Maybe it is not so small after all. In the example above it makes about 22% of the entire projected area.Your data shows that this small area accounts for a lot of problems. With the right density of foam, I'll bet you could make a substantial difference. ...

Last edited:

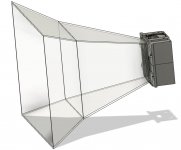

I might have asked already, but could ATH4 be used for creating horn profiles with rectangular throat? I would like to generate some smooth profile for the AMT horn, which starts with a 50x30° rectangular throat.

If it is not possible in the software directly (I think it is not), how would one select the parameters to blend the two horns together in Fusion 360? The throat is roughly 140 x 75 mm and I have around 450 mm printable height from the flange. My idea would be to create a horn that has the same length, height and mouth area with the correct entry angle and then merge it somehow with the rectangular part.

Any better ideas? Thanks!

If it is not possible in the software directly (I think it is not), how would one select the parameters to blend the two horns together in Fusion 360? The throat is roughly 140 x 75 mm and I have around 450 mm printable height from the flange. My idea would be to create a horn that has the same length, height and mouth area with the correct entry angle and then merge it somehow with the rectangular part.

Any better ideas? Thanks!

Attachments

CNC hotwire. Jump to 50 seconds into the video. Complicated shapes are no problem to cut.

FROG3D | FROGWIRE™

FROGWire in Action

that's incredible

I might have asked already, but could ATH4 be used for creating horn profiles with rectangular throat? I would like to generate some smooth profile for the AMT horn, which starts with a 50x30° rectangular throat.

If it is not possible in the software directly (I think it is not), how would one select the parameters to blend the two horns together in Fusion 360? The throat is roughly 140 x 75 mm and I have around 450 mm printable height from the flange. My idea would be to create a horn that has the same length, height and mouth area with the correct entry angle and then merge it somehow with the rectangular part.

Any better ideas? Thanks!

The instructions that I published here can be used to make a throat that's rectangular:

3D Modeling Tips and Tricks

You simply start with a rectangle instead of an ellipse.

Depending on how well behaved your software is, you could actually have a throat of any shape.

You can also have a throat that's circular with a mouth that's rectangular. That's accomplished by starting with rectangle and smoothing the curve. (The smoothing turns the square into a circle.)

Patrick

In your post here you are entusiastic about XT1086

3D Modeling Tips and Tricks

Is it possible to 3D print a much larger verison for 1 1/2 inch throat?

In your post here you are entusiastic about XT1086

3D Modeling Tips and Tricks

Is it possible to 3D print a much larger verison for 1 1/2 inch throat?

I might have asked already, but could ATH4 be used for creating horn profiles with rectangular throat? I would like to generate some smooth profile for the AMT horn, which starts with a 50x30° rectangular throat.

If it is not possible in the software directly (I think it is not), how would one select the parameters to blend the two horns together in Fusion 360? The throat is roughly 140 x 75 mm and I have around 450 mm printable height from the flange. My idea would be to create a horn that has the same length, height and mouth area with the correct entry angle and then merge it somehow with the rectangular part.

Any better ideas? Thanks!

This can easily be done in cad software such as Inventor, with a true matched entry angle OS equation, but the equation curve feature in Fusion is just not powerful enough to do handle these equations in my experience.

If you dont have access to Inventor, i might be able to run your parameters, and you can import the model into Fusion.

You can also use spline functions with tangency to get a result that is very close (within tenths of a millimeter) to OS.

You can also use spline functions with tangency to get a result that is very close (within tenths of a millimeter) to OS.

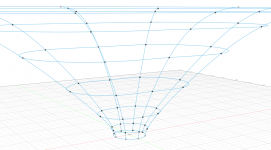

This is what I used. I found that I could get a near perfect match with just three points, two end points and one in the middle. I fit this to a list of generated points from the exact equation.

This is what I used. I found that I could get a near perfect match with just three points, two end points and one in the middle. I fit this to a list of generated points from the exact equation.

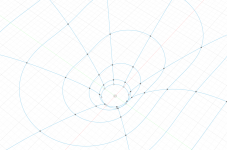

I use a tangency (control vertex spline) as the mouth round-over curve too: very flexible, and doesn't tend to distort the diagonals when "lofting" a circular throat to a non-circular mouth cross section. I believe this is quite close to the variable N-value as a function of angle in the SE termination, that Mabat considered implementing. It makes sense, since splines are litterally just a minimum-energy way of joining two displaced curves.

