FWIW, here's a post detailing DJK's logic in choosing the rear chamber size / tuning frequency for the ported mod. Note his recommendation for a bit of EQ boost and his comments on the use of low Qts woofers . https://community.klipsch.com/index.php?/topic/108425-la-scala-bass-reflex-mod/?p=1202059

If the bass is overdamped, I can employ my old (restored) mcintosh MC2100 that has a damping factor of about 10 🙂

If the bass is overdamped, I can employ my old (restored) mcintosh MC2100 that has a damping factor of about 10 🙂

Last edited:

Here's the computer generated cutlist for the basshorns using 3 sheets of ply. I also decided to double up on the rear face (the sides are already doubled).

Now, I need to figure out how to get the rough cut pieces into my car 🙂

Now, I need to figure out how to get the rough cut pieces into my car 🙂

Attachments

Last edited:

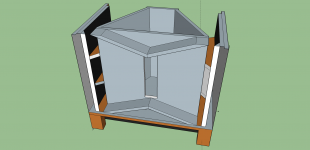

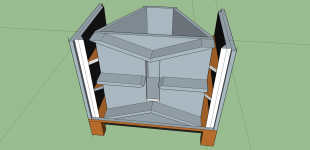

On further introspection, it seems more efficient to add a center brace to the throat area (large unbraced area), rather than double up on the rear.

My personal rule of thumb is to leave no panel width of greater than 8-12" unbraced. I'm stretching the rule a bit but there should be enough scrap to add further bracing if needed. The important thing to note here is that this is a horn, so the orientation of the brace is as important as the position. Also, excessive bracing can affect the flow of sound waves through the horn

My personal rule of thumb is to leave no panel width of greater than 8-12" unbraced. I'm stretching the rule a bit but there should be enough scrap to add further bracing if needed. The important thing to note here is that this is a horn, so the orientation of the brace is as important as the position. Also, excessive bracing can affect the flow of sound waves through the horn

Attachments

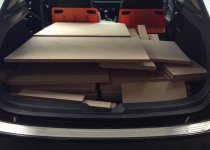

Plywood (3/4" baltic birch) has been been cut (about 2.5 sheets worth + some offcuts) . I had a local lumber yard ( Hardwood Lumber Company of Dallas ) make precision cuts for me this time so I don't have to hack at the ply for days in my cramped garage. I've attached the cut list I used to this post. Amazing what will fit in a compact hatchback. I'll soon post a (slightly) corrected sketchup rendering that matches up with the cutlist

Attachments

Last edited:

Almost done with the pair of midbass horns. Need to glue up the rear chamber, add braces and seal the top. The pic is of a test fit.

Attachments

Last edited:

Zobsky,

You will either need to rout a surround relief slot or use a "donut" gasket to keep the driver surround from hitting the baffle on excursion peaks.

Art

You will either need to rout a surround relief slot or use a "donut" gasket to keep the driver surround from hitting the baffle on excursion peaks.

Art

Zobsky,

You will either need to rout a surround relief slot or use a "donut" gasket to keep the driver surround from hitting the baffle on excursion peaks.

Art

Forgot about that , I'll deal with that then . Will 1/4" MDF be okay ?

Zobsky,

You will either need to rout a surround relief slot or use a "donut" gasket to keep the driver surround from hitting the baffle on excursion peaks.

Art

I'm guessing that doubling up on the gaskets should work. any thoughts ?

Official Speaker Repair Site - Orange County Speaker - Home of GLS Audio Speaker Gasket - 1 Solid Piece (for 1 speaker)

Thanks. Unfortunately, one of the doghouses has already been glued up. Ill see what's possible wrt routing

With only 2.4 mm Xmax, an extra gasket (or 1/4" MDF) should provide plenty of clearance, but increases front chamber volume more than the surround recess I suggested that DJK showed.I'm guessing that doubling up on the gaskets should work. any thoughts ?

Increasing the front chamber volume should slightly reduce the HP frequency.

Last edited:

With only 2.4 mm Xmax, an extra gasket (or 1/4" MDF) should provide plenty of clearance, but increases front chamber volume more than the surround recess I suggested that DJK showed.

Increasing the front chamber volume should slightly reduce the HP frequency.

I bought a 1/4" x 2" x 4" piece of MDF,.. mostly because it's cheaper , incompressible , easily available and more customizable than an off the shelf pair of gaskets . I can always add SOME of the internal offcut circle to the front chamber to reduce its volume . More info after i butcher the wood 🙂

Last edited:

just wondered if you have seen this thread might be of some interest.

https://community.klipsch.com/index.php?/topic/154589-port-location-for-belles-with-bass-reflex/

I just noticed that you have responded there. Others might find the thread of interest.

https://community.klipsch.com/index.php?/topic/154589-port-location-for-belles-with-bass-reflex/

I just noticed that you have responded there. Others might find the thread of interest.

Last edited:

just wondered if you have seen this thread might be of some interest.

https://community.klipsch.com/index.php?/topic/154589-port-location-for-belles-with-bass-reflex/

I just noticed that you have responded there. Others might find the thread of interest.

From his sketch, I like the way his reflex ports straddles the mid-treble horn. Yet another variation to ponder ....

In a week or so when I'm done with the bass bins (I'm taking this build slow and easy, for a change), I'll start tackling the mid-treble section. Do you have any suggestions for the top half? I'd like this to be a 2 way design. I'm not even sure how much a K501 costs but I don't care to pay any more than needed just for a klipsch badge. That said, I came across this post

http://www.diyaudio.com/forums/full...-trynergy-full-range-tractrix-synergy-51.html

and found the horn cheaper at

Official Speaker Repair Site - Orange County Speaker - Home of GLS Audio PH2380 17.5" x 11" Horn

From his sketch, I like the way his reflex ports straddles the mid-treble horn.

More work, but better overall to put them next to the HF horn; otherwise make a foam horn extension to cover its perimeter out to the vents similar to the one used on the Altec M19.

GM

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- zobsky contemplates a variation on the belle klipsch