Thanks, I'll re-run my calculations based on actual T/S measurements (both drivers measured similarly)

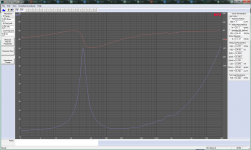

Here is what the raw "unbroken-in driver measures as (Dayton WT3) . The Qts measures closer to 0.31, which should be ideal 🙂 . I'll play with your method using my measurements.

Here is what the raw "unbroken-in driver measures as (Dayton WT3) . The Qts measures closer to 0.31, which should be ideal 🙂 . I'll play with your method using my measurements.

Attachments

Last edited:

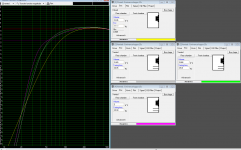

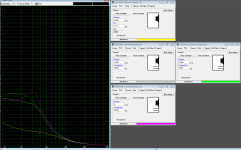

Here's some more WinISD results. The first graph plots relative SPL, and the second Group Delay (i'm guessing that's as close a measure of transient response that WinISD can provide)

Row 1: Optimal Max Flat Enclosure (a bit larger than the stock doghouse volume of 2.3 cu ft)

Row 2: Optimal CS4, followed by Optimal SBB4

Row 3: Using the full volume of the mid-treble top

With actual driver data available, it appears that some increase in volume is desirable, though not maybe the full 3 cuft (less mid-high horn, port and bracing volume) that my top unit will comprise of.

Keep in mind that if I pick the 18sound XT1464 driver, the top unit is going to be a bit over 1 ft tall in itself

Row 1: Optimal Max Flat Enclosure (a bit larger than the stock doghouse volume of 2.3 cu ft)

Row 2: Optimal CS4, followed by Optimal SBB4

Row 3: Using the full volume of the mid-treble top

With actual driver data available, it appears that some increase in volume is desirable, though not maybe the full 3 cuft (less mid-high horn, port and bracing volume) that my top unit will comprise of.

Keep in mind that if I pick the 18sound XT1464 driver, the top unit is going to be a bit over 1 ft tall in itself

Attachments

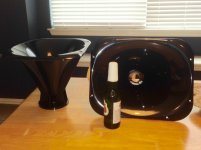

Ordered a pair of XT1464 Constant Directivity waveguides . They are fairly tall so I'll have to size the cabinet tops appropriately . Stay tuned

0005 XT1464 - Coaxials XT1464 : Eighteen Sound - professional loudspeakers

0005 XT1464 - Coaxials XT1464 : Eighteen Sound - professional loudspeakers

Not much progress this weekend on account of the weather though I have started cutting wood for the tops.

I've gone back and forth quite a few times about port location. I really wanted to implement slot ports on either side of mid-high horn, as earlier suggested but decided not to because

1. The mid-high cab is already about 14" tall (on account of the large waveguide) . A slot port would have a rather large aspect ratio (unless further divided - a'la onken)

2. Slot ports are hard to resize once installed - unless made removable

3. A big factor against implementing slot ports on the front was that it won't let me experiment further with other large format DIY horns (synergy, large wood tractrix) that would arguably occupy most of the entire front face of the top cab.

So, I've ordered 4 of these adjustable ports for the rear of the top-cabs.

Parts Express Speaker Cabinet Port Tube 4-5/16" ID Adjustable

I've gone back and forth quite a few times about port location. I really wanted to implement slot ports on either side of mid-high horn, as earlier suggested but decided not to because

1. The mid-high cab is already about 14" tall (on account of the large waveguide) . A slot port would have a rather large aspect ratio (unless further divided - a'la onken)

2. Slot ports are hard to resize once installed - unless made removable

3. A big factor against implementing slot ports on the front was that it won't let me experiment further with other large format DIY horns (synergy, large wood tractrix) that would arguably occupy most of the entire front face of the top cab.

So, I've ordered 4 of these adjustable ports for the rear of the top-cabs.

Parts Express Speaker Cabinet Port Tube 4-5/16" ID Adjustable

Out of curiosity.

How do you plan to seal the top cab to the horns I saw on your garage floor?

I would think that fasteners that don't show would be difficult to implement....

John

How do you plan to seal the top cab to the horns I saw on your garage floor?

I would think that fasteners that don't show would be difficult to implement....

John

Out of curiosity.

How do you plan to seal the top cab to the horns I saw on your garage floor?

