyer tried what you suggest many years ago, even patented it. But it never went anywhere in his products.

Meyer tried what you suggest many years ago, even patented it. But it never went anywhere in his products.

Last edited:

It is 30ppi open-cell foam if I'm not mistaken?

There are a few manufacturers that put foam in the throats. The Italian manufacturer Outline is an example, Swedish Procella Audio is another:

There are a few manufacturers that put foam in the throats. The Italian manufacturer Outline is an example, Swedish Procella Audio is another:

Last edited:

Putting a piece in the throat seems a decent alternative to "foaming the horn". Apart from the positive effects, mentioned by you previously, it's probably much simpler to cut a small piece properly. Besides, large and thick pieces of foam are not exactly cheap.

It also makes an excellent subsitute for the bugscreen that I'll probably have to cut out of the Chinese drivers in order to measure the exit angle.

It also makes an excellent subsitute for the bugscreen that I'll probably have to cut out of the Chinese drivers in order to measure the exit angle.

Last edited:

Amir has some money to spend on measuring equipment. His reviews certainly get better over time. A smart guy and a kind of rebel. I appreciate his contributions to the audio community.

Last edited:

As for the foam plug, it should be noted that the subjective benefit is still not supported by any data. 😉

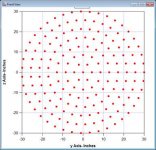

To return back to the release 4.5.0 for a while, I didn't mention the new featues:

Besides a new way of meshing there is now a great flexibility for the throat details. It can be OS, conical or OS with a conical extension or even conical with a conical extension. The entry angle can also be set negative.

For the BEM part, there is now a possibility to select the shape of the wavefront at the throat - either flat or spherical, independently of the direction of the velocity, which can be set axial or radial. By default, for a non-zero throat angle the corresponding spherical wave is now automatically used.

That all may be not so useful from a practical point of view but gives opportunities to test the influence of some of the things you may still be wondering about.

Besides a new way of meshing there is now a great flexibility for the throat details. It can be OS, conical or OS with a conical extension or even conical with a conical extension. The entry angle can also be set negative.

For the BEM part, there is now a possibility to select the shape of the wavefront at the throat - either flat or spherical, independently of the direction of the velocity, which can be set axial or radial. By default, for a non-zero throat angle the corresponding spherical wave is now automatically used.

That all may be not so useful from a practical point of view but gives opportunities to test the influence of some of the things you may still be wondering about.

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)