Good idea! How do you fence it for a straight cut?I got a Graff Termit blade for my cheap Harbor freight angle grinder. Turns it into one of those mini saws for about a third of the proce, and it cuts nice and clean through thin Ply.

Last edited:

You can add this - Safety Guard for Angle Grinders and this - Laser Marker. The safety guard is a little flimsy but you can run it along a thick straight edge like you would a circular saw as long as you don't press too hard. The laser will help you follow your line. It may not be table saw straight but it won't look like a drunk driving walk test.

I used to have a circular saw steel "sled" with metal rollers which rode on 1.5" aluminum angle stock. Two pieces of angle stock were provided. One about 10 feet long, the other 5 feet. It ideally needed a piece of wood attached under the angle to limit lateral flex.

It took careful position of clamps to work well.

If a person wasn't too concerned about a few screw holes on the back side of a panel then a piece of wood screwed down as a saw guide would help - if panels are large enough,

I'm horrible at woodworking among many other things. 😱

It took careful position of clamps to work well.

If a person wasn't too concerned about a few screw holes on the back side of a panel then a piece of wood screwed down as a saw guide would help - if panels are large enough,

I'm horrible at woodworking among many other things. 😱

I have this device that just might be used with one of the 4½" saws to get straight edges. If that doesn't work out I can use it with a router to straighten edges cut by other means.

Joint-a-Billi-T Matched Edge Wood Joiner - YouTube

Joint-a-Billi-T Matched Edge Wood Joiner - YouTube

I lined the wings of my K5/XKi hybrids with felt and there is a definite improvement. The vocals lost the boxy sound. on this passage Amy LaVere & Will Sexton- No Battle Hymn (live in KUTX Studio 1A) - YouTube I will do some more work in the rear after I find suitable replacement screws. The #4 flat head wood screws would be too much of a PITA to remove/reinstall.

For sheet goods see Make a Simple Circular Saw Cutting Guide | Rockler Skill Builders - YouTube

I would want a thicker fence that shown.

For cutting small stock a table, radial arm or chop saw is best but one can turn a circular saw into a table saw of sorts.

Build A Table Saw In 10 Minutes - YouTube

I would want a thicker fence that shown.

For cutting small stock a table, radial arm or chop saw is best but one can turn a circular saw into a table saw of sorts.

Build A Table Saw In 10 Minutes - YouTube

Last edited:

Flush mounting of a speaker to its baffle looks neat. If one doesn't have router skills it could be done by gluing an overlay piece to the baffle. My K5/Xkis have front mounted PA130s, the baffles are small enough that I could use face plate turning on the lathe to get neat speaker holes in thin plywood. Would there be any reason to do this other than for appearance?

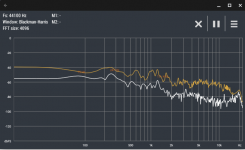

I could easily do that as my felt is vinyl backed and easy to cut w/electric scissors. Testing would be subjective. I down loaded a SA app but it looks strange on the low end. The pic is with a Sony boombox playing in the kitchen and I am in the den.

Attachments

I used my K5/XKi pair to troubleshoot a Carver-Wharfdale system. We were trying to determine if his noise problem was from the receiver or the speakers. It was from the right channel Wharfdale. He was impressed at how well my little boxes performed. I had them connected to his B outputs so I could just flick from A to B for comparison.

The PA130-8 XKi is a slick little inexpensive speaker. Very pleasant sounding with a bass kick deeper than one thinks it should have.

Did it sound as good or better than the Wharfdale?

Did it sound as good or better than the Wharfdale?

Vocals were a little better on the Wharfdale because I haven't finished padding my rear chambers yet (I still haven't purchased friendlier screws for the rear panels). I thought the bass was a little better on mine but we were near field and didn't move back to the sweet spot for either. I have mine back home now and had to rework my banana plugs, now I see the advantage of premade cords like you use.

Last edited:

hey XRK971.

I have some little 6CX and believe they are close to Beta6A in spec.

Would an XKi have any advantage with such a high fs driver over a 0.44X K15?

Def_Driver ‘Beta 6A’ | Eminence 6” speaker 4.5mm xmax

Sd=129.9cm2

Fs=123Hz

Mms=11g

Qms=3.46

Qes=0.66

Re=5.18 ohm

BL=8.13TM

Le=0.43mH

Vas=3.51L

I have some little 6CX and believe they are close to Beta6A in spec.

Would an XKi have any advantage with such a high fs driver over a 0.44X K15?

Def_Driver ‘Beta 6A’ | Eminence 6” speaker 4.5mm xmax

Sd=129.9cm2

Fs=123Hz

Mms=11g

Qms=3.46

Qes=0.66

Re=5.18 ohm

BL=8.13TM

Le=0.43mH

Vas=3.51L

-questions when dealing with small XKi with sizable vent.

X says 17 liters total for BG20 usable to 70Hz. Not including the baffle and upper panels, but including vent and driver volumes, the total would be around 20 liters.

Is that volume adequate in hopes to reach the model's low end? What happens if the vent and driver displacements aren't included?

Does the vent at the top mitigate the cavity peak?

What would you make the internal size of this particular XKi ?

X says 17 liters total for BG20 usable to 70Hz. Not including the baffle and upper panels, but including vent and driver volumes, the total would be around 20 liters.

Is that volume adequate in hopes to reach the model's low end? What happens if the vent and driver displacements aren't included?

Does the vent at the top mitigate the cavity peak?

What would you make the internal size of this particular XKi ?

Last edited:

- Home

- Loudspeakers

- Full Range

- XKi - X's ab initio Karlson 6th Order Bandpass