I would think that fasteners that don't show would be difficult to implement....

John

Well,

1. I plan to screw the top cab into a spacer sheet that will be glued to the bottom cab. Unlike most lascala or belles, I'm going to load the woofer from the top, rather than the bottom, and build up plywood spacers around the trapezoidal woofer cutout hole. I was thinking of using some weather stripping to ensure a tight rattle free seal.

2. As to how I propose to physically attach the 2 segments, I plan to make the front face of the top cab removable . Since the tops are so tall, there should be plenty of space for my right angle impact drill and / or a stubby screwdriver to work in there. An alternative would be to drill through the bottom of the top cab and install threaded inserts into spacers before building up the cabinet too much. Something like this E-Z Lok Threaded Insert, Zinc, Hex-Flanged, 1/4"-20 Internal Threads, 13mm Length (Pack of 100): Helical Threaded Inserts: Amazon.com: Industrial & Scientific

or this

http://www.amazon.com/E-Z-Threaded-...sbs_328_3?ie=UTF8&refRID=0MBE951WP7MS5NV1EB7J

(cheap online but totally overpriced at the local home improvement stores).

I don't think I've done the best job explaining my plan, .. hopefully, things will become clearer in due course.

Last edited:

Thanks, I'll just follow along then...

Not much is going to get done today but I'll try to get te spacers done. Here's what I mean. The too cabinet will screw into te spacer (which will also mass load / brace the top of the midbass cabinet . I thought about using a solid piece of ply / MDF but It didn't make sense from wastage perspective so I just made up a spacer out of scrap

Attachments

I've cut up plywood for the tops and commenced assembly. I haven't yet cut out a circle in the bottom of the top to connect the air volume with the horn rear chamber.

Attachments

Last edited:

I had some time this weekend to work on my project .

Getting there, a lot of flush trimming and routing equity in this pair of cabs.

The side walls of the top cabs are now double thick .

I need to brace / build up the top and bottom surfaces a bit more and cut access holes in the too cabs to mAre it's internal volume accessible to the horn back chamber

After that, I need to route out the removable waveguide baffles and devise a method to attach them to the top cabinet (I'm thinking of screwing them into cleats at this point

Getting there, a lot of flush trimming and routing equity in this pair of cabs.

The side walls of the top cabs are now double thick .

I need to brace / build up the top and bottom surfaces a bit more and cut access holes in the too cabs to mAre it's internal volume accessible to the horn back chamber

After that, I need to route out the removable waveguide baffles and devise a method to attach them to the top cabinet (I'm thinking of screwing them into cleats at this point

Attachments

Last edited:

I saw this on the Klipsch forum. Very impressive.

Thanks for the compliments and patience

The weather (and accordingly the garage) is beginning to get hot so I have to plan my workshop sessions around the temperature . Hopefully, I'll get some sound out of them by this weekend or early next week

Last edited:

that's really impressive - if I could move enough junk and get to a saw, then might flip my unused FH1 over, add a ported chamber and mount a 511 in the chamber and tweeter on top - it would look awful but might function if air leaks were sealed. I want to dump the FH1's so my K's can get play but a La Scala would do well with movies and concerts

Thanks Freddy,..

Here's another still from "50 shades of brace" . The tops are really solid now. You can't tell from the picture but the topmost face of the top cab is double thick.

At this point, the only parts of this entire cab that could use further bracing / reinforcement are the doghouse and the rear faces (might skin them in 1/4" ply or MDF) and the angled faces of the doghouse (might brace and / or glue some hardibacker / thin ply). I don't want to affect the stock volume too much.

How do you like FH1 vs K15 / lascala. Looks like I might be getting my K15 back this year as my friend is leaving town . Did you ever try the pvc elbow bass mod on one of yours ?

Here's another still from "50 shades of brace" . The tops are really solid now. You can't tell from the picture but the topmost face of the top cab is double thick.

At this point, the only parts of this entire cab that could use further bracing / reinforcement are the doghouse and the rear faces (might skin them in 1/4" ply or MDF) and the angled faces of the doghouse (might brace and / or glue some hardibacker / thin ply). I don't want to affect the stock volume too much.

How do you like FH1 vs K15 / lascala. Looks like I might be getting my K15 back this year as my friend is leaving town . Did you ever try the pvc elbow bass mod on one of yours ?

Attachments

Last edited:

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- zobsky contemplates a variation on the belle klipsch