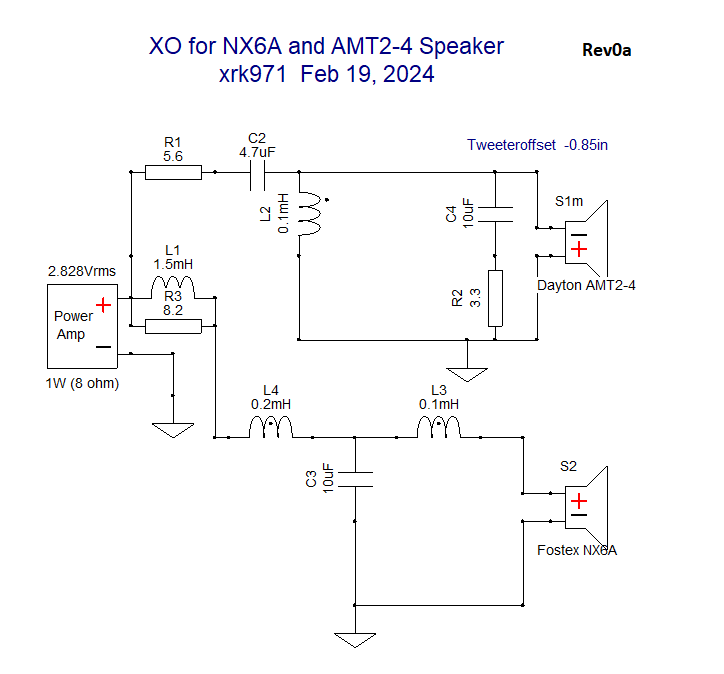

I have the first cut crossover built and listening to it now. 3.5kHz symmetric higher order. Nice smooth phase variation through XO region. Low distortion overall. Very good overall sensitivity of 86dB at 2.83vrms and 1m.

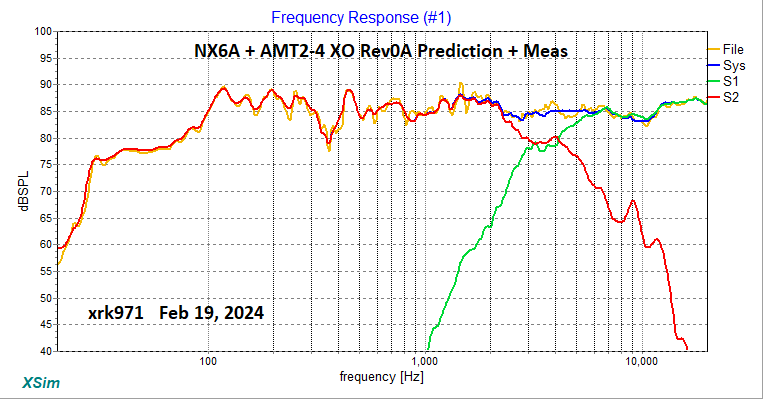

Predicted and measured (orange) frequency response:

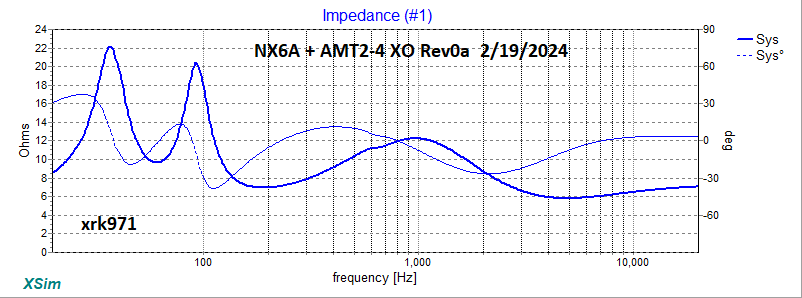

Predicted impedance shows box tuning at 61Hz and never dips below 6ohms:

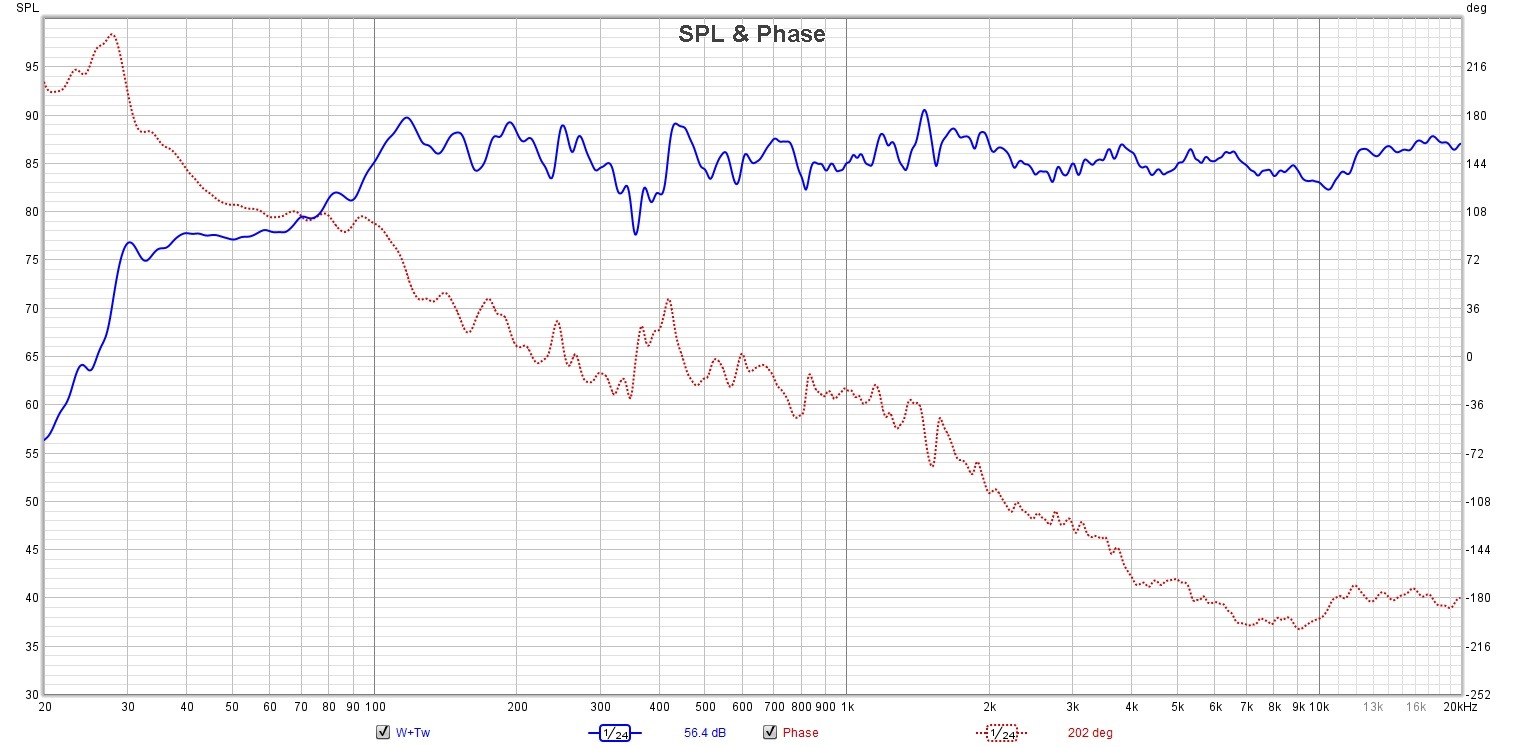

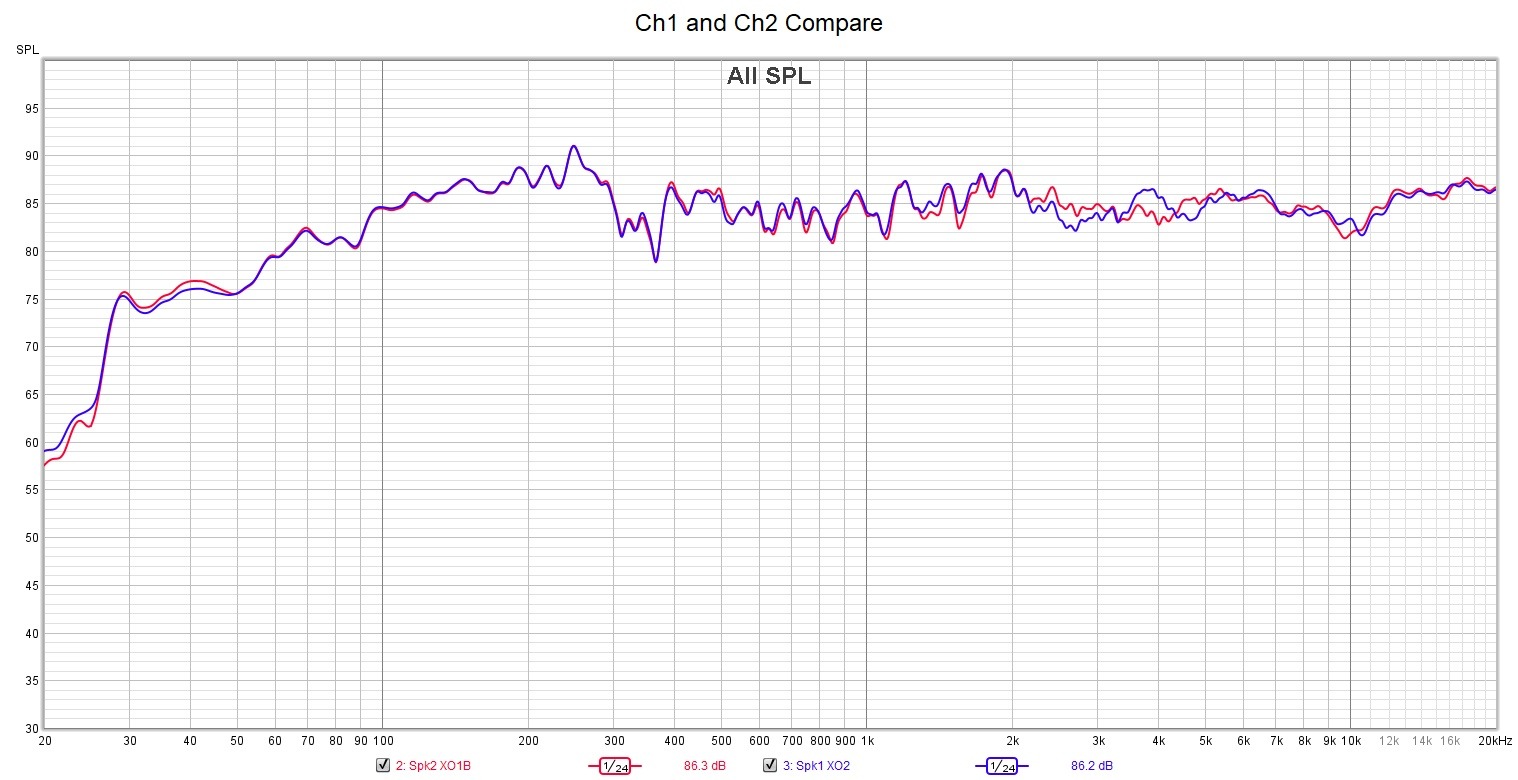

Measured XO response in detail:

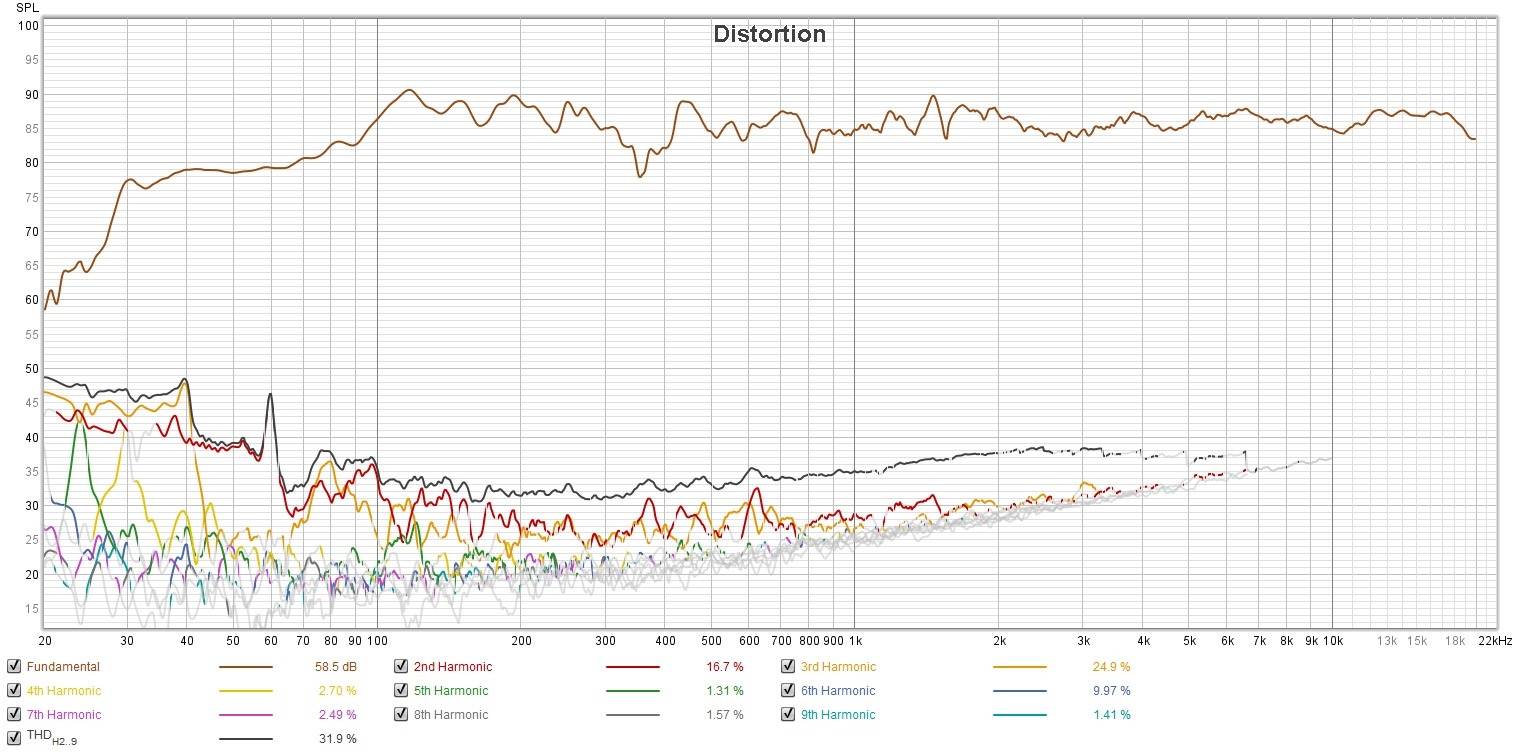

Measured Distortion (2.0Vrms at 0.5m):

Phase response is smooth and linear in variation:

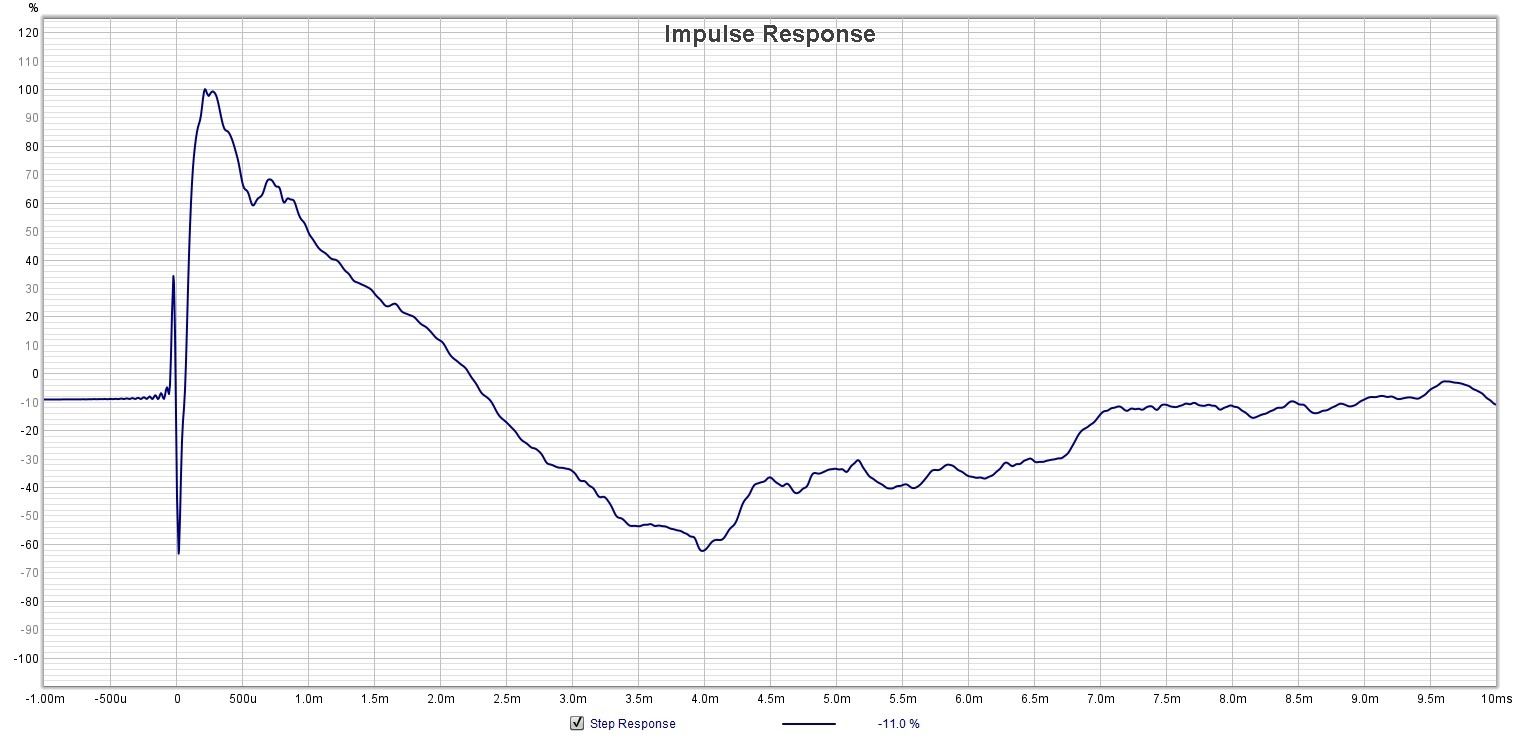

Step Response almost looks like idea right triangle - indicative of good time alignment for good transient snaps:

You can listen to it here:

Predicted and measured (orange) frequency response:

Predicted impedance shows box tuning at 61Hz and never dips below 6ohms:

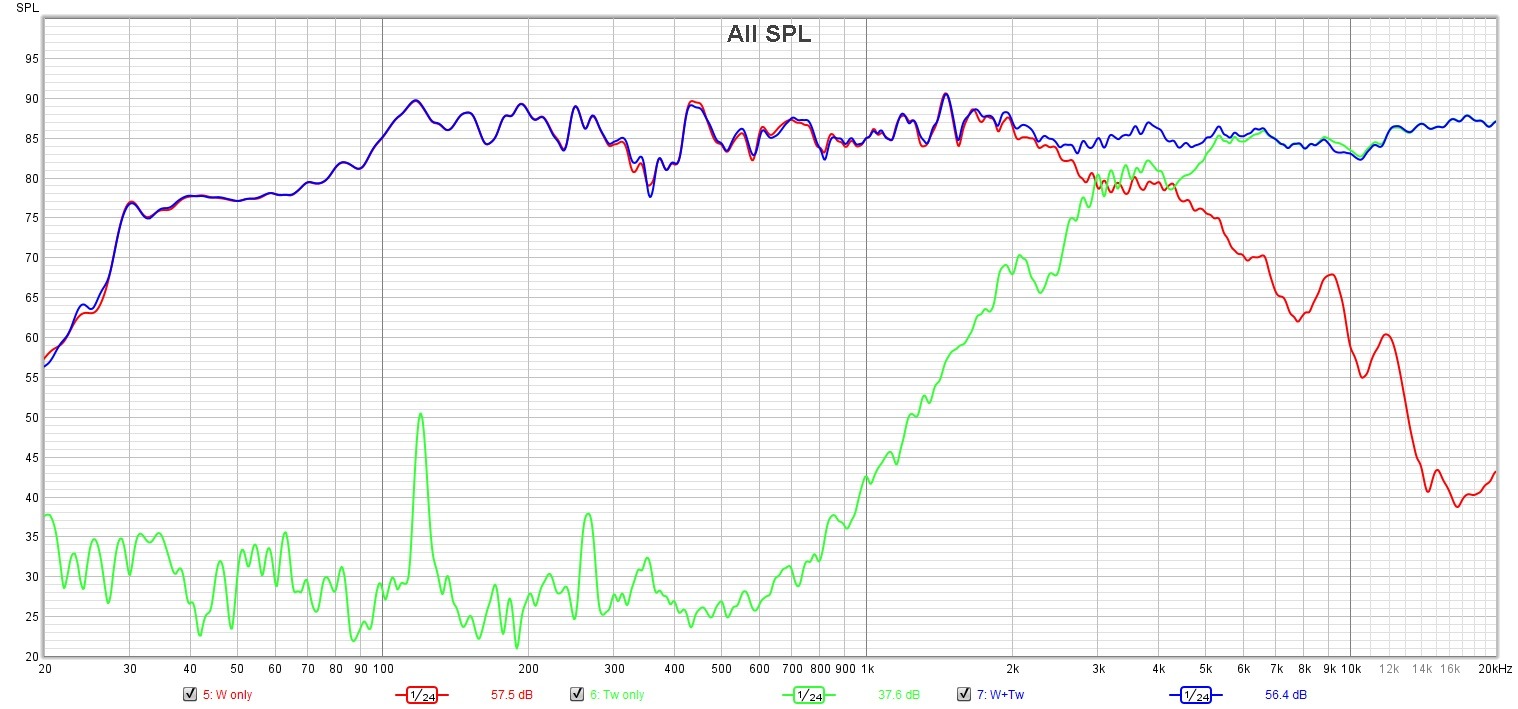

Measured XO response in detail:

Measured Distortion (2.0Vrms at 0.5m):

Phase response is smooth and linear in variation:

Step Response almost looks like idea right triangle - indicative of good time alignment for good transient snaps:

You can listen to it here:

Last edited:

That looks really good, especially distortion in bass is low. Phase is smooth at crossover. Nice.

Ultimately it may need a sub, but thats personal prefference.

Ultimately it may need a sub, but thats personal prefference.

The room gain seems to be helping quite a bit. The midrange on this speaker is very clear.

In measuring the drivers for the XO I accidentally stumbled upon quantitative evidence of break-in. The distortion in the woofer at start was awful. I thought I had a rattle or something stuck in the voice coil. But after playing 45Hz for 5min it went down a bit. I let it play 2.8vrms of 45Hz for an hour. Distortion (nasty 3rd and 5th) went down by 15dB in 150Hz to 700Hz range. Dramatic.

Might still improve a little even who knows. Suspension loosened up is all I can think of.

In measuring the drivers for the XO I accidentally stumbled upon quantitative evidence of break-in. The distortion in the woofer at start was awful. I thought I had a rattle or something stuck in the voice coil. But after playing 45Hz for 5min it went down a bit. I let it play 2.8vrms of 45Hz for an hour. Distortion (nasty 3rd and 5th) went down by 15dB in 150Hz to 700Hz range. Dramatic.

Might still improve a little even who knows. Suspension loosened up is all I can think of.

Hi X, it looks great!

You write "Fostex NX6A woofer" but I think you mean "Fostex 8578100100 woofer" for the NX6A speaker - just to avoid confusion🙂

You write "Fostex NX6A woofer" but I think you mean "Fostex 8578100100 woofer" for the NX6A speaker - just to avoid confusion🙂

On my bench is of course the HyperSET, getting closer to the finish: https://www.diyaudio.com/community/threads/building-the-hyperset.409303/post-7606543

Anyone need a 1:4 stereo fan out with independent levels? Opamp based I am sure but at this price, I am willing to take a gamble and order it. Looks very useful.

$8 on Aliexpress here.

One could pair this with line level passive filters to make a nifty 2-to-4 way active analog crossover using this to feed to feed two stereo amps (2 way) or 4 stereo amps (4 way).

$8 on Aliexpress here.

One could pair this with line level passive filters to make a nifty 2-to-4 way active analog crossover using this to feed to feed two stereo amps (2 way) or 4 stereo amps (4 way).