Patrick

In your post here you are entusiastic about XT1086

3D Modeling Tips and Tricks

Is it possible to 3D print a much larger verison for 1 1/2 inch throat?

That should be possible.

You could enlarge Bateman's waveguide up to 150%, but directivity will suffer as the slot of the XT1086 is only marginally wider than the 1" entrance (the slot width defines pattern control in the horizontal plane).

Another option is redesigning the slot, but you'd probably end up with a traditional diffraction slot including some pinching > generally not recommended.

I have a pair of medium-sized oldskool 2" 90x60° diffraction horns, a little bigger than the JBL 2352. These look like scaled-up JBL 2380(A)s, but the slot design - or lack thereof - is by far the ugliest I've seen. It's much worse than even the throat area of the BMS 2236. The vertical pathway consists of 2 slits (up and below) towards the slot opening with sharp edges along the axial boundary with the horizontal (circular) pathway. Imagine a round to rectangular duct with a trench milled trough the center. This trench however, naturally as wide as the slot, is the perfect "adapter" for a piece of open-cell foam, which I only had to cut into a trapezoid. Looking from the front into the mouth, the entire slot opening is filled with foam.

Last edited:

Hey Team.

Firstly thanks to Mabat for the awesome work and everybody else for the input. I have read the thread from the start and it's been awesome watching this grow.

With v4.5 I have few questions, I used ath4.3.4 to build a few horns and got the basics working reasonably well, now with v4.5 I am lost as to how to set the horn H & V wall angles?

Cheers for any input.

Dean

Firstly thanks to Mabat for the awesome work and everybody else for the input. I have read the thread from the start and it's been awesome watching this grow.

With v4.5 I have few questions, I used ath4.3.4 to build a few horns and got the basics working reasonably well, now with v4.5 I am lost as to how to set the horn H & V wall angles?

Cheers for any input.

Dean

CNC hotwire...

That's pretty cute, thanks for the link, made me think about the option to manually hot wire cut a Styrofoam block to make a mould.

Should be reasonably easy and inexpensive, fast, and easy to extend even for wide horns.

A hyperbolic (aka OS) profile is neatly created by a skewed line rotated about an axis.

For non axisymmetric horns a couple of profile templates would define the bulk of the cut.

I know Scaled Composites did this for prototype aircraft and were very successful so it must be tolerably accurate.

Anyone tried it for horn moulds?

Best wishes

David

Last edited:

See page 7 of the new User Guide for version 4.5.1 (now in preparation). There's an explanation how this works...., now with v4.5 I am lost as to how to set the horn H & V wall angles?

Just don't look much at the other things as 4.5.1 has not been released yet - there are some pretty new features, adding further flexibility, e.g. a possibility of setting the parameters not only to constants but also to any mathematical expressions dependent on the angle around the waveguide. This will also bring the possibility to specify the coverage angle directly.

Last edited:

BTW, I consider making also the length of the waveguide a possible function of the angle around the waveguide. I suppose this could be handy for free-standing variations but would require rather massive re-writing of the core parts. Still not sure if it is worth the effort.

That si true. Also for the Fusion spline import just a sparse point cloud can be used with good results (depending on the complexity of the shape of course) -...You can also use spline functions with tangency to get a result that is very close (within tenths of a millimeter) to OS.

Attachments

Last edited:

BTW, I consider making also the length of the waveguide a possible function of the angle around the waveguide. I suppose this could be handy for free-standing variations but would require rather massive re-writing of the core parts. Still not sure if it is worth the effort.

That would be a nice feature.

I won't dare urge you to implement it

At least I am.

It seems a number of ATH4 horns have now been made. Perhaps a separate ATH4 build thread makes sense, in which the practical aspects can be discussed.

This thread can then remain dedicated to the development of ATH4.

It's just a suggestion.

Last edited:

Great idea! I would love to see what others are actually building.... Perhaps a separate ATH4 build thread makes sense, in which the practical aspects can be discussed.

Personally, I'm going to try to make a mould by stacking slices of Wedi boards filled out with Acrylic One. I really want to make a non-axisymmetric one and this is about the only way I can imagine doing it quite readily at home. It may be labourous but that's not the problem right now. I don't care about extreme precision as I'm convinced it doesn't really matter - much less than the overal shape and the mouth flare.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)