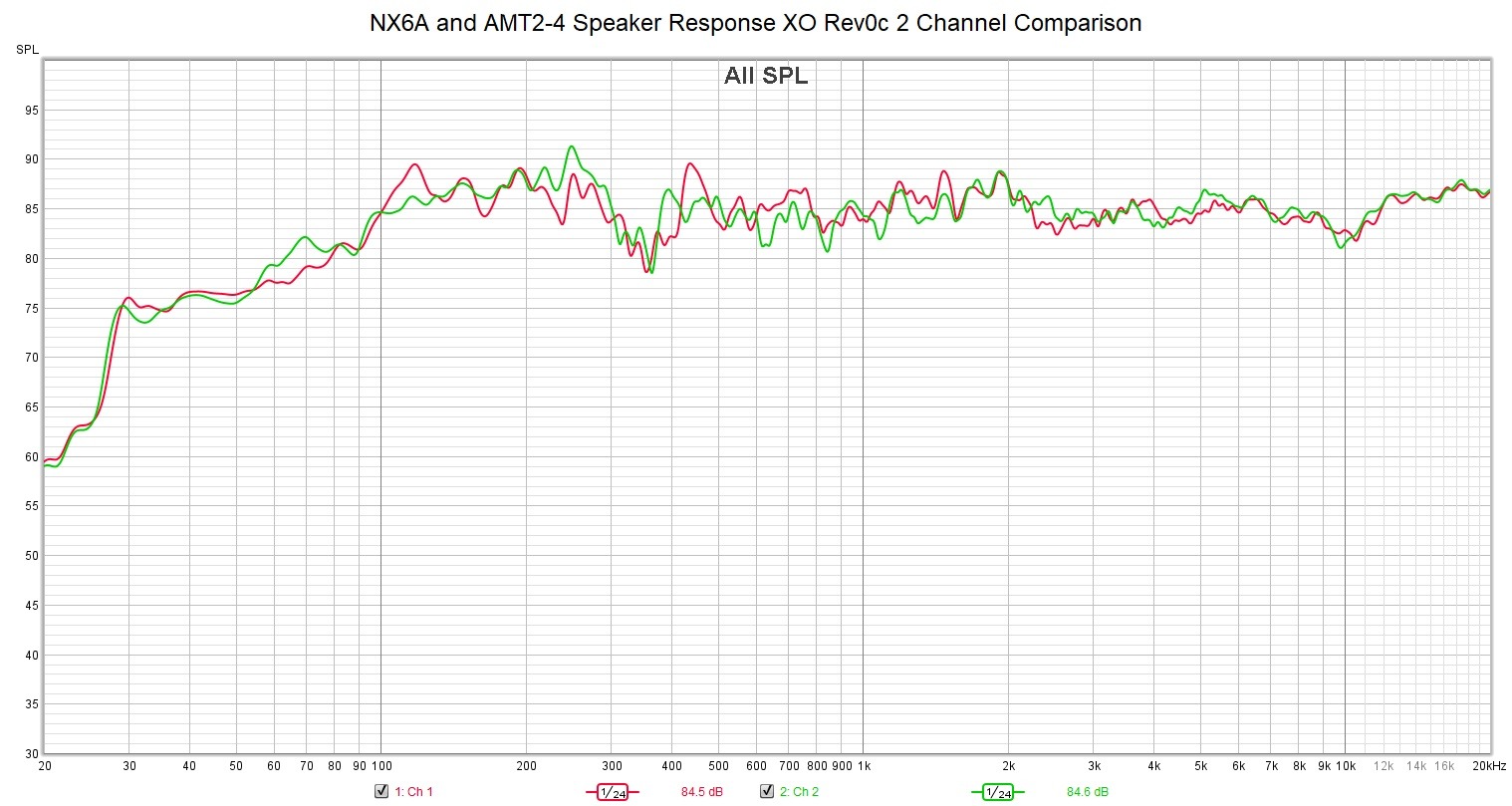

On the bench last night and tonight was the second channel of the Fostex NX6A / AMT2-4 speaker that I have been working on. I built up the second crossover and got a much smoother measurement of the bass response around 100Hz. It did not have the peak and rapid falloff.

The green is the second speaker with the second crossover. The red is the first speaker with the first crossover.

This puzzled me so I put the second crossover onto the first cabinet and the strange behavior went away! The only difference was the screw terminal block I was using (steel contacts). So I redid the crossover without the terminal block and the measured response between the two speakers is nearly identical in the woofer bass range.

This bass behavior is much nicer than before. A smooth shallow falloff without the sudden jump and a bump near 120Hz. The lesson here is not to use steel connectors or terminal blocks on crossovers!

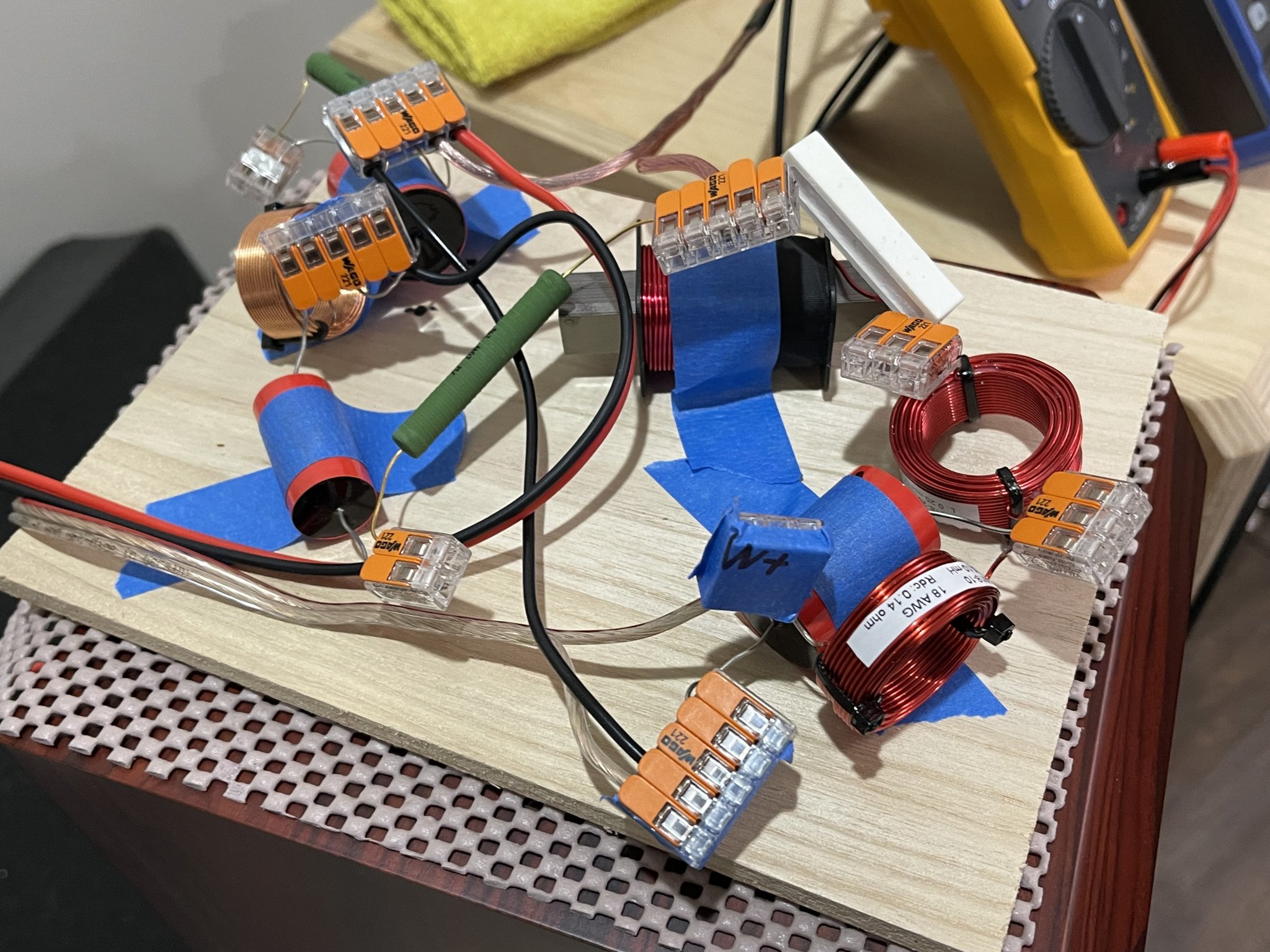

Here’s the crossover without the steel terminal block. All Wago connectors. I’m going to do about a week of long term listening and adjust voicing to see where I want the tweeter padding level to be set at.

The green is the second speaker with the second crossover. The red is the first speaker with the first crossover.

This puzzled me so I put the second crossover onto the first cabinet and the strange behavior went away! The only difference was the screw terminal block I was using (steel contacts). So I redid the crossover without the terminal block and the measured response between the two speakers is nearly identical in the woofer bass range.

This bass behavior is much nicer than before. A smooth shallow falloff without the sudden jump and a bump near 120Hz. The lesson here is not to use steel connectors or terminal blocks on crossovers!

Here’s the crossover without the steel terminal block. All Wago connectors. I’m going to do about a week of long term listening and adjust voicing to see where I want the tweeter padding level to be set at.

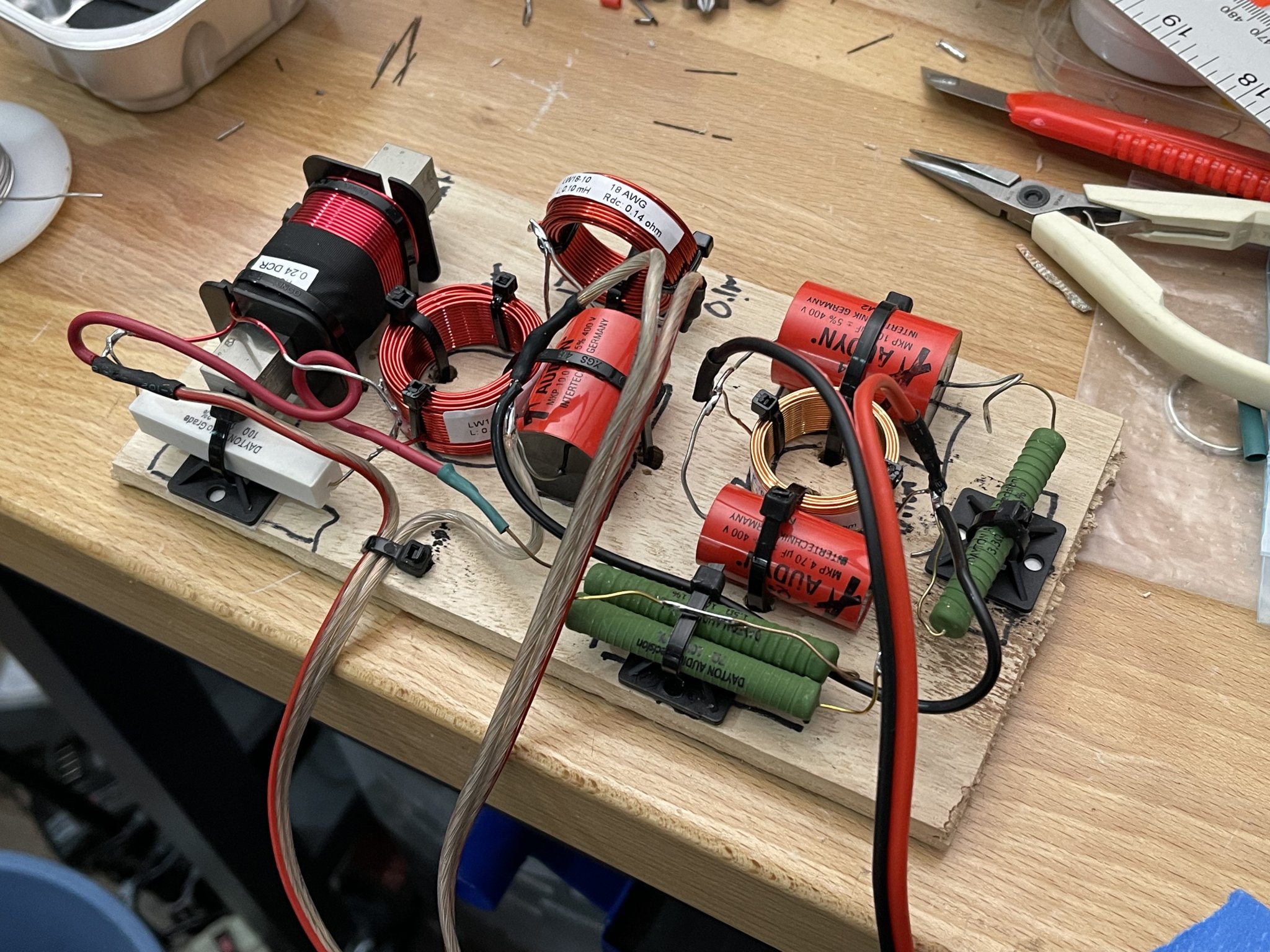

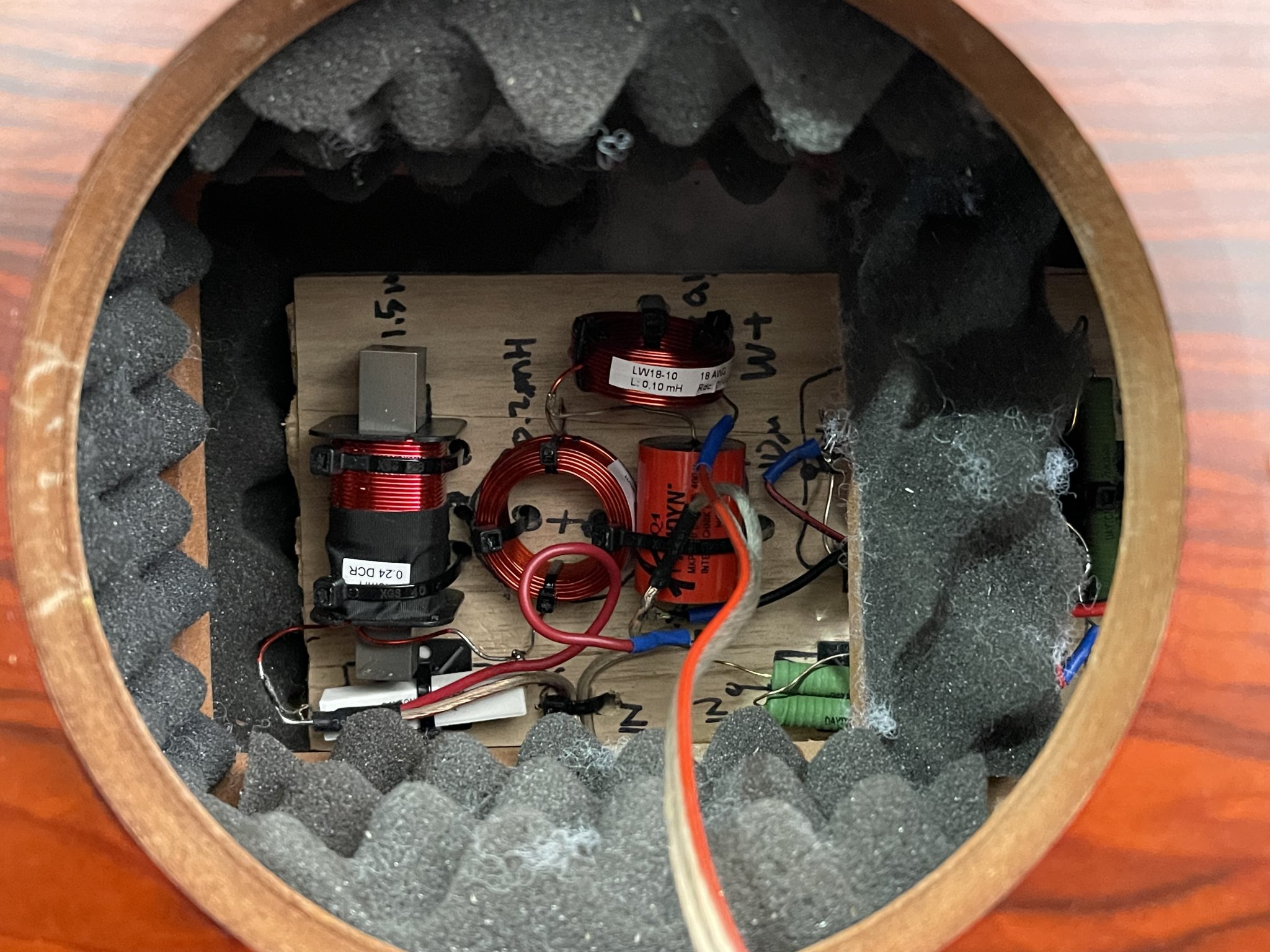

on the bench tonight is the final Cap for the NX6A and AMT2-4 speaker. After listening all day I felt confident that the XO voicing was spot on. So I proceeded to make a soldered P2P XO on a plank.

Well, I guess the speakers are done and I can just enjoy them now.

Well, I guess the speakers are done and I can just enjoy them now.

X,

Do you mind going over the basic details and operation of ‘Solid Works’ as well as 3D printing in general? I see you used SW and a 3D printer for the tweeter bezel as well as a binding post cup, both of which look very nice, especially for small hobbyist and prototype work! Some questions would be:

Which 3D printer for a good price/feature combination?

Is Solid Works free or one purchases a license to use it? Which computer interfaces for best compatibility?

Learning curve?

I’m used to using Front Panel Express, but that can get very expensive for prototypes.

Thank you!

Best,

Anand.

Do you mind going over the basic details and operation of ‘Solid Works’ as well as 3D printing in general? I see you used SW and a 3D printer for the tweeter bezel as well as a binding post cup, both of which look very nice, especially for small hobbyist and prototype work! Some questions would be:

Which 3D printer for a good price/feature combination?

Is Solid Works free or one purchases a license to use it? Which computer interfaces for best compatibility?

Learning curve?

I’m used to using Front Panel Express, but that can get very expensive for prototypes.

Thank you!

Best,

Anand.

I have a professional copy of SW from many years ago. Today, there is a hobbyist version that appears to use the same engine, called 3D Experience SW and it’s very reasonable at $48 a year.

https://www.solidworks.com/solution/3dexperience-solidworks-makers

The learning curve is not too bad if you watch all the tutorials in YT. I have not used the above version but looking at the SW interface, appears very similar to the regular professional version which costs $4500/yr! I bought mine before they went to subscription model so I have an infinity license.

Making something like the bezel adapter requires drawing a circle sketch, then extrude it to a “boss”, then cutting into it like a milling remove material operation by drawing another circle, then cut holes for the screws using same remove material operation. Followed by a chamfer operation. Drawing precise dimensioned CAD sketches is key and those concepts using construction lines, offset, extend, trim, mirror, make array, etc all come in handy. The tricky things are compound curves, blended curves to flats etc. more advanced stuff takes time to develop the skills to make on CAD.

As far as 3D printers, very good popular printers are $700 and up. Too cheap and you spend a lot of time debugging or fixing or adjusting them to work right. I have a Dremel 3D Digilab 3D45 printer that is more in the professional category and works like a tool. Very little futzing and have not had an issue with complete blowouts where filament keeps printing a spaghetti mess. You pay the price for professional reliability though. It’s your time though and the print quality is consistently good. They use their own brand of filament so it’s a bit more expensive but they control the quality and melt properties tightly for a frustration-free experience. Watch YT videos on reviews of 3D printers. The Prusa is highly rated for hobbyists. I have friends who have this one and they love it.

I see this model with two heads and box to prevent external breezes from affecting temperature- looks very tempting and is quite well rated. Can do dual color prints etc.

In the world of CAD, Windows PC is the king if you want to have broad compatibility. You will need a computer with a “CAD” graphics card if you want snappy response when doing 3D modeling of complex shapes or assemblies. But if a regular PC, get a lot of memory 32 GB minimum.

Also, a 3D mouse on left hand and regular mouse on right hand (or vice versa) makes workflow much faster.

Hope that helps.

P.S.,

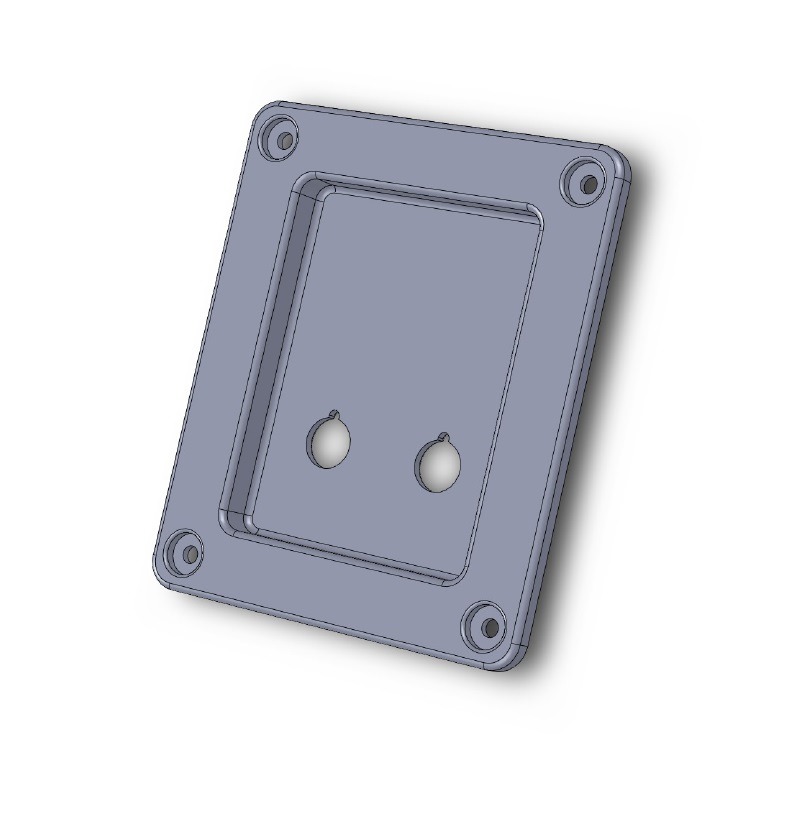

To give you an idea of effort involved, the binding post plate took me 20 min to make in SW but 4.5 hrs to print because I made the walls 2mm thick and there was a lot of support structure underneath. It turned out well though:

By contrast, the bezel adapter took 10min to make on SW and 1hr to print. Much less material.

One other tool needed for making models fit reality precisely is a dial caliper to measure down to thousands of an inch or 1/10th of a mm.

https://www.solidworks.com/solution/3dexperience-solidworks-makers

The learning curve is not too bad if you watch all the tutorials in YT. I have not used the above version but looking at the SW interface, appears very similar to the regular professional version which costs $4500/yr! I bought mine before they went to subscription model so I have an infinity license.

Making something like the bezel adapter requires drawing a circle sketch, then extrude it to a “boss”, then cutting into it like a milling remove material operation by drawing another circle, then cut holes for the screws using same remove material operation. Followed by a chamfer operation. Drawing precise dimensioned CAD sketches is key and those concepts using construction lines, offset, extend, trim, mirror, make array, etc all come in handy. The tricky things are compound curves, blended curves to flats etc. more advanced stuff takes time to develop the skills to make on CAD.

As far as 3D printers, very good popular printers are $700 and up. Too cheap and you spend a lot of time debugging or fixing or adjusting them to work right. I have a Dremel 3D Digilab 3D45 printer that is more in the professional category and works like a tool. Very little futzing and have not had an issue with complete blowouts where filament keeps printing a spaghetti mess. You pay the price for professional reliability though. It’s your time though and the print quality is consistently good. They use their own brand of filament so it’s a bit more expensive but they control the quality and melt properties tightly for a frustration-free experience. Watch YT videos on reviews of 3D printers. The Prusa is highly rated for hobbyists. I have friends who have this one and they love it.

I see this model with two heads and box to prevent external breezes from affecting temperature- looks very tempting and is quite well rated. Can do dual color prints etc.

In the world of CAD, Windows PC is the king if you want to have broad compatibility. You will need a computer with a “CAD” graphics card if you want snappy response when doing 3D modeling of complex shapes or assemblies. But if a regular PC, get a lot of memory 32 GB minimum.

Also, a 3D mouse on left hand and regular mouse on right hand (or vice versa) makes workflow much faster.

Hope that helps.

P.S.,

To give you an idea of effort involved, the binding post plate took me 20 min to make in SW but 4.5 hrs to print because I made the walls 2mm thick and there was a lot of support structure underneath. It turned out well though:

By contrast, the bezel adapter took 10min to make on SW and 1hr to print. Much less material.

One other tool needed for making models fit reality precisely is a dial caliper to measure down to thousands of an inch or 1/10th of a mm.

Last edited:

On my bench tonight - what else - the HypetSET.

Real panel finished, connectors wired.

Real panel finished, connectors wired.

Hi Plott,

Wow, you have done an amazing job! Looks fantastic. I love the layout - you have an excellent sense of balance and placement. I couldn’t have done it any better. Thanks for the attribution on the lettering.

I see you are using Viborg XLR’s. They look great. I have mostly used Neutrik but these look nice and premium because they are all metal and grey color. Nice!

Looking forward to hearing your listening impressions and more photos!

Thanks!

X

Wow, you have done an amazing job! Looks fantastic. I love the layout - you have an excellent sense of balance and placement. I couldn’t have done it any better. Thanks for the attribution on the lettering.

I see you are using Viborg XLR’s. They look great. I have mostly used Neutrik but these look nice and premium because they are all metal and grey color. Nice!

Looking forward to hearing your listening impressions and more photos!

Thanks!

X

Hi X,

many thanks, glad you like it! I really like to design layouts😀

Yes, the XLRs are Viborg, they have a great price/performance ratio; the RCAs are Furutech as is the IEC inlet.

Tomorrow I will get all the panels, so I think the first listening could be tomorrow in the very late evening hours.

As I wrote, the test bed version was very very promising, so I'm really looking for the listening in my system.

Pictures will follow, of course.

many thanks, glad you like it! I really like to design layouts😀

Yes, the XLRs are Viborg, they have a great price/performance ratio; the RCAs are Furutech as is the IEC inlet.

Tomorrow I will get all the panels, so I think the first listening could be tomorrow in the very late evening hours.

As I wrote, the test bed version was very very promising, so I'm really looking for the listening in my system.

Pictures will follow, of course.